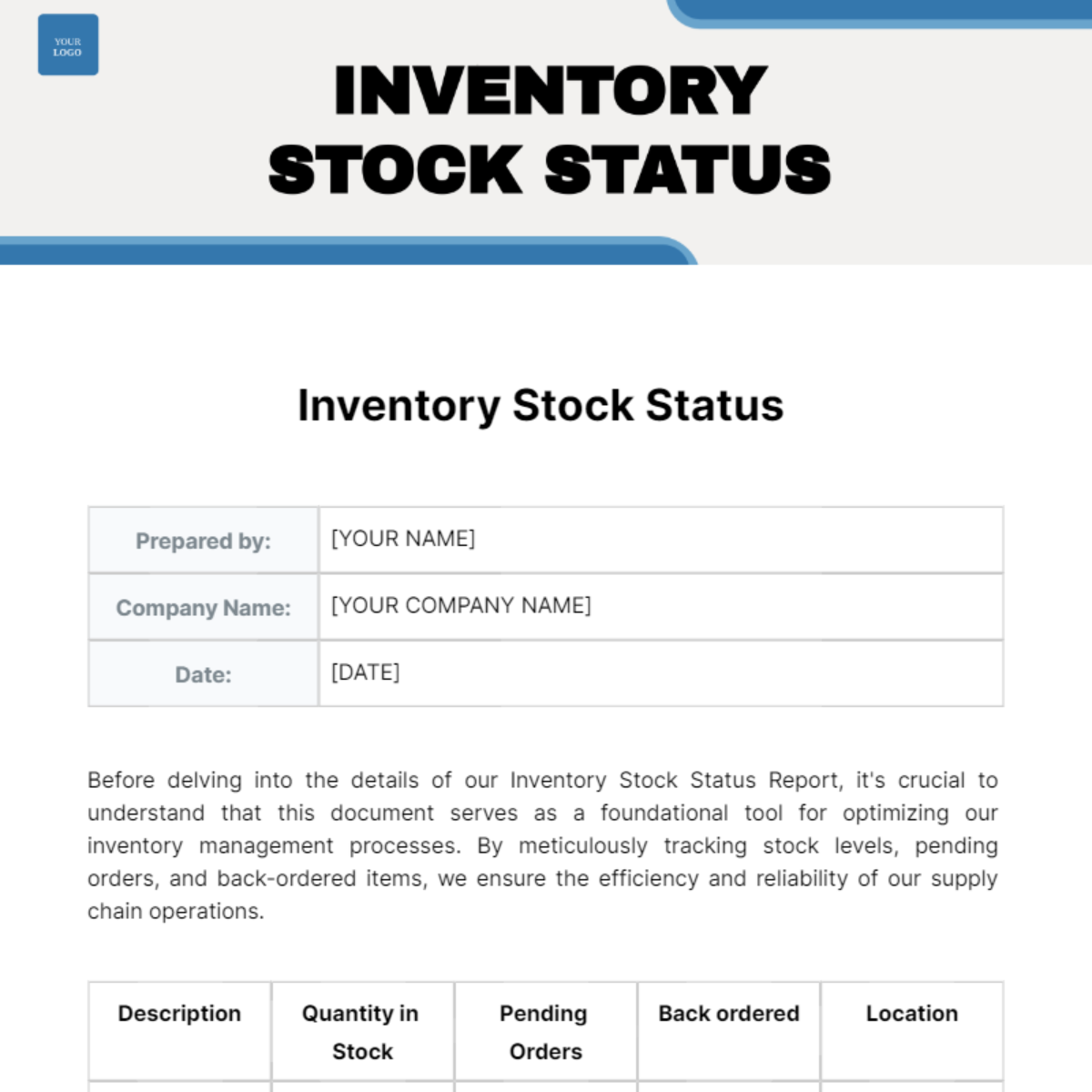

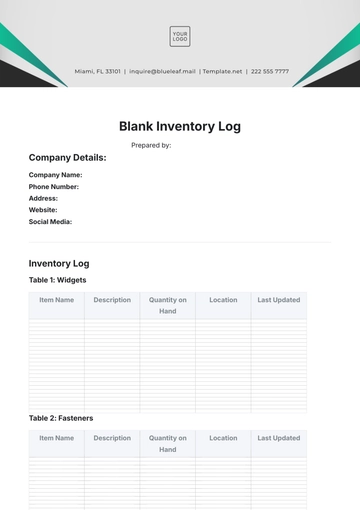

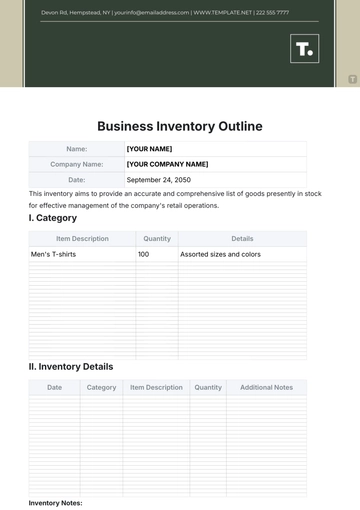

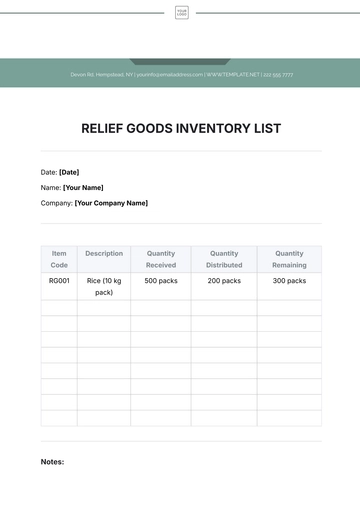

Inventory Stock Status

Prepared by: | [YOUR NAME] |

|---|

Company Name: | [YOUR COMPANY NAME] |

|---|

Date: | [DATE] |

|---|

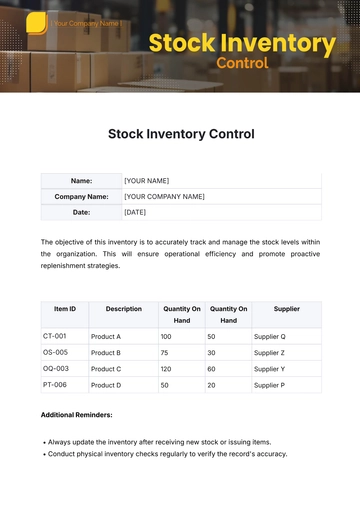

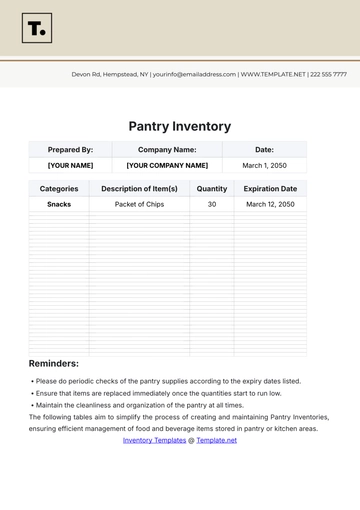

Before delving into the details of our Inventory Stock Status Report, it's crucial to understand that this document serves as a foundational tool for optimizing our inventory management processes. By meticulously tracking stock levels, pending orders, and back-ordered items, we ensure the efficiency and reliability of our supply chain operations.

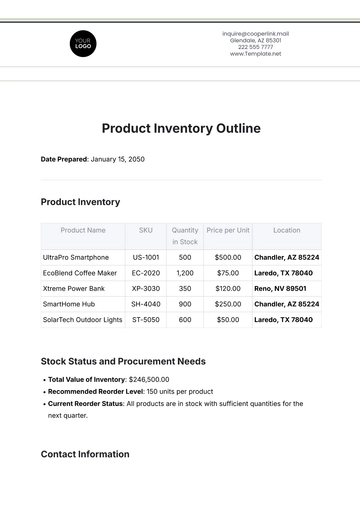

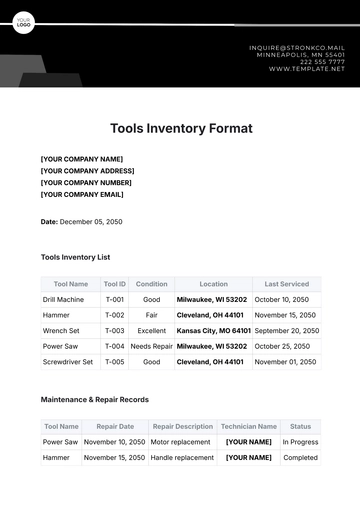

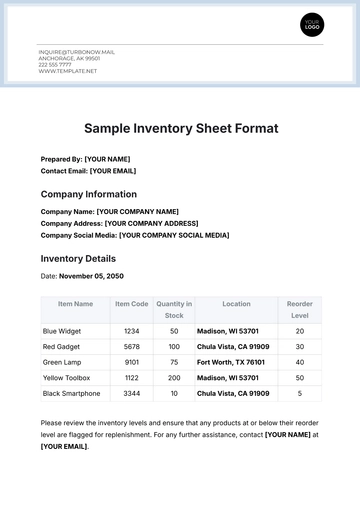

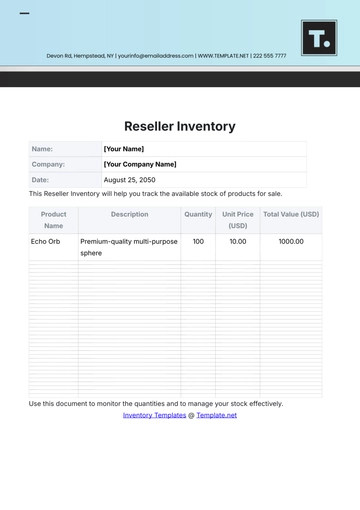

Description | Quantity in Stock | Pending Orders | Back ordered | Location |

Widget A | 500 | 100 | 0 | Warehouse 1 |

Gadget B | 300 | 150 | 20 | Warehouse 2 |

Component C | 800 | 200 | 0 | Warehouse 1 |

Device D | 100 | 50 | 10 | Warehouse 3 |

Equipment E | 600 | 300 | 0 | Warehouse 2 |

Tool F | 200 | 100 | 5 | Warehouse 3 |

Accessory G | 900 | 0 | 0 | Warehouse 1 |

Material H | 1500 | 500 | 25 | Warehouse 2 |

Supply I | 1200 | 400 | 0 | Warehouse 1 |

Product J | 700 | 200 | 15 | Warehouse 3 |

Additional Notes:

Inventory levels are updated daily to ensure accuracy. Pending orders and back-ordered items are reviewed weekly to adjust for any changes in demand or supply chain disruptions.

Items are strategically placed in warehouses based on their demand and shipping locations to optimize for delivery times.

Items with a high number of backorders will be flagged for urgent restocking. Communication with suppliers is prioritized to reduce any potential delays.

These are closely monitored to ensure stock levels are adequately maintained to meet customer demand, with adjustments made as necessary.

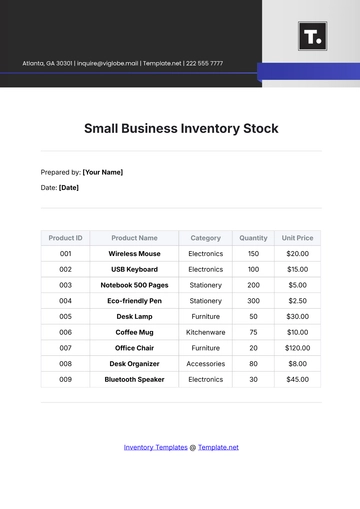

Inventory Templates @ Template.net