Free Workplace Annual Incident Summary Report

Executive Summary

[Your Company Name], in the year [2050], has reached a critical juncture in its journey towards enhancing workplace safety and managing incidents effectively. This extensive report delves into the analysis of [45] reported workplace incidents, a slight uptick from the previous year. These incidents have been methodically categorized, and analyzed, and their broader implications discussed in depth. The findings underscore the pressing need for augmented safety protocols, enhanced maintenance of equipment, and comprehensive employee training and awareness initiatives. A set of detailed recommendations, aimed at addressing these needs and mitigating future risks, forms the crux of this report. The primary objective is to foster a safer work environment, reduce the incidence of accidents, and ensure the wellbeing of all employees.

Introduction

The purpose of this report is to offer a thorough summary and analysis of all workplace incidents that transpired at [Your Company Name] during the year [2050]. The aim is to systematically identify trends, discern root causes, assess the effectiveness of existing safety measures, and propose substantial improvements. The analysis encompasses incidents across various departments and facilities within the organization, thereby presenting a comprehensive picture of the safety challenges and concerns encountered over the course of the year.

The importance of this analysis cannot be overstated, as it serves as a crucial tool in understanding the dynamics of workplace safety within the company. It is intended to provide insights that will guide the development of more effective safety protocols, enhance employee training programs, and ultimately lead to a significant reduction in workplace incidents.

Methodology

The methodology employed for this report involved an in-depth examination of various sources of information. Incident logs provided a chronological record of each reported incident, offering crucial details about their nature and circumstances. Employee interviews were conducted to gain firsthand accounts and perspectives on the incidents, which added a qualitative depth to the analysis. Maintenance records were reviewed to assess the condition and history of equipment involved in incidents. Finally, insights and reviews from the health and safety committee were incorporated to ensure a comprehensive understanding of each incident and its broader implications.

Both qualitative and quantitative research methods were utilized to allow for a detailed and nuanced understanding of each incident. This approach enabled the identification of patterns and commonalities among the incidents, as well as the assessment of their individual and collective impact on the company. Comparative assessments against industry benchmarks and standards were also conducted to evaluate [Your Company Name]’s performance in the context of the wider industry.

Incident Summary

A. Overview of Incidents

In [2050], [Your Company Name] encountered [45] workplace incidents, indicating a 10% increase compared to the previous year. These incidents encompassed a range of situations from minor equipment malfunctions to significant safety breaches. Notably, a major incident involving a CNC machine malfunction in March highlighted the potential risks associated with equipment and operational failures.

The incidents reported in [2050] varied in their nature and severity, affecting different departments and aspects of the company's operations. Some were isolated events, while others pointed to systemic issues that required comprehensive solutions. Understanding the nature and scope of these incidents is crucial for developing effective strategies to prevent their recurrence.

B. Categories of Incidents

The incidents reported in [2050] were categorized into four main types:

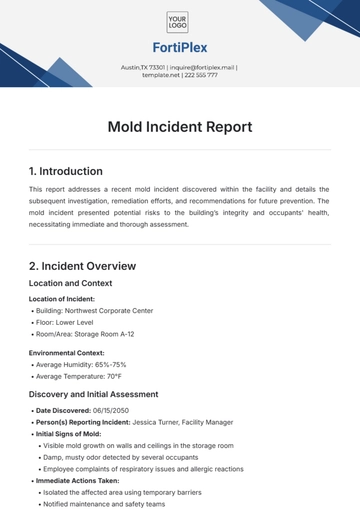

Equipment-related Incidents (18 incidents)

These involved various machinery malfunctions, electrical issues, and hazards related to using tools and equipment. They ranged from minor equipment failures to significant malfunctions that posed serious safety risks.

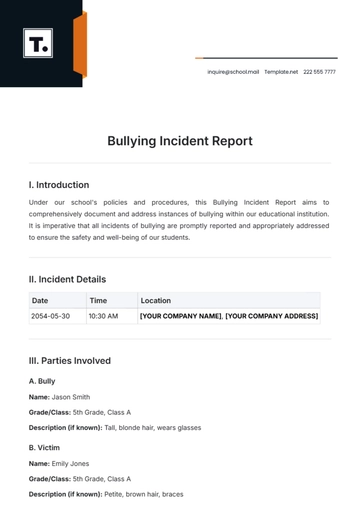

Health and Safety Protocol Violations (15 incidents)

These incidents included instances where employees did not comply with safety gear requirements, disregarded standard operating procedures, or engaged in unsafe work practices. These violations often led to near-misses or actual accidents, highlighting gaps in training and awareness.

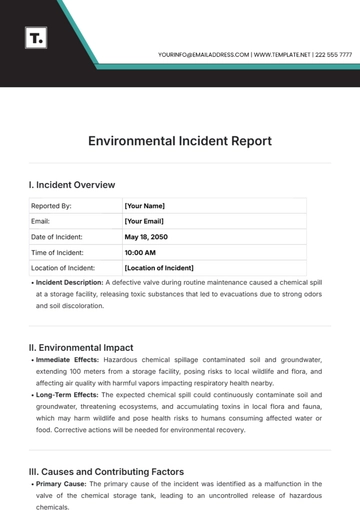

Environmental Hazards (6 incidents)

These were incidents related to chemical spills, compromised air quality, and ergonomic challenges that posed risks to the health and safety of employees. They often resulted from inadequate hazard communication, insufficient control measures, and poor workplace environment management.

Other (6 incidents)

This category comprised various incidents that did not fall into the other categories, including administrative oversights, security breaches, and miscellaneous safety hazards. These incidents, while not directly related to operational activities, underscored the need for comprehensive safety management across all aspects of the company’s operations.

Detailed Analysis

A. Incident Types and Frequencies

The most frequently reported incidents in [2050] were related to equipment, accounting for [40%] of the total incidents. These incidents were primarily associated with older machinery that required maintenance or replacement. This finding highlights the need for a robust maintenance program and regular equipment audits to prevent such incidents.

Health and safety violations constituted [33%] of the incidents, underscoring a significant gap in employee adherence to established safety protocols. This indicates a need for more rigorous training and awareness programs, as well as stricter enforcement of safety rules and procedures.

B. Severity of Incidents

The severity of the incidents reported in [2050] varied. Fortunately, there were no fatalities, but the CNC machine incident in March was particularly severe, resulting in serious injury requiring extensive medical treatment and rehabilitation. Other incidents ranged from minor injuries and near-misses to more severe cases that necessitated immediate medical attention.

The varying severity of these incidents underscores the importance of not only preventing major accidents but also addressing smaller incidents and near-misses. Often, minor incidents can be early warning signs of larger systemic issues that need to be addressed to prevent more serious accidents.

C. Time Analysis

An analysis of the timing of incidents revealed a higher occurrence in the latter half of the year, particularly during the third and fourth quarters. This pattern could suggest a correlation between increased production targets, end-of-year deadlines, and a higher rate of incidents. It may also indicate issues related to worker fatigue, reduced vigilance, or seasonal factors affecting safety.

The increase in incidents during the latter part of the year calls for a closer examination of work schedules, deadlines, and the potential impact of increased workload on employee safety. It also suggests the need for seasonal safety campaigns and targeted interventions during periods of higher risk.

Root Cause Analysis

A. Common Causes

The analysis identified several common causes across the different categories of incidents:

Equipment-related incidents

These were largely due to aging machinery, lack of regular maintenance, and occasional operational misuse. In some cases, equipment failures were also linked to design flaws or manufacturing defects.

Health and safety protocol violations

Often resulted from inadequate training, employee complacency, or a disregard for established procedures. In many instances, these violations were associated with a lack of awareness or understanding of the risks involved.

Environmental hazards

Primarily attributed to insufficient hazard communication, inadequate control measures, and sometimes poor housekeeping practices. These incidents highlighted the need for better environmental management and employee training on handling hazardous materials and working in potentially dangerous environments.

B. Contributing Factors

Several contributing factors were noted in the analysis:

Training deficiencies

Particularly evident in relation to safety protocol refreshers and new equipment operation. Many incidents could have been prevented with more comprehensive and regular training programs.

Communication gaps

Between operational staff and the maintenance department, leading to delayed or inadequate responses to reported issues. This was further exacerbated by a lack of clear communication channels and protocols for reporting and addressing safety concerns.

Culture of under-reporting

A significant number of minor incidents were not reported, leading to a lack of awareness of potential hazards and a complacency regarding safety norms. This culture of under-reporting can mask underlying issues and prevent the company from taking proactive measures to improve safety.

Impact Assessment

A. Direct Impacts

The direct impacts of these incidents were multifaceted. They included tangible aspects like production downtime, financial costs related to equipment repair or replacement, medical treatment expenses, and in some cases, legal liabilities due to workplace injuries.

The financial implications of these incidents were significant, not only in terms of immediate costs but also in terms of long-term impacts on the company’s financial health. Production downtime, in particular, had a ripple effect on the company’s ability to meet client demands and maintain its competitive edge in the market.

B. Indirect Impacts

The indirect impacts of the incidents were significant yet less tangible. These included a decrease in overall employee morale, particularly following high-severity incidents. There was also an observed impact on the company’s reputation within the industry, and a noted decrease in trust among employees towards the company’s commitment to safety.

The decline in employee morale following incidents can have far-reaching effects on productivity, employee retention, and overall workplace culture. Similarly, the company's reputation as a safe and responsible employer is crucial for attracting and retaining talent, as well as for maintaining its position in the market.

Response and Management

A. Immediate Responses

In response to each incident, [Your Company Name] took immediate and appropriate actions. These actions varied depending on the nature of the incident but generally included providing medical aid, conducting investigations, temporarily halting operations if necessary, and repairing or replacing faulty equipment.

The immediate response to each incident was crucial in mitigating its impact and preventing further harm. The company’s quick action in providing medical aid and addressing safety concerns played a significant role in managing the aftermath of each incident.

B. Long-term Measures

The company has implemented several long-term measures in response to the incidents. These measures include a comprehensive review and update of all safety protocols, the initiation of a complete equipment audit across all facilities, and the enhancement of employee training programs with a focus on safety and proper equipment usage.

The long-term measures taken by the company reflect its commitment to addressing the root causes of the incidents and preventing their recurrence. The comprehensive review of safety protocols and equipment audits are particularly important in ensuring that all potential hazards are identified and addressed. Furthermore, the enhancement of employee training programs is critical in building a strong safety culture and ensuring that all employees are equipped with the knowledge and skills to work safely.

Preventive Measures and Recommendations

A. Strategies for Prevention

To prevent the recurrence of similar incidents, several strategies have been proposed:

1. Implementation of a predictive maintenance program

This program is designed to proactively identify and address potential equipment failures before they result in incidents. By using advanced diagnostics and monitoring tools, the company can anticipate maintenance needs and prevent equipment-related incidents.

2. Regular safety audits and compliance checks

Conducting these audits ensures adherence to safety protocols and standards. These checks will not only identify areas of non-compliance but also provide opportunities for continuous improvement in safety practices.

3. Enhanced control measures for environmental hazards

Strengthening measures to manage environmental hazards involves improving communication strategies, implementing more effective control mechanisms, and ensuring strict adherence to environmental safety standards.

B. Training and Awareness Programs

Recommended training and awareness initiatives include:

Regular safety training sessions and refresher courses for all employees

These sessions are crucial in emphasizing the importance of safety in the workplace. They should cover a range of topics, from basic safety principles to specific procedures related to particular equipment or tasks.

Specialized training programs for staff involved in operating and maintaining high-risk equipment

Employees working with high-risk equipment require specialized training that addresses the specific risks and safety procedures associated with that equipment.

Company-wide safety awareness campaigns

These campaigns are designed to reinforce the culture of safety and encourage reporting of hazards and incidents. They can include informational posters, safety workshops, and regular safety messages from company leadership.

Future Plans

Looking forward, [Your Company Name] plans to:

Invest in newer, safer, and more efficient equipment technologies

This investment will not only improve operational efficiency but also reduce the risk of equipment-related incidents.

Establish a cross-departmental safety committee

This committee will oversee and advise on safety-related matters, ensuring that a diverse range of perspectives and expertise is brought to bear on safety issues.

Integrate advanced digital tools for incident reporting and analysis

These tools will enhance the company's ability to respond quickly and effectively to future incidents. They will also facilitate more detailed data analysis, aiding in the identification of trends and the development of targeted prevention strategies.

Conclusion

The year [2050] has been a period of significant learning and development for [Your Company Name] in the realm of workplace safety. This report has identified key areas where improvements are necessary and outlined a comprehensive plan to address these issues. The implementation of these recommendations is critical for creating a safer, more vigilant, and responsive work environment. The company's unwavering commitment to continuous improvement in safety and incident management is evident, and the initiatives detailed in this report are expected to make a substantial contribution towards achieving a zero-incident workplace.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Introducing the Workplace Annual Incident Summary Report Template by Template.net. This editable and customizable template, enhanced with our Ai Editor Tool, simplifies annual incident reporting. Effortlessly compile comprehensive summaries to track workplace incidents. Streamline your reporting process and ensure compliance with Template.net's user-friendly solution.

You may also like

- Sales Report

- Daily Report

- Project Report

- Business Report

- Weekly Report

- Incident Report

- Annual Report

- Report Layout

- Report Design

- Progress Report

- Marketing Report

- Company Report

- Monthly Report

- Audit Report

- Status Report

- School Report

- Reports Hr

- Management Report

- Project Status Report

- Handover Report

- Health And Safety Report

- Restaurant Report

- Construction Report

- Research Report

- Evaluation Report

- Investigation Report

- Employee Report

- Advertising Report

- Weekly Status Report

- Project Management Report

- Finance Report

- Service Report

- Technical Report

- Meeting Report

- Quarterly Report

- Inspection Report

- Medical Report

- Test Report

- Summary Report

- Inventory Report

- Valuation Report

- Operations Report

- Payroll Report

- Training Report

- Job Report

- Case Report

- Performance Report

- Board Report

- Internal Audit Report

- Student Report

- Monthly Management Report

- Small Business Report

- Accident Report

- Call Center Report

- Activity Report

- IT and Software Report

- Internship Report

- Visit Report

- Product Report

- Book Report

- Property Report

- Recruitment Report

- University Report

- Event Report

- SEO Report

- Conference Report

- Narrative Report

- Nursing Home Report

- Preschool Report

- Call Report

- Customer Report

- Employee Incident Report

- Accomplishment Report

- Social Media Report

- Work From Home Report

- Security Report

- Damage Report

- Quality Report

- Internal Report

- Nurse Report

- Real Estate Report

- Hotel Report

- Equipment Report

- Credit Report

- Field Report

- Non Profit Report

- Maintenance Report

- News Report

- Survey Report

- Executive Report

- Law Firm Report

- Advertising Agency Report

- Interior Design Report

- Travel Agency Report

- Stock Report

- Salon Report

- Bug Report

- Workplace Report

- Action Report

- Investor Report

- Cleaning Services Report

- Consulting Report

- Freelancer Report

- Site Visit Report

- Trip Report

- Classroom Observation Report

- Vehicle Report

- Final Report

- Software Report