Free Validation Summary

Summarized By: [YOUR NAME]

Validation Overview

Drug Name: [DRUG NAME]

Manufacturing Process Validation Date: [VALIDATION DATE]

Quality Assurance Specialist: [YOUR NAME]

Objective: To ensure the new manufacturing process for [DRUG NAME] meets regulatory standards for safety, efficiency, and quality.

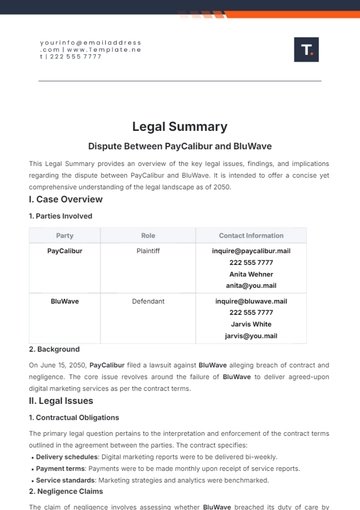

Process Validation Phases

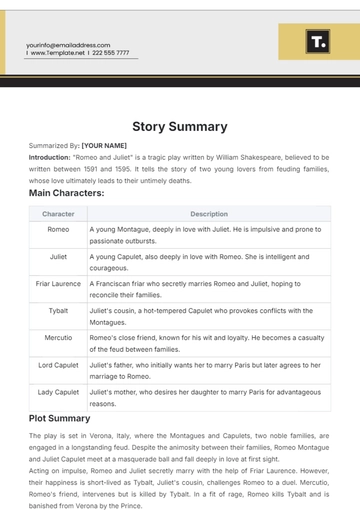

Phase | Objective | Key Activities | Outcome |

Design | Establish process parameters and controls. | Process design Risk assessment | Defined critical process parameters and controls. |

Qualification | Confirm process design under actual conditions. | Installation Qualification (IQ) Operational Qualification (OQ) Performance Qualification (PQ) | Verified equipment and process operate within specified parameters. |

Continuous Monitoring | Ensure ongoing process control and quality. | Trend analysis Quality control checks | Confirmed consistent product quality and process stability. |

Validation Results

Installation Qualification (IQ): Confirmed that all equipment and systems are installed according to specifications.

Operational Qualification (OQ): Verified that the equipment and processes operate within designated parameters during worst-case conditions.

Performance Qualification (PQ): Demonstrated that the manufacturing process produces [DRUG NAME] consistently and meets all predetermined quality criteria.

Critical Control Points Identified

Temperature Control: Essential for ensuring active ingredient stability.

Mixing Time: Critical for the uniform distribution of the active ingredient.

Sterilization Process: Key for preventing microbial contamination.

Regulatory Compliance

Guidelines Followed: Followed all applicable FDA and international regulatory guidelines for drug manufacturing.

Documentation: Comprehensive documentation prepared, including SOPs, validation protocols, and quality control records.

Conclusion

The validation of the new manufacturing process for [DRUG NAME] has been successfully completed, with all phases meeting or exceeding the regulatory requirements for safety, efficiency, and quality. This process ensures that [DRUG NAME] is manufactured consistently to the highest standards, supporting its approval for market release.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Discover the epitome of efficiency with the Validation Summary Template from Template.net. Crafted for precision, it's both editable and customizable, ensuring seamless adaptation to your unique needs. Harness its power effortlessly within our Ai Editor Tool, and streamline your validation processes with unparalleled ease and finesse.