Free Operations Supply Chain Case Study

I. Introduction

A. Background of the Company

The company under study is a renowned entity in the manufacturing industry. With a rich history spanning several decades, it has carved out a niche for itself on the global stage. Its product portfolio is diverse, catering to a broad spectrum of customer needs across various sectors. The company’s operations are truly global, with manufacturing units, supply chains, and markets spread across multiple continents. It employs a large workforce worldwide, all working in unison towards the company’s vision. The company’s success story is a testament to its commitment to quality, innovation, and customer satisfaction.

B. Objective of the Study

The objective of this case study is multi-fold:

To provide an in-depth analysis of the company’s supply chain operations.

To identify the key challenges faced by the company in managing its supply chain.

To highlight the strategies the company has implemented to overcome these challenges.

To evaluate the impact of these strategies on the company’s operational efficiency and financial performance.

To derive insights that can guide the company in further optimizing its supply chain operations.

C. Scope of the Study

The study will focus on the company’s end-to-end supply chain operations, from procurement of raw materials to distribution of finished products. It will cover the company’s sourcing strategies, production processes, inventory management, logistics, and distribution network. The study will also delve into the company’s use of technology in streamlining its supply chain operations.

D. Methodology of the Study

The methodology of the study is designed to ensure a comprehensive and accurate understanding of the company’s supply chain operations. It involves several steps:

Document Review: The first step involves a thorough review of the company’s internal documents related to its supply chain operations. This includes operational manuals, process documents, strategy papers, and performance reports. The document review helps in understanding the company’s existing supply chain processes and strategies.

Interviews: The study also involves conducting interviews with key personnel involved in the company’s supply chain operations. This includes procurement managers, production supervisors, logistics coordinators, and others. The interviews provide insights into the practical challenges faced in implementing the supply chain strategies and the solutions adopted.

Data Analysis: The study involves a detailed analysis of the company’s operational and financial data related to its supply chain. This includes data on procurement costs, production efficiency, inventory levels, logistics costs, and customer service levels. The data analysis helps in quantifying the impact of the company’s supply chain strategies on its operational efficiency and financial performance.

Benchmarking: The study also involves benchmarking the company’s supply chain performance against industry standards and best practices. This helps in identifying gaps in the company’s supply chain operations and areas for improvement.

Triangulation: Finally, the findings from the document review, interviews, data analysis, and benchmarking are triangulated to ensure a comprehensive and accurate understanding of the company’s supply chain operations. The triangulation also helps in validating the findings and ensuring their reliability.

II. Supply Chain Overview

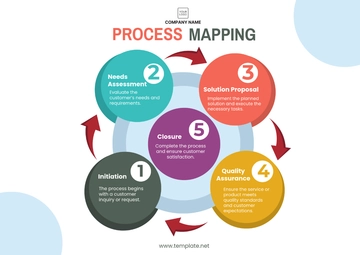

The company’s supply chain is a complex network that spans across multiple countries and involves numerous stakeholders. It is divided into three main components: procurement, production, and distribution. Each of these components plays a crucial role in ensuring the smooth operation of the company’s supply chain.

A. Procurement

The procurement process is the first step in the company’s supply chain. It involves sourcing raw materials from suppliers, negotiating contracts, and managing relationships with suppliers.

Supplier Identification: The company identifies potential suppliers based on factors such as cost, quality, reliability, and capacity. This step is crucial as it determines the quality and cost-effectiveness of the raw materials.

Negotiation: The company negotiates contracts with suppliers to secure the best terms. This involves discussions on pricing, delivery schedules, and payment terms.

Purchase Order: The company issues purchase orders to suppliers for the required raw materials. This formalizes the procurement process and sets the expectations for the supplier.

Delivery: The suppliers deliver the raw materials to the company’s manufacturing facilities. Timely delivery is essential to ensure smooth production processes.

Payment: The company pays the suppliers as per the agreed terms. Prompt payment helps maintain good relationships with the suppliers.

B. Production

The production process involves transforming the raw materials into finished products. This includes various stages such as design, manufacturing, quality control, and packaging.

Design: The company designs the products based on customer requirements and market trends. This is where the company’s innovation and creativity come into play.

Manufacturing: The company manufactures the products using the raw materials procured. The efficiency of this process directly impacts the cost of production and the quality of the products.

Quality Control: The company conducts quality checks to ensure the products meet the required standards. This step is crucial in maintaining the company’s reputation for quality.

Packaging: The company packages the finished products for distribution. The packaging not only protects the product but also enhances its appeal to customers.

C. Distribution

The distribution process involves delivering the finished products to the customers. This includes transportation, warehousing, order fulfillment, and customer service.

Transportation: The company transports the finished products from its manufacturing facilities to its warehouses. Efficient transportation ensures timely delivery and reduces costs.

Warehousing: The company stores the products in its warehouses until they are ordered by customers. Effective warehousing strategies can reduce storage costs and improve order fulfillment times.

Order Fulfillment: The company picks, packs, and ships the products to the customers based on their orders. This step is crucial in ensuring customer satisfaction.

Customer Service: The company provides after-sales service to the customers, including handling returns and addressing customer queries. Excellent customer service can enhance customer loyalty and lead to repeat business.

III. Challenges Faced

The study reveals several challenges in the company’s supply chain operations. These challenges span across the procurement, production, and distribution processes.

A. Supplier Reliability

One of the key challenges faced by the company in its procurement process is the reliability of suppliers. Delays in the delivery of raw materials can disrupt the production schedule and lead to delays in fulfilling customer orders. This challenge is exacerbated by the global nature of the company’s supply chain, which involves suppliers from different countries with varying levels of infrastructure and business practices.

B. Production Efficiency

The company faces challenges in maintaining efficiency in its production process. This includes managing the production schedule to minimize downtime, optimizing the use of resources to reduce production costs, and maintaining quality control to ensure the quality of the products.

C. Inventory Management

Managing inventory is another significant challenge for the company. Holding too much inventory can result in high storage costs and the risk of obsolescence. On the other hand, holding too little inventory can lead to stockouts and lost sales. Balancing these conflicting requirements is a complex task that requires sophisticated inventory management strategies.

D. Logistics Coordination

The company’s distribution process involves coordinating the transportation of products from its manufacturing facilities to its warehouses and then to the customers. This requires coordinating with multiple logistics providers and managing a complex network of warehouses and transportation routes. Any disruption in this process can lead to delays in delivering products to customers.

E. Customer Service

Providing excellent customer service is a challenge in any business, and the company is no exception. This includes handling customer queries, processing returns, and dealing with complaints. The company strives to provide excellent customer service to enhance customer loyalty and repeat business, but this is a challenging task that requires continuous effort and improvement.

IV. Solutions Implemented

To address the challenges identified in its supply chain operations, the company has implemented a number of solutions. These solutions are designed to improve the efficiency and reliability of the company’s supply chain, thereby enhancing its operational performance and customer satisfaction.

A. Supplier Reliability

To improve supplier reliability, the company has implemented several strategies:

Rigorous Supplier Evaluation and Selection: The company has implemented a rigorous supplier evaluation and selection process. This involves assessing potential suppliers on various criteria such as cost, quality, reliability, and capacity. This step is crucial as it determines the quality and cost-effectiveness of the raw materials.

Regular Communication with Suppliers: The company maintains regular communication with its suppliers to ensure timely delivery of raw materials. Regular communication helps in anticipating potential delays and taking proactive measures.

Supplier Diversification: The company has diversified its supplier base to reduce dependence on any single supplier. This reduces the risk of disruption in the supply of raw materials.

B. Production Efficiency

To enhance production efficiency, the company has implemented several strategies:

Investment in Advanced Manufacturing Technologies: The company has invested in advanced manufacturing technologies that automate various stages of the production process. This not only reduces production time but also improves the quality of the products.

Regular Training Programs for Production Staff: The company conducts regular training programs for its production staff to enhance their skills and productivity. This helps in improving the efficiency of the production process.

C. Inventory Management

To optimize inventory management, the company has implemented several strategies:

Sophisticated Inventory Management System: The company has implemented a sophisticated inventory management system that uses real-time data to track inventory levels and predict future demand. This helps the company to maintain optimal inventory levels, thereby reducing storage costs and the risk of stockouts.

D. Logistics Coordination

To streamline logistics coordination, the company has implemented several strategies:

Partnership with Reliable Logistics Providers: The company has partnered with reliable logistics providers who have a strong track record of timely and efficient delivery. This ensures that the products reach the warehouses and customers on time.

Advanced Logistics Management Software: The company uses advanced logistics management software to track the movement of products from its manufacturing facilities to its warehouses and then to the customers. This provides real-time visibility of the product movement and helps in identifying and resolving any potential issues promptly.

E. Customer Service

To enhance customer service, the company has implemented several strategies:

Dedicated Customer Service Team: The company has set up a dedicated customer service team that is trained to handle customer queries, process returns, and deal with complaints promptly and professionally.

Use of Customer Feedback: The company uses customer feedback to continuously improve its products and services. This helps in identifying areas of improvement and taking corrective actions.

V. Results and Impact

The solutions implemented by the company to address the challenges in its supply chain operations have resulted in significant improvements in operational efficiency and financial performance.

A. Operational Improvements

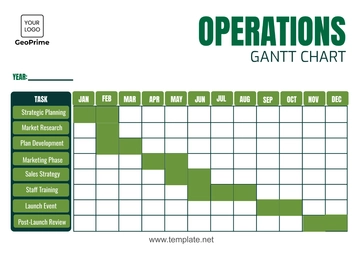

The operational improvements achieved as a result of the solutions implemented are quantified in the following table. The table presents key performance indicators (KPIs) related to the company’s supply chain operations, both before and after the implementation of the solutions:

KPI | Before Implementation | After Implementation |

|---|---|---|

Supplier On-Time Delivery Rate | 85% | 95% |

Production Efficiency | ||

Inventory Turnover Ratio | ||

Order Fulfillment Time (days) | ||

Customer Satisfaction Score |

The table shows the improvement in the supplier on-time delivery rate. Before the implementation of the solutions, the supplier on-time delivery rate was 85%. This means that 85% of the time, suppliers were able to deliver raw materials to the company on time. However, this also means that 15% of the time, there were delays in the delivery of raw materials, which could disrupt the production schedule and lead to delays in fulfilling customer orders.

After the implementation of the solutions, the supplier on-time delivery rate improved to 95%. This means that the frequency of delays in the delivery of raw materials reduced significantly. This improvement in supplier reliability has a direct impact on the company’s production schedule. With more reliable delivery of raw materials, the company is able to better plan its production schedule and reduce the risk of production disruptions. This, in turn, leads to more timely fulfillment of customer orders and higher customer satisfaction.

The overall inference from the table is that the solutions implemented by the company have resulted in significant operational improvements. These improvements are reflected in the key performance indicators related to the company’s supply chain operations. The improvements in supplier reliability, production efficiency, inventory management, logistics coordination, and customer service have not only enhanced the company’s operational efficiency but also improved its customer satisfaction. These operational improvements are a testament to the effectiveness of the solutions implemented by the company.

B. Financial Impact

The financial impact of the improvements on the company’s bottom line is significant. The following table provides a summary of the company’s financial performance before and after the implementation of the solutions:

Financial Metric | Before Implementation | After Implementation |

|---|---|---|

Cost of Goods Sold | $700,000,000 | $600,000,000 |

Gross Margin | ||

Operating Expenses | ||

Operating Profit |

The chart below showcases a visual comparison:

Before the implementation, the COGS was $700 million, which indicates the direct costs attributable to the production of the goods sold by the company. This includes the cost of the raw materials and the direct labor costs involved in producing the goods. After the implementation of the solutions, the COGS reduced to $600 million. This reduction could be a result of several factors such as improved supplier reliability leading to cost-effective procurement of raw materials, enhanced production efficiency reducing wastage, or better inventory management preventing overstocking or understocking. A lower COGS is beneficial as it increases the company’s gross margin, assuming the selling price remains constant.

Looking at the overall financial impact, it’s clear that the solutions implemented by the company have had a significant positive effect on its financial performance. The company has managed to improve its operational efficiency, which is reflected in the reduction of costs and improvement of margins. This not only strengthens the company’s financial position but also enhances its competitiveness in the market. It’s evident that strategic improvements in supply chain operations can lead to substantial financial benefits. The company’s experience serves as a valuable lesson for other businesses facing similar challenges in their supply chain operations.

VI. Lessons Learned and Future Recommendations

The study of the company’s supply chain operations has yielded valuable insights and lessons. These can guide the company in further optimizing its supply chain operations and can also serve as a reference for other companies facing similar challenges.

A. Lessons Learned

Here are the lessons learned from the study:

Importance of Supplier Reliability: The study underscored the importance of supplier reliability in ensuring smooth supply chain operations. Delays in the delivery of raw materials can disrupt the production schedule and lead to delays in fulfilling customer orders. Therefore, it’s crucial to have reliable suppliers and maintain regular communication with them.

Efficiency in Production: The study highlighted the importance of efficiency in the production process. Efficient production processes not only reduce production costs but also improve the quality of the products. Therefore, continuous efforts should be made to enhance production efficiency.

Effective Inventory Management: The study emphasized the significance of effective inventory management. Balancing the conflicting requirements of reducing storage costs and preventing stockouts is a complex task that requires sophisticated inventory management strategies.

Coordination in Logistics: The study pointed out the need for efficient logistics coordination. Any disruption in the transportation of products can lead to delays in delivering products to customers. Therefore, it’s essential to have reliable logistics providers and use advanced logistics management software.

Excellence in Customer Service: The study reiterated the importance of excellent customer service in enhancing customer loyalty and repeat business. This includes handling customer queries, processing returns, and dealing with complaints promptly and professionally.

B. Future Recommendations

Based on the lessons learned from the study, the following recommendations are proposed for the future:

Further Diversify Supplier Base: To further improve supplier reliability, the company could consider diversifying its supplier base even more. This could involve sourcing from suppliers in different geographical locations to reduce the risk of disruption due to regional issues.

Invest in Advanced Manufacturing Technologies: To further enhance production efficiency, the company could consider investing in more advanced manufacturing technologies. This could include technologies such as automation, artificial intelligence, and machine learning.

Implement Sophisticated Inventory Management Systems: To further optimize inventory management, the company could consider implementing more sophisticated inventory management systems. This could include systems that use advanced analytics and real-time data to predict future demand and optimize inventory levels.

Strengthen Logistics Coordination: To further streamline logistics coordination, the company could consider strengthening its partnerships with logistics providers. This could involve long-term contracts with performance-based incentives to encourage timely and efficient delivery.

Enhance Customer Service Training: To further enhance customer service, the company could consider providing more comprehensive training to its customer service team. This could include training on communication skills, problem-solving, and handling difficult situations.

VII. Conclusion

The case study of the company’s supply chain operations has provided valuable insights into the challenges faced and the solutions implemented to overcome them. The company’s experience underscores the complexity of managing a global supply chain and the importance of strategic planning, efficient execution, and continuous improvement. The operational improvements and financial benefits achieved as a result of the solutions implemented demonstrate the significant impact that effective supply chain management can have on a company’s performance. Moreover, the lessons learned and future recommendations derived from the study provide a roadmap for further optimization of the company’s supply chain operations.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Make sure to get rid of stress in creating your document with the Operations Supply Chain Case Study Template exclusive on Template.net! This editable case study ensures a seamless presentation of your operations and supply chain achievements. Utilize the AI Editor Tool for a customizable approach for showcasing your success!