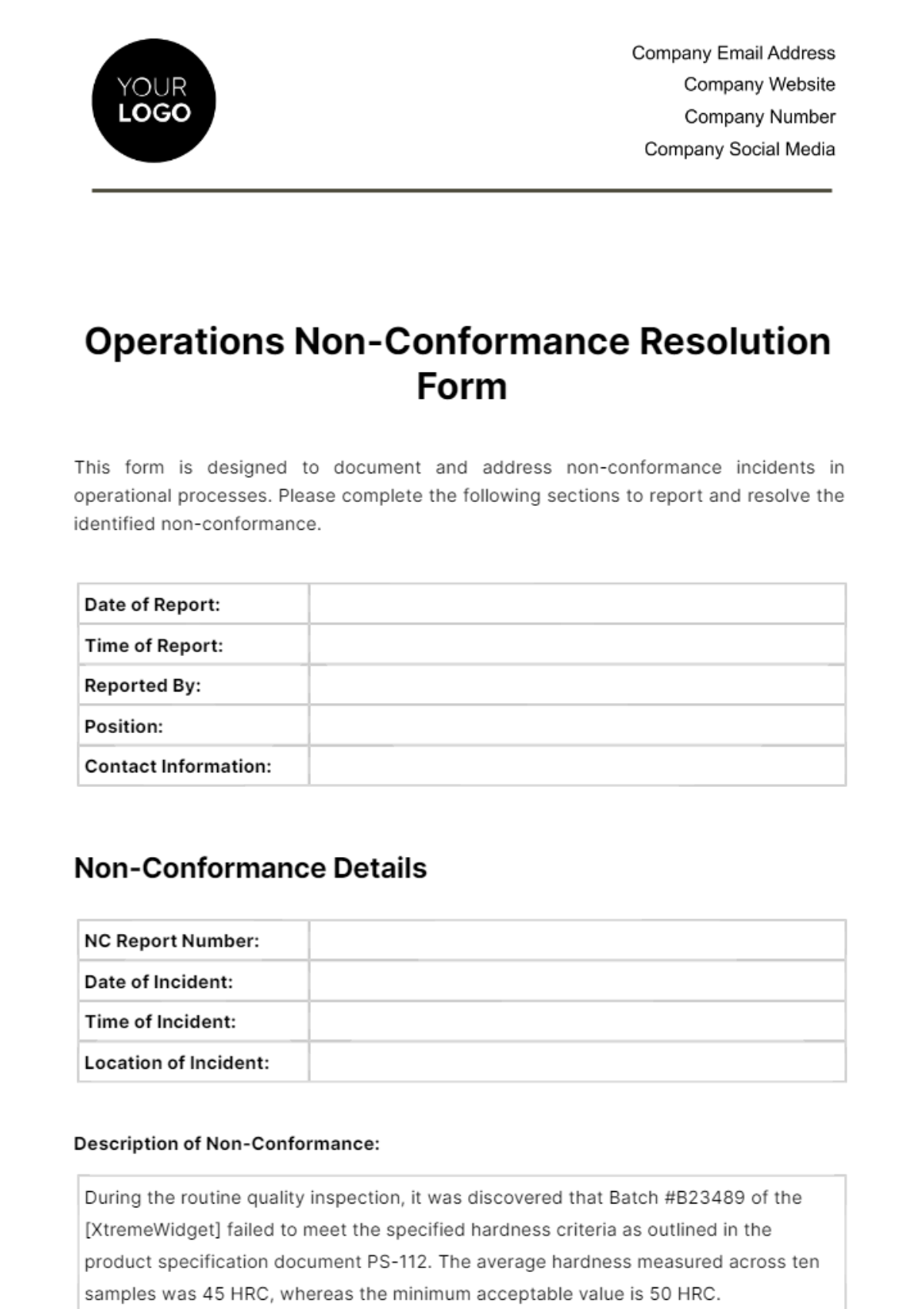

Free Operations Non-Conformance Resolution Form

This form is designed to document and address non-conformance incidents in operational processes. Please complete the following sections to report and resolve the identified non-conformance.

Date of Report: | |

Time of Report: | |

Reported By: | |

Position: | |

Contact Information: |

Non-Conformance Details

NC Report Number: | |

Date of Incident: | |

Time of Incident: | |

Location of Incident: |

Description of Non-Conformance:

During the routine quality inspection, it was discovered that Batch #B23489 of the [XtremeWidget] failed to meet the specified hardness criteria as outlined in the product specification document PS-112. The average hardness measured across ten samples was 45 HRC, whereas the minimum acceptable value is 50 HRC. |

Impact Assessment

Immediate Impact:

The immediate production schedule is affected as Batch #B23489 cannot proceed to the packaging stage. There is a potential delay in fulfilling customer orders for [XtremeWidget], impacting customer satisfaction and timely delivery commitments. |

Potential Long-Term Impact:

Initial Response and Containment Actions

Action Taken:

The affected batch was immediately quarantined to prevent it from proceeding further in the production process. A re-inspection of the preceding and succeeding batches was initiated to determine the extent of the issue. |

Responsible Person(s): [Name(s)]

Date of Action: [Month Day, Year]

Root Cause Analysis

Investigation Lead: [Name]

Team Members: [Name(s)]

Analysis Method Used: [5 Whys]

Root Cause(s) Identified:

The root cause was identified as an incorrect setting on the hardness testing machine used for Batch #B23489, which was not calibrated correctly, leading to inaccurate hardness measurements. |

Corrective Action Plan

Corrective Actions:

Re-calibrate all hardness testing machines in the quality control department.

Planned Completion Date: [Month Day, Year]

Preventive Actions:

Implement a monthly maintenance and calibration schedule for all testing equipment to prevent recurrence. Develop a checklist for daily verification of equipment calibration by the operators.

Follow-Up and Resolution Verification

Follow-Up Date: [Month Day, Year]

Verification of Corrective Actions

Comments:

The implementation of a rigorous equipment maintenance and calibration program has significantly improved the accuracy and reliability of the testing data, preventing similar non-conformance incidents. |

Approval

Report Prepared By:

Name: [Your Name]

Position: Quality Assurance Manager

Signature:

Date: [Date]

Reviewed By:

Name: [Name]

Position: [Position]

Signature:

[Month Day, Year]

Approved By:

Name: [Name]

Position: [Position]

Signature:

[Month Day, Year]

[Your Company Name] is committed to maintaining the highest standards of quality, safety, and compliance. This form is a crucial part of our continuous improvement efforts to identify, resolve, and prevent non-conformance in our operations. Thank you for your diligence and cooperation in this process.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Streamline your operations with Template.net's Operations Non-Conformance Resolution Form Template. Our editable and customizable template, powered by cutting-edge AI technology, empowers you to efficiently address and resolve non-conformances in your processes. Simplify documentation, enhance collaboration, and ensure compliance with ease. Get started today and optimize your operational efficiency like never before.