Free Hazard Identification Documentation

Section 1: Introduction to Hazard Identification

Purpose of the Document

This document serves as a comprehensive guide for identifying potential hazards in the workplace. It is designed to aid in the proactive identification and assessment of risks that could lead to accidents, injuries, or health issues. This documentation is a crucial element in our commitment to creating and maintaining a safe work environment for all employees.

Scope of Hazard Identification

The scope of this document extends to various types of hazards that may be present in our diverse work settings. This includes but is not limited to, physical hazards like slips, trips, and falls; chemical hazards such as exposure to toxic substances; biological hazards including exposure to infectious agents; and ergonomic hazards related to workstation design and repetitive tasks.

Type of Hazard | Description |

Physical | Hazards that involve bodily injury risks, such as falls, machinery accidents, and electrical shocks. |

Chemical | Hazards are related to the use, storage, and disposal of chemicals, including toxins, corrosives, and irritants. |

Biological | Hazards from exposure to infectious agents like bacteria, viruses, and fungi. |

Ergonomic | Hazards linked to workplace ergonomics, including repetitive strain injuries and poor workstation layout. |

Section 2: Hazard Identification Process

Process Overview

The hazard identification process is a systematic approach that encompasses several key steps:

Initial Assessment: Conducting walkthroughs and inspections to identify potential hazards.

Employee Feedback: Gathering input from employees regarding perceived hazards and concerns.

Hazard Analysis: Analyzing identified hazards for potential risk factors.

Documentation: Recording identified hazards and their details.

Ongoing Monitoring: Continuously monitoring the workplace to identify new hazards as they arise.

Roles and Responsibilities

Effective hazard identification requires collaboration across various roles within the organization:

Role | Responsibilities |

Health & Safety Officer | Overseeing the hazard identification process, ensuring compliance with safety regulations. |

Department Supervisors | Conduct regular inspections, encouraging staff feedback, and addressing immediate hazards. |

Employees | Report potential hazards and participate in safety training programs. |

Maintenance Team | Ensuring that all equipment and facilities are in safe working condition. |

Safety Committee | Reviewing and updating safety policies, and analyzing accident reports to identify recurring hazards. |

Section 3: Types of Hazards

Physical Hazards

Physical hazards are one of the most common workplace risks. They are present in most occupational settings in various forms and can lead to serious injuries or fatalities if not properly managed.

Hazard Type | Source | Example Incidents |

Falls | Uneven flooring, slippery surfaces | Slips on wet floors, trips over loose cables |

Machinery | Moving parts, improper guards | Injuries from entanglement or cuts |

Electrical | Exposed wiring, faulty equipment | Electric shocks, burns |

Noise | Machinery, work environment | Hearing loss due to prolonged exposure to high decibel levels |

Chemical Hazards

Chemical hazards arise from exposure to harmful chemicals in the workplace. These can include solids, liquids, gases, mists, dusts, fumes, and vapors, and can affect health through inhalation, skin contact, or ingestion.

Chemical Type | Common Use | Potential Health Effects |

Acids | Cleaning, manufacturing processes | Skin burns, respiratory issues |

Solvents | Degreasing, painting | Neurological effects, organ damage |

Gases | Welding, refrigeration | Asphyxiation, lung damage |

Pesticides | Agriculture, pest control | Nausea, nerve damage |

Biological Hazards

Biological hazards include exposure to harmful biological substances like bacteria, viruses, fungi, and other living organisms. These can cause a variety of health problems, ranging from mild allergic reactions to serious infections.

Biological Agent | Source | Health Impact |

Bacteria | Contaminated surfaces, food, water | Infections, food poisoning |

Viruses | Human contact, airborne transmission | Colds, flu, more severe diseases |

Fungi | Moldy environments, soil | Allergies, respiratory issues |

Animal and Insect Bites | Wildlife, infested areas | Bites, stings, disease transmission |

Ergonomic Hazards

Ergonomic hazards are associated with the design of workstations, tools, and the tasks employees perform. Poor ergonomic conditions can lead to musculoskeletal disorders and other physical injuries.

Ergonomic Issue | Cause | Possible Injury |

Poor Posture | Inadequate furniture, improper workstation setup | Back and neck pain |

Repetitive Motion | Continuous typing, assembly line work | Carpal tunnel syndrome, tendonitis |

Manual Handling | Lifting, pushing, pulling heavy objects | Muscle strains, joint injuries |

Poor Lighting | Inadequate lighting in work areas | Eye strain, headaches |

Section 4: Risk Assessment Methodology

Risk Evaluation Criteria

To effectively evaluate and prioritize risks, we use a criteria-based approach that considers the likelihood of occurrence and the potential severity of the hazard. This assessment helps in categorizing risks as high, medium, or low priority.

Risk Level | Likelihood of Occurrence | Severity of Impact |

High | Very likely to occur | Severe injury or health impact |

Medium | Possible to occur | Moderate injury or health impact |

Low | Unlikely to occur | Minor injury or health impact |

Risk Prioritization

After evaluating the risks, they are prioritized to focus on the most critical hazards first. The prioritization is based on a risk matrix that considers both the likelihood and the severity of the potential outcomes.

Risk Level | Description | Action Required |

High | High likelihood and severe impact | Immediate action to mitigate risk |

Medium | Moderate likelihood or impact | Action required within a specific timeframe |

Low | Low likelihood and impact | Monitor and review periodically |

Section 5: Control Measures and Safety Procedures

Elimination and Substitution

The most effective way to manage a hazard is to eliminate it or substitute it with a less hazardous alternative. This could involve redesigning a process or using safer materials.

Hazard Type | Current Practice | Safer Alternative |

Toxic Chemicals | Use of harsh cleaning agents | Substitution with environmentally friendly products |

Heavy Lifting | Manual handling of heavy objects | Use of mechanical lifting aids |

Engineering Controls

Engineering controls involve modifying equipment or processes to reduce exposure to hazards. This can include installing safety guards on machinery or improving ventilation systems.

Hazard Type | Control Measure | Expected Outcome |

Machine Accidents | Installation of safety guards | Prevention of injuries from machinery |

Poor Ventilation | Improved air filtration systems | Reduction in airborne contaminants |

Administrative Controls

These controls involve changing work practices and procedures to reduce risk. This might include providing training, altering work schedules to reduce exposure, and implementing safety protocols.

Control Type | Description | Example |

Training Programs | Regular safety training sessions | Training on handling hazardous materials |

Work Scheduling | Rotating shifts to limit exposure to hazards | Reducing prolonged exposure to noisy environments |

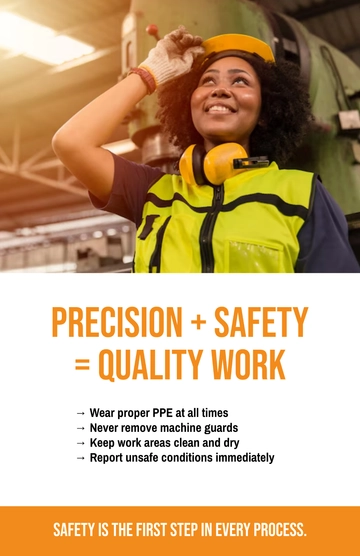

Personal Protective Equipment (PPE)

PPE is essential for providing a last line of defense against hazards. It includes items like safety goggles, helmets, gloves, and ear protection.

Hazard Type | PPE Required | Function |

Chemical Exposure | Safety goggles, gloves | Protects against chemical splashes |

Noise | Earplugs or earmuffs | Prevents hearing damage |

Section 6: Documentation and Record Keeping

Hazard Identification Records

Maintaining accurate records of identified hazards is crucial for tracking and managing safety concerns over time. These records should include details of the hazard, the assessment of its risk, and any control measures implemented.

Date | Hazard Identified | Risk Level | Control Measures Implemented |

01/03/2023 | Exposed wiring in warehouse | High | Repaired wiring, installed protective covers |

15/04/2023 | Slippery floor in kitchen area | Medium | Installed anti-slip mats, scheduled regular cleaning |

Risk Assessment Documentation

Documenting risk assessments is key to understanding and managing workplace hazards. This documentation should detail the hazard, the assessment process, and the decisions made regarding control measures.

Date | Hazard Assessed | Assessment Method | Outcome |

10/02/2023 | Elevated noise levels in factory | Noise level monitoring | Installation of sound dampening panels |

20/05/2023 | Manual lifting tasks in stockroom | Ergonomic assessment | Introduction of lifting aids and training |

Section 7: Training and Communication

Employee Training Programs

Effective training programs are essential for ensuring that all employees are aware of potential hazards and know how to respond appropriately. These programs should cover a wide range of topics, from general safety principles to specific procedures for handling particular hazards.

Training Topic | Description | Frequency |

General Safety Induction | Overview of workplace safety policies and procedures | For new employees and annually for all staff |

Hazard-Specific Training | Detailed training on specific hazards, such as chemical handling or machine operation | As required based on job role |

Emergency Response | Training on emergency procedures, including evacuation plans and first-aid | Bi-annually |

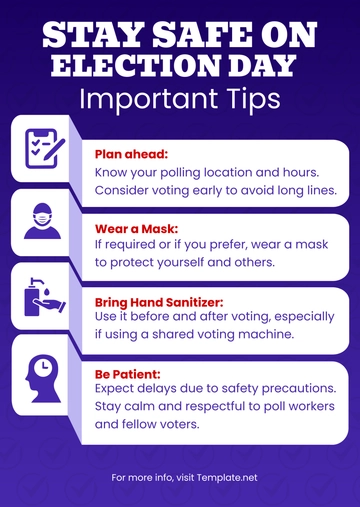

Communication Protocols

Regular and effective communication is key to maintaining a safe work environment. This includes not only disseminating information about identified hazards and safety procedures but also encouraging a culture where employees feel comfortable reporting potential risks.

Communication Method | Purpose | Frequency |

Safety Meetings | To discuss recent incidents, upcoming safety initiatives, and general safety tips | Monthly |

Safety Bulletins | To provide updates on new hazards, changes in safety procedures, or after-incident reports | As needed |

Suggestion Box | To allow employees to anonymously submit safety concerns or suggestions | Continuously available |

Section 8: Review and Continuous Improvement

Review Schedule

Regular reviews of the hazard identification and risk assessment process are crucial for ensuring that safety procedures remain effective and relevant. These reviews should be scheduled at regular intervals and after any significant incident or change in workplace practices.

Review Type | Description | Frequency |

Comprehensive Safety Review | Full review of all safety policies and procedures | Annually |

Post-Incident Review | Examination of procedures following a safety incident | After each incident |

Regulatory Compliance Review | Ensuring ongoing compliance with local and national safety regulations | Bi-annually |

Continuous Improvement Strategies

An effective safety program is dynamic and evolves based on new information, technology, and feedback. Strategies for continuous improvement should focus on learning from experiences, both within the organization and from industry best practices.

Improvement Strategy | Description |

Feedback Mechanisms | Regular surveys and feedback forms to gather input from employees on safety concerns and suggestions |

Benchmarking | Comparing safety practices with industry standards and best practices to identify areas for improvement |

Technology Integration | Implementing new technologies or tools to enhance safety, such as wearables for monitoring physical strain or environmental sensors |

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Uncover the ideal solution for identifying hazards with Template.net's Hazard Identification Documentation Template. This editable and customizable template, powered by our Ai Editor Tool, facilitates meticulous hazard assessment. Seamlessly tailor the document to your needs, ensuring comprehensive risk mitigation. Safeguard your projects effectively with Template.net's innovative resources.