Free Operations Inventory Audit Checklist

Ensure your business operations are running smoothly and efficiently by conducting a comprehensive inventory audit. This checklist is designed to help you keep track of your inspection and ensure each item is properly accounted for, maintaining an objective and professional approach throughout the process.

Section 1: Physical Inventory Assessment

Count all physical items in the inventory: Conduct a thorough count of all inventory items, including those in storage and on the sales floor.

Document any damaged items: Identify and record details of any damaged or unusable inventory to assess for write-offs or insurance claims.

Record discrepancy between expected and actual counts: Note any

differences between the recorded inventory levels and the actual physical count to identify potential issues in stock management or theft.

Ensure proper labeling of all items: Verify that all items are correctly labeled with relevant information, including SKU numbers, descriptions, and barcodes.

Count inventory in off-site locations: Include inventory stored at off-site locations or in transit to ensure a complete inventory count.

Section 2: Inventory Record Examination

Review inventory records for accuracy: Examine the inventory records for accuracy, ensuring they match the physical inventory count.

Verify inventory valuation: Confirm the valuation of inventory items is up to date and reflects the current market value or cost price.

Assess inventory categorization: Ensure inventory items are categorized correctly in the records for ease of management and reporting.

Audit for obsolete inventory: Identify items that are obsolete or have not moved in a significant amount of time to consider for clearance or write-off.

Section 3: Inventory Reconciliation Procedures

Reconcile physical counts with inventory records: Match the results of the physical inventory count with the inventory records to identify discrepancies.

Investigate discrepancies: Conduct a thorough investigation into any discrepancies found during the reconciliation process to determine their causes.

Update inventory records: Adjust the inventory records to reflect the actual physical inventory count and reconcile any differences.

Review and adjust inventory policies: Based on findings, review and potentially adjust inventory management policies to prevent future discrepancies.

Section 4: Inventory Control Systems Review

Evaluate the effectiveness of inventory control systems: Assess the systems in place for inventory control for their effectiveness and efficiency.

Check for system updates or upgrades: Ensure that the inventory management software is up-to-date with the latest features and security patches.

Assess integration with other systems: Verify how well the inventory system integrates with other business systems, such as accounting and sales, for seamless operation.

Review user access controls: Evaluate the access controls in place for the inventory system to ensure that only authorized personnel can alter inventory records.

Section 5: Supplier and Procurement Analysis

Review supplier performance: Assess the performance of suppliers in terms of delivery times, quality of goods, and adherence to contracts.

Audit procurement policies: Examine the procurement policies for efficiency, cost-effectiveness, and alignment with business goals.

Evaluate inventory levels in relation to demand: Ensure that inventory levels are optimized based on historical sales data and forecasted demand.

Analyze lead times: Analyze the lead times for receiving goods from suppliers to adjust inventory levels accordingly and prevent stockouts or excess inventory.

Section 6: Risk Management and Compliance

Identify inventory risks: Identify potential risks related to inventory management, such as theft, damage, or obsolescence.

Evaluate compliance with regulations: Ensure that inventory management practices comply with relevant industry regulations and standards.

Develop risk mitigation strategies: Develop strategies to mitigate identified risks, including insurance, security measures, and inventory audits.

Review environmental and sustainability practices: Assess the inventory management practices for their environmental impact and sustainability, considering waste reduction and recycling efforts.

Section 7: Reporting and Improvement Recommendations

Generate audit reports: Compile the findings from the inventory audit into detailed reports for review by management.

Recommend improvements: Based on the audit findings, recommend improvements to inventory management practices, procedures, and policies.

Plan for follow-up audits: Schedule follow-up audits to assess the implementation of recommended improvements and their effectiveness.

Engage with stakeholders: Present findings and recommendations to stakeholders, including management and department heads, to align on inventory management strategies.

This comprehensive checklist ensures a thorough review of your inventory management practices, highlighting areas for improvement and ensuring that your operations are efficient, compliant, and aligned with your business objectives.

Prepared By: [Your Name]

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Ensure efficient operations with Template.net's customizable Operations Inventory Audit Checklist Template. Editable in our advanced Ai Editor Tool, this template is designed to streamline your audit processes. It provides a comprehensive inventory assessment framework ideal for marketing industry professionals. Take control of your inventory and simplify audits today marvellously, using our professionally tailored, editable and customizable tool.

You may also like

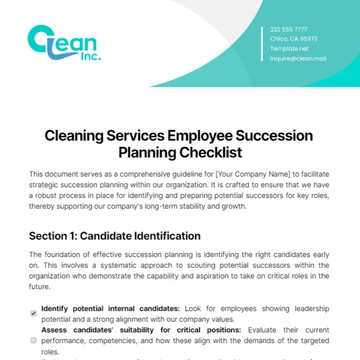

- Cleaning Checklist

- Daily Checklist

- Travel Checklist

- Self Care Checklist

- Risk Assessment Checklist

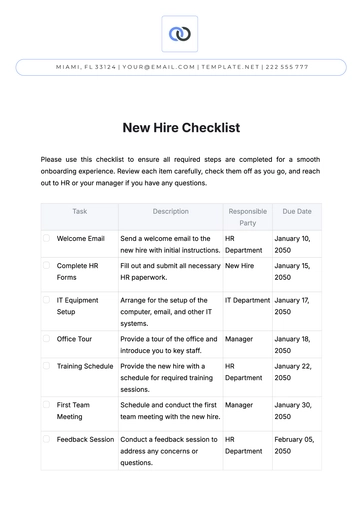

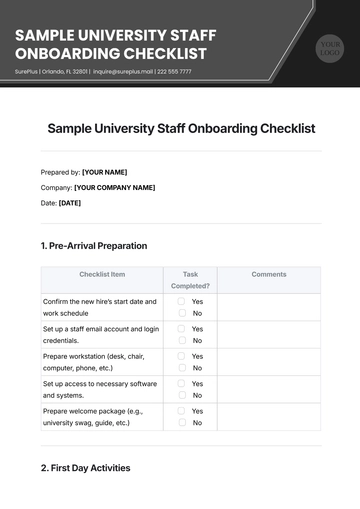

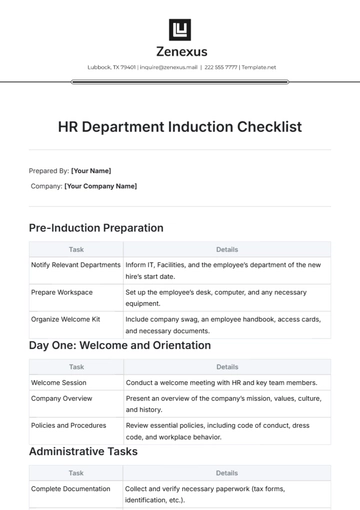

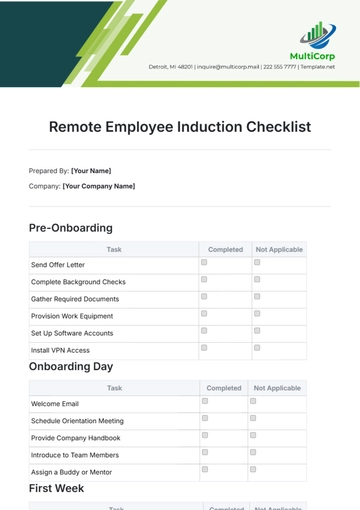

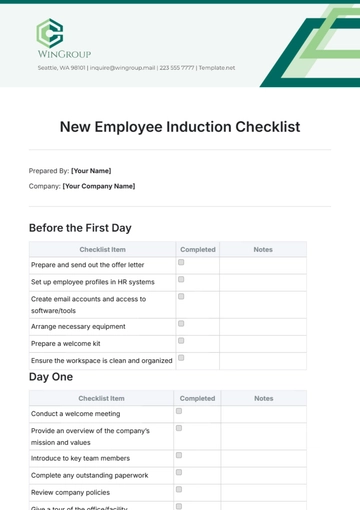

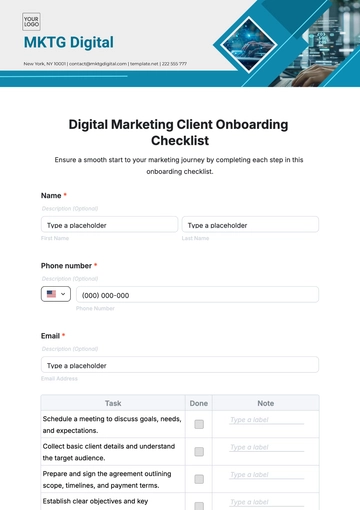

- Onboarding Checklist

- Quality Checklist

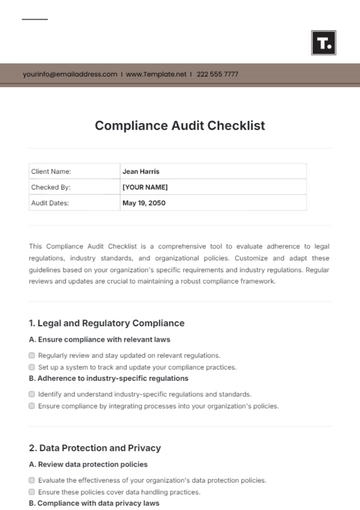

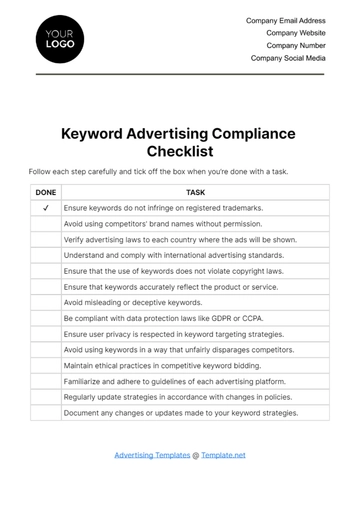

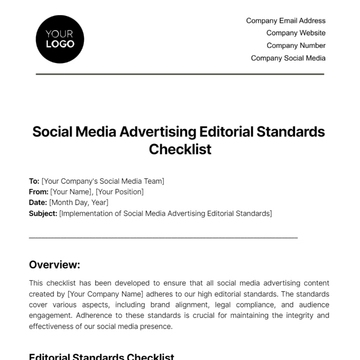

- Compliance Checklist

- Audit Checklist

- Registry Checklist

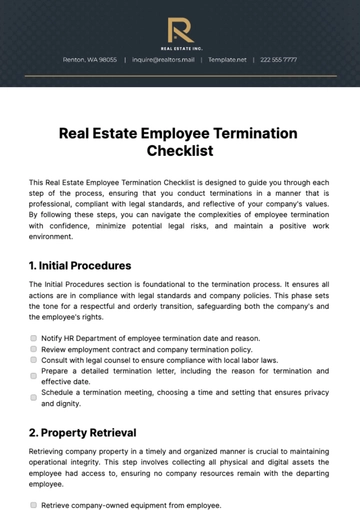

- HR Checklist

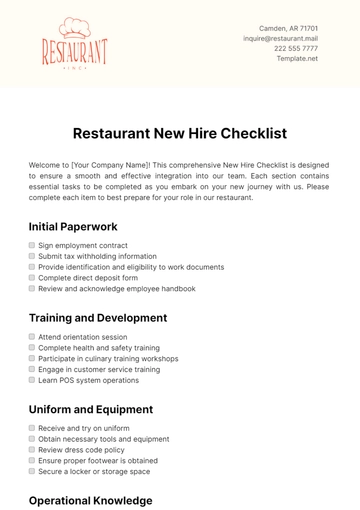

- Restaurant Checklist

- Checklist Layout

- Creative Checklist

- Sales Checklist

- Construction Checklist

- Task Checklist

- Professional Checklist

- Hotel Checklist

- Employee Checklist

- Moving Checklist

- Marketing Checklist

- Accounting Checklist

- Camping Checklist

- Packing Checklist

- Real Estate Checklist

- Cleaning Checklist Service

- New Employee Checklist

- Food Checklist

- Home Inspection Checklist

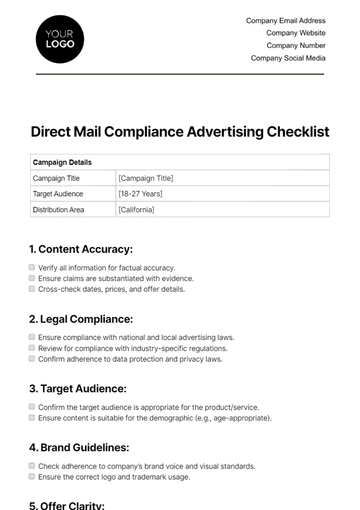

- Advertising Checklist

- Event Checklist

- SEO Checklist

- Assessment Checklist

- Inspection Checklist

- Baby Registry Checklist

- Induction Checklist

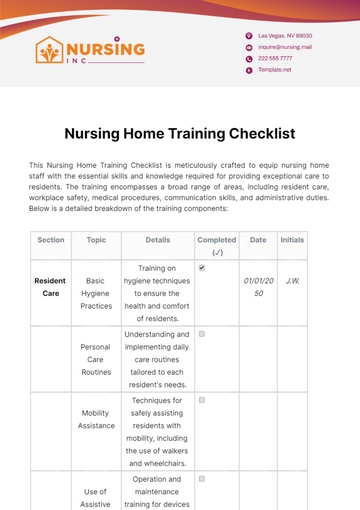

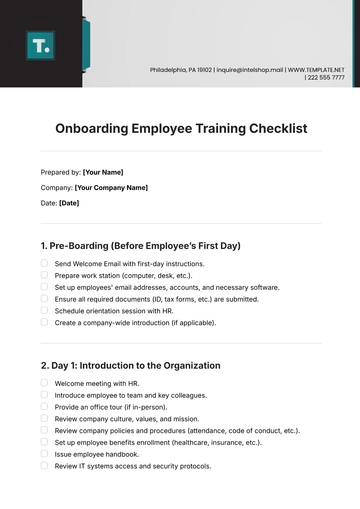

- Employee Training Checklist

- Medical Checklist

- Safety Checklist

- Site Checklist

- Job Checklist

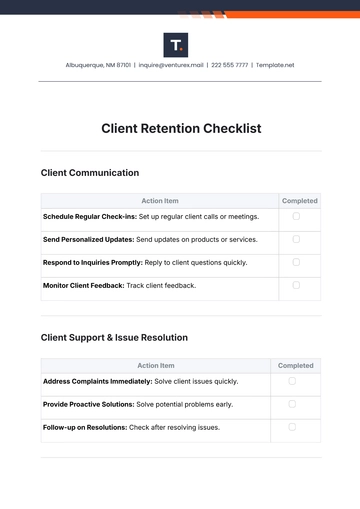

- Service Checklist

- Nanny Checklist

- Building Checklist

- Work Checklist

- Office Checklist

- Training Checklist

- Website Checklist

- IT and Software Checklist

- Performance Checklist

- Project Checklist

- Startup Checklist

- Education Checklist

- Home Checklist

- School Checklist

- Maintenance Checklist

- Planning Checklist

- Manager Checklist

- Wedding Checklist

- Vehicle Checklist

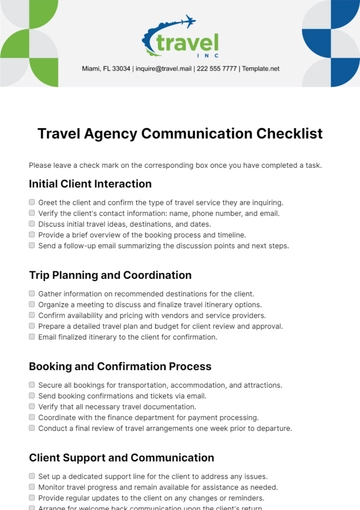

- Travel Agency Checklist

- Vehicle Inspection Checklist

- Interior Design Checklist

- Backpacking Checklist

- Business Checklist

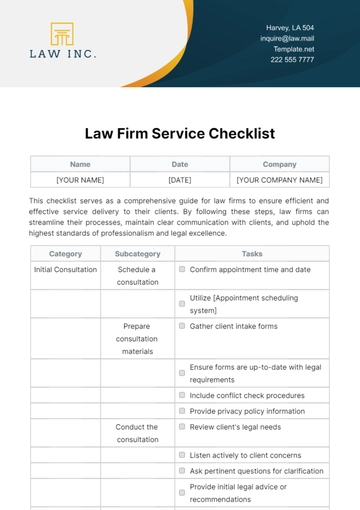

- Legal Checklist

- Nursing Home Checklist

- Weekly Checklist

- Recruitment Checklist

- Salon Checklist

- Baby Checklist

- Equipment Checklist

- Trade Show Checklist

- Party Checklist

- Hospital Bag Checklist

- Evaluation Checklist

- Agency Checklist

- First Apartment Checklist

- Hiring Checklist

- Opening Checklist

- Small Business Checklist

- Rental Checklist

- College Dorm Checklist

- New Puppy Checklist

- University Checklist

- Building Maintenance Checklist

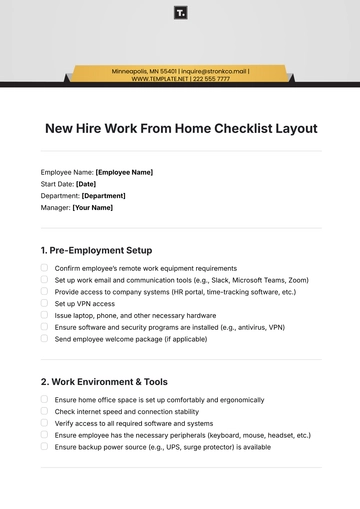

- Work From Home Checklist

- Student Checklist

- Application Checklist