Free Performance Qualification Protocol

Prepared by: | [YOUR NAME] |

|---|---|

Company Name: | [YOUR COMPANY NAME] |

Department: | [YOUR DEPARTMENT] |

Date: | [DATE] |

I. Objective

The objective of this Performance Qualification (PQ) Protocol is to ensure that the [YOUR COMPANY NAME] meets predefined acceptance criteria and performs as intended under operational conditions. This protocol outlines the procedures, acceptance criteria, and responsibilities for conducting the PQ of the [YOUR COMPANY NAME].

II. Scope

This PQ Protocol applies to the [Your Company Name] located at [Production Facility A]. The PQ will be performed by qualified personnel by relevant standard operating procedures (SOPs) and regulatory requirements.

III. Responsibilities

Project Manager: Oversees the entire PQ process and ensures that it is conducted in compliance with established protocols and timelines.

Quality Assurance (QA) Representative: Reviews and approves the PQ Protocol. Monitors the execution of PQ activities to ensure compliance with regulatory requirements.

Operations Personnel: Execute the PQ activities as per the protocol and provide necessary support.

Maintenance Personnel: Ensure that the [YOUR COMPANY NAME] is properly maintained and calibrated for the PQ.

Documentation Specialist: Maintains accurate records of all PQ activities and results.

IV. Equipment and Materials Required

[YOUR COMPANY NAME]

Calibration tools and standards

Test materials specific to your processes

Data logging equipment

Environmental monitoring devices

V. Procedure

Preparation:

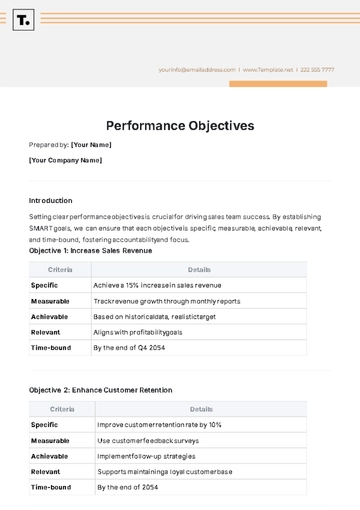

Review the User Requirement Specifications (URS) and Design Qualification (DQ) documentation to understand the intended performance criteria of the [YOUR COMPANY NAME].

Ensure that the [YOUR COMPANY NAME] is installed and calibrated as per manufacturer specifications.

Verify that all necessary documentation, including SOPs, calibration certificates, and maintenance records, are available and up to date.

Execution:

a. Initial System Checks:

Power on the [YOUR COMPANY NAME] and perform basic functionality tests.

Verify that safety features are operational and emergency stop procedures are in place.

b. Functional Testing:

Execute predefined test scripts to assess the functionality of the [YOUR COMPANY NAME] under normal operating conditions.

Document any deviations from expected performance and investigate root causes.

c. Performance Testing:

Conduct performance tests under simulated operational conditions to evaluate the [YOUR COMPANY NAME] against acceptance criteria.

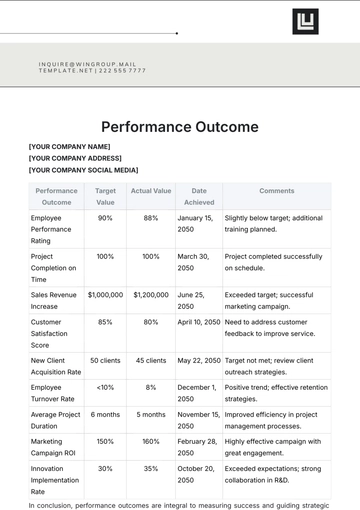

Measure key performance parameters such as accuracy, precision, speed, and reliability.

d. Data Integrity Testing:

Verify the integrity of data generated by the [YOUR COMPANY NAME] through data logging, recording, and retrieval procedures.

Ensure compliance with data integrity regulations and guidelines.

e. Environmental Conditions Testing:

Validate the performance of the [YOUR COMPANY NAME] under varying environmental conditions (e.g., temperature, humidity) as specified in the URS.

f. Operational Qualification (OQ):

If applicable, ensure that any OQ requirements are addressed as part of the PQ process.

VI. Documentation

Record all test results, observations, and deviations in the PQ Report.

Include details of any corrective actions taken to address deviations.

Obtain signatures from relevant personnel to attest to the completion and accuracy of the PQ activities.

VII. Conclusion

Review the PQ Report for completeness and accuracy.

Submit the PQ Report to the QA Representative for review and approval.

Upon approval, the [YOUR COMPANY NAME] is considered qualified for operational use.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Explore the Performance Qualification Protocol Template, available exclusively on Template.net. This versatile resource is fully editable and customizable to suit your validation requirements precisely. With seamless integration with our Ai Editor Tool, streamline protocol creation effortlessly. Elevate your validation procedures today with this essential template solution, ensuring precision and compliance every step of the way.