Free Safety Harness Inspection Checklist

Inspectors' Name: [Your Name]

Date: August 1, 2050

Facility: [Your Company Name]

Safeguard your team with our Safety Harness Inspection Checklist Template, designed to ensure the proper functioning of safety harnesses in high-risk work settings. This user-friendly template simplifies the inspection process, allowing for thorough assessments and quick corrective actions.

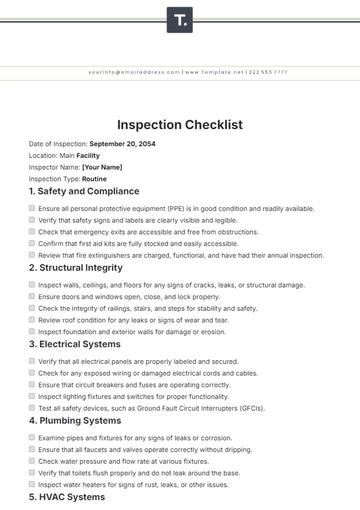

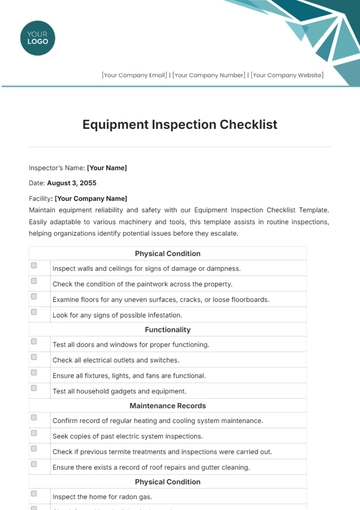

Structural Components

Inspect the condition of the foundation, structural integrity and any visible damage.

Evaluate the stability and condition of the walls, ensuring they're level and straight.

Examine roof structure, trusses and sheathing for water intrusion or damage signs.

Check the floor condition and support, notably for signs of unusual sagging or deflection.

Verify the condition of attic structural components including rafters, joists, collar ties, and ridge boards;

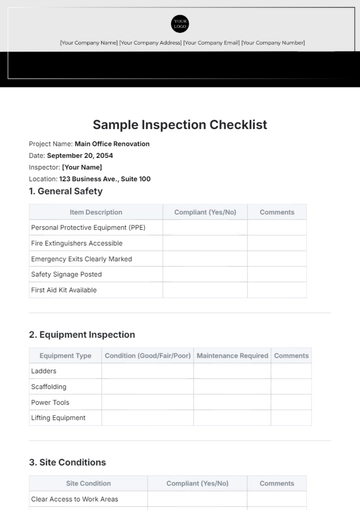

Harness Integrity

Professionally inspect the harness for any visible damage, charring, or signs of wear and tear.

Confirm the harness is not damaged or worn, specifically on the load-bearing parts.

Ensure the harness is serviceable, checking for broken stitches or burnt or cut fibres.

Check for damage to metallic parts, including corrosion or deformation.

Inspect the harness and equipment for compatibility.

Webbing and Straps

Inspect each strap on the harness for any cuts, frays, or wear.

Check all webbing for evidence of heat or chemical damage.

Ensure that the stitching securing strap ends are intact and have not become loose.

Look for evidence of dirt or grit in the webbing fibres as it can shorten product lifespan.

Make sure all strap-length adjusters are functioning properly and securely.

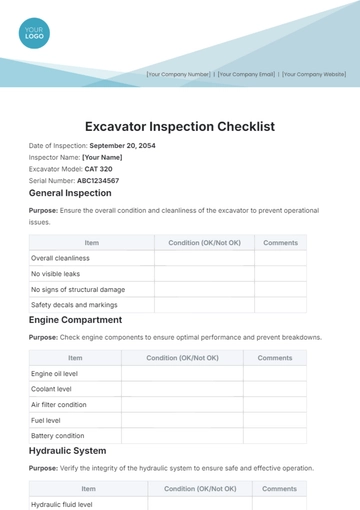

Buckles and Connectors

Check buckles and connectors for signs of deformation, corrosion or damage.

Ensure all fastenings and backstops are secure and functioning properly.

Examine carabiner gates for evidence of distortion and check for the smooth operation of the locking mechanism.

Verify that all buckles are securely attached and free from sharp edges or burrs.

Ensure all connectors are compatible with the elements to which they are attached.

Stitching and Rivets

Inspect all stitching for signs of loose or pulled threads, cuts, or abrasion damage.

Ensure all rivets are intact, firmly attached, and show no signs of deformation.

Evaluate for any evidence of bad stitching patterns or colour variations which may indicate an issue.

Check that there's no evidence of stitching distortion caused by excessive force or misuse.

Confirm whether the stitch is keeping its shape as per its original specifications.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

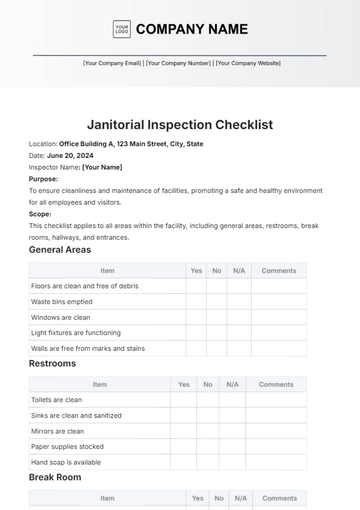

Ensure workplace safety with our Safety Harness Inspection Checklist Template. Offered by Template.net, this customizable and downloadable checklist is editable in our AI Editor Tool. Easily conduct comprehensive safety inspections to mitigate risks. Stay compliant and prioritize employee well-being with this printable template. Our AI Editor Tool is perfect for enhancing productivity.

You may also like

- Cleaning Checklist

- Daily Checklist

- Travel Checklist

- Self Care Checklist

- Risk Assessment Checklist

- Onboarding Checklist

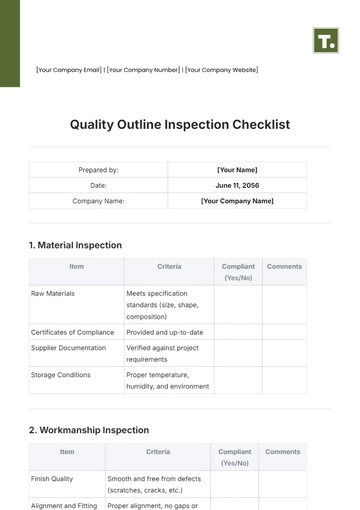

- Quality Checklist

- Compliance Checklist

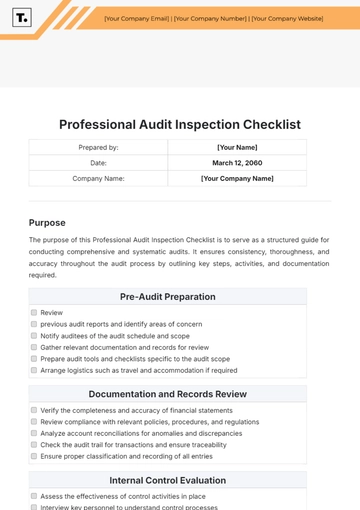

- Audit Checklist

- Registry Checklist

- HR Checklist

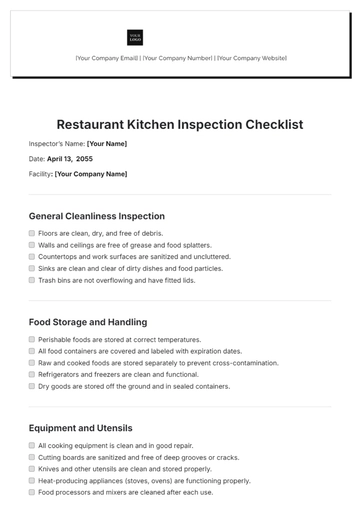

- Restaurant Checklist

- Checklist Layout

- Creative Checklist

- Sales Checklist

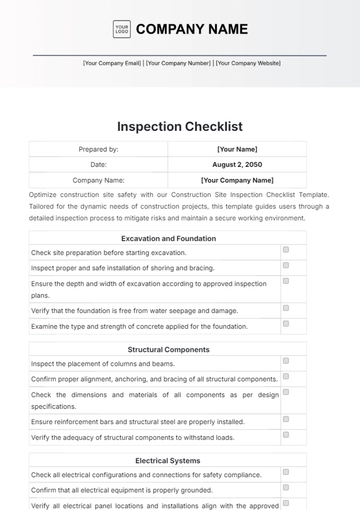

- Construction Checklist

- Task Checklist

- Professional Checklist

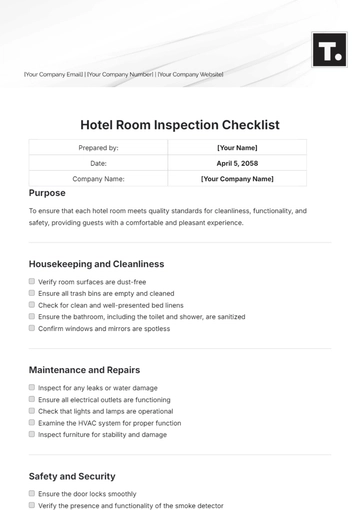

- Hotel Checklist

- Employee Checklist

- Moving Checklist

- Marketing Checklist

- Accounting Checklist

- Camping Checklist

- Packing Checklist

- Real Estate Checklist

- Cleaning Checklist Service

- New Employee Checklist

- Food Checklist

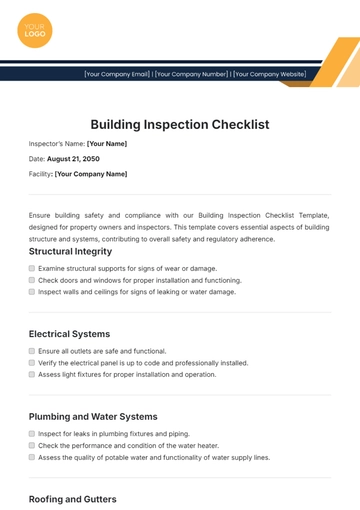

- Home Inspection Checklist

- Advertising Checklist

- Event Checklist

- SEO Checklist

- Assessment Checklist

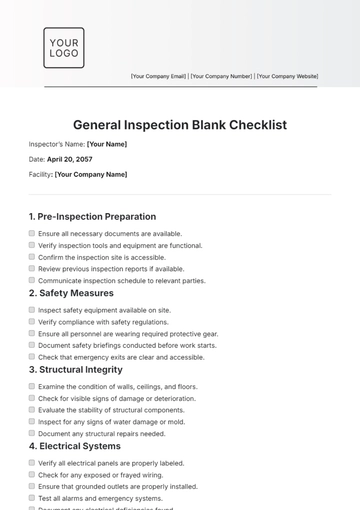

- Inspection Checklist

- Baby Registry Checklist

- Induction Checklist

- Employee Training Checklist

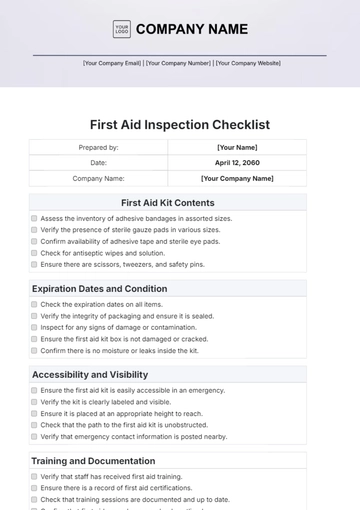

- Medical Checklist

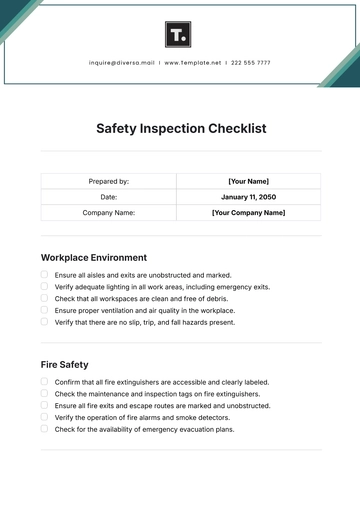

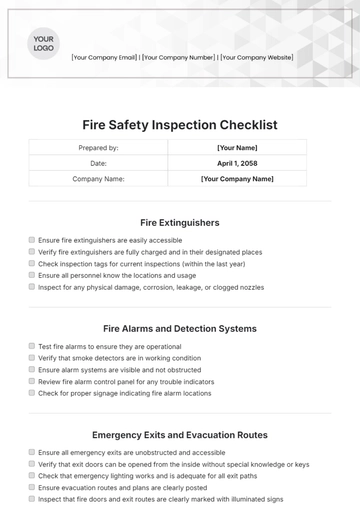

- Safety Checklist

- Site Checklist

- Job Checklist

- Service Checklist

- Nanny Checklist

- Building Checklist

- Work Checklist

- Office Checklist

- Training Checklist

- Website Checklist

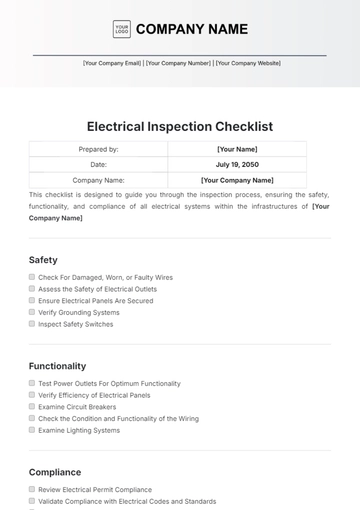

- IT and Software Checklist

- Performance Checklist

- Project Checklist

- Startup Checklist

- Education Checklist

- Home Checklist

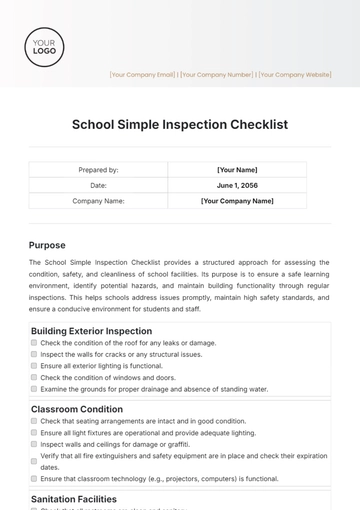

- School Checklist

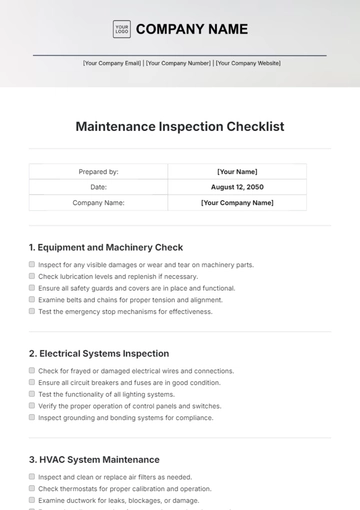

- Maintenance Checklist

- Planning Checklist

- Manager Checklist

- Wedding Checklist

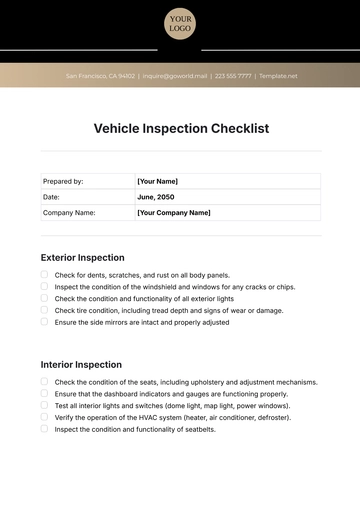

- Vehicle Checklist

- Travel Agency Checklist

- Vehicle Inspection Checklist

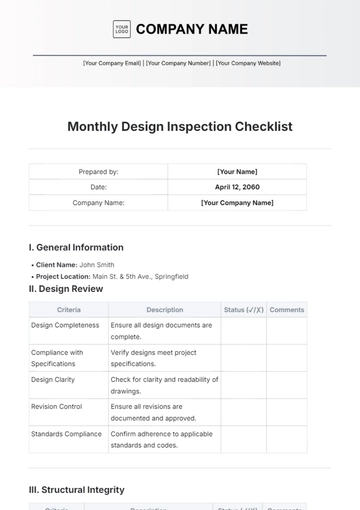

- Interior Design Checklist

- Backpacking Checklist

- Business Checklist

- Legal Checklist

- Nursing Home Checklist

- Weekly Checklist

- Recruitment Checklist

- Salon Checklist

- Baby Checklist

- Equipment Checklist

- Trade Show Checklist

- Party Checklist

- Hospital Bag Checklist

- Evaluation Checklist

- Agency Checklist

- First Apartment Checklist

- Hiring Checklist

- Opening Checklist

- Small Business Checklist

- Rental Checklist

- College Dorm Checklist

- New Puppy Checklist

- University Checklist

- Building Maintenance Checklist

- Work From Home Checklist

- Student Checklist

- Application Checklist