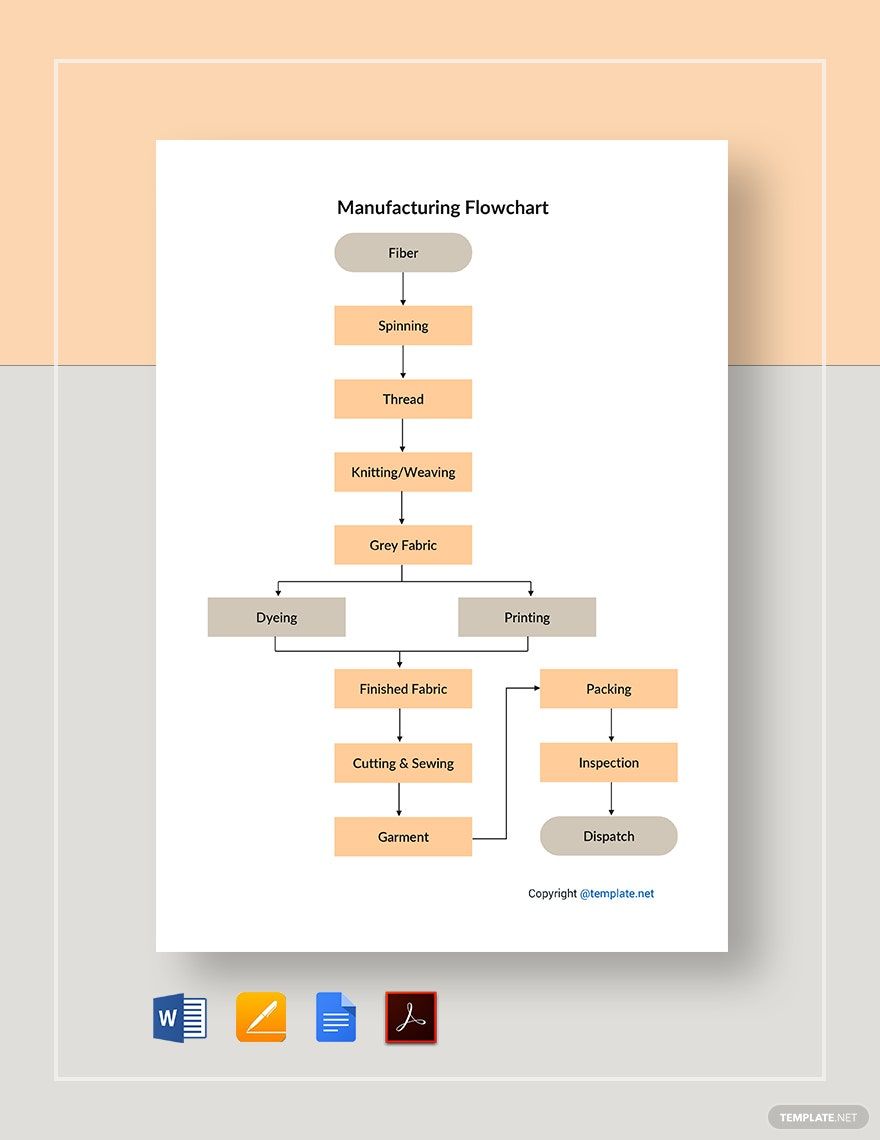

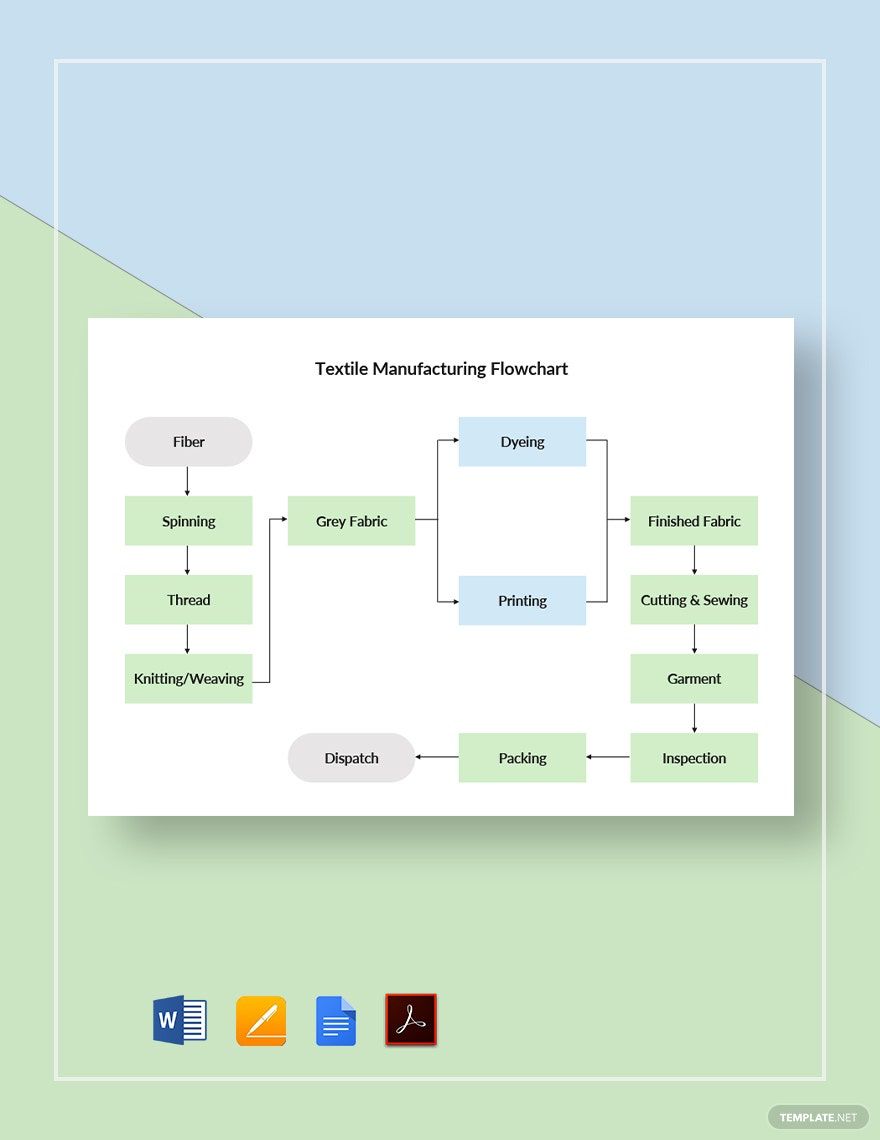

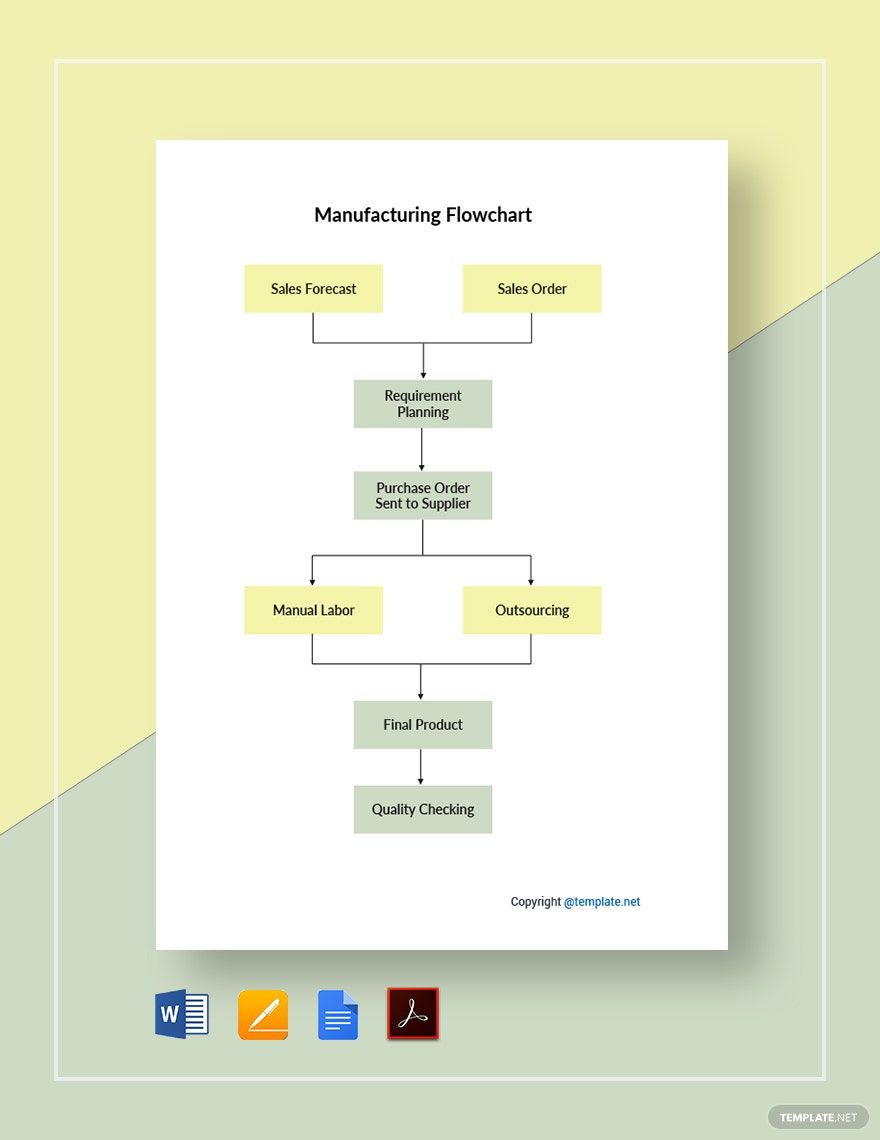

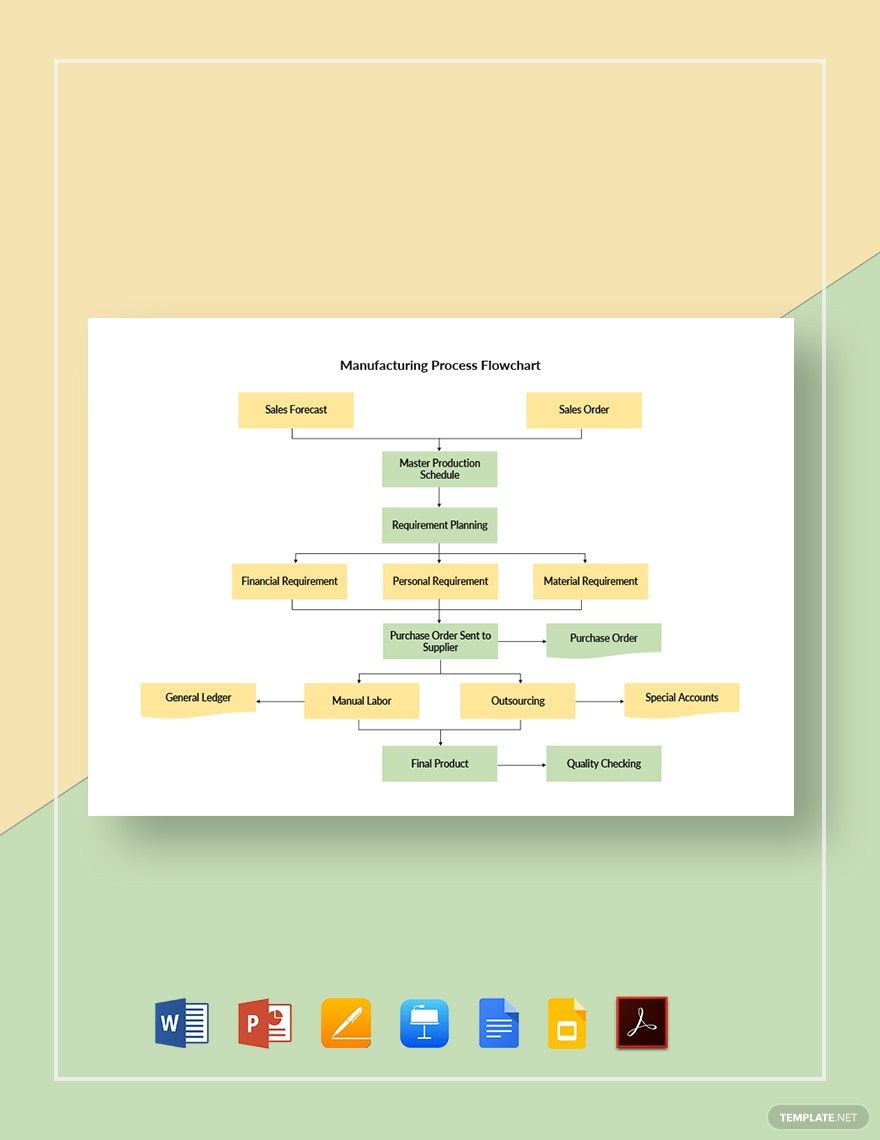

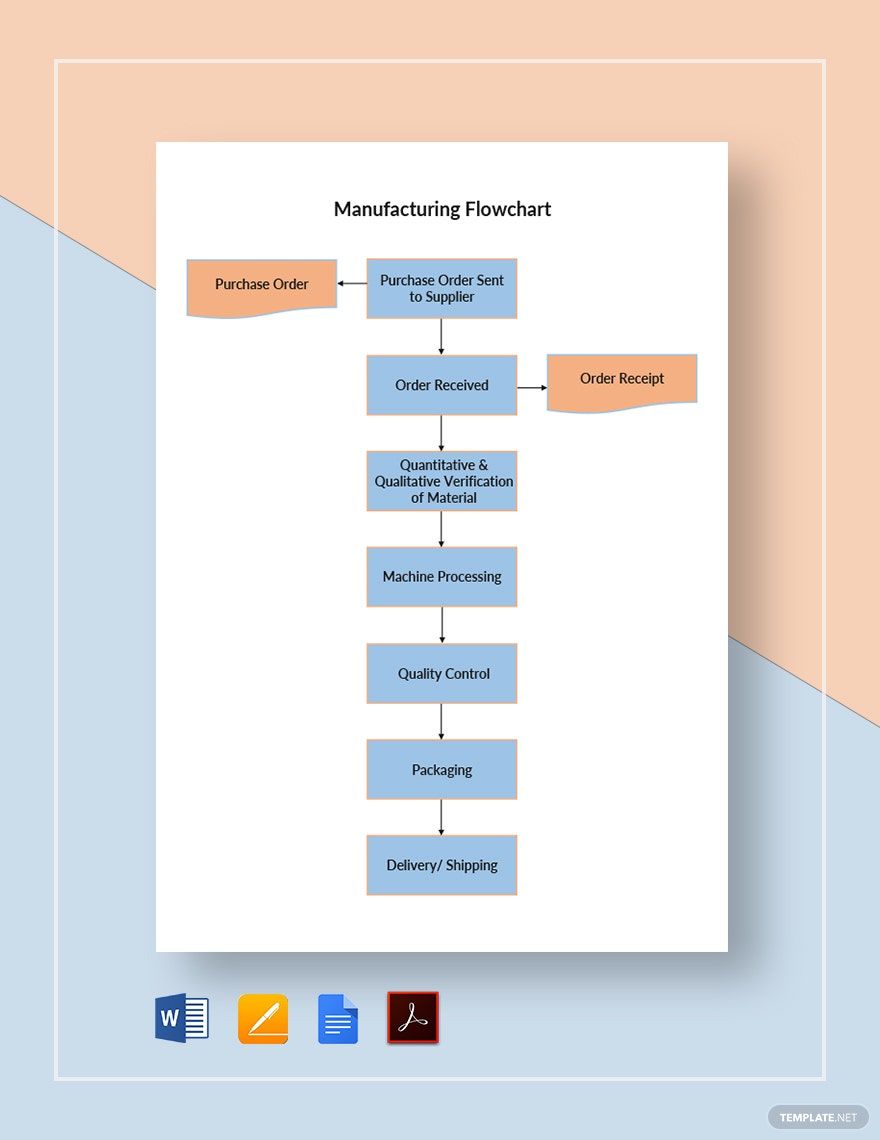

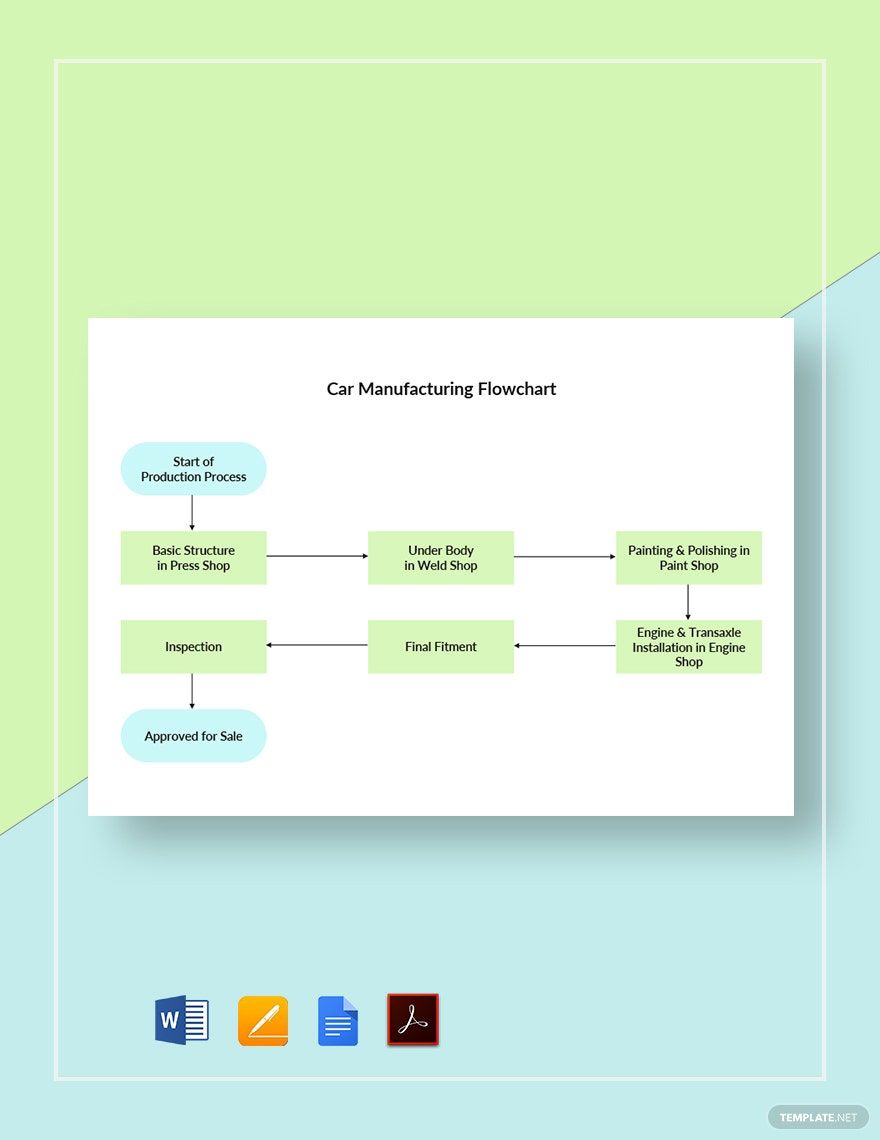

Finished goods, such as bread, cotton, glass, denim, are just one of the several products being manufactured by different manufacturing companies. Since the said industry has massive competitors around, you need to think of clever ways to step ahead of the competition. Using a tool that helps you visualize each phase you make for the project is indeed helpful at all. So, we cater to a wide selection of editable and pre-made templates of Manufacturing Flowchart in Word. Relying on our templates helps you big time because it was 100% customizable, printable, and downloadable in other file formats. You don't have to start from zero because we got your needs covered. Download our template today that are available to get in A4 & US Letter Sizes.

How to Create Manufacturing Flowchart in Word

United States has approximately 12.85 million manufacturing jobs that pay 12 percent more than the other jobs and employs a workforce around 8.5 percent, according to the U.S Bureau of Labor Statistics. Thus, it's no wonder why manufacturing plays a dominant role in the business industry.

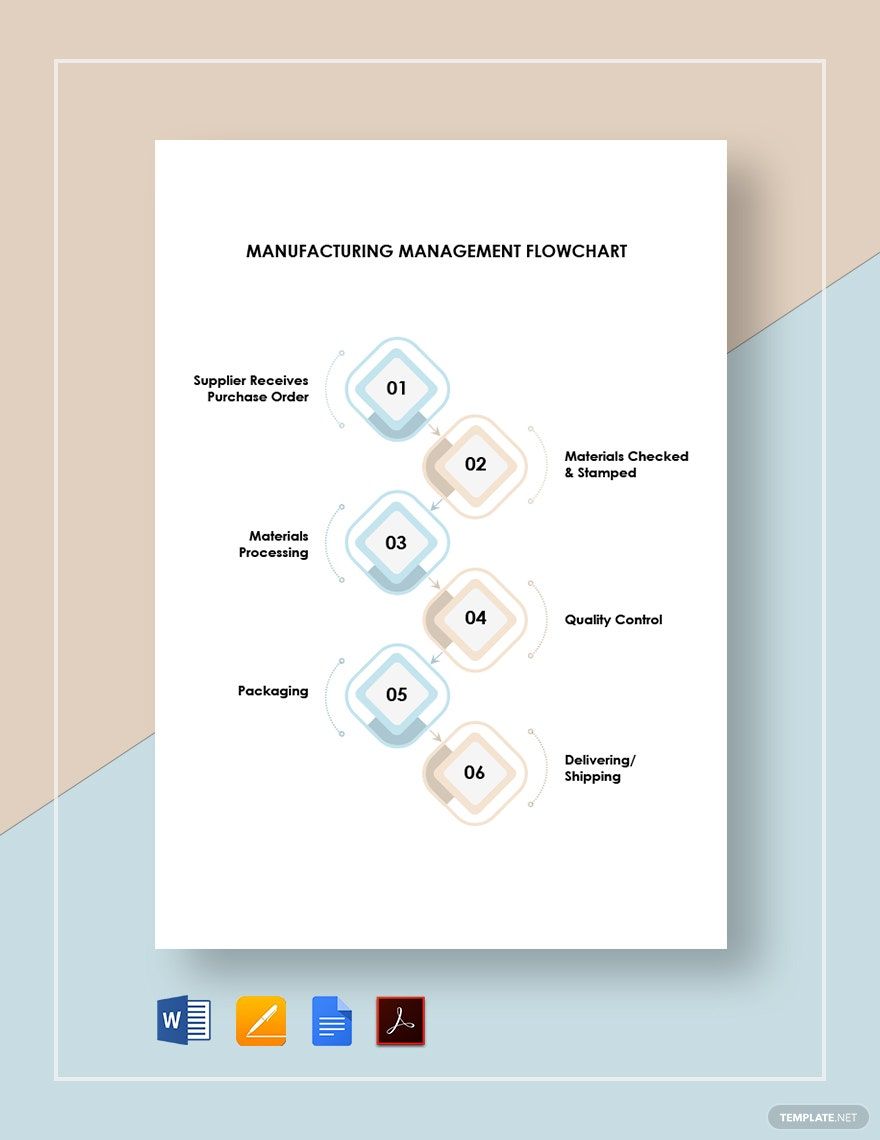

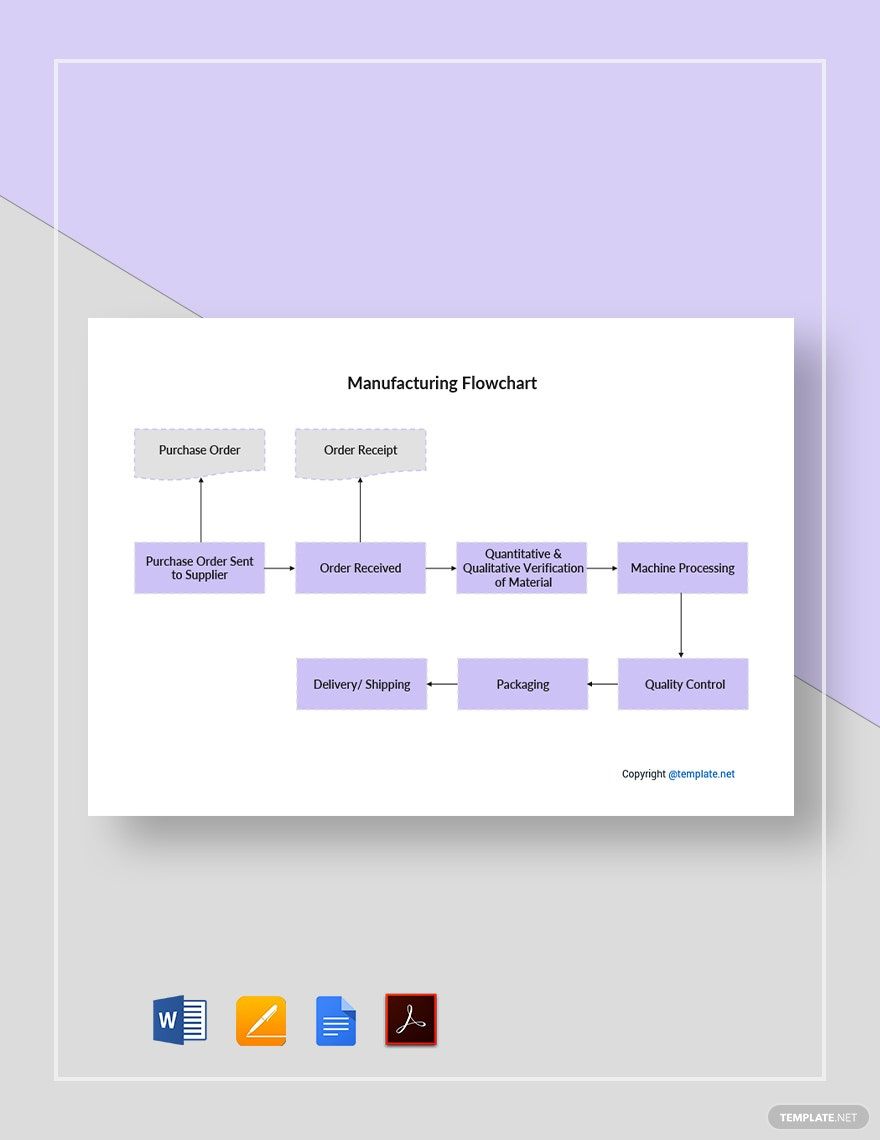

It's always crucial to produce a massive amount of production per day, especially if there are bulk orders from the clients. To be more productive, use a production process flow diagram that visualizes each vital process. Follow our tips below to help you in crafting an excellent Manufacturing Flowchart Templates in Word.

1. Produce a Workflow Diagram

Before you start working on the process, it's better to create a diagram or your manufacturing process flowchart. Good thing, we have a wide selection of templates that are perfect to tailor to your needs. Choose the right one you're comfortable in using without the need to start from the beginning.

2. Jot Down Each Process

Given that you already have the chart, list down each process on its specific box or shapes. It will be your visual guide to identifying everything so easily. Make sure to input every necessary detail to ensure that you're on the right track.

3. Incorporate From Start to End

Be mindful of organizing your input by incorporating them all from start to finish. You can use an arrow to connect each step and see how each process able to flow. Keep your simple chart neat, free from any errors or typos, and easy to understand.

4. Present in the Organization

If done, present the output in your organization to give awareness about the workflow. Everything is always achievable, especially if there are proper planning and strategies. Execute the plans to increase the productivity of produced items per day.