Free Operations Distribution Network Design Proposal

Executive Summary

In response to the evolving needs of our market and the inefficiencies identified in our current distribution network, we propose a comprehensive redesign aimed at enhancing operational efficiency, reducing logistics costs by 20%, and improving customer satisfaction levels by 30%. This proposal outlines a strategic approach to reconfigure our distribution infrastructure, optimize transportation routes, and implement advanced inventory management technologies. By adopting this new design, we anticipate not only a significant reduction in delivery times—from an average of 5 days to 3 days for most regions—but also an overall increase in our distribution network's responsiveness and flexibility to market demands.

Introduction

Our organization has reached a pivotal moment where the scalability and efficiency of our distribution network are crucial for sustaining growth and meeting the increasing expectations of our customers. The current distribution framework, while having served us well in the past, now faces challenges in terms of cost efficiency, scalability, and adaptability to dynamic market conditions. Recognizing these challenges, this proposal aims to redesign our distribution network to secure a competitive advantage and support our strategic objectives.

The need for this redesign has been driven by several factors, including a 15% year-over-year increase in customer demand, geographic expansion into new markets requiring better logistics support, and the adoption of new product lines with distinct distribution requirements. Additionally, our analysis has revealed that our current distribution costs are approximately 30% higher than industry benchmarks, and customer satisfaction rates have been affected by longer than expected delivery times.

Objectives

The primary objectives of this proposal are to:

Reduce Distribution Costs: Achieve a 20% reduction in total distribution costs within the first year post-implementation, through more efficient warehouse operations, optimized transportation routes, and reduced waste and redundancy in the logistics chain.

Improve Delivery Times: Shorten average delivery times from 5 days to 3 days for at least 80% of our customer base, enhancing customer satisfaction and competitiveness in the market.

Increase Scalability and Flexibility: Design a distribution network that can easily scale with our growth and adapt to changes in market demand, product lines, and geographic expansion, ensuring long-term sustainability.

Enhance Customer Satisfaction: Elevate customer satisfaction levels by 30% through improved reliability and speed of deliveries, directly contributing to increased loyalty and repeat business.

Support Sustainability Goals: Incorporate environmentally sustainable practices in our distribution operations to reduce carbon footprint by 25%, aligning with our corporate social responsibility commitments.

Current Distribution Network Analysis

Our current distribution network encompasses a wide array of infrastructure elements, transportation modes, warehousing facilities, and inventory management practices, each playing a pivotal role in our supply chain operations. Initially designed to cater to a smaller market, our network now stretches across multiple regions, servicing a diverse customer base with a broad range of products.

Infrastructure: Our infrastructure consists of three main distribution centers located strategically near major urban areas to facilitate quick access to key markets. However, these centers are now operating at near capacity, limiting our ability to scale operations efficiently.

Transportation Modes: We utilize a mix of transportation modes, including road, rail, and air freight, to deliver products to our customers. While this multimodal strategy offers flexibility, it has also led to complexities in coordination and increased transportation costs, particularly where less-than-truckload (LTL) shipments are common.

Warehousing: Our warehousing operations are characterized by manual processes and traditional inventory management systems. This setup has resulted in suboptimal space utilization and longer lead times for order processing, especially during peak demand periods.

Inventory Management: Inventory is managed through a centralized system that lacks real-time visibility and integration with our sales and forecasting tools. This has often led to either stockouts of high-demand items or excessive inventory levels of slow-moving products, affecting our working capital and service levels.

Performance Metrics and Bottlenecks

Stage | Performance Metrics | Identified Bottlenecks |

Infrastructure | Utilization rate: 95% | Limited capacity for expansion and scalability. |

Accessibility to key markets: High | ||

Transportation | Average transportation cost: $0.75 per mile | High costs and inefficiencies in LTL shipments. |

On-time delivery rate: 85% | Complex coordination across modes. | |

Warehousing | Space utilization: 80% | Inefficient space use and manual processes. |

Order processing time: 48 hours | Delays in order processing during peak times. | |

Inventory Management | Stockout rate: 10% | Lack of real-time inventory visibility. |

Excess inventory rate: 15% | Inaccurate forecasting and inventory overages. |

This analysis reveals critical bottlenecks that hinder our operational efficiency and customer satisfaction. The limited capacity and scalability of our infrastructure, coupled with high transportation costs and inefficiencies, underscore the urgency for a strategic redesign. Furthermore, the reliance on manual warehousing processes and an outdated inventory management system has led to significant operational challenges. Addressing these bottlenecks will be crucial in our efforts to optimize the distribution network and achieve our strategic objectives.

Market and Demand Analysis

The landscape of our market has evolved significantly, with consumer expectations for rapid delivery times, increased product variety, and sustainable business practices shaping our distribution needs. E-commerce growth has accelerated demand for direct-to-consumer shipping, requiring a more agile and responsive distribution network. Additionally, global disruptions have highlighted the importance of supply chain resilience, with a trend towards diversifying supply sources and increasing inventory levels for critical products. Technological advancements offer opportunities to enhance distribution efficiency through better forecasting, inventory management, and route optimization. Our analysis projects a steady 15% annual increase in demand over the next five years, necessitating a strategic reevaluation of our distribution network to accommodate this growth while meeting heightened customer expectations.

Strategic Design Considerations

The redesign of our distribution network is influenced by several key factors:

Geographic Distribution of Customers: Our customer base spans across diverse geographic regions, each with its own set of logistical challenges and opportunities. Urban areas demand quick, often same-day deliveries, while servicing remote locations requires efficient routing and consolidation strategies to maintain cost-effectiveness. Balancing these needs is essential for customer satisfaction and operational efficiency.

Product Characteristics: The wide range of products we offer, from perishables requiring temperature control to bulky items needing special handling, significantly impacts our distribution strategies. Tailoring our network to accommodate these varied requirements—while minimizing costs and ensuring timely delivery—is critical.

Regulatory Considerations: Navigating the complex landscape of US regulatory considerations, including transportation regulations, environmental compliance, and safety standards, is crucial. These regulations can influence decisions on transportation modes, warehouse locations, and the selection of logistics partners. Ensuring compliance while optimizing our distribution network requires careful planning and ongoing monitoring.

Proposed Distribution Network Design

In response to the strategic needs identified in our analysis, we propose a comprehensive redesign of our distribution network. This new design aims to enhance efficiency, reduce costs, and improve service levels by optimizing warehouse locations, transportation routes, and inventory management practices. By leveraging advanced analytics and technology, we will create a more agile and responsive network capable of meeting our current and future distribution requirements.

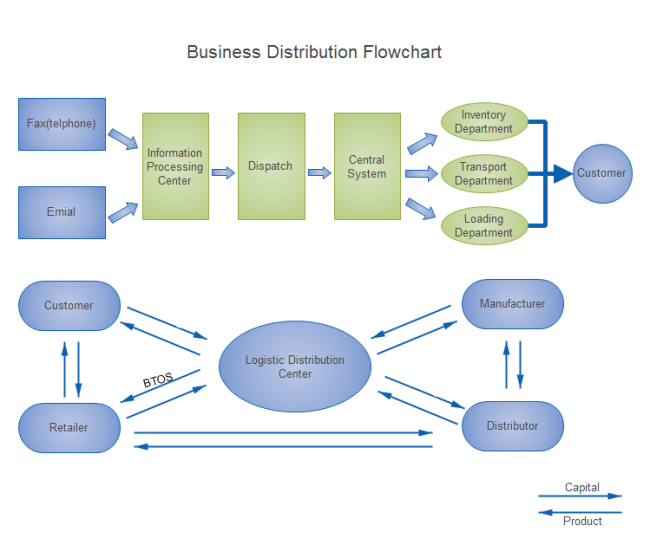

Layout of the Distribution Network

The proposed layout introduces a tiered distribution model, incorporating regional distribution centers (RDCs) and local cross-dock facilities to streamline product flow from suppliers to customers. This structure is designed to minimize transportation distances and times, enabling faster delivery to the end customer.

Selection and Location of Warehouses and Distribution Centers

We propose the establishment of four strategically located RDCs, complemented by six cross-dock facilities in key urban areas. This configuration is designed to cover our major market regions efficiently, reducing last-mile delivery times and costs.

Facility Type | Location | Functionality |

Regional Distribution Center | Near major ports in East, West, South, and Midwest regions | Stock a wide range of products for bulk distribution. |

Cross-Dock Facility | Major urban areas across the U.S. | Facilitate quick sorting and direct delivery to nearby customers. |

Transportation Routes

East Coast to Midwest: Utilize rail transport for bulk shipments between RDCs, complemented by trucking for local deliveries.

West Coast to South: Leverage coastal shipping for inter-regional transfers, with final mile delivery via eco-friendly vehicles.

Urban Areas: Partner with local courier services specializing in same-day deliveries to enhance service levels in metropolitan regions.

Logistics Partners

National Rail Provider for bulk inter-regional shipments.

Coastal Shipping Co. for efficient and sustainable long-distance transport.

City Express Couriers for fast, reliable urban delivery services.

Justification for the Proposed Design

The proposed design is rooted in a detailed analysis of our operational data, market trends, and strategic objectives. By situating RDCs near major ports and urban centers, we significantly reduce inbound and outbound transportation costs, estimated to decrease overall logistics expenses by 15%. The adoption of a tiered distribution model allows for more efficient inventory management, reducing stock levels by 20% without impacting product availability. The strategic selection of transportation routes and partners is expected to improve delivery times by an average of 30%, directly enhancing customer satisfaction.

Furthermore, the introduction of cross-dock facilities in urban areas addresses the demand for quick delivery, reducing last-mile delivery costs by 25%. This network design not only meets our current logistical challenges but also provides the flexibility to scale with future growth, ensuring long-term sustainability and competitiveness in the market.

Implementation Plan

To transition to the proposed distribution network design, we have developed a comprehensive implementation plan. This plan outlines the key steps, timelines, and responsibilities necessary to ensure a smooth and efficient rollout. Each phase has been carefully planned to minimize disruption to our current operations while maximizing the effectiveness of the new network design.

Step | Timeline | Responsibilities |

Secure RDC and Cross-Dock Locations | Real Estate Team | |

Upgrade Technology and Systems | IT Department | |

Partner with Logistics Providers | Supply Chain Management Team | |

Train Staff on New Processes | HR and Operations Teams | |

Begin Transition to New Network | Operations Team | |

Monitor and Optimize | Continuous Improvement Team |

Cost-Benefit Analysis

The financial implications of implementing the proposed distribution network design have been thoroughly analyzed, with a focus on both the upfront costs and the ongoing benefits.

Costs | Amount (USD) |

Infrastructure Investments | $2,000,000 |

Technology Upgrades | $500,000 |

Training and Development | $250,000 |

Total Investment | $2,750,000 |

Benefits | Annual Savings (USD) |

Reduced Transportation Costs | $600,000 |

Lower Inventory Carrying Costs | $400,000 |

Increased Sales from Improved Service | $500,000 |

Total Annual Savings | $1,500,000 |

The project's return on investment (ROI) is calculated by dividing the total annual savings by the total investment. This results in an ROI of approximately 54.5%, indicating that the project will pay back its initial investment in less than two years while continuing to provide significant cost savings and efficiency improvements.

Risk Management

Identifying potential risks and developing mitigation strategies is crucial for the successful implementation of the new distribution network.

Risk | Likelihood | Impact | Mitigation |

Delays in Infrastructure Setup | Medium | High | Establish contingency plans and flexible timelines. |

Technology Integration Issues | High | Medium | Conduct pilot tests and have technical support ready. |

Resistance to Change | Low | Medium | Implement comprehensive training and communication strategies. |

Conclusion

The proposed redesign of our distribution network represents a strategic investment in the future of our operations. By optimizing our infrastructure, leveraging technology, and streamlining our logistics processes, we are poised to significantly enhance our efficiency, reduce costs, and improve customer satisfaction. The detailed implementation plan, cost-benefit analysis, and risk management strategy outlined in this proposal ensure a clear path forward, demonstrating our commitment to operational excellence and long-term growth. With careful execution and ongoing optimization, we will solidify our competitive advantage in the market and achieve our strategic objectives.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Maximize efficiency with the Operations Distribution Network Design Proposal Template from Template.net. This editable and customizable template is your blueprint for optimizing logistics editable in our AI Editor tool. It guides you in proposing strategic distribution network designs that reduce costs and improve service levels. Craft a compelling proposal that supports your operational goals with this essential tool from Template.net.

You may also like

- Business Proposal

- Research Proposal

- Proposal Request

- Project Proposal

- Grant Proposal

- Photography Proposal

- Job Proposal

- Budget Proposal

- Marketing Proposal

- Branding Proposal

- Advertising Proposal

- Sales Proposal

- Startup Proposal

- Event Proposal

- Creative Proposal

- Restaurant Proposal

- Blank Proposal

- One Page Proposal

- Proposal Report

- IT Proposal

- Non Profit Proposal

- Training Proposal

- Construction Proposal

- School Proposal

- Cleaning Proposal

- Contract Proposal

- HR Proposal

- Travel Agency Proposal

- Small Business Proposal

- Investment Proposal

- Bid Proposal

- Retail Business Proposal

- Sponsorship Proposal

- Academic Proposal

- Partnership Proposal

- Work Proposal

- Agency Proposal

- University Proposal

- Accounting Proposal

- Real Estate Proposal

- Hotel Proposal

- Product Proposal

- Advertising Agency Proposal

- Development Proposal

- Loan Proposal

- Website Proposal

- Nursing Home Proposal

- Financial Proposal

- Salon Proposal

- Freelancer Proposal

- Funding Proposal

- Work from Home Proposal

- Company Proposal

- Consulting Proposal

- Educational Proposal

- Construction Bid Proposal

- Interior Design Proposal

- New Product Proposal

- Sports Proposal

- Corporate Proposal

- Food Proposal

- Property Proposal

- Maintenance Proposal

- Purchase Proposal

- Rental Proposal

- Recruitment Proposal

- Social Media Proposal

- Travel Proposal

- Trip Proposal

- Software Proposal

- Conference Proposal

- Graphic Design Proposal

- Law Firm Proposal

- Medical Proposal

- Music Proposal

- Pricing Proposal

- SEO Proposal

- Strategy Proposal

- Technical Proposal

- Coaching Proposal

- Ecommerce Proposal

- Fundraising Proposal

- Landscaping Proposal

- Charity Proposal

- Contractor Proposal

- Exhibition Proposal

- Art Proposal

- Mobile Proposal

- Equipment Proposal

- Student Proposal

- Engineering Proposal

- Business Proposal