Free Supplier Management Procedure

Introduction:

This Supplier Management Procedure Template outlines the process for managing suppliers effectively within [YOUR COMPANY NAME]. It establishes guidelines for identifying, evaluating, selecting, and monitoring suppliers to ensure the quality and reliability of goods and services procured.

Scope:

This procedure applies to all departments and personnel involved in the procurement and supplier management processes within [YOUR COMPANY NAME]. It encompasses activities related to supplier identification, qualification, performance evaluation, and relationship management.

Purpose:

The purpose of this procedure is to establish a systematic approach to supplier management that enables [YOUR COMPANY NAME] to build strong, collaborative partnerships with suppliers, minimize risks, and optimize procurement outcomes. By following this template, [YOUR COMPANY NAME] can ensure the consistent delivery of high-quality products and services to meet organizational needs.

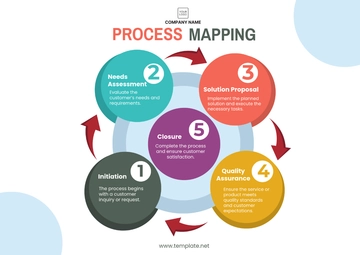

I. Supplier Identification and Selection

Identify Supplier Needs: Determine the goods or services required and assess the specific requirements and criteria for selecting suppliers.

Consider factors such as product quality, price, reliability, delivery times, and supplier reputation.

Search for Potential Suppliers: Conduct market research and supplier evaluations to identify potential suppliers that meet the defined criteria.

Utilize supplier directories, trade publications, industry networks, and online platforms to identify suitable suppliers.

II. Supplier Evaluation and Qualification

Assess Supplier Capabilities: Evaluate potential suppliers based on predefined criteria, including financial stability, technical capabilities, production capacity, and quality management systems.

Conduct site visits, audits, or supplier surveys to assess supplier facilities and capabilities firsthand.

Perform Due Diligence: Verify the legal and regulatory compliance of potential suppliers, including certifications, licenses, and adherence to ethical standards.

Review supplier contracts, terms, and conditions to ensure alignment with [YOUR COMPANY NAME]'s policies and requirements.

III. Supplier Onboarding

Negotiate Terms and Agreements: Negotiate contractual terms, pricing, delivery schedules, and service level agreements (SLAs) with selected suppliers.

Ensure clear communication of expectations and responsibilities to both parties.

Establish Communication Channels: Set up regular communication channels with suppliers to facilitate ongoing collaboration, feedback, and issue resolution.

Designate a primary contact person or team responsible for managing communication with suppliers.

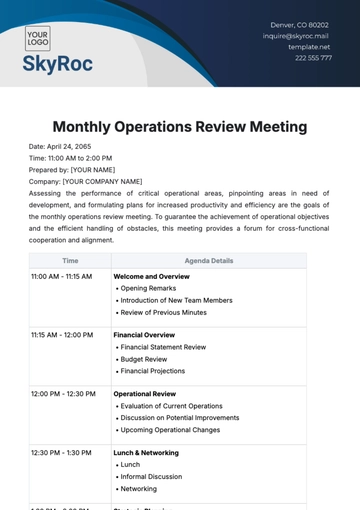

IV. Supplier Performance Monitoring

Monitor Delivery and Quality: Track supplier performance against established metrics, including on-time delivery, product quality, and service levels.

Address any deviations or deficiencies promptly through corrective actions or performance improvement plans.

Conduct Regular Reviews: Schedule periodic performance reviews with key suppliers to discuss performance, address concerns, and identify opportunities for improvement.

Use performance data and feedback to drive continuous improvement and strengthen supplier relationships.

V. Supplier Relationship Management

Cultivate Strategic Partnerships: Foster long-term, mutually beneficial relationships with key suppliers through collaboration, transparency, and trust.

Explore opportunities for joint initiatives, innovation, and value creation with strategic suppliers.

Resolve Disputes and Issues: Handle supplier disputes and issues promptly and fairly through effective communication, negotiation, and conflict resolution strategies.

Seek win-win solutions that preserve the integrity of the supplier relationship while addressing concerns.

Additional Reminders and Tips:

Maintain open and transparent communication with suppliers to foster trust and collaboration.

Continuously evaluate and diversify the supplier base to minimize dependence on single suppliers and mitigate risks.

Document all supplier-related activities, agreements, and performance evaluations for future reference and audit purposes.

Prepared by | Company Name | Department | Date |

|---|---|---|---|

[YOUR NAME] | [YOUR COMPANY NAME] | [YOUR DEPARTMENT] | [DATE] |

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Elevate supplier relations with the Supplier Management Procedure Template from Template.net. This editable and customizable resource simplifies the creation of comprehensive supplier management protocols. Tailor procedures to your company's unique requirements effortlessly using our intuitive Ai Editor Tool. Strengthen supply chain efficiency and collaboration with this essential template for effective supplier management.