Free Safety Harness Inspection Checklist

[Your Name]

[Your Company Name]

Date: May 15, 2055

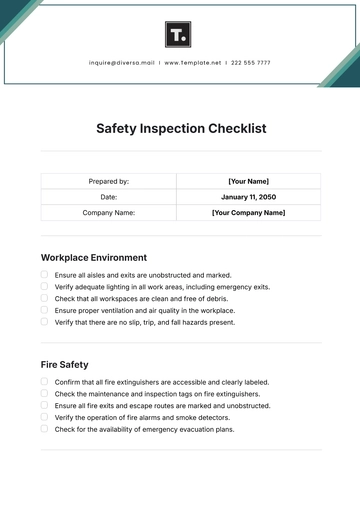

Consistent adherence to this checklist helps maintain a safe construction environment. Follow manufacturer guidelines and relevant safety regulations.

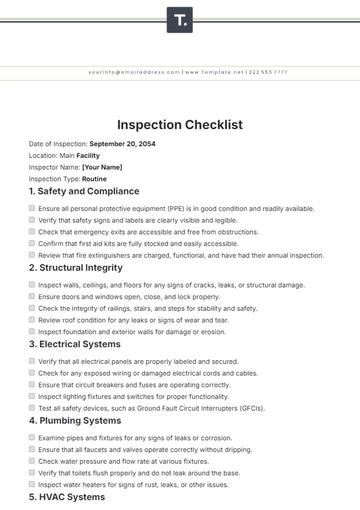

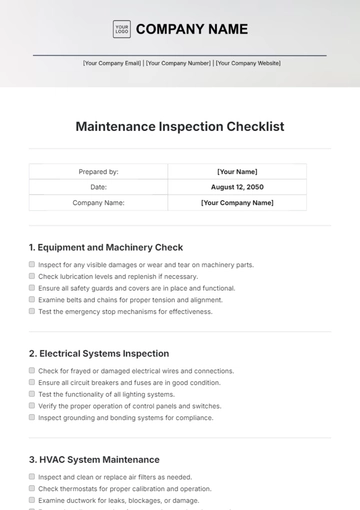

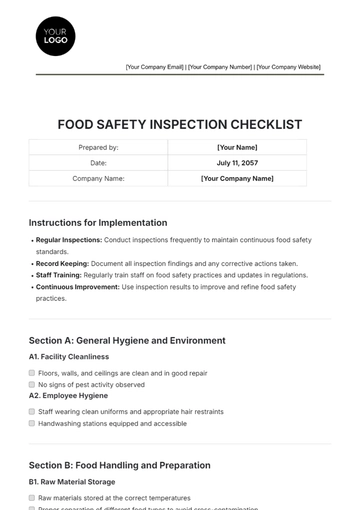

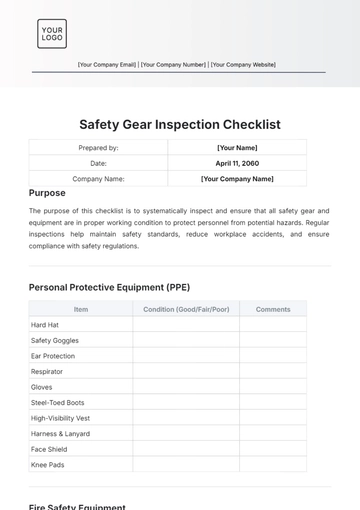

Visual Inspection:

Check for damage, wear, or distortion on all harness components.

Examine webbing, stitching, and metal parts for signs of wear and tear.

Hardware Inspection:

Confirm functionality of buckles, D-rings, and connectors.

Inspect rivets and grommets for proper attachment.

Labels and Markings:

Ensure legibility of safety labels and compliance with construction industry standards.

Adjustment Points:

Verify proper functioning of adjustment points.

Check straps and buckles for damage.

Webbing and Straps:

Inspect webbing for cuts, burns, or chemical exposure.

Check for UV damage and ensure straps lie flat.

Fall Protection Equipment:

Inspect additional fall protection equipment for proper function.

Check self-retracting lifelines for smooth retraction.

Fit and Comfort:

Confirm proper fit according to industry guidelines.

Ensure user comfort with no pressure points.

Tool and Equipment Attachment Points:

Check condition and security of attachment points.

Fall Indicator:

Ensure the fall indicator is in the correct position and not activated.

Inspection Records:

Maintain detailed records of inspections, including dates, findings, and actions taken.

Log inspector names.

Compliance with Regulations:

Ensure compliance with construction industry safety regulations.

Training:

Verify user training in harness use, inspection, and maintenance.

Replacement Consideration:

Immediately replace any harness that fails inspection or shows significant damage.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Ensure workplace safety with Template.net "Safety Harness Inspection Checklist Template." This customizable and downloadable tool is essential for maintaining the effectiveness of safety harnesses. Tailor the checklist effortlessly using the help of our AI Editor Tool, ensuring a comprehensive inspection. Download now from Template.net to streamline safety protocols and enhance overall workplace security, promoting a very secure and hazard-free environment.

You may also like

- Cleaning Checklist

- Daily Checklist

- Travel Checklist

- Self Care Checklist

- Risk Assessment Checklist

- Onboarding Checklist

- Quality Checklist

- Compliance Checklist

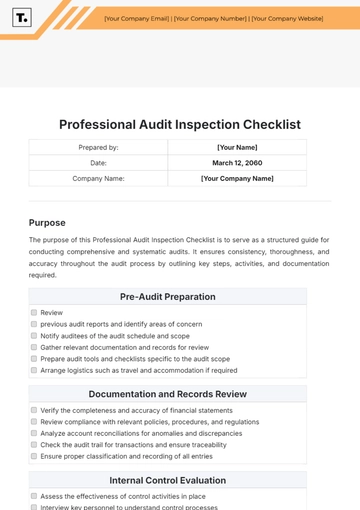

- Audit Checklist

- Registry Checklist

- HR Checklist

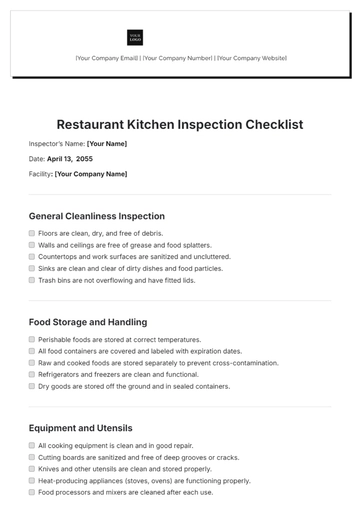

- Restaurant Checklist

- Checklist Layout

- Creative Checklist

- Sales Checklist

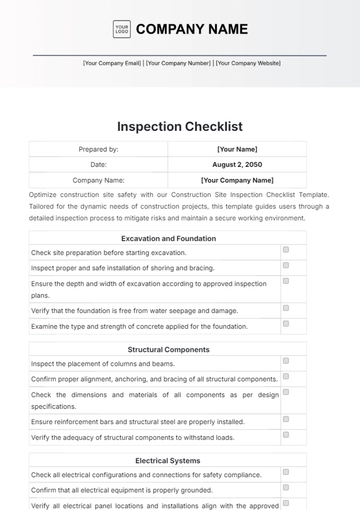

- Construction Checklist

- Task Checklist

- Professional Checklist

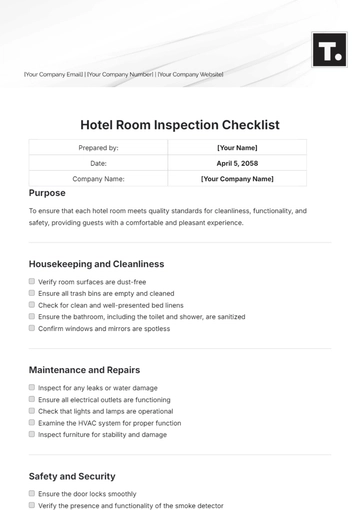

- Hotel Checklist

- Employee Checklist

- Moving Checklist

- Marketing Checklist

- Accounting Checklist

- Camping Checklist

- Packing Checklist

- Real Estate Checklist

- Cleaning Checklist Service

- New Employee Checklist

- Food Checklist

- Home Inspection Checklist

- Advertising Checklist

- Event Checklist

- SEO Checklist

- Assessment Checklist

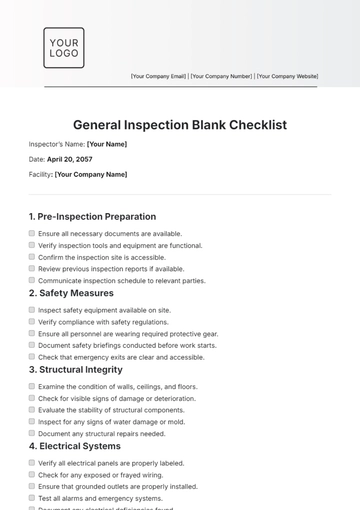

- Inspection Checklist

- Baby Registry Checklist

- Induction Checklist

- Employee Training Checklist

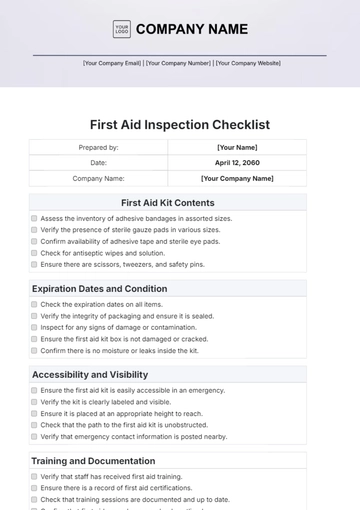

- Medical Checklist

- Safety Checklist

- Site Checklist

- Job Checklist

- Service Checklist

- Nanny Checklist

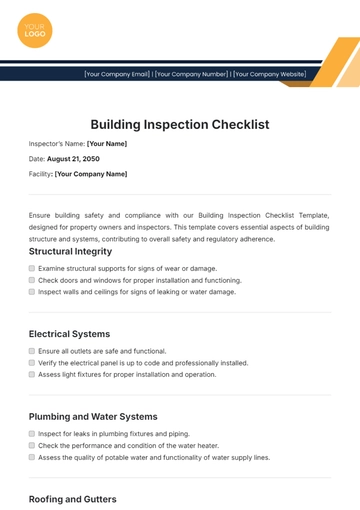

- Building Checklist

- Work Checklist

- Office Checklist

- Training Checklist

- Website Checklist

- IT and Software Checklist

- Performance Checklist

- Project Checklist

- Startup Checklist

- Education Checklist

- Home Checklist

- School Checklist

- Maintenance Checklist

- Planning Checklist

- Manager Checklist

- Wedding Checklist

- Vehicle Checklist

- Travel Agency Checklist

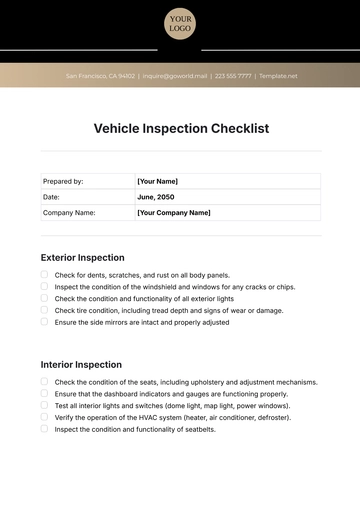

- Vehicle Inspection Checklist

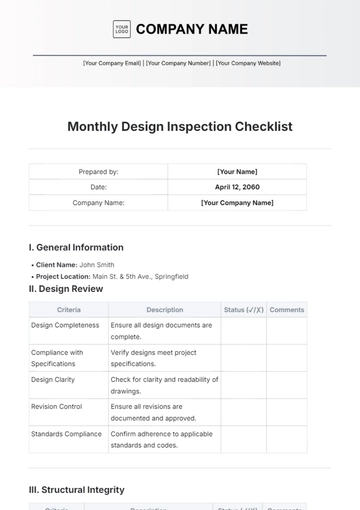

- Interior Design Checklist

- Backpacking Checklist

- Business Checklist

- Legal Checklist

- Nursing Home Checklist

- Weekly Checklist

- Recruitment Checklist

- Salon Checklist

- Baby Checklist

- Equipment Checklist

- Trade Show Checklist

- Party Checklist

- Hospital Bag Checklist

- Evaluation Checklist

- Agency Checklist

- First Apartment Checklist

- Hiring Checklist

- Opening Checklist

- Small Business Checklist

- Rental Checklist

- College Dorm Checklist

- New Puppy Checklist

- University Checklist

- Building Maintenance Checklist

- Work From Home Checklist

- Student Checklist

- Application Checklist