Free Material Handling Risk Assessment

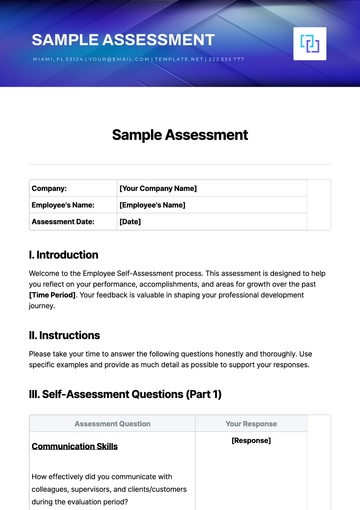

1. Risk Identification

Handling a variety of materials including bulk chemicals, construction materials, and electronic components. Chemicals are stored in drums and bags, construction materials in bulk, and electronic components in small, delicate packages.

Activities involve manual lifting, use of forklifts for bulk materials, and conveyor belts for electronic components. Key processes include loading and unloading from trucks, warehousing, and internal transportation.

Potential hazards include chemical spills, ergonomic injuries from manual lifting, and accidents involving forklifts or conveyor belts.

2. Risk Evaluation

Workers in the chemical storage area are exposed to potential chemical spills daily. Forklift operators and manual handlers are at risk of mechanical injuries throughout their shifts.

Chemical spills are categorized as high risk due to potential health impacts. Mechanical injuries from forklifts and manual lifting are classified as medium risk.

The likelihood of chemical spills is low with current safety measures, but the probability of ergonomic injuries is medium given the frequency of manual handling.

3. Control Measures

Implementing spill containment measures in chemical areas, ergonomic training for manual handlers, and regular maintenance and safety checks for forklifts and conveyor systems.

Ensuring availability and use of PPE such as chemical-resistant gloves and aprons, safety helmets, and back support belts for lifting.

Establishing clear procedures for chemical spill response, immediate reporting and response to mechanical injuries, and routine drills for emergency preparedness.

4. Training and Awareness

Mandatory training sessions for all new employees and annual refresher courses covering safe handling practices, PPE usage, and emergency response.

Monthly safety meetings, regular safety bulletins, and visible signage throughout the facility to reinforce safety practices and hazard awareness.

5. Documentation and Compliance

Maintaining detailed records of all risk assessments, control measures, training attendance, and incident reports in a digital safety management system.

Regular audits to ensure compliance with OSHA standards and local safety regulations, with a focus on material handling and chemical storage.

Biannual review of the risk assessment to incorporate changes in handling processes, introduction of new materials, or updates in safety regulations.

Assessed by:

[Your Name]

[Your Company Name]

[Your Email]

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Introducing Template.net's Material Handling Risk Assessment Template, a vital tool for evaluating workplace safety hazards. Fully customizable and editable with our Ai Editor Tool, this template empowers businesses to tailor risk assessments to their specific material handling processes. Streamline safety protocols and mitigate risks effortlessly with our user-friendly platform. Simplify risk assessments and enhance workplace safety with this comprehensive template solution.