Free Operations Quality Benchmarking Analysis

Prepared by: | [YOUR NAME] |

Company: | [YOUR COMPANY NAME] |

I. Introduction

In the contemporary business environment, where competition is fierce and customer expectations are continuously evolving, maintaining operational excellence is imperative for the sustained success of any organization. Operations Quality Benchmarking Analysis serves as a strategic approach for companies to assess and elevate their operational performance to industry-leading standards. This analysis delves into the intricate details of Operations Quality Benchmarking, elucidating its significance, methodologies, and multifaceted benefits.

II. Understanding Operations Quality Benchmarking

Operations Quality Benchmarking is not merely a comparison of numbers; rather, it embodies a systematic process of evaluating the intricacies of an organization's operational dynamics. It encompasses a holistic examination of operational processes, quality control mechanisms, resource utilization, and customer satisfaction metrics. By benchmarking against industry leaders or competitors, organizations gain invaluable insights into their operational strengths and weaknesses, thereby paving the path for continuous improvement and innovation.

III. Methodologies for Operations Quality Benchmarking

A. Identifying Key Performance Indicators (KPIs)

The first step in Operations Quality Benchmarking involves identifying a comprehensive set of KPIs that encapsulate various facets of operational performance, such as product quality, process efficiency, customer satisfaction, and resource utilization.

B. Data Collection and Analysis

Data is the cornerstone of benchmarking analysis. Organizations gather data from diverse sources, including internal performance reports, customer feedback, industry publications, and market research. Through rigorous analysis, patterns, trends, and outliers are discerned, offering valuable insights into areas ripe for improvement.

C. Benchmarking against Industry Standard

Armed with data, organizations embark on a journey of comparison, juxtaposing their performance metrics against industry benchmarks and best practices. Direct benchmarking against competitors or indirect benchmarking through industry reports elucidates the organization's relative standing and highlights areas of excellence and deficiency.

D. Root Cause Analysis

Delving deeper into performance differentials, root cause analysis uncovers the underlying factors contributing to operational inefficiencies or quality discrepancies. It involves a meticulous examination of processes, systems, and organizational culture to pinpoint areas warranting intervention.

E. Development of Improvement Strategies

With a profound understanding of performance differentials and root causes, organizations devise targeted improvement strategies tailored to their unique circumstances. These strategies encompass a spectrum of initiatives, ranging from process optimization and technology integration to employee training and cultural transformation.

F. Implementation and Monitoring

The efficacy of improvement strategies hinges on their seamless execution and diligent monitoring. Organizations institute mechanisms for tracking progress, evaluating outcomes, and recalibrating strategies as necessary. Continuous monitoring ensures that improvements are sustained and refined over time, fostering a culture of perpetual enhancement.

IV. Benefits of Operations Quality Benchmarking

A. Performance Improvement

Operations Quality Benchmarking serves as a catalyst for performance enhancement, enabling organizations to streamline processes, eliminate bottlenecks, and elevate productivity and efficiency levels.

B. Cost Reduction

By identifying and rectifying inefficiencies, organizations realize significant cost savings, stemming from reduced rework, lower defect rates, optimized resource utilization, and streamlined processes.

C. Enhanced Competitive Advantage

Benchmarking against industry standards empowers organizations to differentiate themselves in the market by offering superior products, services, and customer experiences. It bolsters brand reputation and fosters customer loyalty, thereby solidifying the organization's market position.

D. Risk Mitigation

Proactively addressing operational deficiencies through benchmarking mitigates risks associated with quality lapses, compliance violations, and customer dissatisfaction. It fortifies organizational resilience and safeguards against reputational damage and financial losses.

E. Promotion of Continuous Improvement

Operations Quality Benchmarking instills a culture of continuous improvement within the organization, catalyzing innovation, agility, and adaptability. It fosters a mindset of introspection and learning, wherein every setback is viewed as an opportunity for growth and refinement.

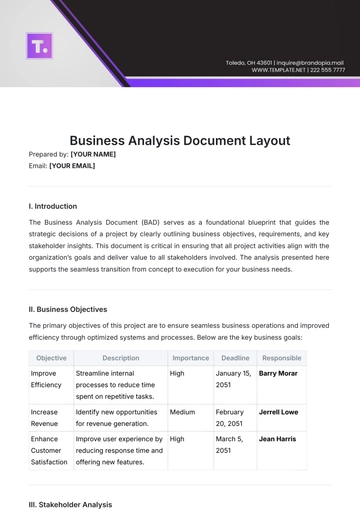

V. Case Studies

A. [Company A]

Through meticulous Operations Quality Benchmarking, [Company A] identified opportunities to revamp its supply chain processes, resulting in a [20%] reduction in lead times and a [15%] increase in on-time deliveries.

B. [Company B]

Leveraging benchmarking insights, [Company B] revamped its customer service operations, leading to a [30%] reduction in response times and a [25%] improvement in customer satisfaction scores.

VI. Conclusion

Operations Quality Benchmarking Analysis transcends the realm of mere performance evaluation; it embodies a transformative journey towards operational excellence and organizational resilience. By embracing benchmarking as a strategic imperative, organizations embark on a voyage of self-discovery, uncovering hidden potential and unlocking new avenues for growth. Through meticulous analysis, targeted interventions, and relentless pursuit of improvement, organizations chart a course towards sustainable success and enduring competitiveness.

For further inquiries or assistance with embarking on your Operations Quality Benchmarking journey, please feel free to contact us at [Your Company Email].

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Enhance your operations with the Operations Quality Benchmarking Analysis Template from Template.net. This editable and customizable tool enables you to compare your operational performance against industry benchmarks. Easily analyze key metrics and identify areas for improvement. With our Ai Editor Tool, you can modify the template to suit your specific needs. Elevate your operations by benchmarking against industry standards with this comprehensive template.