Free Operations Global Sourcing Strategy Document

Prepared By: | [Your Name] |

Company: | [Your Company Name] |

Date: | [Date] |

1. Introduction

The Operations Global Sourcing Strategy Document provides a comprehensive approach to optimizing procurement and supply chain operations through strategic global sourcing. This document ensures that sourcing practices align with organizational objectives, including cost reduction, operational efficiency, quality improvement, and sustainability.

2. Objectives

The primary objectives of this strategy include:

Cost Efficiency: Achieving competitive pricing through global supplier partnerships.

Operational Resilience: Reducing risks associated with supplier disruptions.

Quality Assurance: Ensuring consistent product and service quality across global suppliers.

Sustainability: Promoting ethical sourcing practices to align with corporate social responsibility goals.

Innovation: Leveraging global markets to access advanced technologies and materials.

3. Global Sourcing Framework

The strategy is based on a structured framework that includes:

Market Analysis: Assessing global supply markets for cost, quality, and risk factors.

Supplier Mapping: Identifying potential suppliers across regions with relevant capabilities.

Regional Diversification: Balancing sourcing across geographies to mitigate risks.

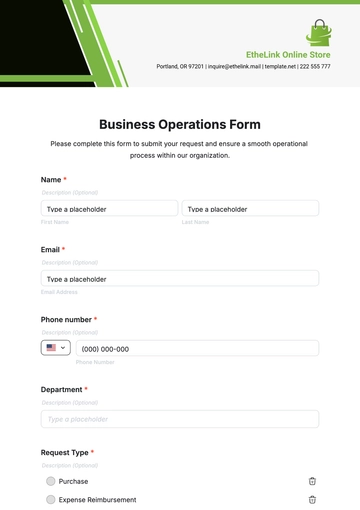

4. Supplier Selection and Evaluation

The selection process focuses on:

Supplier Capabilities: Evaluating technical, financial, and production capacities.

Compliance: Ensuring adherence to international regulations and certifications.

Performance Metrics: Establishing benchmarks for delivery, quality, and service.

5. Risk Management Strategy

Risk management is critical to ensuring uninterrupted operations. Key components include:

Supplier Redundancy: Maintaining multiple suppliers for critical components.

Geopolitical Risk Assessment: Evaluating political and economic stability in supplier regions.

Contingency Planning: Preparing for disruptions with alternative sourcing plans.

6. Cost Optimization Plan

The strategy emphasizes:

Negotiation Strategies: Leveraging volume purchases and long-term contracts.

Transportation Optimization: Reducing costs through efficient logistics and shipping routes.

Currency Hedging: Mitigating risks associated with exchange rate fluctuations.

7. Sustainability and Ethical Sourcing

Commitment to sustainability includes:

Environmentally Friendly Practices: Partnering with suppliers who prioritize low-carbon operations.

Labor Standards: Ensuring ethical labor practices and compliance with fair wage laws.

Sustainable Materials: Sourcing eco-friendly materials to minimize environmental impact.

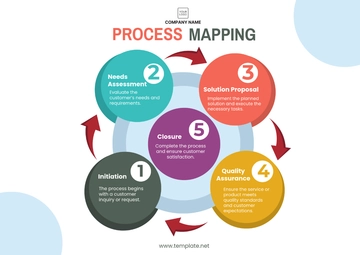

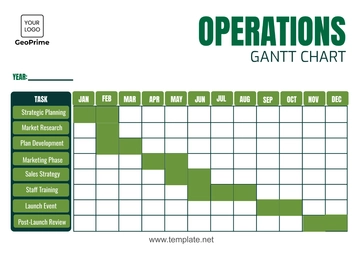

8. Implementation Roadmap

Phase 1: Initial Market Research and Supplier Identification (Months 1–3)

Phase 2: Supplier Engagement and Contract Negotiation (Months 4–6)

Phase 3: Pilot Testing and Onboarding (Months 7–9)

Phase 4: Full-scale Implementation and Monitoring (Months 10–12)

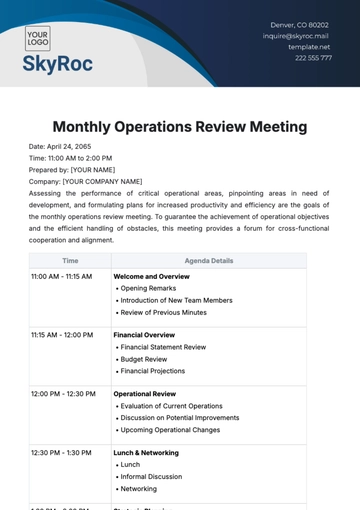

9. Performance Monitoring and KPIs

To evaluate the success of the global sourcing strategy, the following KPIs will be tracked:

Cost Savings: Percentage reduction in procurement costs.

Supplier Performance: Adherence to quality and delivery timelines.

Risk Mitigation: Reduction in supply chain disruptions.

Sustainability Goals: Progress towards sustainability benchmarks.

10. Conclusion

This Operations Global Sourcing Strategy provides a robust framework for achieving efficiency, resilience, and sustainability in sourcing activities. By adopting a global perspective and leveraging international markets, the organization is poised to meet its operational and strategic objectives effectively.

For further inquiries or feedback, please contact:

Name: [YOUR NAME]

Email: [YOUR EMAIL]

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Expedite your strategic planning with Template.net's Operations Global Sourcing Strategy Document Template! This editable and fully customizable dossier is your blueprint to success. Crafted to be editable in our Ai Editor Tool, it ensures a painless, streamlined process for your strategic needs. Boost your consistency, articulate your strategy, and impress your stakeholders with our professional-grade template. Let's revolutionize the marketing industry together.