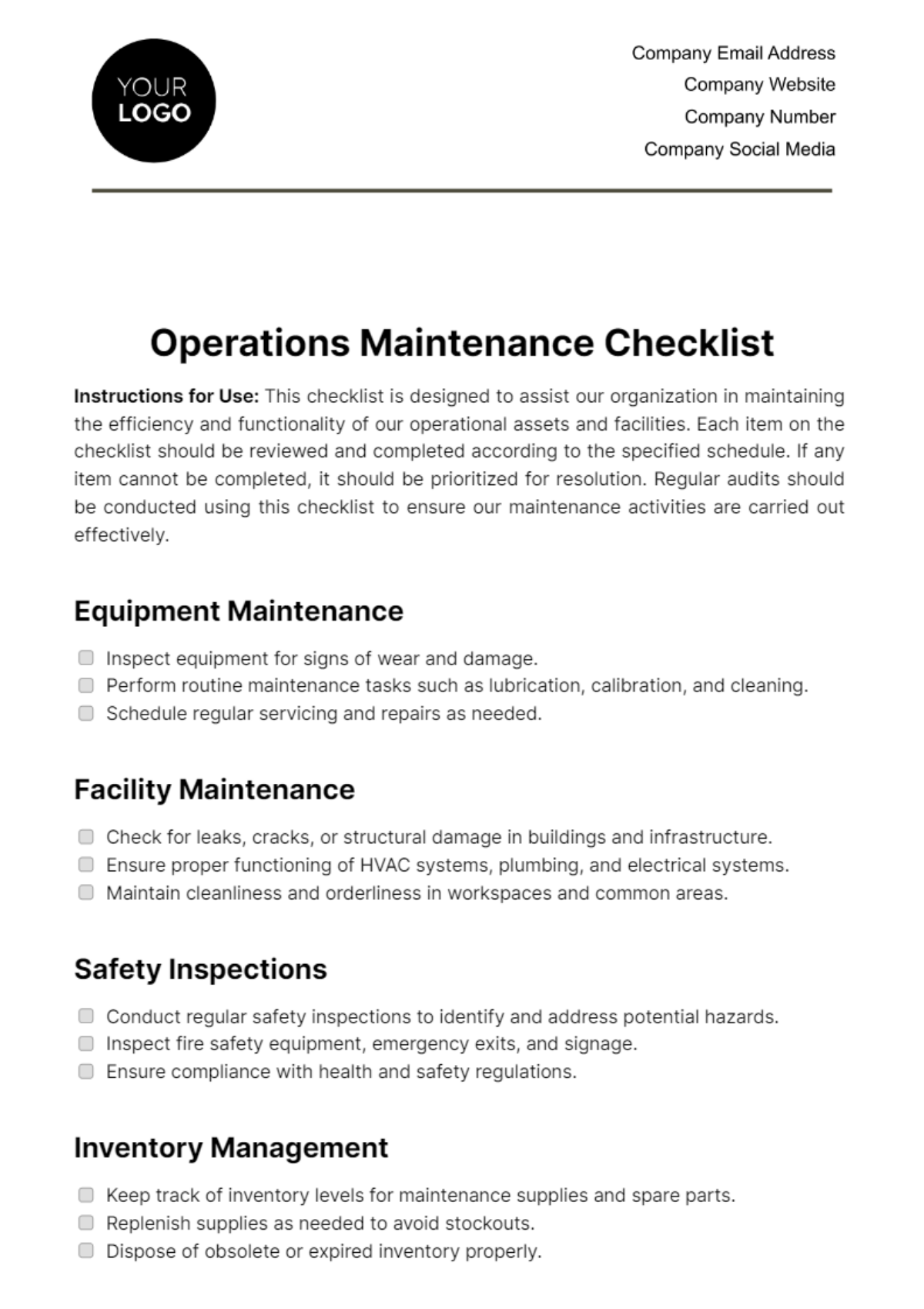

Free Operations Maintenance Checklist

Instructions for Use: This checklist is designed to assist our organization in maintaining the efficiency and functionality of our operational assets and facilities. Each item on the checklist should be reviewed and completed according to the specified schedule. If any item cannot be completed, it should be prioritized for resolution. Regular audits should be conducted using this checklist to ensure our maintenance activities are carried out effectively.

Equipment Maintenance

Inspect equipment for signs of wear and damage.

Perform routine maintenance tasks such as lubrication, calibration, and cleaning.

Schedule regular servicing and repairs as needed.

Facility Maintenance

Check for leaks, cracks, or structural damage in buildings and infrastructure.

Ensure proper functioning of HVAC systems, plumbing, and electrical systems.

Maintain cleanliness and orderliness in workspaces and common areas.

Safety Inspections

Conduct regular safety inspections to identify and address potential hazards.

Inspect fire safety equipment, emergency exits, and signage.

Ensure compliance with health and safety regulations.

Inventory Management

Keep track of inventory levels for maintenance supplies and spare parts.

Replenish supplies as needed to avoid stockouts.

Dispose of obsolete or expired inventory properly.

Groundskeeping

Maintain landscaping and outdoor areas.

Trim vegetation, remove debris, and repair pathways.

Ensure proper drainage to prevent flooding or erosion.

Documentation and Record-Keeping

Keep detailed records of maintenance activities, including dates, tasks performed, and any issues identified.

Document equipment manuals, warranties, and service contracts.

Maintain a log of maintenance expenses for budgeting and planning purposes.

Training and Skills Development

Provide training to maintenance staff on equipment operation and maintenance procedures.

Encourage continuous learning and skills development to keep up with new technologies and best practices.

Cross-train staff to ensure flexibility and coverage during absences or emergencies.

Communication and Collaboration

Foster open communication between maintenance staff, supervisors, and other departments.

Encourage collaboration and coordination on maintenance projects and initiatives.

Solicit feedback from employees and stakeholders to identify areas for improvement.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Optimize your maintenance routines with the Operations Maintenance Checklist Template from Template.net. This editable and customizable template is designed to streamline your maintenance process, ensuring nothing is overlooked. Editable in our AI Editor tool, it offers a structured approach to maintaining your operations efficiently.

You may also like

- Cleaning Checklist

- Daily Checklist

- Travel Checklist

- Self Care Checklist

- Risk Assessment Checklist

- Onboarding Checklist

- Quality Checklist

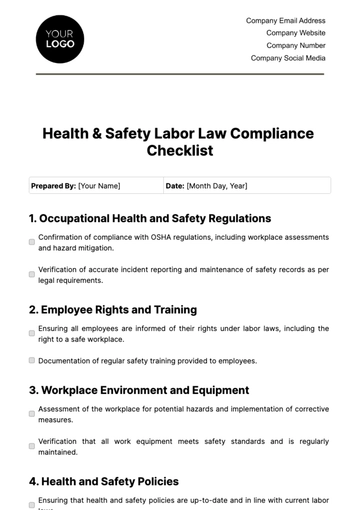

- Compliance Checklist

- Audit Checklist

- Registry Checklist

- HR Checklist

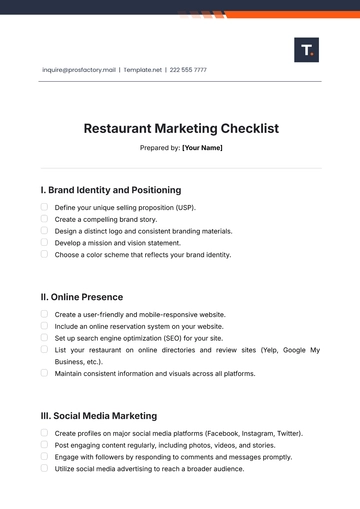

- Restaurant Checklist

- Checklist Layout

- Creative Checklist

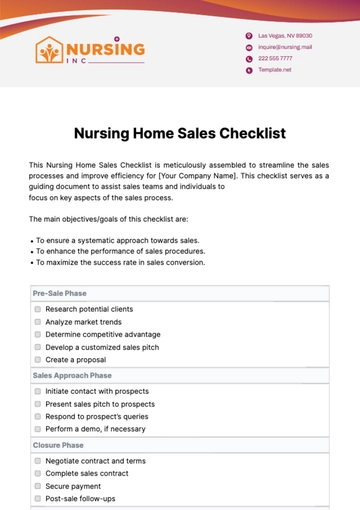

- Sales Checklist

- Construction Checklist

- Task Checklist

- Professional Checklist

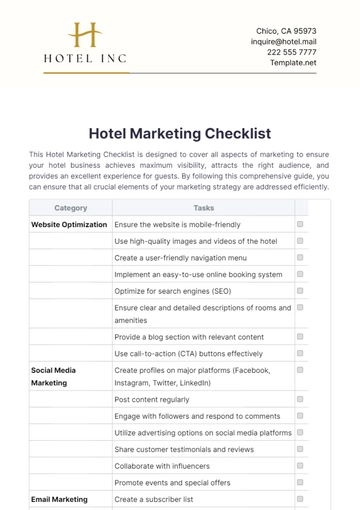

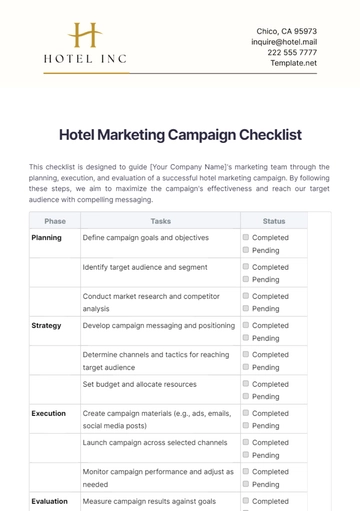

- Hotel Checklist

- Employee Checklist

- Moving Checklist

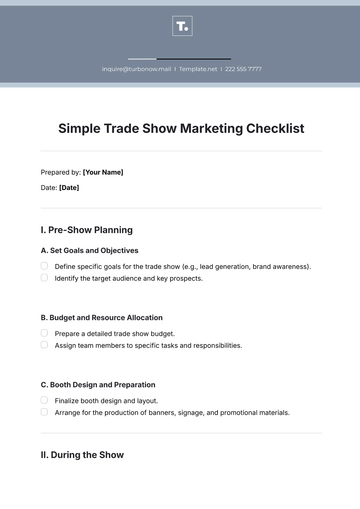

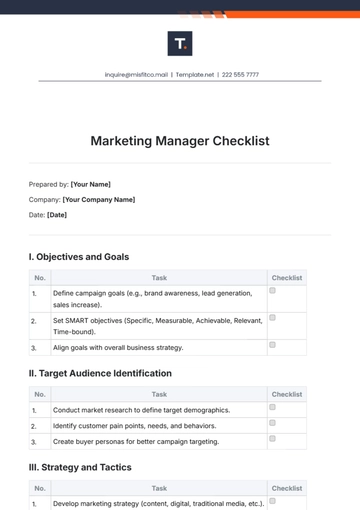

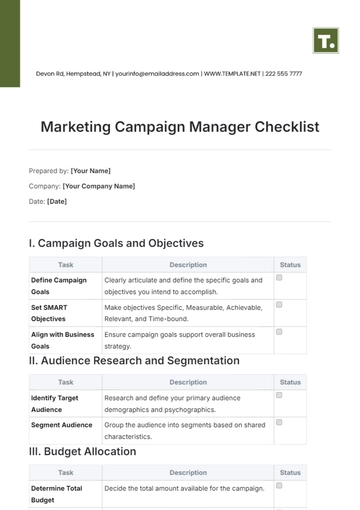

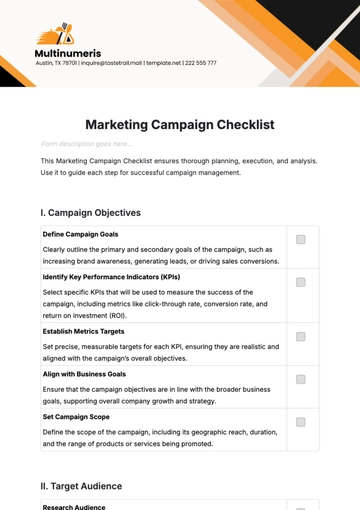

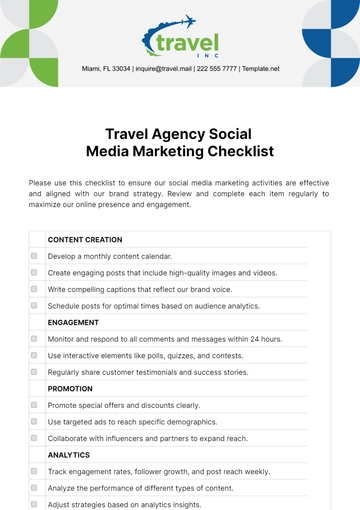

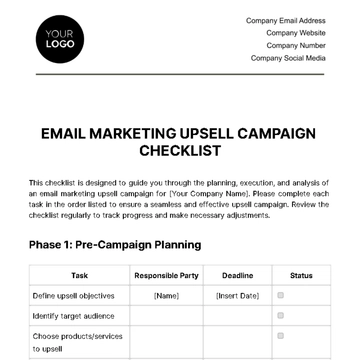

- Marketing Checklist

- Accounting Checklist

- Camping Checklist

- Packing Checklist

- Real Estate Checklist

- Cleaning Checklist Service

- New Employee Checklist

- Food Checklist

- Home Inspection Checklist

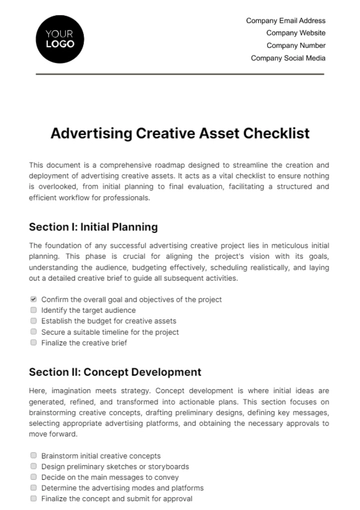

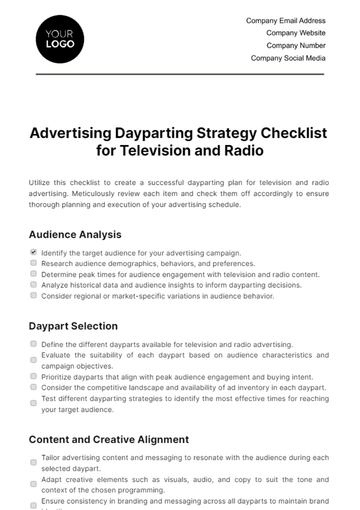

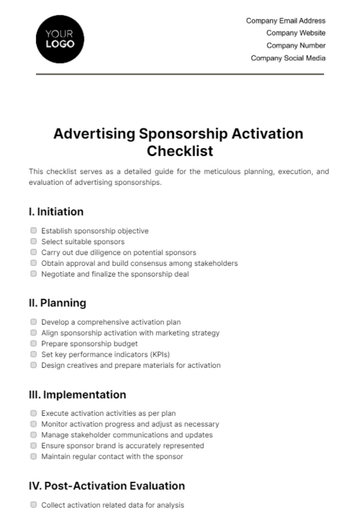

- Advertising Checklist

- Event Checklist

- SEO Checklist

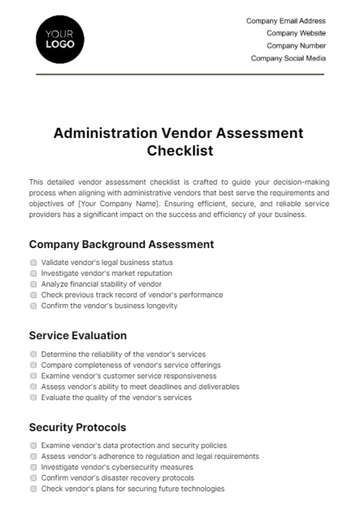

- Assessment Checklist

- Inspection Checklist

- Baby Registry Checklist

- Induction Checklist

- Employee Training Checklist

- Medical Checklist

- Safety Checklist

- Site Checklist

- Job Checklist

- Service Checklist

- Nanny Checklist

- Building Checklist

- Work Checklist

- Office Checklist

- Training Checklist

- Website Checklist

- IT and Software Checklist

- Performance Checklist

- Project Checklist

- Startup Checklist

- Education Checklist

- Home Checklist

- School Checklist

- Maintenance Checklist

- Planning Checklist

- Manager Checklist

- Wedding Checklist

- Vehicle Checklist

- Travel Agency Checklist

- Vehicle Inspection Checklist

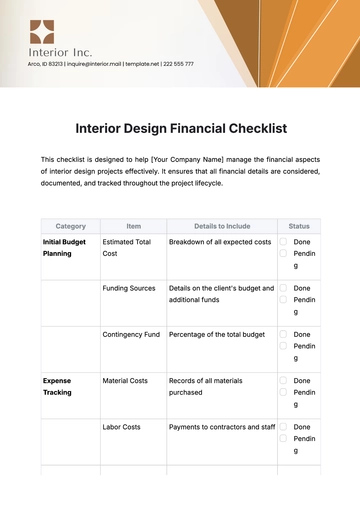

- Interior Design Checklist

- Backpacking Checklist

- Business Checklist

- Legal Checklist

- Nursing Home Checklist

- Weekly Checklist

- Recruitment Checklist

- Salon Checklist

- Baby Checklist

- Equipment Checklist

- Trade Show Checklist

- Party Checklist

- Hospital Bag Checklist

- Evaluation Checklist

- Agency Checklist

- First Apartment Checklist

- Hiring Checklist

- Opening Checklist

- Small Business Checklist

- Rental Checklist

- College Dorm Checklist

- New Puppy Checklist

- University Checklist

- Building Maintenance Checklist

- Work From Home Checklist

- Student Checklist

- Application Checklist