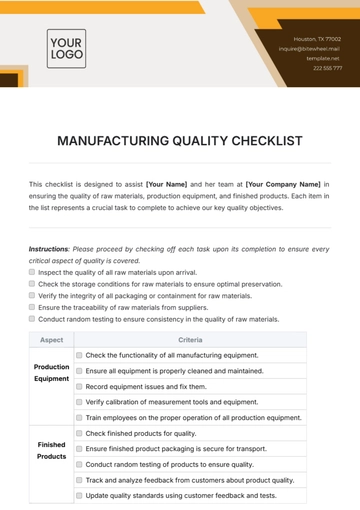

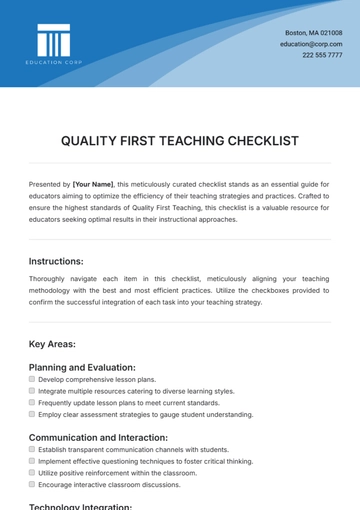

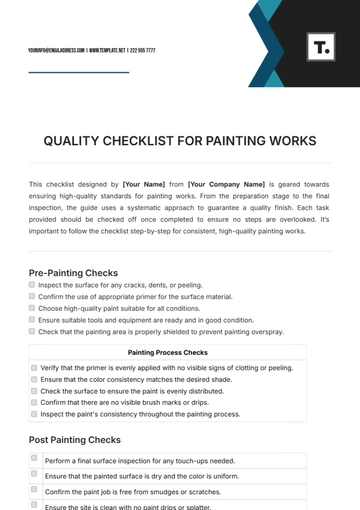

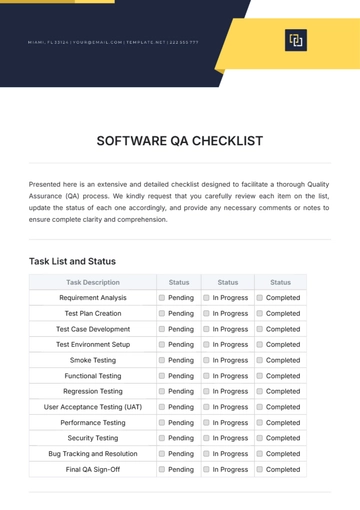

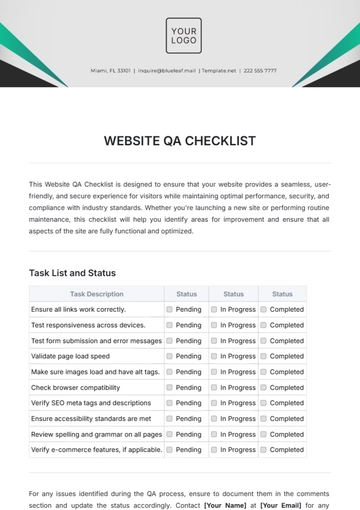

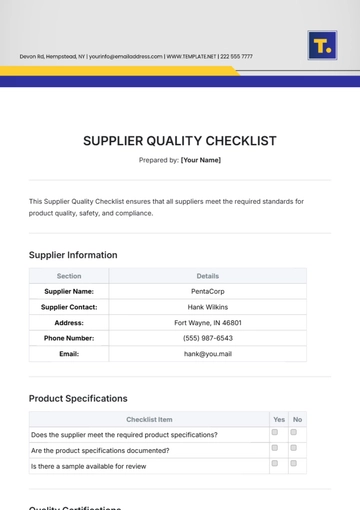

Free Manufacturing Quality Checklist

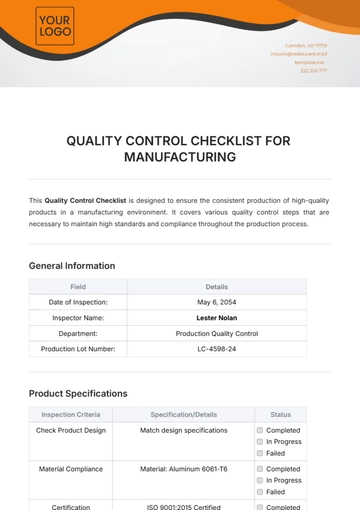

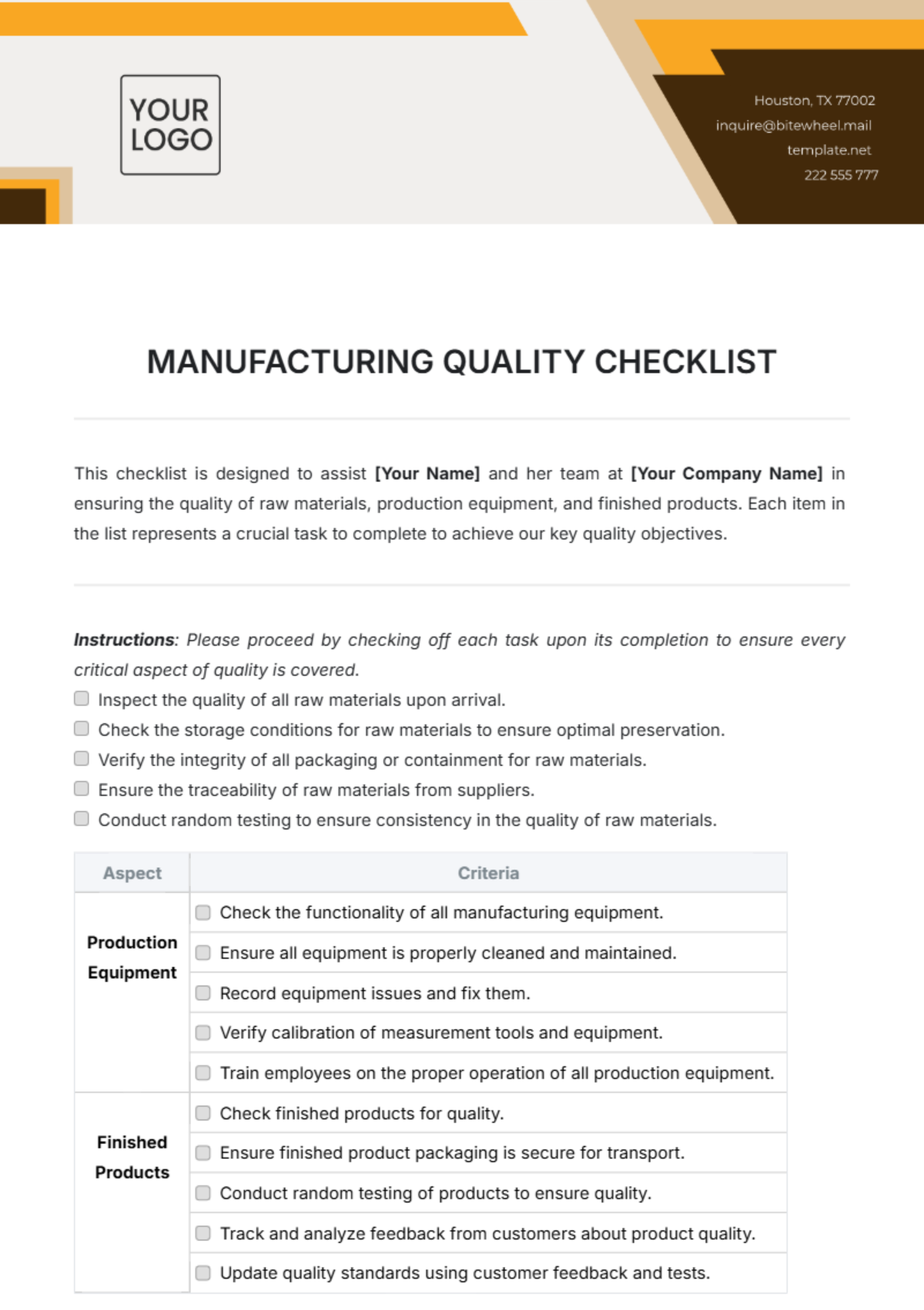

This checklist is designed to assist [Your Name] and her team at [Your Company Name] in ensuring the quality of raw materials, production equipment, and finished products. Each item in the list represents a crucial task to complete to achieve our key quality objectives.

Instructions: Please proceed by checking off each task upon its completion to ensure every critical aspect of quality is covered.

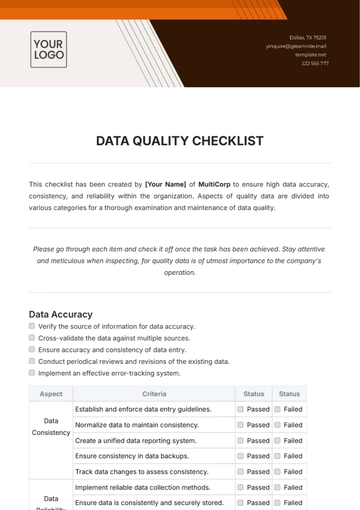

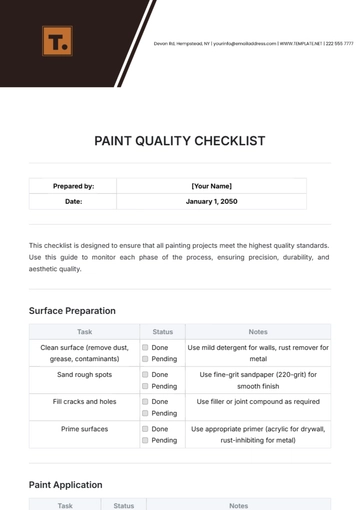

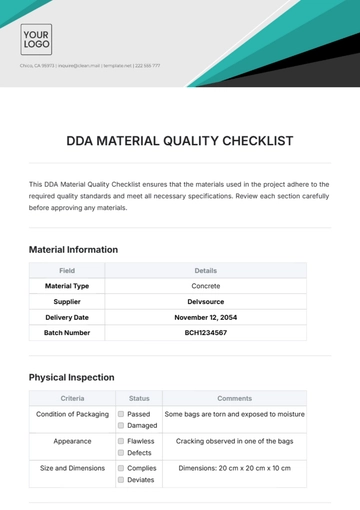

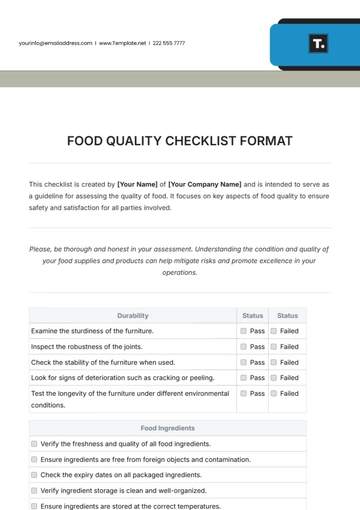

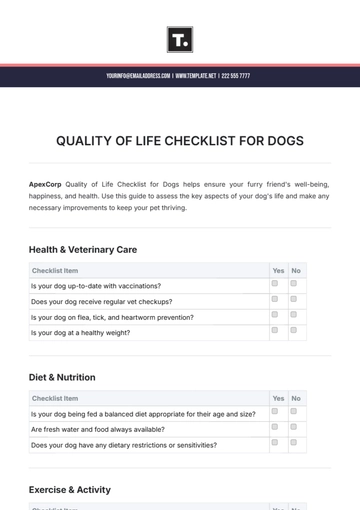

Inspect the quality of all raw materials upon arrival.

Check the storage conditions for raw materials to ensure optimal preservation.

Verify the integrity of all packaging or containment for raw materials.

Ensure the traceability of raw materials from suppliers.

Conduct random testing to ensure consistency in the quality of raw materials.

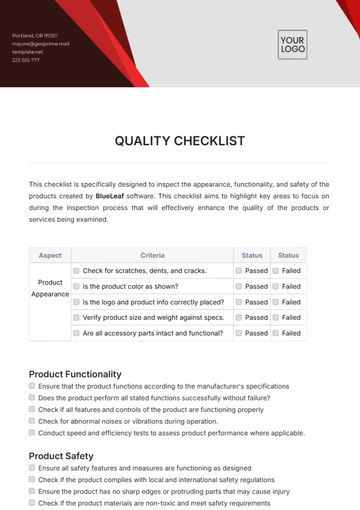

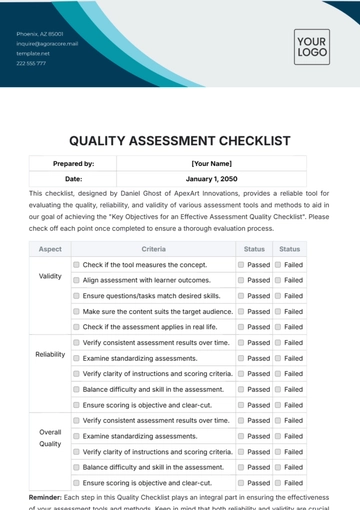

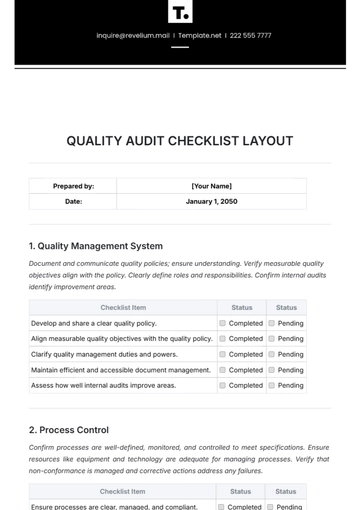

Aspect | Criteria |

|---|---|

Production Equipment |

|

| |

| |

| |

| |

Finished Products |

|

| |

| |

| |

|

Reminder: It's essential to regularly review and update this checklist in line with best industry practices, technological advancements, and product development. Remember, consistency in following this checklist will be crucial in continuously providing high-quality goods and services.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Optimize your manufacturing processes with Template.net's Manufacturing Quality Checklist Template. Expertly designed, it's fully customizable and editable in our user-friendly AI Editor Tool. Streamline inspections for production lines, materials, and final products effortlessly. Tailor this versatile template to your specific needs for comprehensive manufacturing excellence. Download now for a powerful tool that guarantees top-tier quality at every step of your production.

You may also like

- Cleaning Checklist

- Daily Checklist

- Travel Checklist

- Self Care Checklist

- Risk Assessment Checklist

- Onboarding Checklist

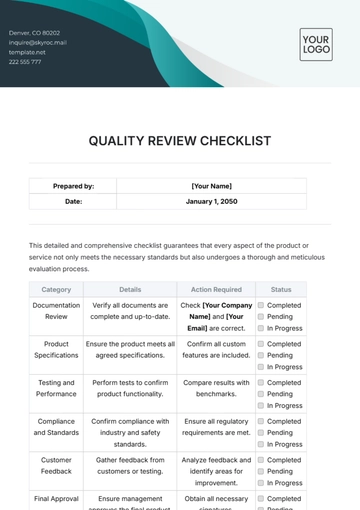

- Quality Checklist

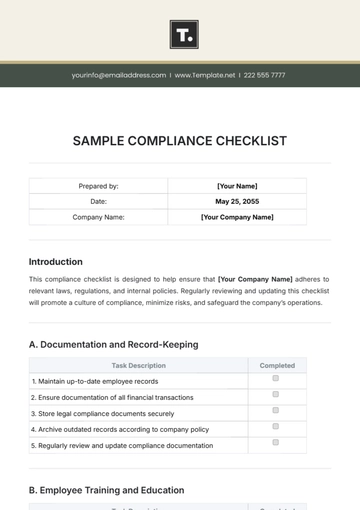

- Compliance Checklist

- Audit Checklist

- Registry Checklist

- HR Checklist

- Restaurant Checklist

- Checklist Layout

- Creative Checklist

- Sales Checklist

- Construction Checklist

- Task Checklist

- Professional Checklist

- Hotel Checklist

- Employee Checklist

- Moving Checklist

- Marketing Checklist

- Accounting Checklist

- Camping Checklist

- Packing Checklist

- Real Estate Checklist

- Cleaning Checklist Service

- New Employee Checklist

- Food Checklist

- Home Inspection Checklist

- Advertising Checklist

- Event Checklist

- SEO Checklist

- Assessment Checklist

- Inspection Checklist

- Baby Registry Checklist

- Induction Checklist

- Employee Training Checklist

- Medical Checklist

- Safety Checklist

- Site Checklist

- Job Checklist

- Service Checklist

- Nanny Checklist

- Building Checklist

- Work Checklist

- Office Checklist

- Training Checklist

- Website Checklist

- IT and Software Checklist

- Performance Checklist

- Project Checklist

- Startup Checklist

- Education Checklist

- Home Checklist

- School Checklist

- Maintenance Checklist

- Planning Checklist

- Manager Checklist

- Wedding Checklist

- Vehicle Checklist

- Travel Agency Checklist

- Vehicle Inspection Checklist

- Interior Design Checklist

- Backpacking Checklist

- Business Checklist

- Legal Checklist

- Nursing Home Checklist

- Weekly Checklist

- Recruitment Checklist

- Salon Checklist

- Baby Checklist

- Equipment Checklist

- Trade Show Checklist

- Party Checklist

- Hospital Bag Checklist

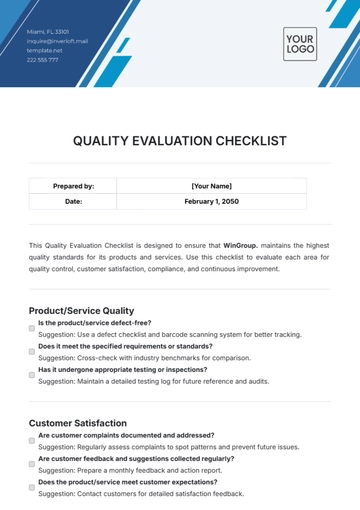

- Evaluation Checklist

- Agency Checklist

- First Apartment Checklist

- Hiring Checklist

- Opening Checklist

- Small Business Checklist

- Rental Checklist

- College Dorm Checklist

- New Puppy Checklist

- University Checklist

- Building Maintenance Checklist

- Work From Home Checklist

- Student Checklist

- Application Checklist