Free Construction Safety Risk Assessment

Project Details

Project Name: High-Rise Office Tower Construction

Location: 1234 Main St., Downtown, Cityville

Assessment Date: December 2, 2060

Assessment Conducted By: John Doe, Safety Officer; Jane Smith, Site Supervisor

Project Manager: Michael Johnson

Supervisor(s): Sarah Lee, Alan Mitchell

1. Work Activity Description

Work Activity | Description |

|---|---|

Concrete Pouring | Pouring and setting concrete for the foundation slab on the first floor. Includes the use of mixers, cranes, and manual labor for placing and smoothing concrete. |

2. Risk Identification

Hazard | Potential Risk |

|---|---|

Falling from height (scaffolding) | Workers could fall from scaffolding or elevated platforms during concrete pouring, leading to serious injuries or fatalities. |

Heavy machinery (cranes, mixers) | Workers in proximity to heavy machinery risk injury from moving parts or being struck by falling objects. |

Wet concrete | Exposure to wet concrete can cause skin burns or irritation if contact is not prevented by proper PPE. |

Manual handling of heavy loads | Workers may strain their muscles or suffer injuries from lifting heavy concrete bags or tools. |

Noise exposure | Prolonged exposure to loud machinery and equipment could result in hearing damage or loss. |

Slips, trips, and falls on wet surfaces | The wet concrete and equipment spillage increases the risk of workers slipping, causing falls and injuries. |

3. Risk Assessment

Hazard | Likelihood (1-5) | Severity (1-5) | Risk Score | Risk Level |

|---|---|---|---|---|

Falling from height (scaffolding) | 4 | 5 | 20 | High |

Heavy machinery (cranes, mixers) | 3 | 4 | 12 | High |

Wet concrete | 3 | 3 | 9 | Medium |

Manual handling of heavy loads | 4 | 3 | 12 | High |

Noise exposure | 4 | 3 | 12 | Medium |

Slips, trips, and falls on wet surfaces | 4 | 3 | 12 | High |

4. Control Measures and Mitigation Strategies

Hazard | Control Measures | Responsible Person(s) | Completion Date |

|---|---|---|---|

Falling from height (scaffolding) | Install fall arrest systems, ensure scaffolds are properly secured, and use safety harnesses. | Alan Mitchell, Site Supervisor | December 3, 2060 |

Heavy machinery (cranes, mixers) | Provide proper training for equipment operators, ensure all machinery has functioning safety features (e.g., alarms, warning lights), and enforce exclusion zones around heavy machinery. | Sarah Lee, Safety Officer | December 3, 2060 |

Wet concrete | Provide workers with waterproof gloves, long-sleeve shirts, and boots to prevent skin contact with wet concrete. | John Doe, Safety Officer | December 2, 2060 |

Manual handling of heavy loads | Train workers on proper lifting techniques, provide mechanical aids like dollies, and ensure team lifting for heavy loads. | Jane Smith, Supervisor | December 2, 2060 |

Noise exposure | Provide hearing protection (earplugs, earmuffs) for workers, and ensure machinery is regularly serviced to minimize noise levels. | Michael Johnson, Project Manager | December 3, 2060 |

Slips, trips, and falls on wet surfaces | Use anti-slip mats in work areas, ensure the area is regularly cleaned, and enforce the use of slip-resistant footwear. | Alan Mitchell, Site Supervisor | December 2, 2060 |

5. Emergency Response Plan

Emergency Contact Numbers:

Fire Department: 911

Site Safety Officer: John Doe – (555) 123-4567

Hospital: Cityville General Hospital – (555) 987-6543

First Aid Procedures:

Minor Cuts and Scrapes: Clean the wound, and apply antiseptic, and bandage.

Burns from Wet Concrete: Rinse the affected area immediately with cold water for at least 15 minutes, then apply burn cream and cover with a sterile dressing.

Broken Bones: Immobilize the injured area, apply cold packs to reduce swelling, and transport to a medical facility.

Evacuation Plan:

Evacuation Routes: Use the main staircase to exit the building, with clear signage indicating routes.

Assembly Points: Parking lot area (north side) and adjacent open field (south side).

Special Equipment:

Fire extinguishers (located on every floor)

First aid kits (located at the site entrance and near scaffolding)

Eye wash station (in the vicinity of the concrete mixing area)

6. PPE Requirements

PPE | Required for Task | Additional Comments |

|---|---|---|

Safety Helmet | All workers on site | Required at all times for head protection. |

High-visibility Vest | All workers and visitors on site | Must be worn at all times to ensure visibility. |

Safety Gloves | Workers handling concrete | Waterproof gloves are required to prevent skin exposure to wet concrete. |

Steel-toed Boots | All workers | To protect against foot injury from falling materials. |

Hearing Protection | Workers near heavy machinery | Earplugs or earmuffs are required near concrete mixers, cranes, and other noisy equipment. |

Fall Protection Harness | Workers on scaffolding | Harness and lanyard must be worn at all heights above 6 feet. |

7. Monitoring and Review

Monitoring Method | Responsible Person(s) | Review Frequency | Next Review Date |

|---|---|---|---|

Weekly Safety Audits | Sarah Lee, Safety Officer | Weekly | December 9, 2060 |

Daily Toolbox Talks | John Doe, Safety Officer | Daily | December 3, 2060 |

Equipment Inspections | Alan Mitchell, Site Supervisor | Monthly | December 10, 2060 |

8. Sign-Off

By signing this document, the undersigned acknowledges that the risks have been assessed, and appropriate control measures are in place.

Name | Position | Signature | Date |

|---|---|---|---|

John Doe | Safety Officer |

| December 2, 2060 |

Michael Johnson | Project Manager |

| December 2, 2060 |

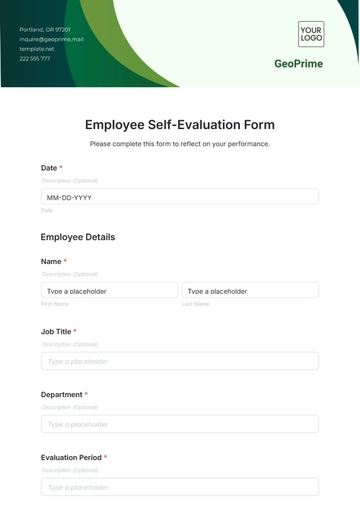

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Improve construction safety standards with Template.net’s Construction Safety Risk Assessment Template. Fully editable and customizable, it identifies and addresses potential hazards. Tailor it effortlessly using our Editable in our Ai Editor Tool.