Free Operations Quality Improvement Strategy Guide

1. Executive Summary

[Your Company Name] is committed to excellence in all aspects of our operations. This Operations Quality Improvement Strategy Guide outlines our systematic approach to enhancing the quality of our products and services. Through this guide, we aim to identify key areas for improvement, implement best practices in quality management, and foster a culture of continuous improvement. Our objective is to not only meet but exceed customer expectations, ensuring our competitive edge in the market. This strategy is an integral component of our broader organizational commitment to operational excellence. By setting clear objectives, employing proven quality improvement methodologies, and engaging our entire workforce in this endeavor, we anticipate significant advancements in our operational capabilities. These improvements will not only enhance customer satisfaction but also drive efficiency, reduce costs, and improve our market position, making [Your Company Name] a leader in quality within our industry.

2. Introduction

The purpose of this strategy guide is to provide a structured approach to quality improvement within [Your Company Name]. Covering all operational areas, from production to customer service, this guide sets forth our methodology for assessing, planning, and implementing quality improvements. By following this guide, we aim to enhance operational efficiency, product quality, and customer satisfaction. In the dynamic landscape of our industry, staying ahead requires not just meeting but exceeding the evolving expectations of our customers and stakeholders.

This guide is crafted to align with our strategic vision of becoming the benchmark for quality in our sector. It serves as a testament to our proactive stance on quality improvement, underlining our belief that the pursuit of excellence is a continuous journey. Through this guide, we set the stage for transformative change, laying down a roadmap that will lead [Your Company Name] towards unparalleled quality and operational excellence.

3. Quality Improvement Framework

Our quality improvement framework at [Your Company Name] is built on a foundation of Total Quality Management (TQM) principles, Lean methodologies, and the disciplined rigor of Six Sigma. This comprehensive framework is designed to integrate quality improvement into every facet of our operations, ensuring that excellence is a standard, not an exception. We recognize that quality is not solely the responsibility of the quality department but a collective commitment that involves every employee, from executive leadership to frontline staff.

The framework is structured to encourage continuous improvement, customer focus, process optimization, and waste reduction. It emphasizes the importance of data-driven decision-making and employs statistical methods to identify areas of improvement. Our approach is holistic, recognizing that quality extends beyond the products and services we offer to encompass every interaction within the operational cycle. This includes supplier interactions, production processes, employee engagement, and customer satisfaction metrics.

A. Principles of Quality Management:

Customer Focus: Understanding and meeting customer needs and expectations are paramount. We regularly gather and analyze customer feedback to align our improvement initiatives with their values.

Leadership Commitment: Our leaders foster a quality culture by setting clear expectations, providing necessary resources, and leading by example. They ensure that the organization's vision, mission, and quality objectives are clearly communicated and understood at all levels.

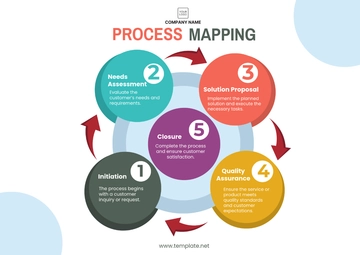

Process Approach: We view our operations as a series of interconnected processes. By understanding and managing these processes effectively, we can achieve more efficient outcomes and improve the quality of our products and services.

Continuous Improvement: Continuous improvement is the heart of our framework. We employ iterative cycles of planning, doing, checking, and acting (PDCA) to make ongoing enhancements to our operations.

B. Alignment with Organizational Goals and Objectives:

Our quality improvement framework is not a standalone initiative; it is deeply integrated with our overall business strategy. The goals and objectives set within this framework support our broader organizational aims, such as increasing market share, reducing operational costs, enhancing product innovation, and improving employee satisfaction and engagement. By aligning our quality improvement efforts with these strategic goals, we ensure that our initiatives are not only relevant but also contribute significantly to our long-term success.

4. Assessment of Current Operations

To understand our starting point, we conducted a comprehensive assessment of our current operations using a variety of tools, including process mapping, SWOT analysis, and customer feedback. Key Performance Indicators (KPIs) were established to measure our operational efficiency, product quality, and customer satisfaction levels. Baseline performance data was collected to identify areas requiring immediate attention.

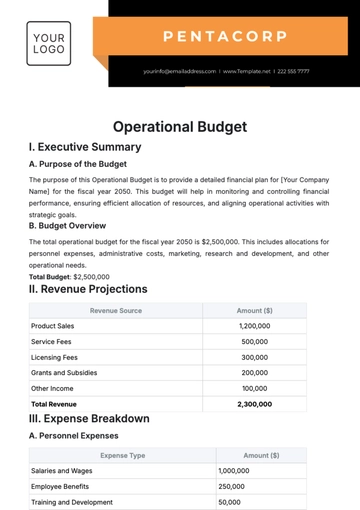

Table 1: Baseline Performance Data

KPI | Baseline Measurement | Target |

|---|---|---|

Customer Satisfaction | 85% | 95% |

Defect Rate | 2% | <1% |

Order Fulfillment Time | 48 Hours | 24 Hours |

5. Areas for Improvement

Following a comprehensive assessment of our current operations, several key areas have been identified as critical for improvement to meet and exceed our quality objectives at [Your Company Name]. These areas have been prioritized based on their impact on customer satisfaction, operational efficiency, and overall product quality.

Customer Service Enhancement: Our goal is to transform our customer service into a seamless, responsive unit that exceeds customer expectations. We aim to reduce response times, improve resolution rates, and enhance overall customer communication. Strategies include implementing advanced customer service platforms, training customer service representatives in conflict resolution and customer engagement, and establishing a feedback loop for continuous service improvement.

Production Efficiency: Inefficient processes lead to waste, increased costs, and delayed deliveries. Our focus is on streamlining production processes through lean manufacturing principles, minimizing waste, and optimizing resource use. This will involve a thorough analysis of current production workflows, identification of bottlenecks, and the implementation of just-in-time (JIT) production techniques to enhance throughput.

Product Quality: A cornerstone of our competitive advantage is the quality of our products. Initiatives to improve product quality will include enhancing our quality control (QC) processes, investing in state-of-the-art QC equipment, and conducting regular quality audits. By reducing defect rates and ensuring consistent product quality, we aim to build stronger trust with our customers and reduce costs associated with rework and returns.

Each area of improvement has been assigned specific, measurable targets that align with our strategic objectives. By focusing our efforts on these areas, we anticipate not only an improvement in our operational performance but also an increase in customer loyalty and market share.

6. Quality Improvement Tools and Techniques

To address the identified areas for improvement effectively, [Your Company Name] will leverage a variety of quality improvement tools and techniques. These tools are selected based on their proven effectiveness in enhancing operational quality and efficiency.

Table 2: Different Tools and Techniques

Tools & Techniques | Details |

|---|---|

Six Sigma | Our commitment to minimizing defects and improving process quality will be supported by Six Sigma methodologies. By utilizing DMAIC (Define, Measure, Analyze, Improve, Control) and DMADV (Define, Measure, Analyze, Design, Verify) frameworks, we will target process improvements and design quality into our products from the outset. |

PDCA Cycle | The Plan-Do-Check-Act (PDCA) cycle will be employed across all departments to foster a culture of continuous improvement. This iterative process allows for quick identification of areas for improvement, implementation of changes, and evaluation of results, facilitating ongoing enhancements in our operations. |

5S Methodology | To improve workplace organization and efficiency, the 5S methodology (Sort, Set in order, Shine, Standardize, Sustain) will be adopted. This approach not only enhances productivity but also contributes to a safer, more organized work environment that fosters quality improvement. |

7. Quality Improvement Team Structure

To drive our quality improvement initiatives, [Your Company Name] has established a dedicated Quality Improvement Team (QIT) structured to ensure cross-functional representation and collaboration. The QIT is composed of members from key departments, including production, quality control, customer service, and management, to ensure a holistic approach to quality improvement.

Roles and Responsibilities: Each QIT member is responsible for championing quality improvement within their department, identifying opportunities for improvement, and collaborating on cross-departmental initiatives. The team is led by a Quality Improvement Manager who coordinates the team's activities, ensures alignment with strategic objectives, and reports progress to senior management.

Cross-Functional Teams: For specific initiatives, cross-functional sub-teams are formed to leverage diverse skills and perspectives. These sub-teams are tasked with tackling specific projects, from redesigning a production process to implementing a new customer feedback system, ensuring that improvements are comprehensive and impactful.

Communication and Collaboration Strategies: Regular QIT meetings are held to share progress, discuss challenges, and plan future initiatives. This fosters an environment of collaboration and continuous learning. Additionally, communication channels such as an internal quality improvement portal and regular updates in company-wide meetings are established to keep the entire organization informed and engaged in the quality improvement process.

8. Quality Improvement Plan

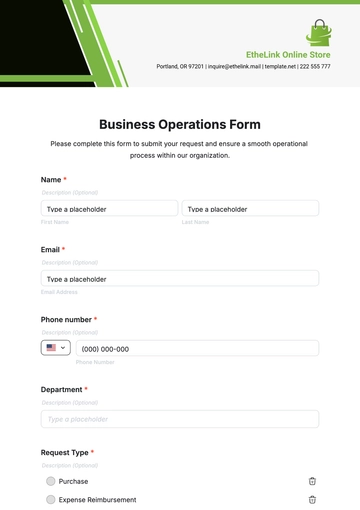

For each identified area of improvement, specific objectives, targets, and timelines have been set. Resources required for each initiative have also been allocated.

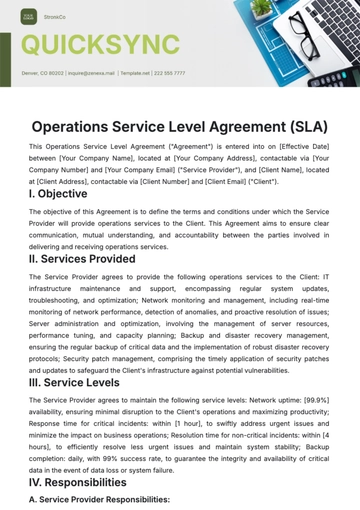

Table 3: Quality Improvement Plan Overview

Area of Improvement | Objective | Target | Resources Allocated |

|---|---|---|---|

Customer Service | Improve response time to customer inquiries | <24 hours | 2 additional CS reps |

Production Efficiency | Reduce waste by 30% | 30% reduction | Lean training for staff |

Product Quality | Reduce defect rate to below 1% | <1% | New QC equipment |

9. Implementation Strategy

The implementation of our quality improvement plan involves:

Table 4: Strategies for Quality Improvement Plan

Strategy | Details |

|---|---|

Training | Providing staff with the necessary training on Lean Six Sigma and other relevant methodologies. |

Quality Control Enhancements | Upgrading equipment and refining QC protocols. |

Process Re-engineering | Redesigning processes to eliminate waste and improve efficiency. |

10. Performance Evaluation and Monitoring

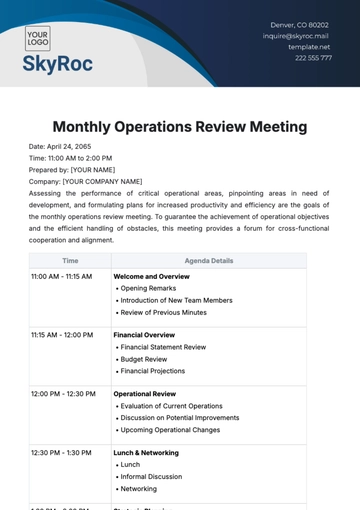

At [Your Company Name], performance evaluation and monitoring are integral to our continuous improvement strategy, embodying our commitment to operational excellence and quality enhancement. This multifaceted process extends beyond the mere tracking of performance metrics; it's a comprehensive assessment that fuels our strategic decisions and improvement initiatives. By meticulously analyzing Key Performance Indicators (KPIs) — such as production efficiency, customer satisfaction levels, and product quality metrics — we gain valuable insights into the effectiveness of our operational processes and quality improvement efforts. This quantitative data, combined with qualitative feedback from customers and team members, provides a holistic view of our performance, highlighting successes and pinpointing areas in need of further enhancement.

Regular, structured review meetings serve as the backbone of our evaluation process, fostering an environment of accountability and continuous learning. These sessions facilitate open discussions on performance trends, challenges faced, and potential strategies for improvement, ensuring that our quality improvement initiatives remain dynamic and responsive to internal and external feedback. Adjustments to our improvement plans are made in real time, based on this comprehensive analysis, allowing us to remain agile and adapt to changing circumstances or emerging opportunities for enhancement. This ongoing cycle of evaluation, discussion, and adjustment ensures that [Your Company Name] not only achieves its quality objectives but also upholds a culture of excellence and continuous improvement.

11. Training and Development

At [Your Company Name], our training and development programs are meticulously designed to support our quality improvement strategy, ensuring that our team has the necessary skills and knowledge to contribute effectively. Our approach includes:

A. Foundational Quality Management Training:

Introduction to quality management principles for all new hires.

Overview of [Your Company Name]'s quality standards and expectations.

B. Advanced Methodology Training:

Lean Six Sigma training for selected team members, focusing on Yellow, Green, and Black Belt certifications.

Workshops on specific quality improvement tools like Root Cause Analysis, 5S, and Kaizen.

C. Technical Skill Enhancement:

Specialized training sessions tailored to different departments, enhancing technical skills directly related to quality improvement in their specific areas.

Regular updates and refresher courses on the latest industry standards and technologies.

D. Leadership Development Programs:

Leadership training for team leads and managers, emphasizing change management, effective communication, and team motivation strategies.

Mentorship programs pairing emerging leaders with experienced executives to foster leadership skills.

E. Problem-solving Workshops:

Collaborative problem-solving sessions that encourage innovative thinking and practical solutions to quality challenges.

Scenario-based training to enhance decision-making skills under pressure.

F. Recognition and Reward System:

A formal recognition program to celebrate individuals and teams who make significant contributions to quality improvement.

Awards, acknowledgments, and incentives for outstanding performance in quality initiatives.

G. Feedback Loop for Training Effectiveness:

Regular assessments to measure the impact of training programs on individual performance and overall quality improvement.

Surveys and feedback mechanisms to continuously adapt and refine training content based on participant input and evolving organizational needs.

12. Supplier and Stakeholder Engagement

In our quest for quality excellence, [Your Company Name] extends its focus beyond internal operations to encompass suppliers and stakeholders, fostering a collaborative approach to quality improvement. We recognize that our suppliers play a crucial role in our quality ecosystem; hence, we engage them through regular assessments, collaborative workshops, and shared quality objectives. This partnership approach ensures that the materials and services we procure meet our high-quality standards, contributing to the overall excellence of our products and services.

Engaging stakeholders — including customers, investors, and community partners — is equally vital. We maintain transparent communication channels to keep stakeholders informed of our quality initiatives and to gather their feedback, which often provides critical insights for further improvements. Customer feedback, in particular, is invaluable in guiding our continuous improvement efforts, enabling us to align our strategies more closely with market needs and expectations. By building strong, collaborative relationships with all stakeholders, [Your Company Name] not only enhances its operational and product quality but also strengthens its reputation as a quality leader in the industry, committed to excellence and continuous improvement in all aspects of its operations.

13. Risk Management

In the journey of continuous quality improvement at [Your Company Name], risk management plays a pivotal role in safeguarding our operations and ensuring the successful implementation of our quality initiatives. Recognizing potential risks and developing effective strategies to mitigate them is crucial for maintaining operational stability and achieving our quality objectives. Our risk management process is structured and proactive, designed to identify, assess, and address risks at every stage of our quality improvement efforts.

A. Risk Identification:

The first step in our risk management process involves a thorough identification of potential risks that could impact our quality improvement projects. This includes risks related to changes in supplier quality, process modifications, technology upgrades, and employee engagement. We utilize a variety of tools such as SWOT analysis, brainstorming sessions, and feedback from stakeholders to compile a comprehensive list of potential risks.

B. Risk Assessment:

Once risks have been identified, we conduct a detailed assessment to determine their likelihood and potential impact on our operations. This assessment helps us prioritize risks based on their severity and the urgency of mitigation actions. We employ risk matrices and scoring systems to quantify risk levels, providing a clear framework for prioritization.

C. Risk Mitigation Strategies:

For each high-priority risk, we develop tailored mitigation strategies aimed at reducing the likelihood of occurrence or minimizing the impact should the risk materialize. These strategies vary depending on the nature of the risk and may include process redesign, increased training and awareness, enhanced quality controls, and stronger supplier agreements.

D. Implementation and Monitoring:

With mitigation strategies in place, we proceed to implement these measures, incorporating them into our quality improvement plans. Continuous monitoring is essential to ensure the effectiveness of our risk mitigation efforts. We establish key indicators to track the status of each risk and the performance of mitigation strategies, allowing for timely adjustments as necessary.

E. Contingency Planning:

Recognizing that not all risks can be fully eliminated, we also develop contingency plans for managing the potential consequences of risk events. These plans outline specific steps to be taken in response to risk occurrences, ensuring that we can quickly and effectively address issues without significant disruption to our operations.

F. Communication and Reporting:

Effective communication is vital to our risk management process. We ensure that all team members, from frontline staff to senior management, are aware of potential risks and their roles in mitigating them. Regular reporting on risk status, mitigation actions, and any incidents that occur keeps stakeholders informed and engaged in our risk management efforts.

14. Conclusion and Next Steps

As we conclude this Operations Quality Improvement Strategy Guide for [Your Company Name], we reflect on the importance of a structured and strategic approach to enhancing the quality of our operations. This guide has provided a comprehensive roadmap for identifying areas of improvement, implementing effective strategies, and continuously evaluating our progress. The journey towards exceptional operational quality is perpetual and demands ongoing commitment, collaboration, and innovation from every member of our organization.

A. Next Steps:

Implementation of the Quality Improvement Plan | Immediate action is required to begin the implementation of the strategies outlined in this guide. Department leads will be responsible for developing detailed action plans for their respective areas, ensuring alignment with the overall quality improvement objectives. |

Training and Development Initiatives | A schedule for the upcoming training and development programs will be circulated to ensure all team members have the opportunity to enhance their skills and knowledge related to quality improvement tools and techniques. |

Regular Performance Reviews | Establishing a regular schedule for performance review meetings is crucial. These reviews will facilitate the monitoring of progress against the set KPIs and objectives, allowing for timely adjustments to our strategies as needed. |

Review and Update of the Strategy Guide | Recognizing that continuous improvement is a dynamic process, this Strategy Guide will be reviewed and updated annually to reflect changes in our operational environment, technological advancements, and lessons learned during implementation. |

In conclusion, the Operations Quality Improvement Strategy Guide marks the beginning of a renewed focus on operational excellence at [Your Company Name]. It is a call to action for everyone within the organization to play an active role in driving quality improvements. By adhering to the principles and strategies outlined in this guide, we are not only committing to higher standards of quality but also to the sustained success and growth of our organization. Together, we will advance towards our goal of becoming a leader in operational quality, setting new benchmarks for excellence in our industry.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Elevate your quality initiatives with Template.net's Operations Quality Improvement Strategy Guide Template. This customizable and editable template, powered by our Ai Editor Tool, is your roadmap to strategic quality enhancement. Designed for operational leaders, it facilitates the development of effective quality improvement strategies. Transform your operations with this indispensable guide, exclusively available at Template.net.