Free Operations Inventory Quality Control Protocol

I. Purpose

The purpose of this Operations Inventory Quality Control Protocol is to establish a systematic approach to managing and maintaining the quality of our inventory. This protocol serves as a guideline for all team members involved in the inventory process, from receiving to storage, handling, and distribution, ensuring that our products meet the highest standards of quality and safety before they reach our customers.

II. Scope

This protocol applies to all inventory managed within our operations, encompassing a wide range of products, from raw materials to finished goods. It covers procedures for receiving, inspecting, storing, handling, and addressing issues related to inventory quality. All personnel involved in these processes are expected to adhere to the guidelines set forth in this document.

III. Importance of Quality Control

Quality control is crucial for maintaining operational efficiency, customer satisfaction, and brand reputation. It ensures that products delivered to our customers are safe, reliable, and meet or exceed expectations. Effective quality control helps in identifying and mitigating potential issues early, reducing waste, and avoiding costly recalls. Furthermore, it ensures compliance with regulatory standards, minimizing legal risks and potential fines.

IV. Quality Control Objectives

Our quality control objectives are as follows:

Ensure Product Integrity: Maintain the highest quality standards throughout the product lifecycle, ensuring that all products are free from defects and meet specified quality criteria.

Compliance with Regulatory Standards: Adhere to all relevant local, national, and international regulations and standards applicable to our products and operations.

Minimize Waste: Implement efficient quality control measures to reduce waste and inefficiency in the inventory process, including minimizing the incidence of defective products.

Enhance Customer Satisfaction: By consistently providing high-quality products, aim to enhance customer trust and satisfaction, thereby fostering loyalty and repeat business.

Continuous Improvement: Regularly review and refine quality control processes to adapt to changing regulations, market demands, and advancements in quality management practices.

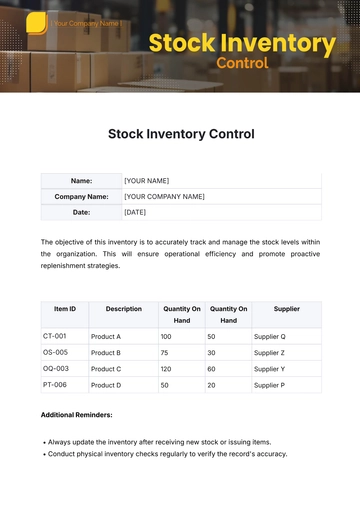

V. Receiving Inventory

The initial step in maintaining our inventory quality begins with rigorous receiving procedures. These procedures are designed to ensure that all incoming inventory meets our strict quality standards before being accepted into our warehouse. By meticulously inspecting all goods upon arrival, we can identify and address any quality issues at the earliest stage, thereby safeguarding our supply chain integrity and operational excellence.

A. Procedures

Preparation and Verification: Upon the arrival of goods, our receiving team verifies the shipment against the purchase order and packing list to ensure accuracy in quantity and product specifications. This step includes checking for any visible damage to the packaging.

Quality Inspection: Selected items from each batch are then subjected to a detailed quality inspection. This inspection may include visual checks, measurements, and functional tests, as applicable, to assess the conformity of the goods with our quality standards.

Documentation: All inspection findings are meticulously documented, including the identification of any discrepancies or defects. This documentation is crucial for traceability and any future audits or investigations.

Decision Making: Based on the inspection results, a decision is made regarding the acceptance, rejection, or need for further assessment of the incoming goods. Items that meet our quality criteria are accepted and moved to the storage area, while those that do not are handled according to our defective inventory management procedures.

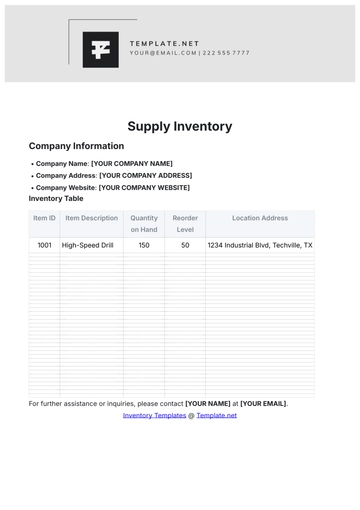

Updating Inventory Records: Accepted items are recorded in our inventory management system, updating stock levels and ensuring accurate tracking of the newly received goods.

B. Criteria for Acceptance

Criteria | Acceptance | Rejection |

Condition of Packaging | Intact, with no signs of damage or tampering | Damaged, breached, or signs of tampering |

Product Quality | Meets specified quality standards and specifications | Fails to meet quality standards; visible defects |

Quantity | Matches the quantity specified in the purchase order | Discrepancies in quantity; over or under delivery |

Documentation | Accurate and complete documentation provided | Missing or inaccurate documentation |

Regulatory Compliance | Complies with all relevant regulations and standards | Non-compliance with regulatory requirements |

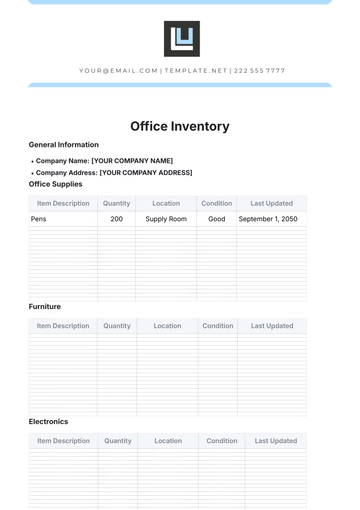

VI. Storage and Handling Guidelines

Proper storage and handling of inventory are pivotal to maintaining its quality from the moment it is received until it reaches the customer. These guidelines are designed to prevent damage, degradation, and loss, ensuring that products remain in their optimal condition throughout their stay in our facilities. Adherence to these best practices is crucial for safeguarding our inventory's integrity, maximizing shelf life, and ensuring the safety of our employees and customers.

A. Best Storage Practices

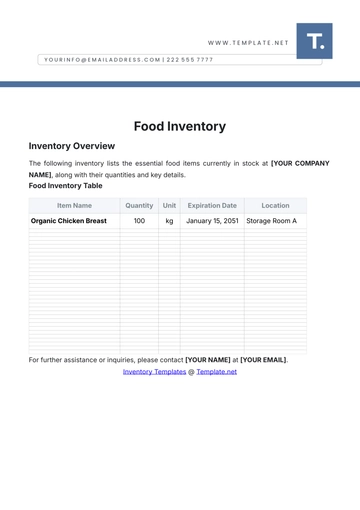

Perishable Goods: Store in temperature-controlled environments, adhering to specific humidity and temperature requirements to preserve freshness and prevent spoilage. Regularly monitor environmental conditions and rotate stock based on expiration dates (FEFO - First Expired, First Out).

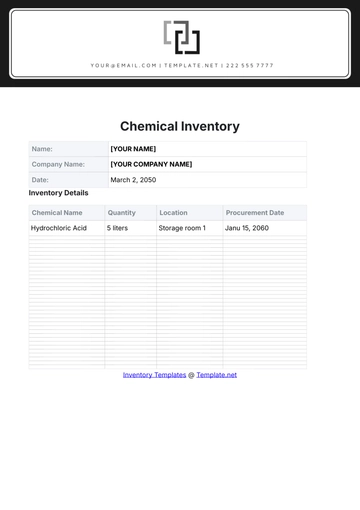

Hazardous Materials: Keep in designated areas with appropriate containment measures to prevent spills or cross-contamination. Ensure that all handling and storage procedures comply with local, national, and international regulations regarding hazardous materials.

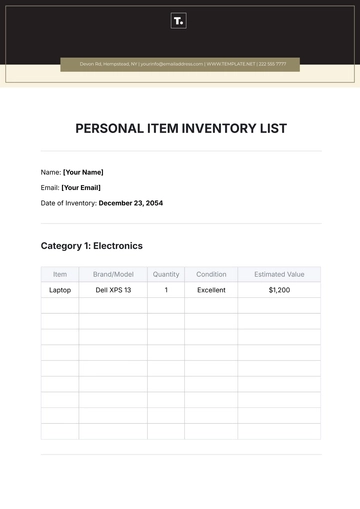

High-Value Items: Secure in restricted-access areas with enhanced security measures, such as surveillance cameras and access control systems, to prevent theft or misplacement.

Bulky or Heavy Items: Store on lower shelves or ground level to minimize the risk of injury during handling and to facilitate easier access. Utilize appropriate shelving and racking systems to support the weight and size of these items.

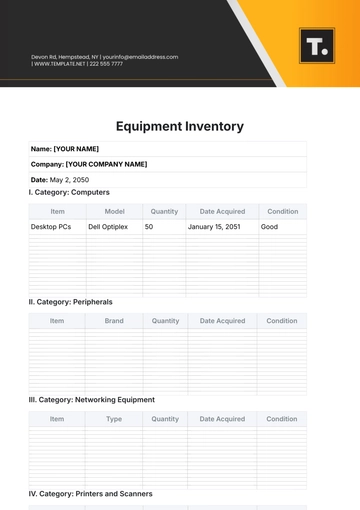

Electronics and Sensitive Equipment: Keep in dry, temperature-controlled environments away from direct sunlight or sources of electromagnetic interference. Use anti-static packaging materials to protect against electrostatic discharge.

B. Handling Procedures

General Handling: Train staff in proper lifting techniques and the use of handling equipment, such as pallet jacks and forklifts, to avoid physical damage to goods and injury to personnel.

Loading and Unloading: Implement protocols for safely loading and unloading inventory, including securing items during transport and using appropriate equipment to handle heavy or awkwardly shaped items.

Inventory Movement: Minimize handling by planning efficient routes within the warehouse and using designated paths to reduce the risk of accidents or damage.

Special Handling for Fragile Items: Use protective packaging, such as bubble wrap or foam inserts, and clearly label boxes as "Fragile" to ensure careful handling by all personnel.

Preventing Cross-Contamination: Establish procedures for cleaning and sanitizing storage areas regularly, especially when dealing with food products, pharmaceuticals, or chemicals, to maintain a safe and hygienic environment.

VII. Quality Inspection Criteria

To uphold our commitment to excellence and ensure the integrity of our inventory, we have established comprehensive quality inspection criteria. These criteria are designed to systematically evaluate the condition and functionality of our inventory through visual inspections, functional tests, and random sampling methods. By rigorously applying these criteria, we can identify and address potential quality issues early, ensuring that only products that meet our high standards reach our customers.

A. Criteria for Visual Inspections

Visual inspections are the first line of defense in identifying defects or non-conformities in our inventory. This process involves a detailed examination of the item's appearance, packaging, and labeling to ensure they meet established quality standards.

Criteria | Description |

Packaging Integrity | Check for any damage, proper seals, and tamper evidence. |

Label Accuracy | Verify product labels for correctness and legibility. |

Product Condition | Examine the item for any visible defects or damage. |

Color and Finish | Ensure the color and finish match specifications. |

Completeness | Confirm all components or parts are present. |

B. Criteria for Functional Tests

Functional tests assess whether items operate as intended, ensuring reliability and customer satisfaction. These tests vary based on the product type but are essential for verifying performance and safety.

Criteria | Description |

Operational Check | Test the item's basic functions to ensure operational integrity. |

Safety Tests | Conduct safety checks to identify any potential hazards. |

Performance Testing | Evaluate the item under expected use conditions. |

Feature Verification | Confirm all advertised features function correctly. |

Durability Testing | Assess the item's ability to withstand typical usage stresses. |

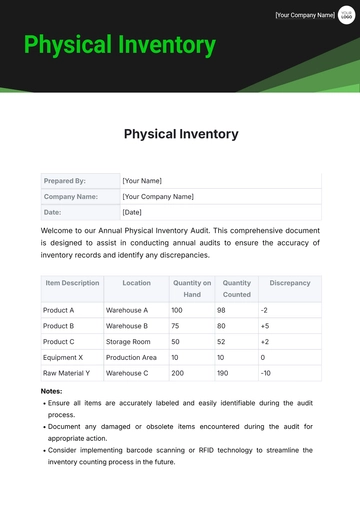

C. Criteria for Random Sampling

Random sampling involves inspecting a subset of items from a larger batch to infer the quality of the entire lot. This method is effective in managing inspection resources while still ensuring inventory quality.

Criteria | Description |

Sample Size Determination | Calculate the number of items to inspect based on batch size and historical quality data. |

Selection Methodology | Use a truly random method to select samples, ensuring unbiased inspection. |

Inspection Depth | Determine the extent of visual and functional testing on sampled items. |

Statistical Analysis | Apply statistical methods to sample results to predict overall batch quality. |

Action Thresholds | Establish quality thresholds that, if not met, trigger additional inspections or actions. |

VIII. Inventory Rotation Practices

Effective inventory rotation is crucial for maximizing the shelf life of products, reducing waste, and ensuring that customers receive high-quality items. By implementing systematic rotation practices, we can also improve inventory accuracy and efficiency. Among these practices, the First Expired, First Out (FEFO) method is particularly significant for products with expiration dates, while other procedures are applied based on product type and storage requirements.

First Expired, First Out (FEFO): This procedure prioritizes the dispatch of products closest to their expiration date, ensuring that items are sold or used before they become unsaleable. FEFO is essential for perishable goods, pharmaceuticals, and any inventory with a defined shelf life.

First In, First Out (FIFO): For non-perishable goods, FIFO is often applied. This method ensures that items received first are sold or used first, reducing the risk of obsolescence and keeping inventory fresh.

Last In, First Out (LIFO): While less common in inventory rotation, LIFO can be used for certain types of materials or products where the newest stock is preferred for specific operational reasons.

Regular Audits: Independent of the rotation strategy, regular audits are conducted to ensure compliance with rotation practices and to identify any deviations that might affect product quality or inventory accuracy.

IX. Defective Inventory Management

Managing defective inventory effectively is essential to maintain operational efficiency and customer satisfaction. Our protocol outlines a systematic approach to identifying, segregating, and managing defective or damaged goods to prevent them from entering the supply chain.

A. Procedures

Identification: Defective items are identified through quality inspections, returns, or during handling and storage operations. This step involves documenting the defect and its likely cause.

Segregation: Once identified, defective items are immediately segregated from saleable inventory to prevent accidental shipment. This segregation is crucial for ensuring that only quality products reach our customers.

Evaluation: Segregated items are then evaluated to determine their disposition, which may include return to the supplier, repair, repurposing, or disposal, depending on the nature of the defect and potential recovery value.

Action: Appropriate action is taken based on the evaluation. This might involve initiating a return process, scheduling repairs, or properly disposing of the item if it cannot be salvaged.

Documentation: All steps and decisions are thoroughly documented for traceability, including details of the defect, actions taken, and final disposition of the item. This documentation is vital for continuous improvement and supplier feedback.

B. Segregation Guidelines

Defect Type | Action Taken |

Cosmetic Damage | Repair if feasible; otherwise, discount/sell as "B-grade" |

Functional Failure | Return to supplier or schedule for repair |

Missing Components | Complete the item if possible; otherwise, return or dispose |

Expiry/Obsolescence | Dispose of following environmental regulations |

X. Documentation and Record-Keeping

Effective documentation and record-keeping are foundational to our inventory quality control protocol. This practice ensures that every item's journey through our supply chain is meticulously tracked, from receipt to sale or disposal. By maintaining comprehensive records, we can quickly trace the history of any item, facilitating audits, compliance with regulatory standards, and the identification of trends or issues in our inventory management processes. Documentation includes details of quality inspections, inventory rotations, handling and storage conditions, and actions taken on defective items. This transparency not only supports operational integrity but also bolsters our commitment to quality and accountability.

XI. Quality Control Training for Staff

To ensure that all team members are equipped with the knowledge and skills necessary to uphold our quality standards, we have implemented a structured quality control training program. This program is designed to promote consistency in our quality control efforts and to foster a culture of continuous improvement.

Program | Frequency | Content |

Quality Inspection Training | Quarterly | Procedures for conducting visual and functional inspections, understanding quality standards. |

Inventory Handling and Storage | Bi-annually | Best practices for safely handling and storing different types of inventory. |

Defective Inventory Management | Annually | Processes for identifying, segregating, and managing defective items. |

Regulatory Compliance | As regulations change | Updates on relevant regulations and how to ensure compliance. |

Continuous Improvement Workshops | Annually | Techniques for identifying areas for improvement and implementing changes. |

XII. Continuous Improvement

Our approach to quality control is not static; it is a dynamic process that evolves in response to new challenges, technologies, and best practices. We are committed to continuous improvement, regularly reviewing our protocols, processes, and performance to identify opportunities for enhancement. This iterative process ensures that our quality control measures remain effective and aligned with our operational goals and customer expectations. Through regular audits, feedback loops, and engagement with industry standards, we strive to elevate our quality control practices and outcomes continuously.

XIII. Commitment

We are deeply committed to maintaining the highest standards of quality throughout our operations. This commitment is reflected in our rigorous quality control protocol, our investment in staff training, and our dedication to continuous improvement. By adhering to these principles, we ensure the integrity of our inventory, the satisfaction of our customers, and the long-term success of our organization. Our quality control protocol is more than just a set of procedures; it is a testament to our dedication to excellence and our promise to deliver the best possible products to our customers.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Ensure product excellence with the Operations Inventory Quality Control Protocol Template from Template.net. This editable and customizable template sets the standard for inventory management and quality assurance editable in our AI Editor tool. Designed to streamline your quality control processes, it helps maintain high inventory standards. Elevate your operations and product quality with this indispensable tool from Template.net.