Free Detailed Operations Supplier Onboarding Guide

I. Introduction

A. Purpose of the Guide

The purpose of this guide is to provide a comprehensive overview of the supplier onboarding process in our company. This process is crucial for ensuring that new suppliers understand our company’s requirements and expectations. It is designed to streamline the integration of new suppliers into our operations, ensuring a smooth transition and setting the stage for a successful partnership.

Importance of Supplier Onboarding

Supplier onboarding is a critical step in establishing a successful supplier relationship. It allows us to communicate our company’s values, expectations, and procedures to the supplier, ensuring alignment from the outset. A well-executed onboarding process can lead to improved supplier performance, stronger relationships, and ultimately, a more robust supply chain.

Goals of the Guide

The goal of this guide is to provide clear, step-by-step instructions for the supplier onboarding process. It aims to ensure that all relevant information is communicated effectively to the supplier, and that the supplier is equipped with the knowledge and resources needed to meet our company’s requirements.

B. Scope of the Guide

This guide covers all aspects of the supplier onboarding process, from initial selection and evaluation of the supplier, through to the integration of the supplier into our operations. It is intended for use by both our company’s procurement team and the suppliers themselves.

Who Should Use This Guide

This guide is intended for use by our company’s procurement team, who are responsible for managing the supplier onboarding process. It can also be used by the suppliers themselves as a resource to understand our company’s requirements and expectations.

What is Covered in This Guide

This guide covers all stages of the supplier onboarding process, including supplier selection, onboarding procedures, post-onboarding activities, and ongoing supplier management. It provides detailed explanations of each step in the process, along with practical tips and best practices.

C. How to Use This Guide

This guide is designed to be user-friendly and easy to navigate. Here’s how to use it:

Start with the Overview: Begin by reading the introduction to understand the purpose and scope of the guide. This will give you a clear idea of what to expect from the supplier onboarding process.

Follow the Process: Follow the guide step-by-step. Each section corresponds to a stage in the supplier onboarding process and provides detailed instructions and tips.

Refer Back as Needed: Use this guide as a reference tool. You can refer back to it at any time during the supplier onboarding process.

D. Updates and Revisions

This guide is a living document. It will be updated and revised as needed to reflect changes in our company’s processes, industry standards, or regulatory requirements.

Regular Updates: We will regularly review and update this guide to ensure it remains accurate and relevant. Updates may be prompted by changes in our company’s processes, feedback from users, or new industry best practices.

Version Control: Each update will be clearly marked with a version number and date of revision. This ensures that users always have access to the most recent and accurate information.

II. Supplier Selection

Before the onboarding process begins, suppliers must go through a selection process. This involves:

A. Supplier Evaluation

The supplier evaluation process is a critical first step in the supplier selection process. It involves assessing potential suppliers based on their ability to meet our company’s requirements in terms of product quality, pricing, delivery times, and service. The following table outlines the key criteria for the supplier evaluation process:

Criteria | Description |

|---|---|

Product Quality | Does the supplier have a track record of delivering high-quality products? |

Pricing | Does the supplier offer competitive pricing? |

Delivery Times | Can the supplier meet our delivery time requirements? |

Service | Does the supplier provide excellent customer service? |

The criteria listed in the table above serve as a guide for evaluating potential suppliers. They are designed to ensure that the suppliers we select are capable of meeting our company’s specific needs and standards.

The importance of these criteria cannot be overstated. Product quality is crucial because it directly impacts the quality of our own products and services. Competitive pricing is important for managing costs and ensuring the financial sustainability of our company. Reliable delivery times are essential for maintaining efficient operations and meeting customer expectations. Excellent customer service is key for resolving issues promptly and maintaining a positive business relationship.

In essence, these criteria help us identify suppliers who are not only capable of meeting our immediate needs, but who can also contribute to our company’s long-term success. By using these criteria as a guide, we can ensure a thorough and objective supplier evaluation process.

B. Supplier Approval

Once a supplier has been evaluated and deemed suitable, they are approved and can proceed to the onboarding process. The approval process is a critical step in ensuring that only qualified and reliable suppliers are added to our company’s supply chain. It typically involves the following steps:

Due Diligence: Due diligence is the process of verifying the information provided by the supplier. This could involve checking references, reviewing financial stability, and verifying certifications. It’s an essential step to ensure that the supplier is reliable and capable of meeting our company’s requirements. For example, checking references can provide insights into the supplier’s track record with other clients, while reviewing financial stability can help assess the supplier’s ability to fulfill large orders or handle long-term contracts.

Risk Assessment: Risk assessment is the process of identifying any potential risks associated with the supplier. This could involve assessing the supplier’s financial stability, business continuity plans, and compliance with laws and regulations. It’s a crucial step to mitigate potential risks that could disrupt our supply chain. For instance, assessing the supplier’s business continuity plans can help ensure that they have measures in place to handle disruptions, such as natural disasters or equipment failures, that could affect their ability to deliver products or services.

Approval: If the due diligence and risk assessment are satisfactory, the supplier is approved. The approved supplier is then added to our approved supplier list and can proceed to the onboarding process. This final step is a formal acknowledgment of the supplier’s ability to meet our company’s standards and requirements. It signifies the beginning of our business relationship with the supplier.

III. Supplier Onboarding Process

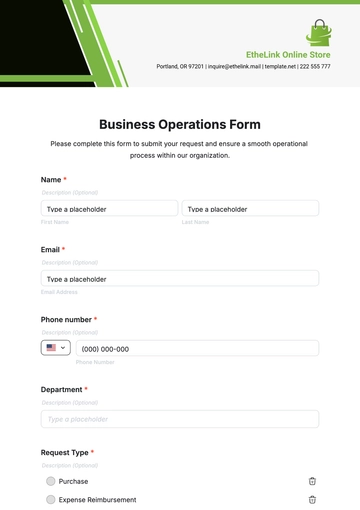

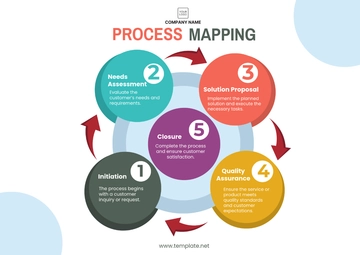

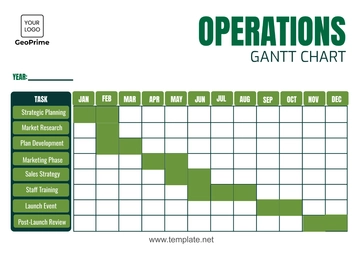

The supplier onboarding process is a systematic method to welcome a new supplier into our company’s operations. This process is designed to ensure that the supplier is well-versed with our company’s requirements and is equipped to fulfill them. The following diagram provides a summary of these steps:

Supplier Registration: The first step in the onboarding process is supplier registration. During this step, the supplier provides necessary information such as company details, contact information, and bank details. This information is entered into our company’s supplier management system. This step is crucial for establishing the supplier’s profile in our system and ensuring we have all the necessary information to conduct business with them.

Documentation: The next step is documentation. The supplier provides necessary documentation, such as business licenses, certificates of insurance, and quality certifications. These documents are reviewed and verified by our company. This step is crucial for ensuring the supplier meets all legal and regulatory requirements and adheres to industry standards.

Agreement on Terms: Once the supplier’s documentation has been reviewed and approved, the next step is to agree on terms. The supplier and our company agree on terms and conditions, such as pricing, payment terms, and delivery schedules. These terms are outlined in a supplier agreement, which is signed by both parties. This step is crucial for establishing clear expectations and guidelines for the business relationship.

Training: After the agreement on terms, the supplier receives training on our company’s policies and procedures, such as order placement, invoicing, and product quality requirements. This step is crucial for ensuring the supplier understands how to do business with our company and meets our operational requirements.

Integration: The final step in the onboarding process is integration. The supplier’s systems are integrated with our company’s systems, allowing for seamless communication and data exchange. This step is crucial for ensuring smooth and efficient business operations.

The supplier onboarding process is of paramount importance to our company. It not only ensures that the supplier is well-equipped to meet our company’s requirements but also establishes a clear and transparent business relationship. This process helps in mitigating any potential misunderstandings or conflicts in the future. Moreover, it allows for seamless integration of the supplier’s systems with ours, promoting efficient business operations. Lastly, it sets the stage for a long-term, mutually beneficial relationship between our company and the supplier.

IV. Post-Onboarding Activities

After the onboarding process, we engage in several activities to ensure a successful supplier relationship:

A. Performance Monitoring

This is a critical activity that involves the following steps:

Defining Metrics: We define key performance indicators (KPIs) such as on-time delivery rate, product quality, and service level. These metrics are tailored to our company’s specific needs and expectations, and they serve as a benchmark for supplier performance.

Setting Targets: We set achievable yet challenging targets for each KPI to provide a clear performance expectation for the supplier. These targets are based on industry standards and our company’s strategic goals.

Data Collection: We collect data related to these KPIs for evaluation. This data is gathered through various means, including supplier reports, system analytics, and direct feedback from internal stakeholders. This ensures a comprehensive view of the supplier’s performance.

Performance Analysis: We analyze the collected data to assess the supplier’s performance against the agreed-upon metrics. This analysis helps us understand the supplier’s strengths and areas for improvement, and it forms the basis for our feedback to the supplier.

Performance Reporting: We generate detailed reports outlining the supplier’s performance. These reports are shared with the supplier and relevant stakeholders within our company, promoting transparency and mutual understanding.

B. Regular Communication

Maintaining open lines of communication with the supplier is crucial. This involves:

Establishing Communication Channels: We establish clear and effective channels of communication with the supplier. These channels could include regular meetings, email correspondence, or a dedicated liaison within our company.

Issue Resolution: We promptly address any issues that arise in the course of the business relationship. This includes setting up regular meetings to discuss any concerns or problems, and working collaboratively to find solutions. This proactive approach helps prevent minor issues from escalating into major problems.

Feedback Provision: We provide constructive feedback to the supplier on their performance. This feedback is based on the results of our performance monitoring and is intended to help the supplier improve. It is delivered in a respectful and supportive manner, fostering a positive business relationship.

Future Planning: We discuss future plans and expectations with the supplier to align our business goals. This includes discussing potential changes in demand, new product introductions, and strategic initiatives. These discussions ensure that the supplier is well-prepared for any changes and can adapt their operations accordingly.

Communication Review: We periodically review our communication practices with the supplier to ensure they remain effective and efficient. This could involve soliciting feedback from the supplier on our communication, and making adjustments as necessary.

C. Continuous Improvement

We strive for continuous improvement in our supplier relationships. This includes:

Identifying Opportunities: We identify areas where the supplier’s performance can be enhanced. This could involve process improvements, technology upgrades, or training opportunities. These opportunities are identified through performance monitoring, feedback from the supplier, and input from internal stakeholders.

Planning Improvements: We develop a detailed plan for implementing the identified improvements. This plan includes clear goals, timelines, and responsibilities. It also considers any potential challenges and outlines strategies to overcome them.

Implementing Improvements: We work with the supplier to implement changes that can improve their performance. This could involve joint projects, investment in new equipment, or changes to operational procedures. We provide support and resources as necessary to ensure the success of these improvements.

Reviewing Results: We review the results of these improvements to ensure they are effective in enhancing the supplier’s performance and our overall relationship. This involves tracking the impact of improvements over time, comparing the results to our targets, and making further adjustments as necessary.

Continuous Improvement Cycle: We repeat this cycle of identifying, planning, implementing, and reviewing improvements on a regular basis to ensure continuous enhancement of the supplier’s performance and our relationship with them. This ongoing commitment to improvement helps ensure the long-term success of our supplier relationships.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Whether initiating supplier relationships or refining onboarding procedures you're in the right place with our editable Detailed Operations Supplier Onboarding Guide Template from Template.net! This customizable guide offers a way to efficiently onboard suppliers effectively. Guarantee a seamless onboarding experience tailored to specific supplier relationships with our AI Editor Tool!