Free Safety Equipment Maintenance Log HR

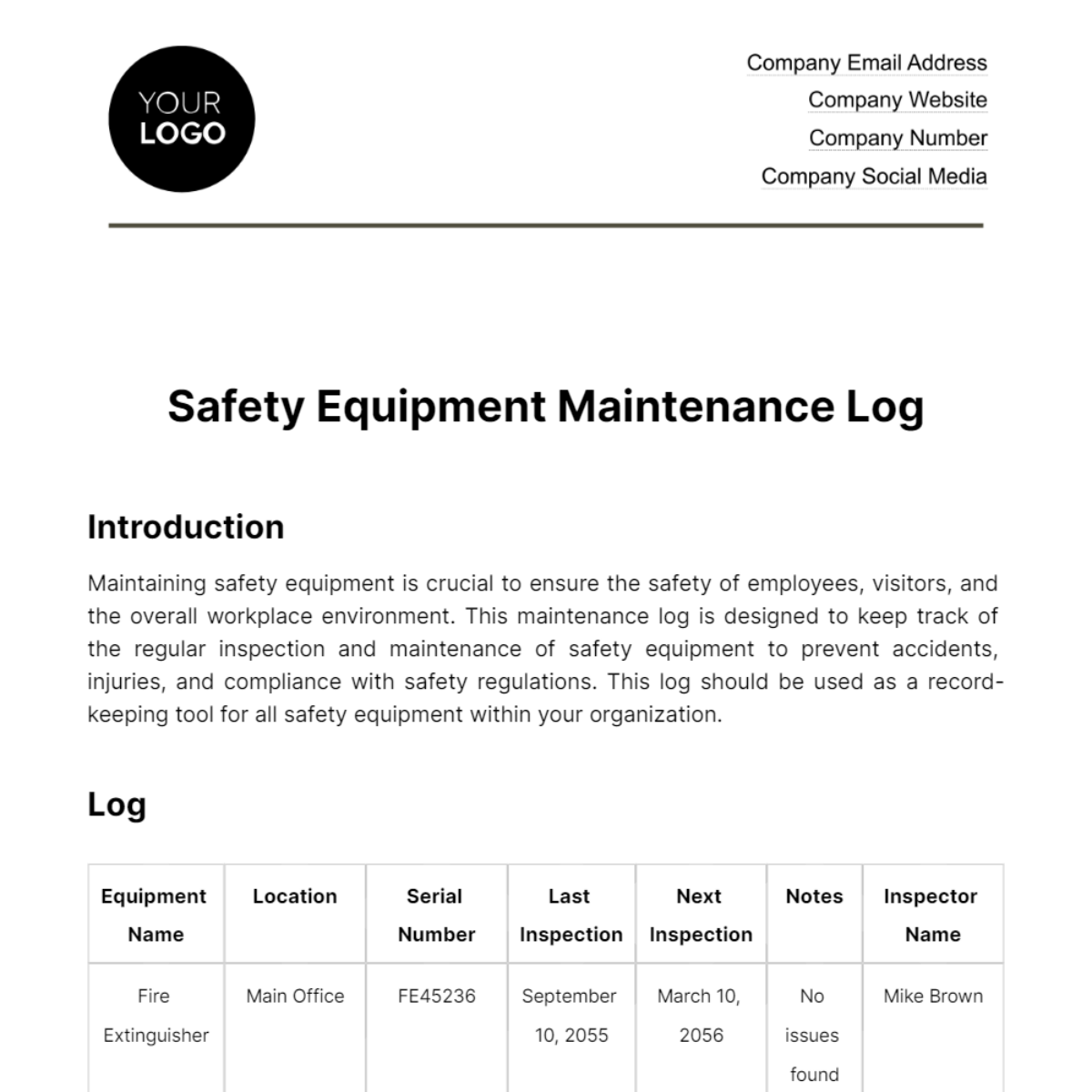

Introduction

Maintaining safety equipment is crucial to ensure the safety of employees, visitors, and the overall workplace environment. This maintenance log is designed to keep track of the regular inspection and maintenance of safety equipment to prevent accidents, injuries, and compliance with safety regulations. This log should be used as a record-keeping tool for all safety equipment within your organization.

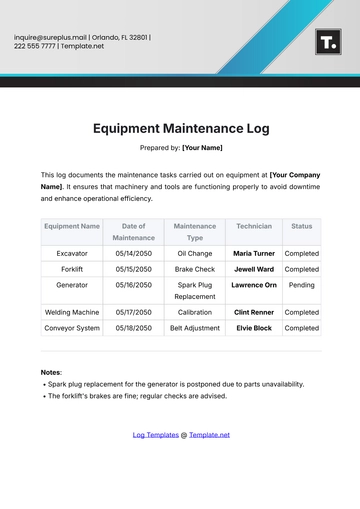

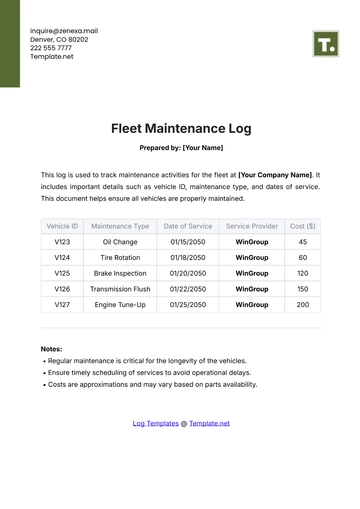

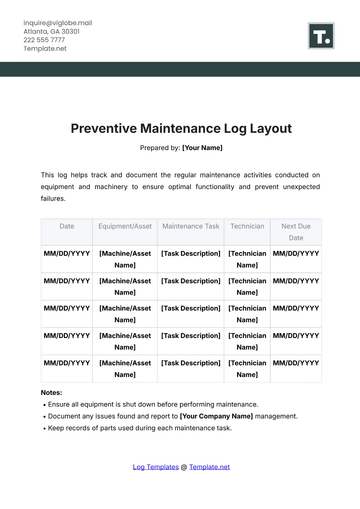

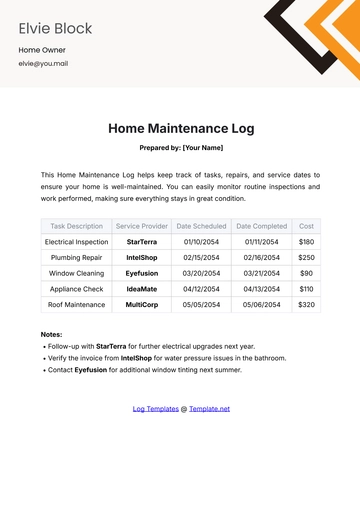

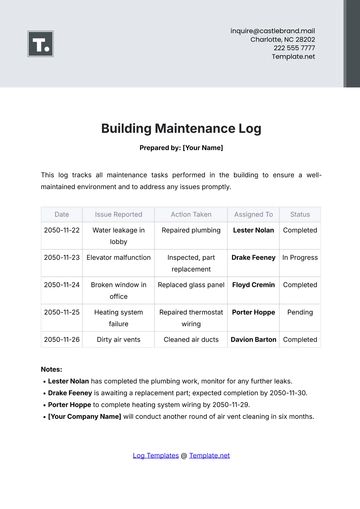

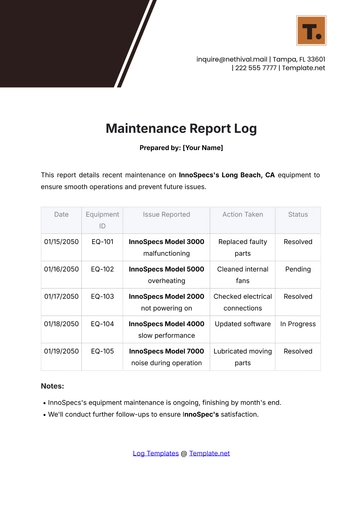

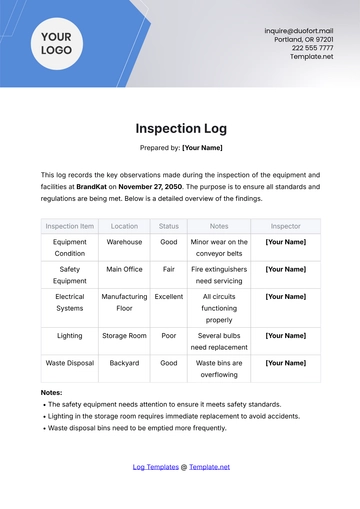

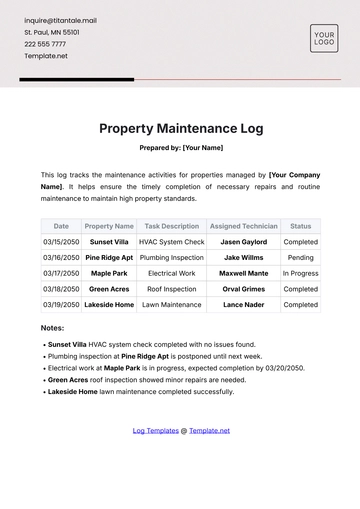

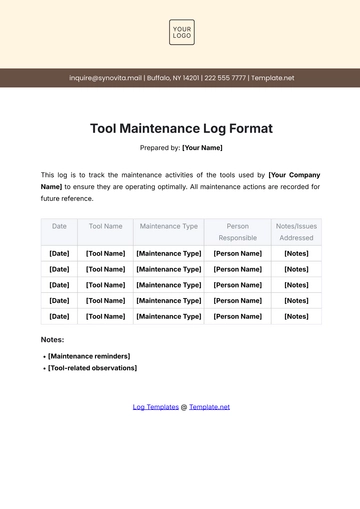

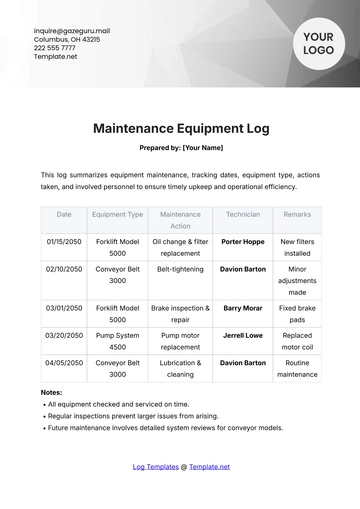

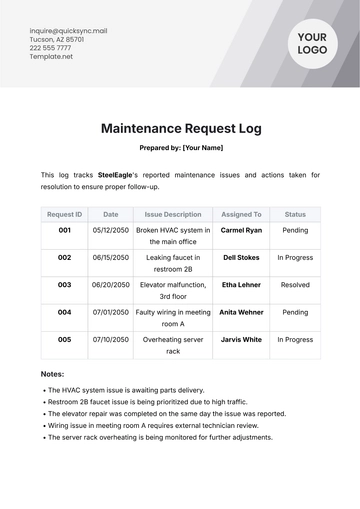

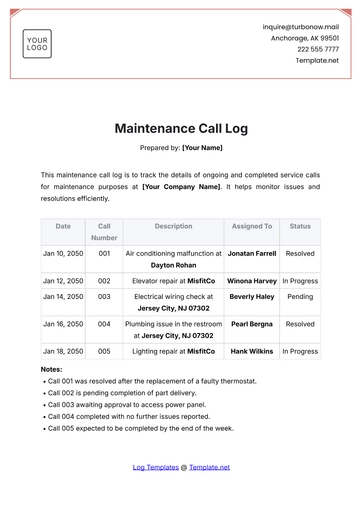

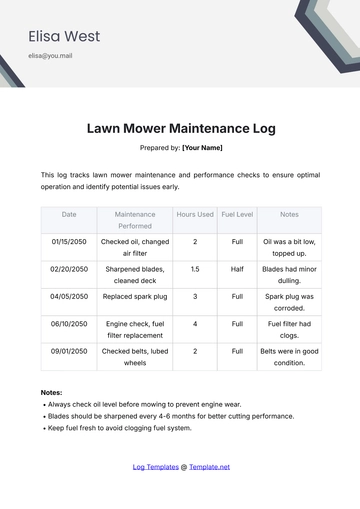

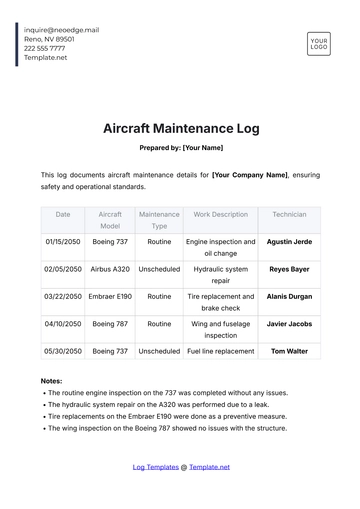

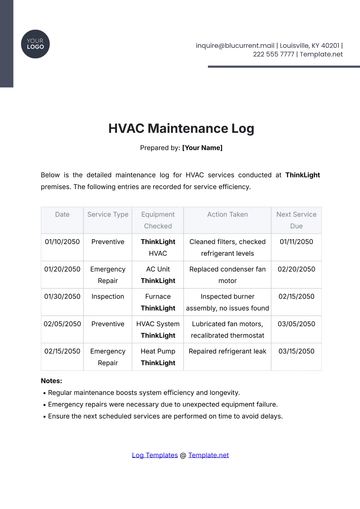

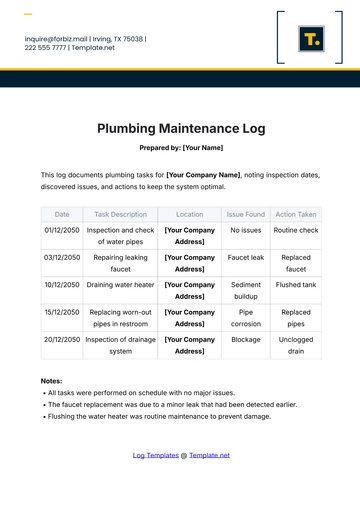

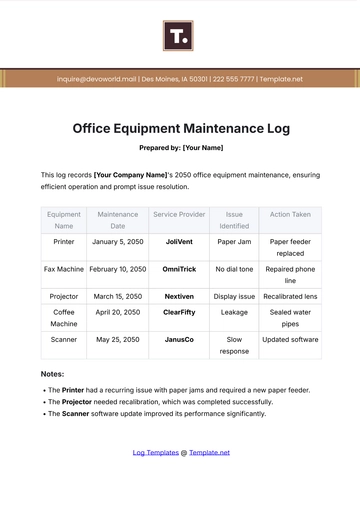

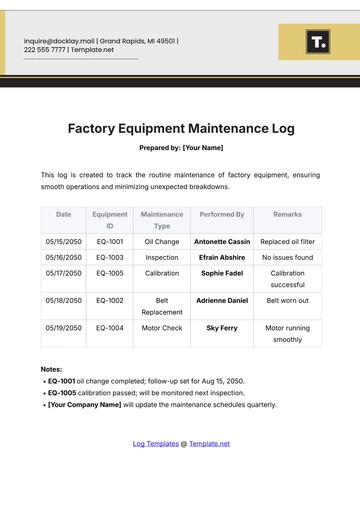

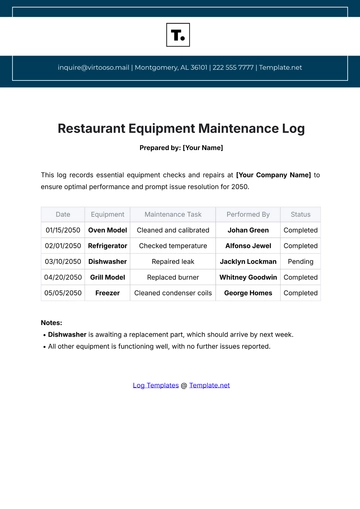

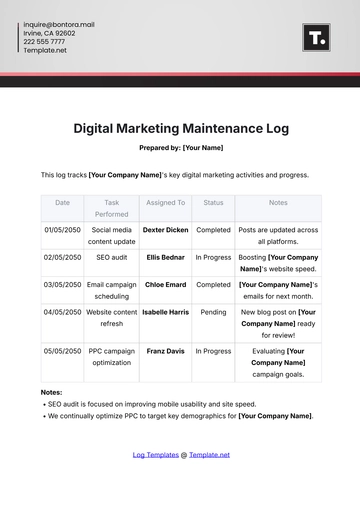

Log

Equipment Name | Location | Serial Number | Last Inspection | Next Inspection | Notes | Inspector Name |

Fire Extinguisher | Main Office | FE45236 | September 10, 2055 | March 10, 2056 | No issues found | Mike Brown |

Instructions

Equipment Name: Enter the name or type of safety equipment being inspected.

Location: Specify the exact location or department where the equipment is installed.

Serial Number: Include the unique identifier or serial number for each piece of equipment, if applicable.

Date of Last Inspection: Record the date when the equipment was last inspected or maintained.

Date of Next Inspection: Indicate the date when the next inspection or maintenance is due. Ensure inspections are scheduled at appropriate intervals based on safety regulations and manufacturer recommendations.

Maintenance Notes: Describe any maintenance or repair work performed during the inspection. Note any issues found and how they were addressed.

Inspector Name: Enter the name of the person responsible for conducting the inspection.

Maintenance Guidelines

Fire Extinguishers: Inspect fire extinguishers for visible damage, pressure gauge readings, and ensure they are properly charged. Replace or recharge as needed. Make sure they are easily accessible and have clear signage.

Eye Wash Stations: Check for water flow and temperature consistency. Ensure the eyewash station is free from obstructions. Replace expired solutions.

First Aid Kits: Verify that first aid kits are fully stocked and that items have not expired. Replace missing or expired items promptly.

Safety Showers: Test the safety shower for water flow and temperature. Ensure that it is easily accessible and that the area around it is clear of obstacles.

Record Keeping

It is essential to maintain a detailed and accurate log for each piece of safety equipment. Regularly review and update this log to ensure that equipment is in proper working condition and complies with safety regulations.

Conclusion

The log is an essential tool for organizations to promote workplace safety. Regular inspections and maintenance of safety equipment can prevent accidents and ensure a safe working environment for all employees. By following the guidelines and keeping this log up to date, you contribute to the well-being of everyone in your organization. Remember that safety is everyone's responsibility.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Maintain safety equipment effectively with our Safety Equipment Maintenance Log HR Template from Template.net! This customizable log allows for seamless edits using the AI Editor Tool. Adjust the log to your maintenance needs, ensuring comprehensive record-keeping. Guarantee streamlined maintenance with your editable template for and organized maintenance of safety equipment!