Free Safety Audit Feasibility Study

Introduction

Purpose of the Study

The objective of this feasibility study is to evaluate the viability and effectiveness of undertaking a Safety Compliance Audit & Inspection within our organization. This study aims to establish a clear framework for assessing our current safety standards, identifying potential hazards, and ensuring compliance with all relevant health and safety regulations. By conducting this audit, we intend to proactively address safety concerns, thereby fostering a safer, more compliant, and productive work environment.

Scope of the Study

This study encompasses a comprehensive review of our organization's safety practices, policies, and procedures. It involves a detailed analysis of our adherence to national and industry-specific safety regulations and the identification of any potential risks or hazards present in our workplace. The scope includes all departments and sectors of the organization, ensuring a thorough and inclusive approach to safety and compliance.

Methodology

Data Collection

Surveys and Questionnaires

To understand the employees' perspective on workplace safety, we will distribute surveys and questionnaires across all departments. These tools will be designed to gauge the awareness and satisfaction levels regarding current safety measures, and to identify any areas of concern that employees may have.

Table 1: Survey Distribution Plan

Department | Number of Employees | Survey Distribution Date | Response Deadline |

Production | 120 | January 15, 2051 | January 22, 2051 |

Logistics | 80 | January 17, 2051 | January 24, 2051 |

HR | 40 | January 18, 2051 | January 25, 2051 |

Finance | 30 | January 19, 2051 | January 26, 2051 |

IT | 50 | January 20, 2051 | January 27, 2051 |

Site Inspections

A series of comprehensive site inspections will be conducted to physically assess the workplace. These inspections will focus on identifying any visible safety hazards, the state of safety equipment, and general adherence to safety protocols.

Table 2: Site Inspection Schedule

Area | Inspection Date | Lead Inspector |

Manufacturing Floor | February 5, 2051 | John Doe |

Warehouse | February 7, 2051 | Jane Smith |

Office Area | February 9, 2051 | Alice Johnson |

Data Center | February 11, 2051 | Bob Lee |

Data Analysis

The data gathered from surveys, questionnaires, and site inspections will be thoroughly analyzed. This analysis will involve identifying common themes, discrepancies between different departments, and any direct feedback regarding safety concerns. The goal is to develop a clear understanding of the current safety culture and identify areas for improvement.

Current Safety Compliance Status

Regulatory Compliance

Our initial review indicates varying levels of compliance across different departments. The table below summarizes the current status.

Table 3: Compliance with Safety Regulations

Department | Compliance Status | Key Issues Identified |

Production | Partially Compliant | Inadequate machine guarding |

Logistics | Compliant | - |

HR | Compliant | - |

Finance | Compliant | - |

IT | Non-Compliant | Insufficient fire safety measures |

Identified Safety Hazards

During preliminary assessments, several safety hazards have been identified, which are detailed below.

Table 4: Identified Safety Hazards

Area | Hazard Type | Description |

Manufacturing Floor | Mechanical | Uncovered moving parts on machinery |

Warehouse | Environmental | Poor lighting in storage areas |

Office Area | Ergonomic | Inadequate workstation setup |

Data Center | Electrical | Overloaded power outlets |

Required Resources

For a comprehensive Safety Compliance Audit & Inspection, various resources are essential to ensure the effectiveness and accuracy of the process. The following sections detail the human and financial resources required.

Human Resources

Audit Team Composition

A dedicated team is required to plan, execute, and analyze the audit process. This team will consist of internal safety officers, external safety consultants, and department representatives. The table below outlines the team structure and their responsibilities.

Table 5: Audit Team Composition

Role | Number of Personnel | Responsibilities |

Lead Safety Auditor | 1 | Overall coordination and oversight of the audit process |

Internal Safety Officers | 3 | Conducting internal inspections, data collection, and analysis |

External Safety Consultants | 2 | Providing expert advice, ensuring regulatory compliance |

Department Representatives | 5 | Assisting in department-specific audits, communication with staff |

Training and Development

To ensure the audit team is well-equipped with the latest safety standards and audit techniques, a series of training sessions will be organized.

Table 6: Training Schedule

Training Topic | Date | Participants |

Safety Compliance Standards | March 1, 2051 | Audit Team |

Audit Procedures and Techniques | March 5, 2051 | Internal Safety Officers |

Reporting and Documentation | March 8, 2051 | All Team Members |

Financial Resources

Budget Estimation

A budget is prepared to cover all expenses related to the audit, including personnel costs, training, external consultancy fees, and miscellaneous expenses.

Table 7: Estimated Budget for Safety Audit

Expense Category | Estimated Cost |

Personnel Salaries | $50,000 |

Training Sessions | $10,000 |

External Consultancy Fees | $30,000 |

Equipment and Materials | $5,000 |

Miscellaneous | $5,000 |

Total | $100,000 |

Potential Challenges

Conducting a comprehensive Safety Compliance Audit & Inspection can encounter several challenges. Identifying these challenges in advance allows us to prepare appropriate strategies to address them effectively.

Internal Resistance

Employee Pushback

One of the primary challenges could be resistance from employees. This resistance might stem from a misunderstanding of the audit's purpose or fear of additional workload or scrutiny.

Table 8: Strategies to Overcome Employee Resistance

Strategy | Description |

Communication Campaign | Regular updates and informative sessions about the audit's importance and process. |

Involvement of Department Representatives | Utilizing department representatives to act as liaisons between the audit team and employees. |

Addressing Concerns | Open forums and feedback channels to address employee concerns and suggestions. |

Management Hesitancy

Management might be hesitant to allocate resources or fully support the audit due to budget constraints or fear of uncovering systemic issues.

Table 9: Approaches to Mitigate Management Hesitancy

Approach | Description |

Demonstrating ROI | Presenting the potential return on investment and long-term benefits of the audit. |

Highlighting Regulatory Compliance | Emphasizing the importance of meeting legal and industry standards. |

Ensuring Transparency | Regular briefings on audit progress and findings to maintain trust and transparency. |

Resource Limitations

Budget Constraints

Limited budget can restrict the depth and scope of the audit, affecting the hiring of external consultants or the purchase of necessary equipment.

Table 10: Solutions for Budget Constraints

Solution | Description |

Phased Implementation | Conducting the audit in phases to spread out the costs. |

Seeking Additional Funding | Exploring options for additional funding or budget reallocations. |

Prioritizing Key Areas | Focusing on high-risk areas first to make the most of available resources. |

Time Constraints

Time limitations can pose a significant challenge, especially when trying to balance the audit with ongoing operational demands.

Table 11: Time Management Strategies

Strategy | Description |

Detailed Scheduling | Creating a detailed timeline to manage and monitor progress efficiently. |

Flexible Working Arrangements | Implementing flexible schedules for audit team members to maximize productivity. |

Regular Progress Reviews | Periodic reviews to ensure the audit is on track and to adjust timelines as needed. |

Benefits and Risks

A Safety Compliance Audit & Inspection, while essential, carries with it both potential benefits and risks. Understanding these allows for better planning and management.

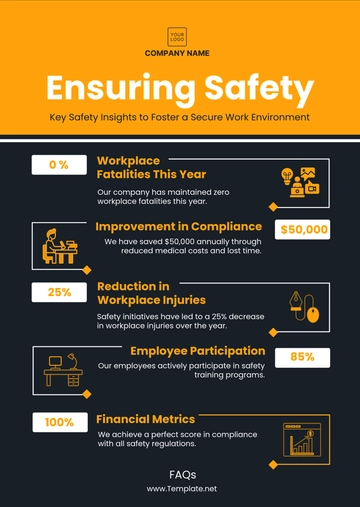

Anticipated Benefits

Improved Safety Standards

The primary benefit of the audit is the significant improvement in safety standards across the organization. Identifying and addressing hazards will reduce the risk of accidents and injuries.

Table 12: Expected Improvements in Safety Standards

Area | Current Issue | Expected Improvement |

Manufacturing Floor | Poor machine guarding | Enhanced protection around machinery |

Warehouse | Inadequate lighting | Improved lighting for safer navigation |

Office Area | Ergonomic risks | Better workstation setups to prevent musculoskeletal problems |

Enhanced Compliance

Ensuring compliance with safety regulations not only avoids legal repercussions but also builds a positive organizational reputation.

Table 13: Compliance Benefits

Regulatory Body | Compliance Aspect | Benefit |

OSHA | Workplace Safety Standards | Reduced legal risks, improved worker confidence |

EPA | Environmental Standards | Enhanced sustainability practices, positive public image |

Reduction in Workplace Accidents

A direct consequence of improved safety measures and compliance is a reduction in the frequency and severity of workplace accidents.

Table 14: Anticipated Reduction in Accidents

Year | Reported Accidents (Before Audit) | Projected Accidents (After Audit) |

2050 | 15 | - |

2051 (Projected) | - | 5 |

Potential Risks

Unforeseen Costs

Unexpected expenses may arise during the audit, such as the need for additional safety equipment or extended consultancy services.

Table 15: Mitigation Strategies for Unforeseen Costs

Challenge | Mitigation Strategy |

Equipment Upgrade | Setting aside a contingency fund for unexpected expenses |

Extended Consultancy | Negotiating fixed-cost contracts with consultants |

Disruption to Regular Work Schedules

The audit process may disrupt normal business operations, leading to temporary productivity losses.

Table 16: Strategies to Minimize Operational Disruption

Disruption Aspect | Strategy |

Employee Availability | Implementing a rotating schedule for audit participation |

Work Area Accessibility | Conducting audits during off-peak hours or weekends |

Implementation Plan

The implementation of the Safety Compliance Audit & Inspection requires a detailed and structured approach. This section outlines the timeline, key milestones, and specific steps necessary for successful execution.

Timeline

A comprehensive timeline ensures that each phase of the audit is conducted systematically and efficiently.

Table 17: Detailed Timeline for Audit Process

Phase | Start Date | End Date | Key Activities |

Planning and Preparation | April 1, 2051 | April 15, 2051 | Finalizing audit team, preparing tools and resources |

Data Collection | April 16, 2051 | May 15, 2051 | Conducting surveys, questionnaires, and site inspections |

Data Analysis | May 16, 2051 | June 15, 2051 | Analyzing collected data, preparing preliminary report |

Implementation of Changes | June 16, 2051 | August 15, 2051 | Applying safety improvements, training staff |

Final Evaluation | August 16, 2051 | September 15, 2051 | Assessing the effectiveness of changes, final report |

Key Milestones

Identifying key milestones helps in tracking progress and ensuring that the audit stays on course.

Table 18: Key Milestones in the Audit Process

Milestone | Date | Description |

Completion of Data Collection | May 15, 2051 | All surveys, questionnaires, and site inspections are completed. |

Preliminary Report | June 15, 2051 | Initial findings and recommendations are compiled. |

Implementation Phase Start | June 16, 2051 | Begin applying recommended safety changes. |

Staff Training Completion | All staff have received updated safety training. | |

Final Evaluation Start | August 16, 2051 | Evaluation of the audit's effectiveness begins. |

Implementation Steps

Outlined below are the specific steps that will be taken during each phase of the implementation.

Planning and Preparation

Form the audit team.

Develop and distribute the audit tools (surveys, checklists).

Schedule training sessions.

Data Collection

Conduct surveys and questionnaires.

Perform comprehensive site inspections.

Gather relevant safety records and documents.

Data Analysis

Analyze feedback from surveys and inspections.

Identify trends and areas of concern.

Draft a preliminary report with findings.

Implementation of Changes

Prioritize safety improvements based on the report.

Make necessary modifications to policies and the physical workplace.

Conduct safety training for all employees.

Final Evaluation

Assess the effectiveness of the implemented changes.

Compile a final report with outcomes and future recommendations.

Plan for ongoing safety audits and continuous improvement.

Conclusion

Summary of Findings

The feasibility study has systematically explored the various aspects involved in conducting a Safety Compliance Audit & Inspection. It has detailed the methodology, resources required, potential challenges, anticipated benefits and risks, and an implementation plan. The findings indicate that while there are challenges such as potential internal resistance and resource limitations, these can be effectively managed through strategic planning and communication.

Recommendations

Based on the findings of this study, it is recommended to proceed with the Safety Compliance Audit & Inspection. The anticipated benefits, including improved safety standards, enhanced compliance, and a reduction in workplace accidents, far outweigh the potential risks. It is advised that the organization follows the proposed implementation plan, allocating the necessary resources and addressing the potential challenges as outlined. Continuous monitoring and evaluation should be conducted to ensure the audit's effectiveness and to facilitate ongoing improvements in our safety protocols.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Unlock the power of safety compliance with Template.net's Safety Audit Feasibility Study Template. This fully editable and customizable template, enhanced with our AI Editor Tool, streamlines your audit process. Effortlessly tailor it to your needs and evaluate safety measures with precision. Simplify your safety audits with Template.net's cutting-edge solutions.