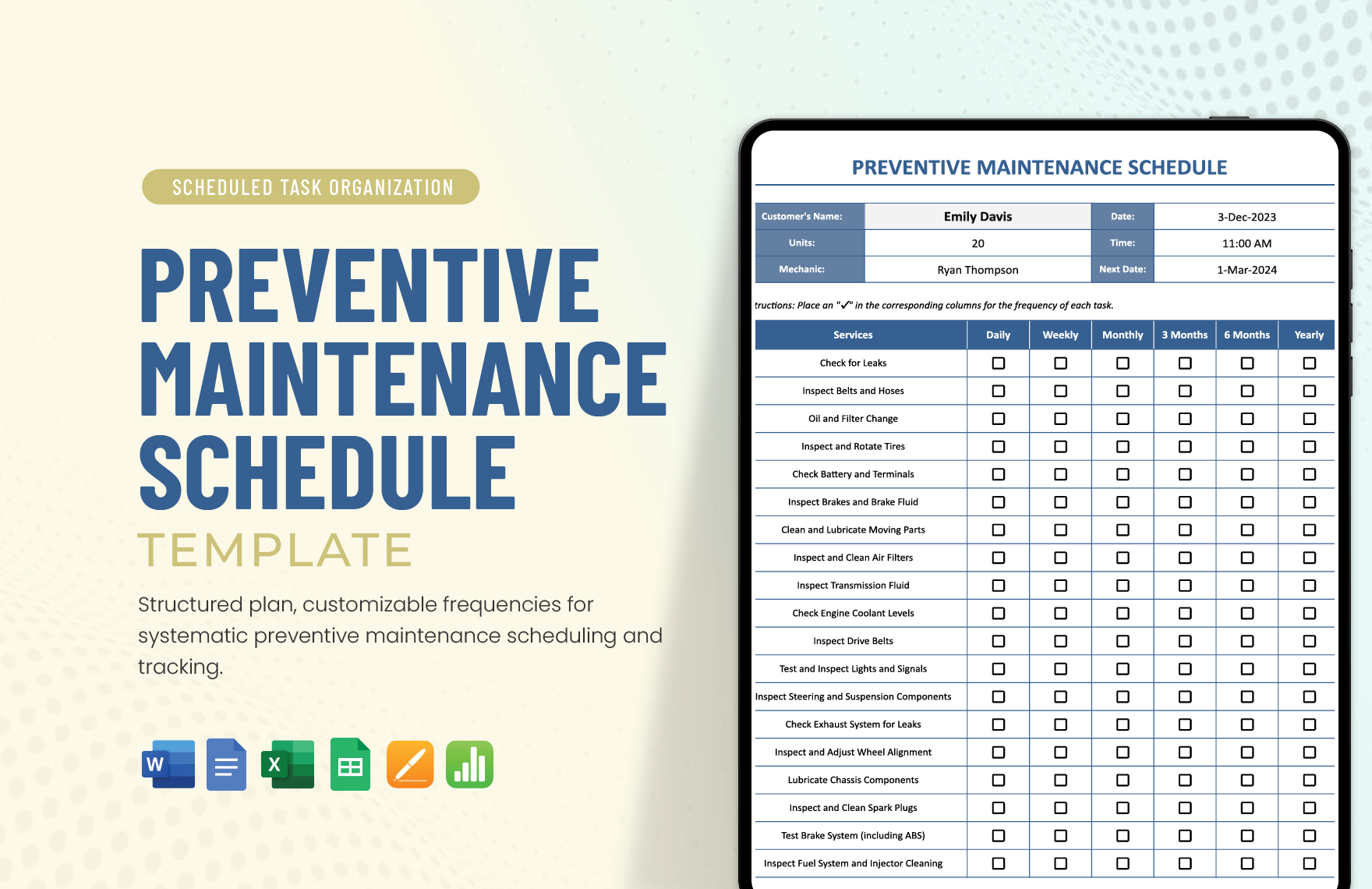

Equipment and buildings are susceptible to damage if maintenance is not done regularly. Chances of damage can occur as time passes; that is why it important to make a schedule of regular preventative maintenance. Buying replacement equipment is more expensive than performing regular maintenance. Are you interested in creating a reliable maintenance schedule? See our Preventive Maintenance Schedule Templates in Apple Numbers. Choose a sample of our original ready-made templates that are editable, printable, and downloadable on your computer or smartphone. Grab a template today and save time and effort by avoiding having to start from scratch every time you need to create a schedule.

Preventive Maintenance Schedule Templates in Apple Numbers

Explore professionally designed preventive maintenance schedule templates in Apple Numbers. Free and customizable for professional use. Download now!

Streamline Your Maintenance Strategy with Ready-to-Use Preventive Maintenance Schedule Templates in Apple Numbers by Template.net

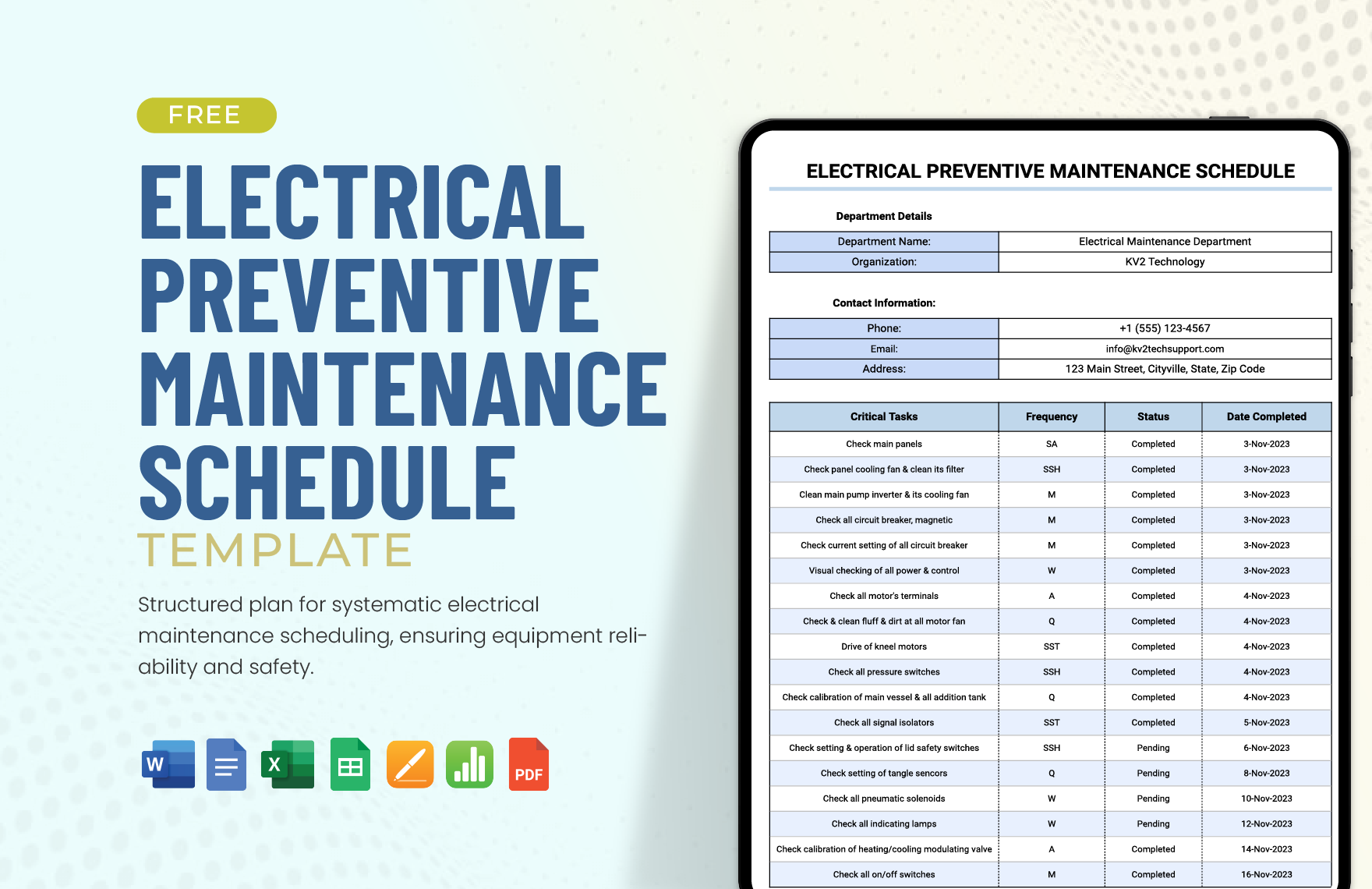

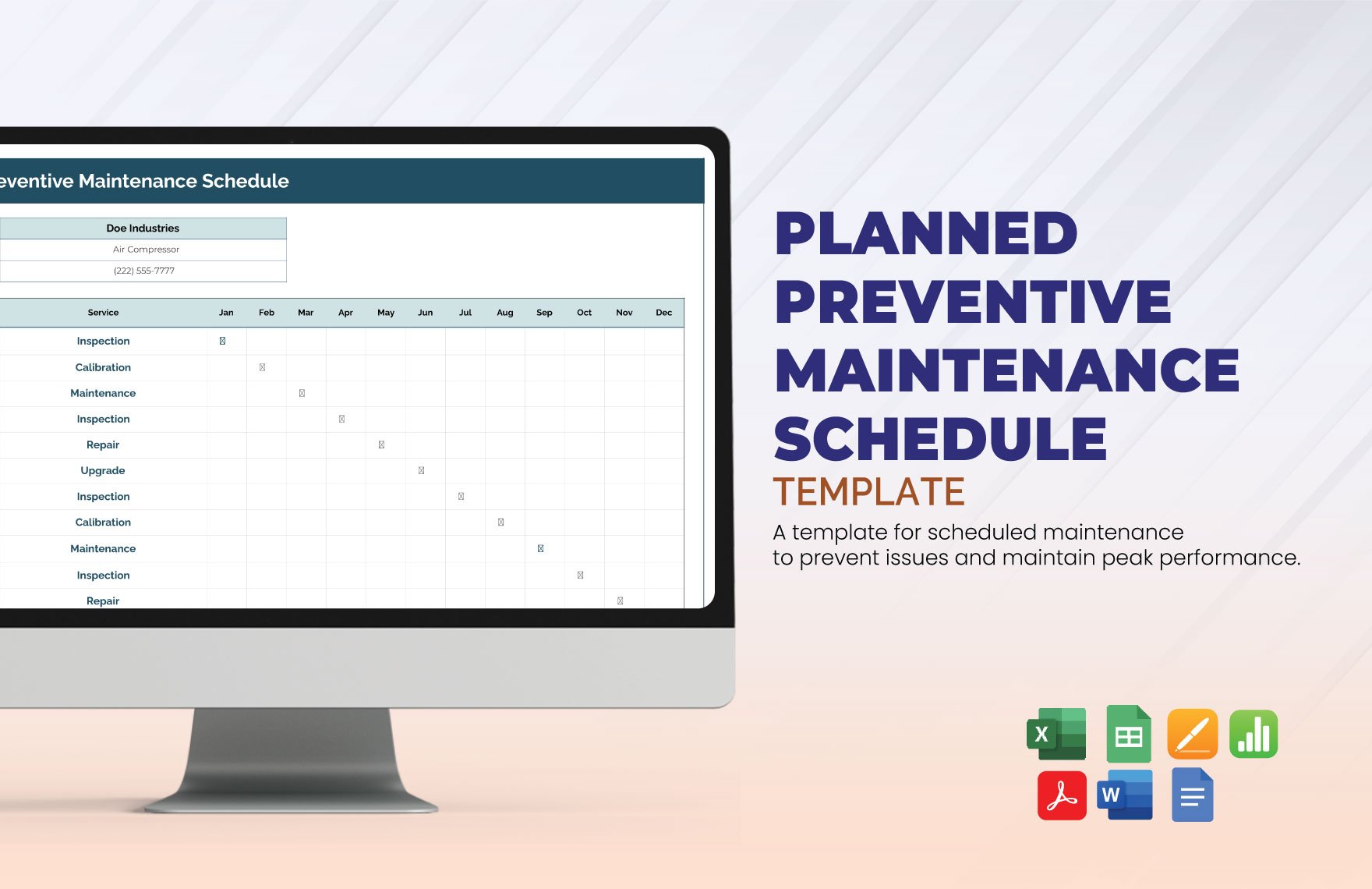

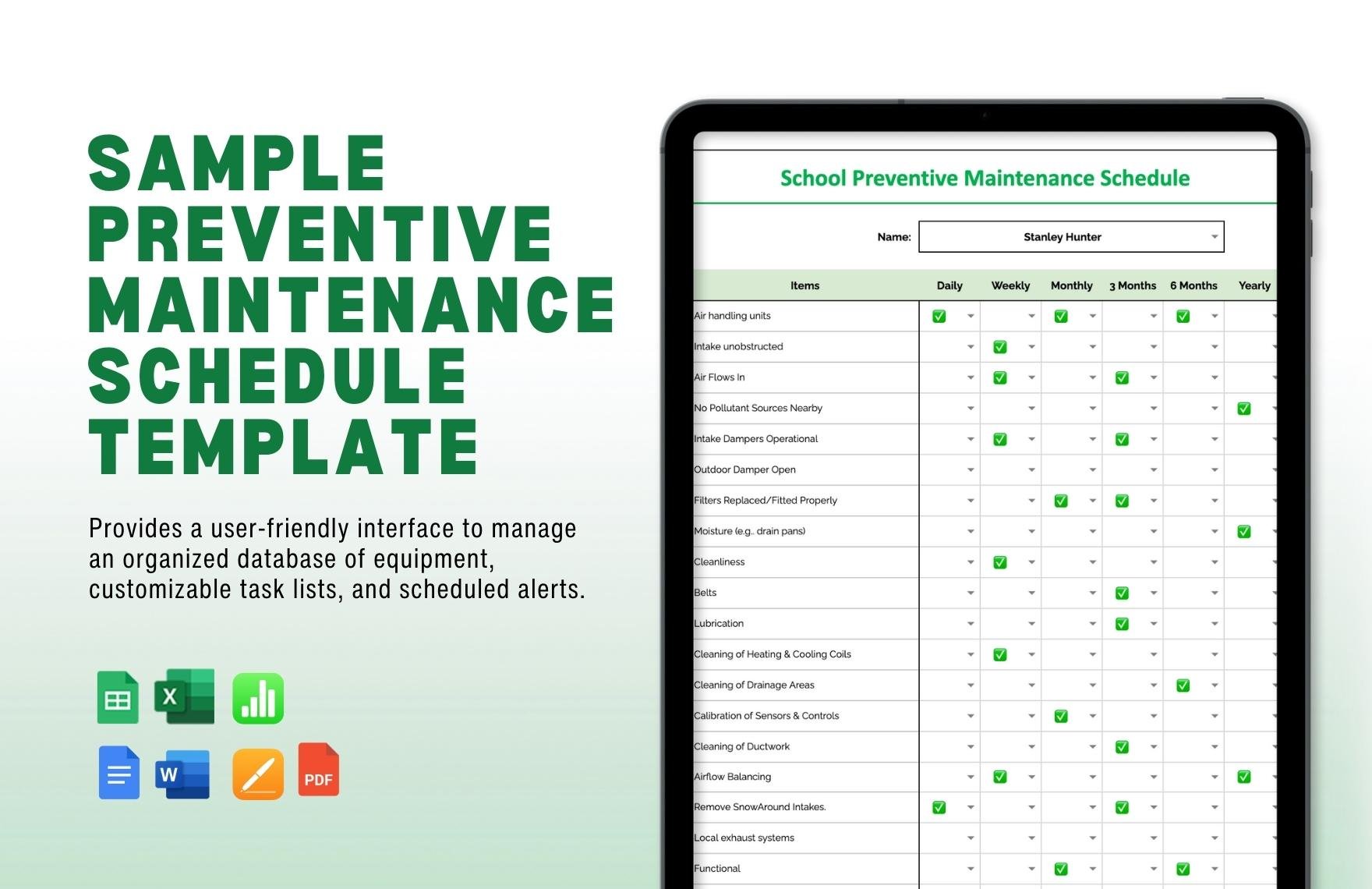

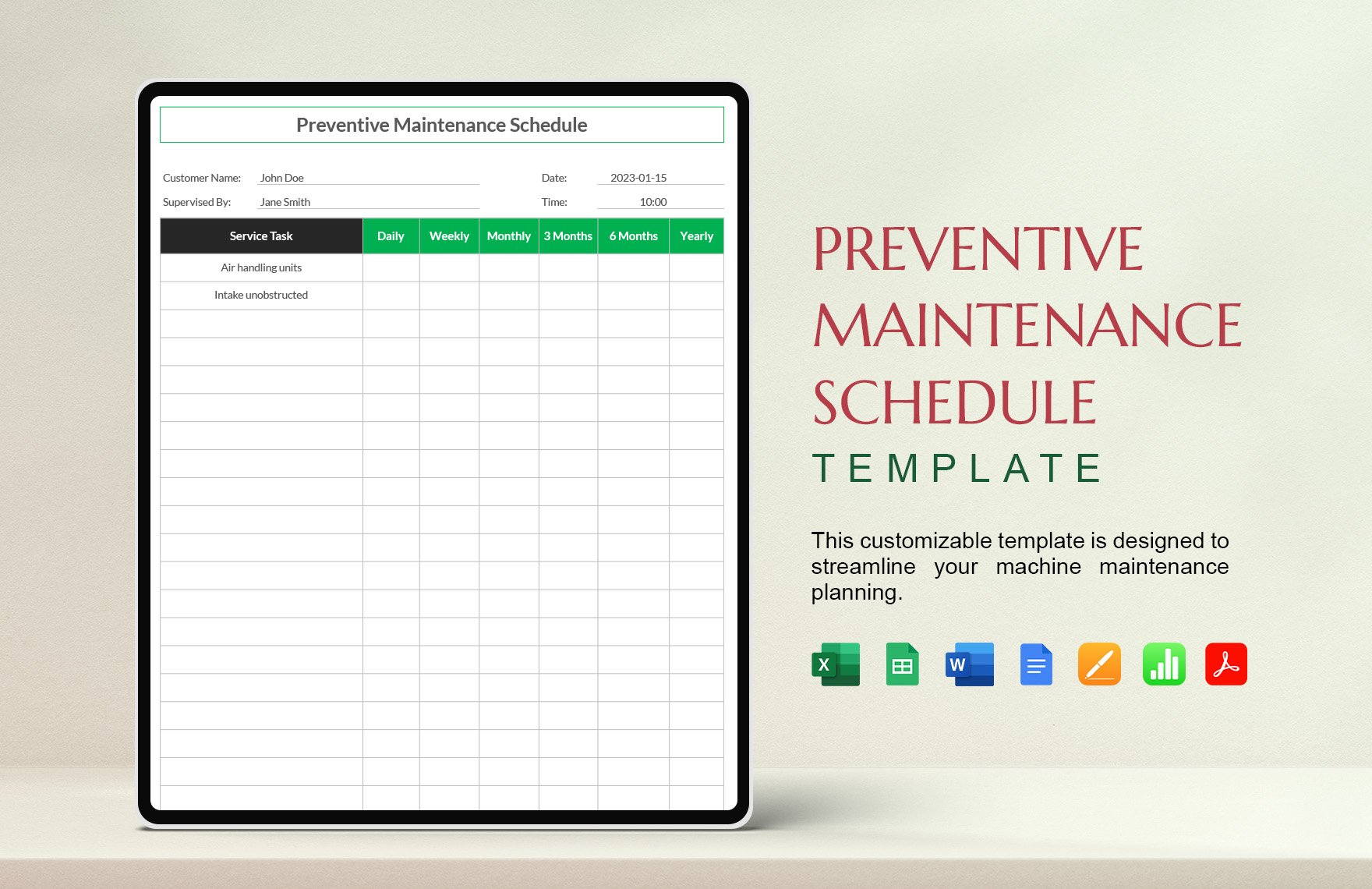

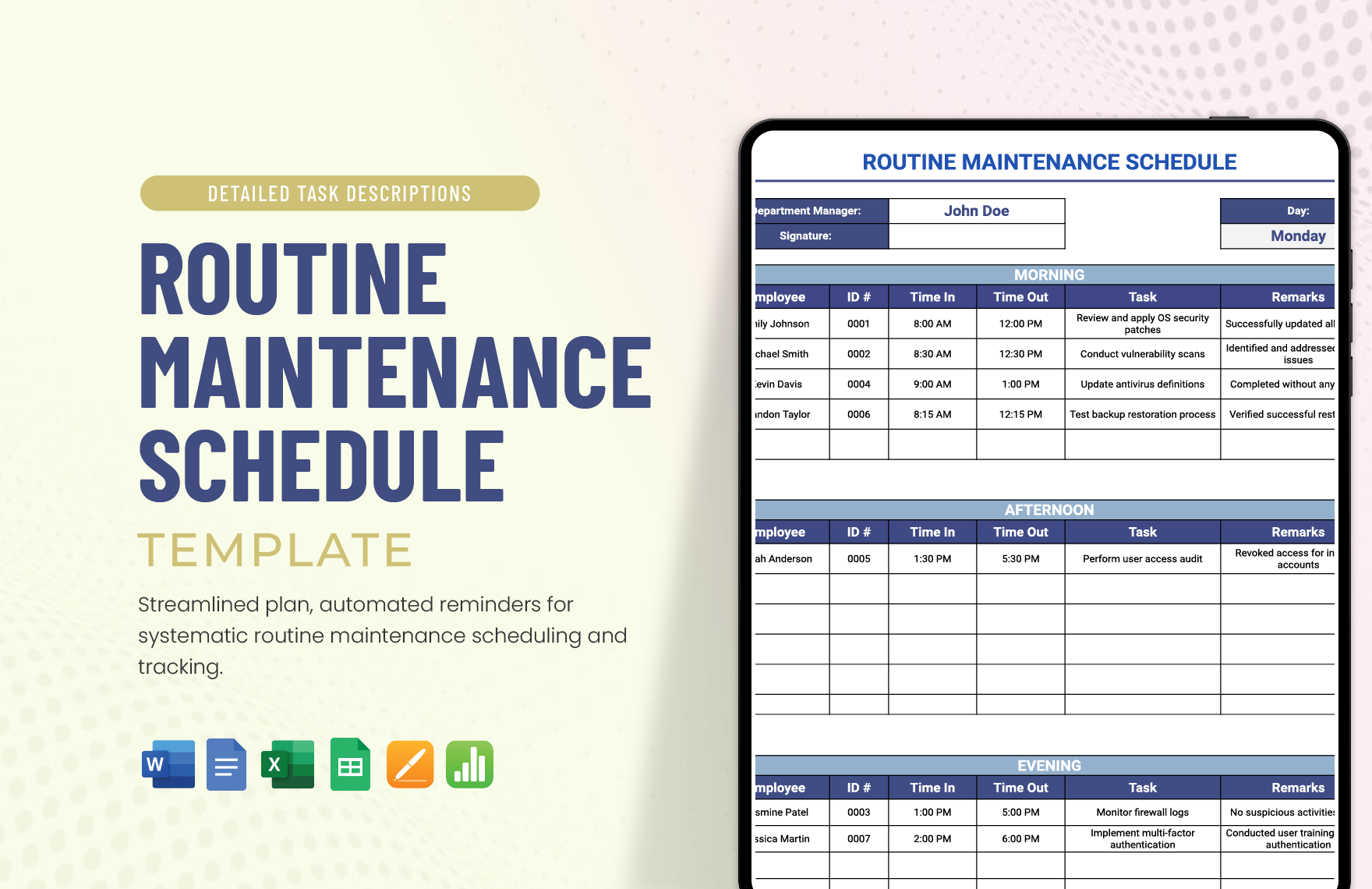

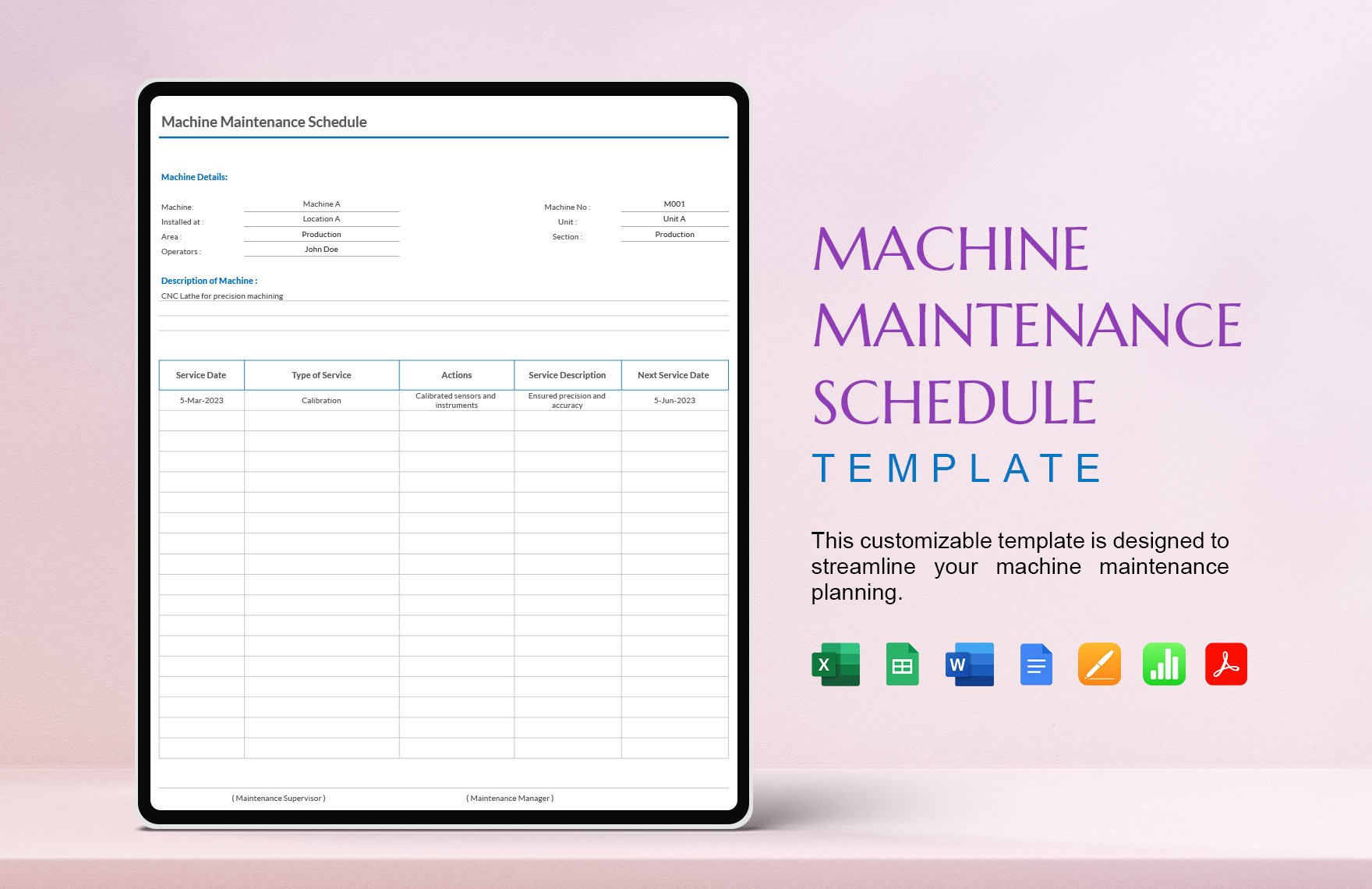

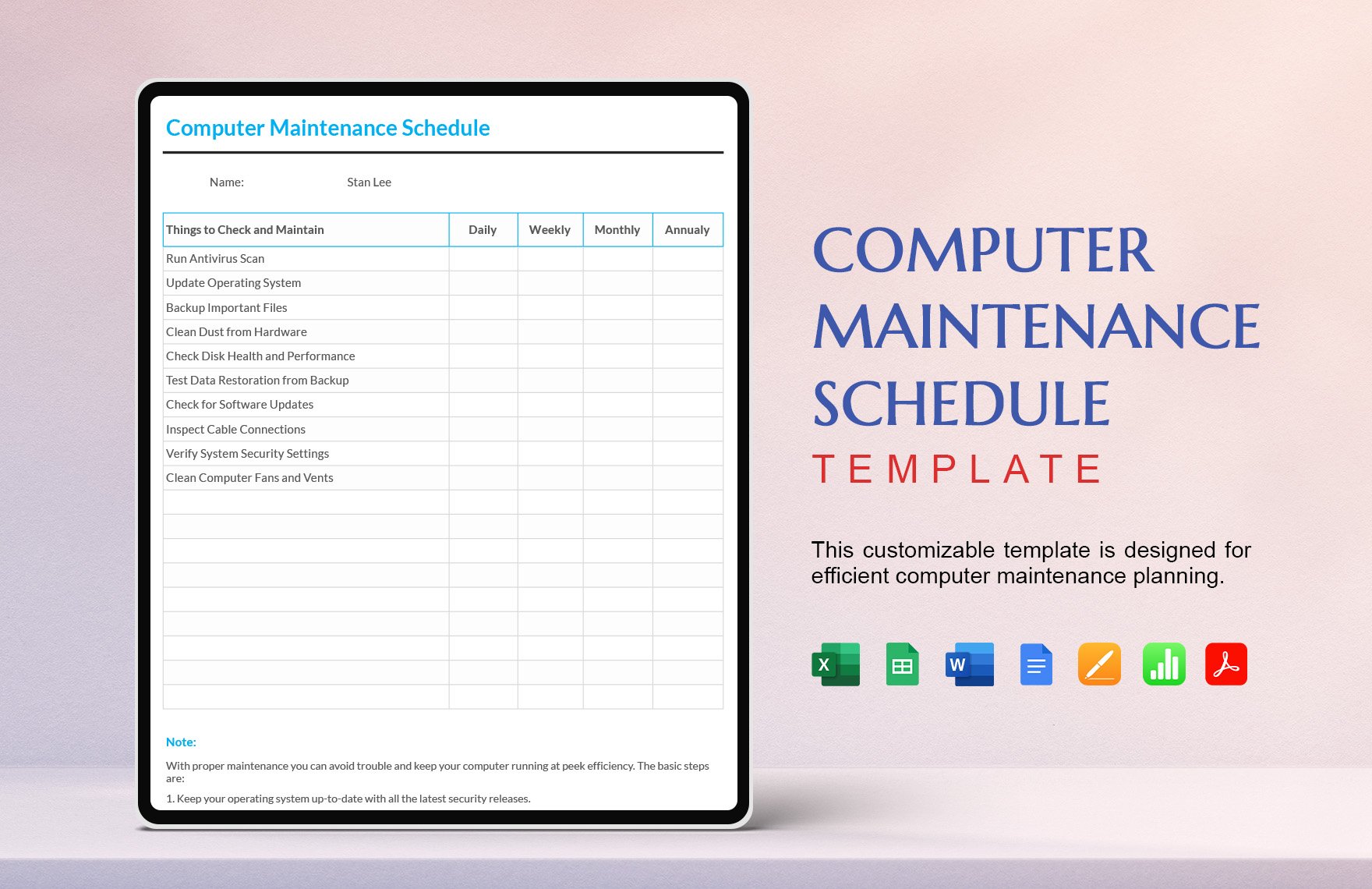

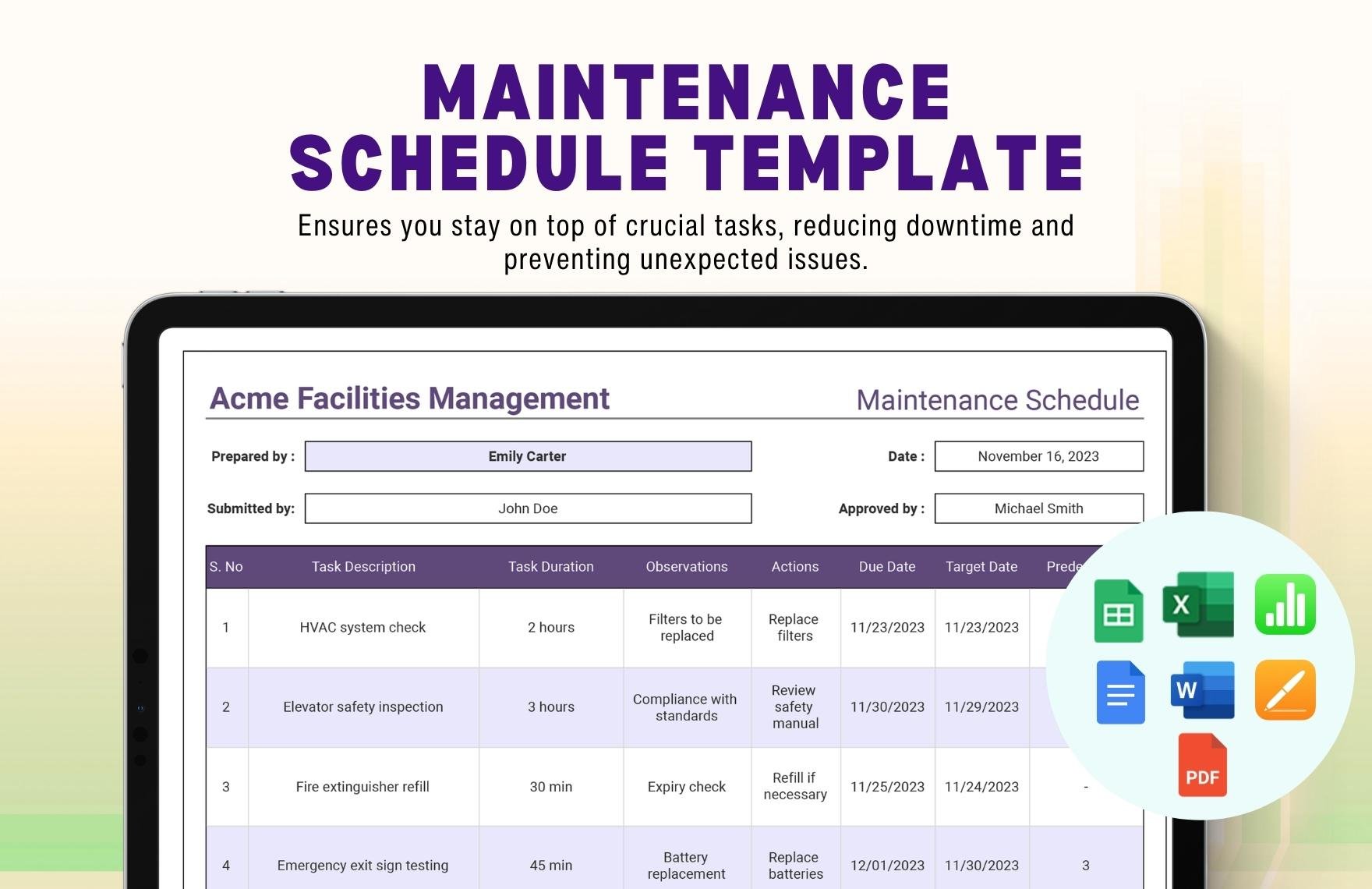

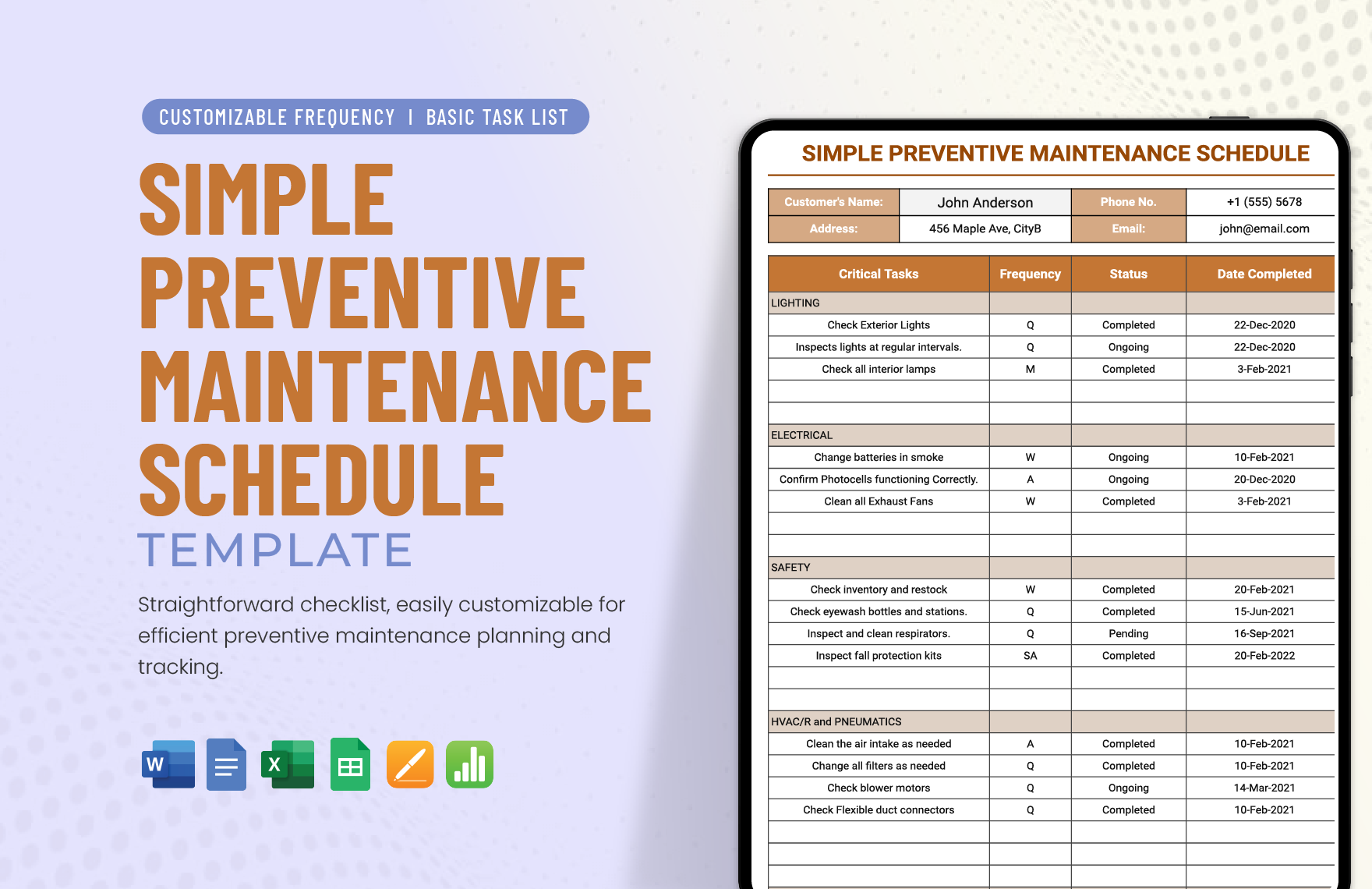

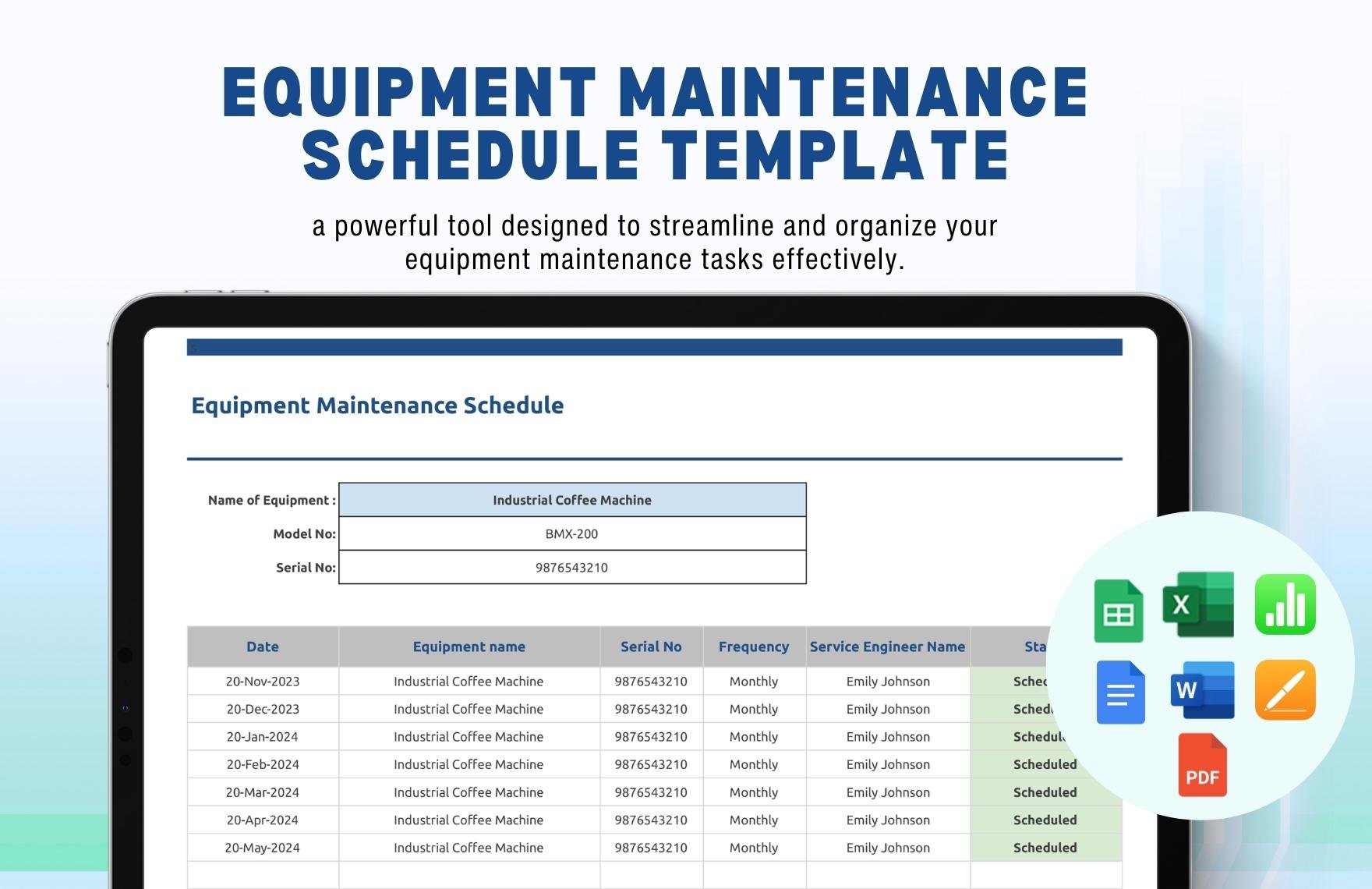

Bring efficiency and organization to your facility management tasks with our pre-designed Preventive Maintenance Schedule Templates in Apple Numbers by Template.net. Designed for facility managers and maintenance teams, these templates empower you to create detailed maintenance schedules without the hassle of designing from scratch. Whether you're aiming to streamline workflows for an entire building or manage equipment service schedules with precision, these templates cater to your organizational needs. Our collection includes free pre-designed templates that are downloadable and printable in Apple Numbers, offering the perfect blend of structure and flexibility. With user-friendly layouts and built-in formulas, anyone can quickly adapt these templates—no design skills needed—allowing you to focus on what truly matters: the smooth operation and longevity of your assets.

Discover an extensive array of pre-designed Preventive Maintenance Schedule Templates that cater to various scenarios and requirements. Our library is refreshed regularly to offer new and innovative designs, ensuring that you have access to the most relevant tools at your disposal. Maximize the impact of your schedules by choosing from both free and premium templates, providing ultimate flexibility in customization. Share your finalized schedules effortlessly by downloading, printing, or exporting them for seamless communication with your team or external contractors. By exploring and leveraging both free and premium options, you can ensure your preventive maintenance strategy is robust, comprehensive, and always one step ahead.

Frequently Asked Questions

What is scheduling?

Scheduling is the process of organizing schedules to optimize work and streamline tasks and production.

What are the advantages of schedules?

- It allows the user to plan each activity.

- It lets the user avoid being overwhelmed by activities, thereby reducing stress.

- It allows the user to prioritize important activities.

- It reduces procrastination.

- It encourages the user to be productive.

- It allows the user to focus on objectives.

What are the types of schedules?

There are three types of schedules, namely, capacity scheduling, resource scheduling, and service schedule. Each of these serves specific purposes.

What tools can be used to create schedules?

The following tools can be used to make schedules.

- Microsoft Word

- Microsoft Excel

- Google Docs

- Google Sheets

- Apple Pages

What is equipment maintenance?

Equipment maintenance is performed to ensure that company equipment is always reliable and in working order. The process involves regular inspection, and when necessary, corrective repairs are performed so that the machinery or company facilities are in tip-top shape.