Free Hazard Analysis Report

Date: December 15, 2053

Report Number: HAR-2023-001

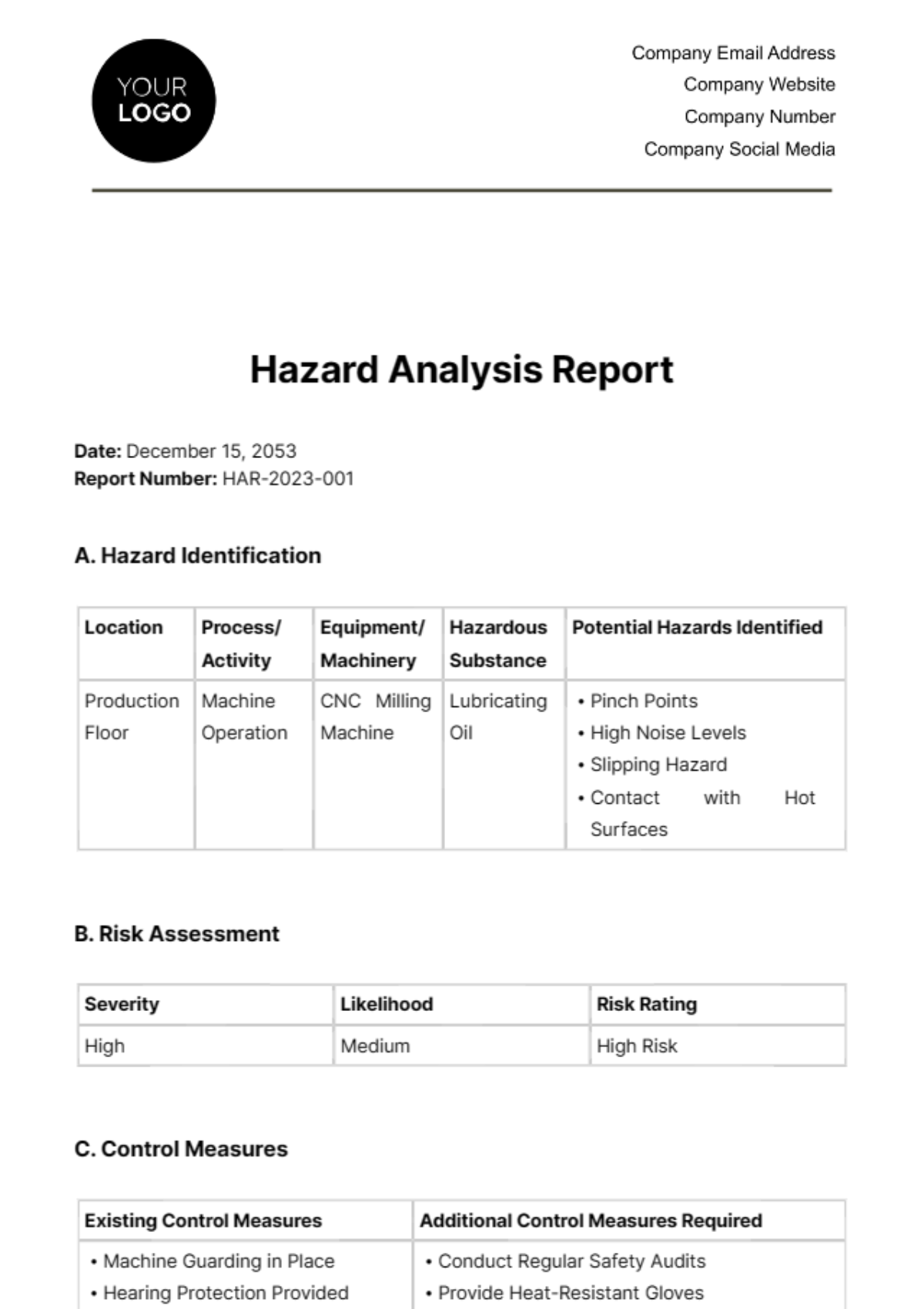

A. Hazard Identification

Location | Process/ Activity | Equipment/ Machinery | Hazardous Substance | Potential Hazards Identified |

Production Floor | Machine Operation | CNC Milling Machine | Lubricating Oil |

|

B. Risk Assessment

Severity | Likelihood | Risk Rating |

High | Medium | High Risk |

C. Control Measures

Existing Control Measures | Additional Control Measures Required |

|

|

D. Parties Involved

[Your Partner Company Name / Second Party]

[Your Partner Company Name / Second Party Email]

[Your Partner Company Name / Second Party Address]

[Your Partner Company Name / Second Party Number]

E. Users/Workers Involved

[Your Client / Subscriber / User Name]

[Your Client / Subscriber / User Email]

F. Hazard History

Previous Incidents | Near-Misses |

None Reported | Two Near-Miss Incidents in the Past 6 Months |

G. Recommendations

1. Immediate Actions Required:

In response to identified hazards, the following immediate actions are deemed necessary to mitigate risks promptly:

a. Conduct Safety Training for Machine Operators:

It is imperative to organize and implement comprehensive safety training sessions for machine operators. This training should encompass all relevant safety protocols and guidelines to ensure operators are well-versed in the safe operation of machinery.

b. Install Heat-Resistant Gloves Dispenser:

To address the specific hazard related to heat exposure, immediate installation of a heat-resistant gloves dispenser is recommended. This will facilitate easy access to protective equipment for personnel working in environments with elevated temperatures.

2. Long-Term Actions

a. Develop Lockout/Tagout Procedure Manual

A comprehensive Lockout/Tagout Procedure Manual should be developed to establish standardized protocols for isolating energy sources during maintenance or repair activities. This manual will serve as a reference guide to ensure consistent adherence to safety procedures over the long term.

b. Conduct Quarterly Safety Audits

Implementing a regular schedule of quarterly safety audits is essential for ongoing hazard identification and risk assessment. These audits will help maintain a proactive approach to safety management, identifying potential hazards before they escalate and ensuring continuous improvement in safety protocols.

3. Responsible Parties

To ensure accountability and effective implementation of the recommended actions, the following responsible parties have been assigned:

a. Safety Manager - [Your Name]

The Safety Manager, [Your Name], is designated as the primary responsible party for overseeing the execution of the hazard mitigation plan. This includes coordinating safety training, overseeing the installation of necessary equipment, and managing the development of the Lockout/Tagout Procedure Manual. As the point of contact for safety-related matters, [Your Name] will also be responsible for organizing and conducting quarterly safety audits to monitor and enhance the overall safety performance within the organization.

H. Approval:

[Your Name]

____________________

[Safety Manager]

[December 20, 2053]

I. Review and Follow-Up

Review Date: [June 15, 2024]

Follow-Up Actions:

Review Effectiveness of Control Measures

Address Any New Hazards

Reviewer's Comments: Safety audit findings are to be documented.

Please make sure to adapt this report to your specific company's situation and needs. Ensure that all control measures and recommendations align with US health and safety regulations and standards relevant to your industry.

Health & Safety Templates @ Template.net

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Unlock comprehensive hazard analysis with Template.net's Hazard Analysis Report Template. This editable and customizable tool, powered by our Ai Editor Tool, facilitates thorough examination and mitigation of risks. Empower your team to proactively address safety concerns and ensure a secure work environment. Trust Template.net for comprehensive hazard analysis solutions.