Free Industrial Maintenance Schedule

Prepared by: [Your Name]

Introduction

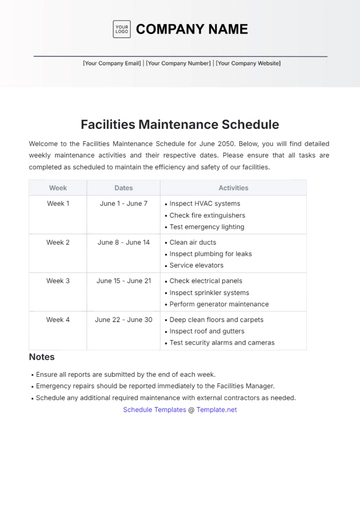

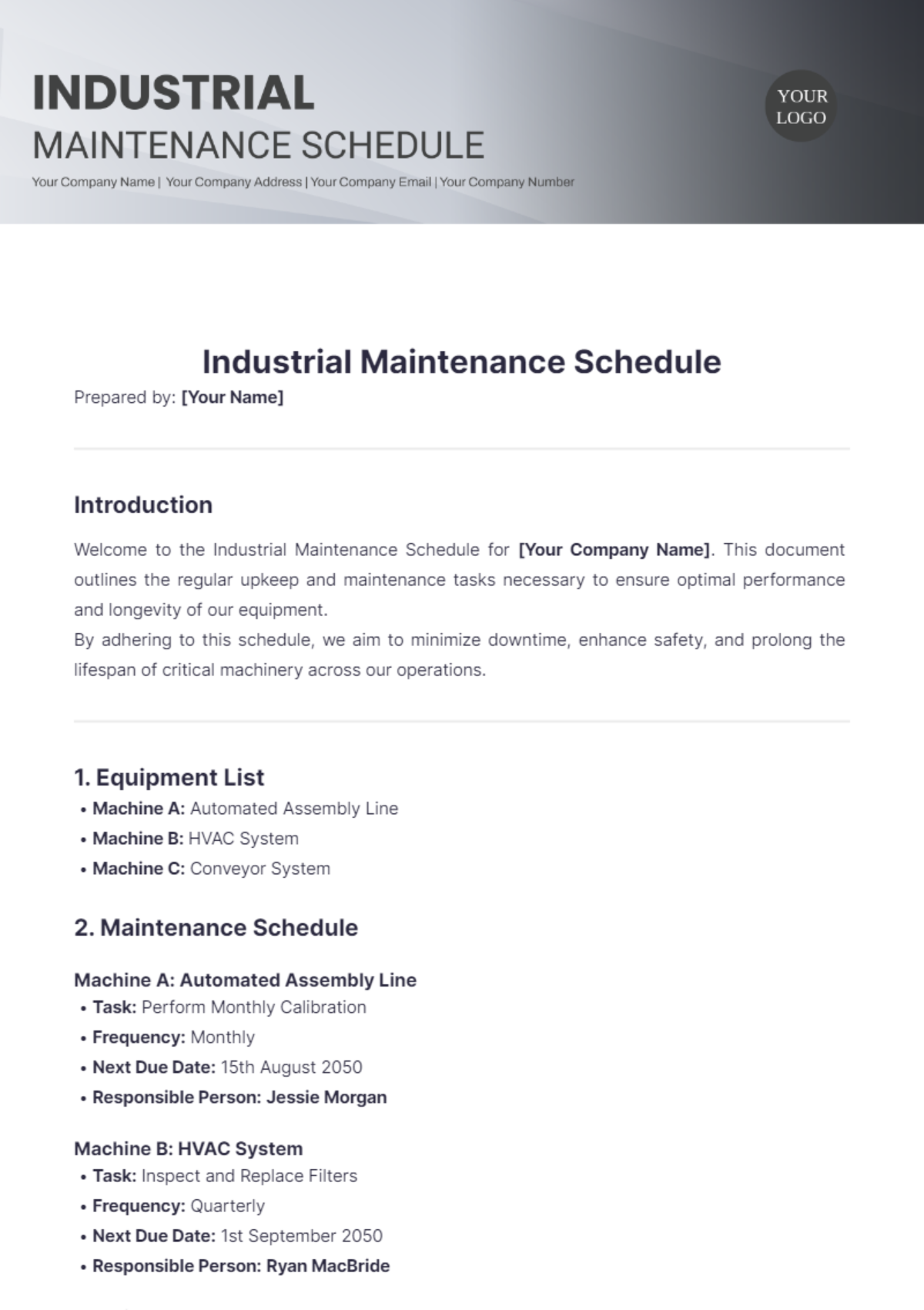

Welcome to the Industrial Maintenance Schedule for [Your Company Name]. This document outlines the regular upkeep and maintenance tasks necessary to ensure optimal performance and longevity of our equipment.

By adhering to this schedule, we aim to minimize downtime, enhance safety, and prolong the lifespan of critical machinery across our operations.

1. Equipment List

Machine A: Automated Assembly Line

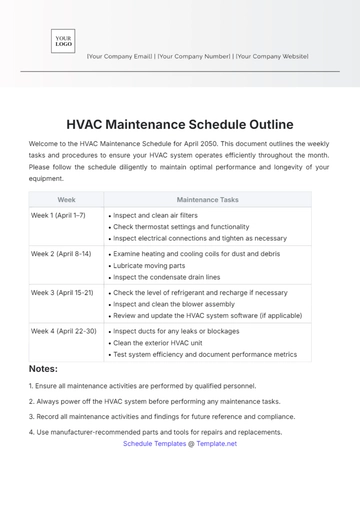

Machine B: HVAC System

Machine C: Conveyor System

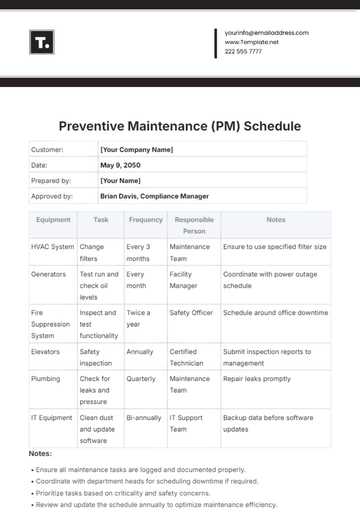

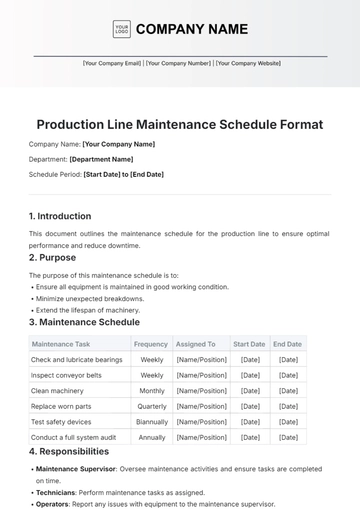

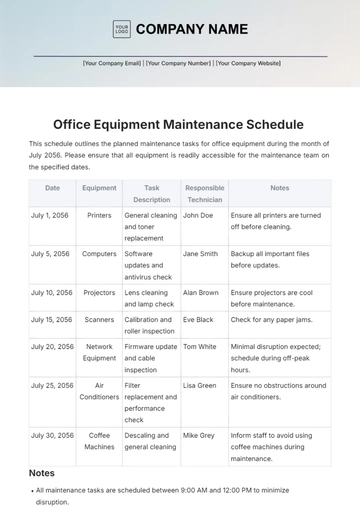

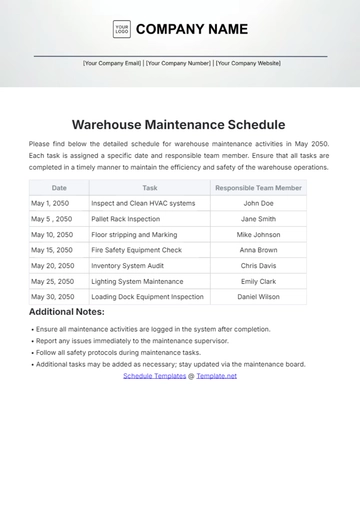

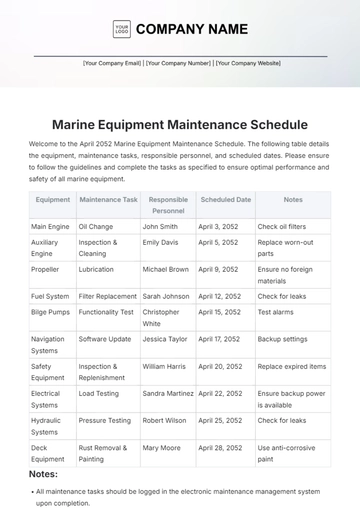

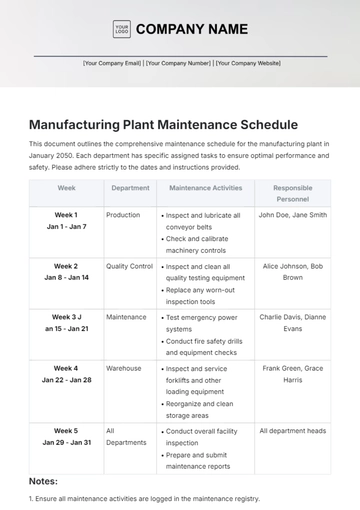

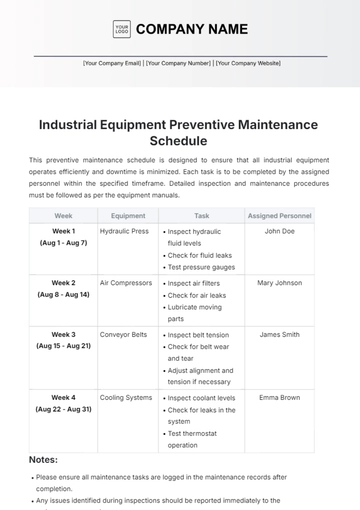

2. Maintenance Schedule

Machine A: Automated Assembly Line

Task: Perform Monthly Calibration

Frequency: Monthly

Next Due Date: 15th August 2050

Responsible Person: Jessie Morgan

Machine B: HVAC System

Task: Inspect and Replace Filters

Frequency: Quarterly

Next Due Date: 1st September 2050

Responsible Person: Ryan MacBride

Machine C: Conveyor System

Task: Check Belt Tension

Frequency: Weekly

Next Due Date: 5th August 2050

Responsible Person: Shane Talon

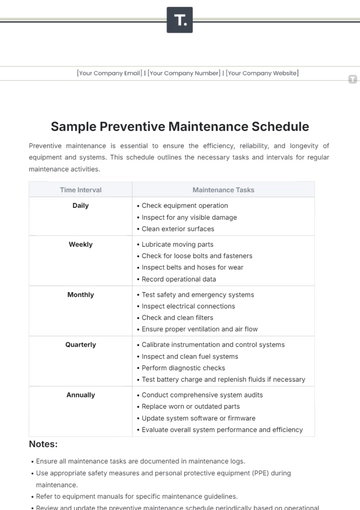

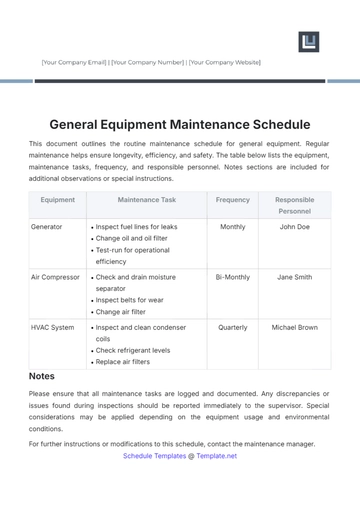

3. Maintenance Tasks

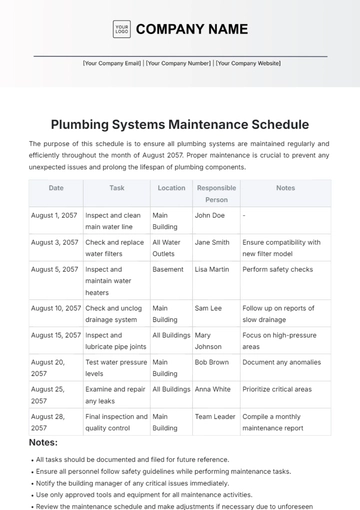

Weekly: Inspect belts and clean equipment.

Monthly: Calibrate sensors, check for leaks.

Quarterly: Replace filters, inspect electrical connections.

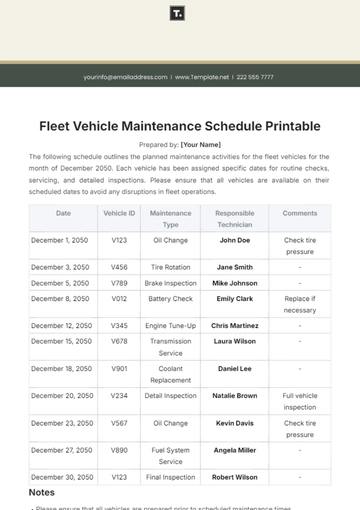

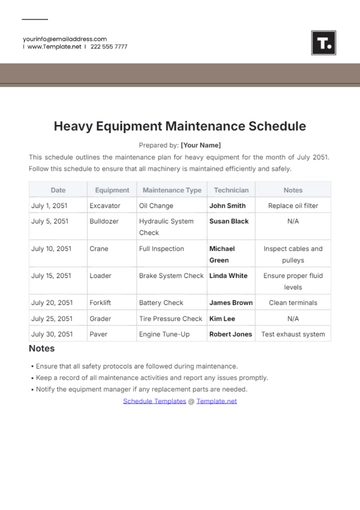

4. Maintenance Log

Date | Equipment | Task Performed | Outcome | Comments |

|---|---|---|---|---|

01/08/2050 | Machine A | Monthly Calibration | Completed | Calibration within tolerance |

07/08/2050 | Machine C | Check Belt Tension | Completed | Tension adjusted as needed |

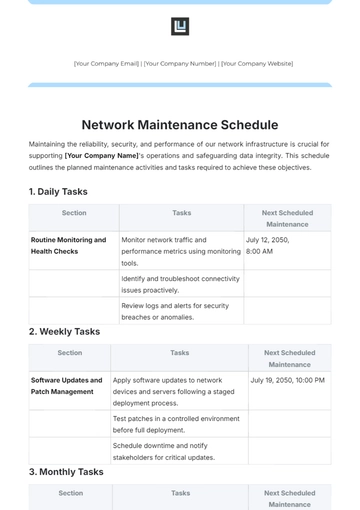

5. Emergency Procedures

In case of equipment failure or urgent maintenance needs, follow these procedures:

Step 1: Immediately notify the maintenance team supervisor at [Your Company Number] or [Your Email].

Step 2: Assess the nature of the issue and prioritize safety.

Step 3: If necessary, initiate equipment shutdown using established lockout/tagout procedures.

Step 4: Coordinate with onsite personnel to clear the affected area.

Step 5: Share updates and resolution times with relevant departments.

For any queries or support, contact us at [Your Company Email] or visit [Your Company Website]. Stay connected with us on [Your Company Social Media].

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

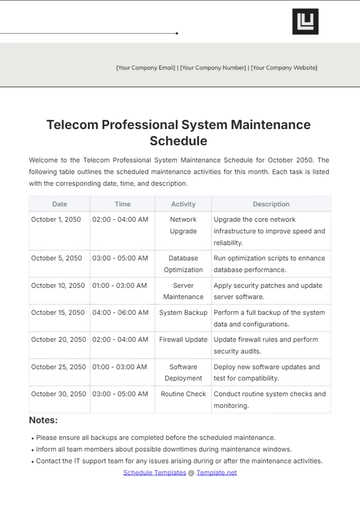

Optimize industrial operations with the Industrial Maintenance Schedule Template from Template.net. This customizable, downloadable, and printable template helps organize maintenance tasks efficiently. Editable in our AI Editor Tool, it allows you to create a clear and structured schedule tailored to your industrial equipment needs, ensuring timely maintenance and minimizing downtime for enhanced productivity.

You may also like

- Schedule Appointment

- Work Schedule

- Weekly Schedule

- Cleaning Schedule

- Payment Schedule

- School Schedule

- Maintenance Schedule

- Daily Schedule

- Class Schedule

- Workout Schedule

- Event Schedule

- Marketing Schedule

- Weekly Cleaning Schedule

- Work From Home Schedule

- Payroll Schedule

- Restaurant Schedule

- Kitchen Cleaning Schedule

- Schedule of Values

- Hourly Schedule

- Study Schedule

- University Schedule

- Construction Schedule

- Preventive Maintenance Schedule

- Fitness Schedule

- Education Schedule

- Training Schedule

- Agency Schedule

- Panel Schedule

- Monthly Schedule

- Nursing Home Schedule

- Project Schedule

- Real Estate Schedule

- Freelancer Schedule

- Medication Schedule

- IT and Software Schedule

- Interior Design Schedule

- Travel Schedule

- Travel Agency Schedule

- Hotel Schedule

- Wedding Schedule

- Camp Schedule