Welding Scope of Work

Project Overview |

|---|

This welding work scope details the required protocols and obligations for the building of a new pipeline, with the project's goal being to provide a first-class pipeline system that aligns with industry standards and the expectations of [CLIENT NAME]. This is guided by the standards of [YOUR COMPANY NAME] and managed by [YOUR NAME]. |

Project Details |

Project Name | [PROJECT TITLE] |

Client | [CLIENT NAME] |

Location | [LOCATION OF PIPELINE CONSTRUCTION] |

Start Date | [START DATE] |

End Date | [END DATE] |

Scope | [PIPELINE MATERIAL] |

Pipeline Length | [LENGTH] METERS |

Pipeline Diameter | [DIAMETER] INCHES |

Pipeline Material | [MATERIAL TYPE] |

Pipeline Specifications | [PIPELINE SPECIFICATIONS] |

Pipeline Route | [ROUTE DESCRIPTION] |

Scope of Work |

|---|

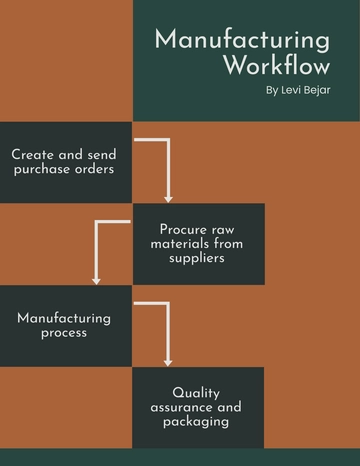

Preparation Phase: Conduct site assessment and obtain necessary permits. Set up safety measures and establish a safety protocol. Procure materials and equipment required for welding.

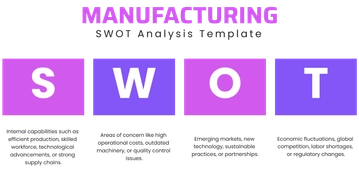

Welding Procedures: Verify welding procedure specifications (WPS) and ensure compliance. Prepare surfaces for welding, including cleaning and preheating if necessary. Perform welding according to approved WPS, ensuring proper penetration and fusion. Conduct non-destructive testing (NDT) as per project requirements. Ensure weld quality meets industry standards and client specifications.

Quality Assurance/Quality Control (QA/QC): Implement QA/QC procedures to monitor and inspect welding activities. Conduct visual inspections and dimensional checks on completed welds. Perform NDT tests such as radiographic testing, ultrasonic testing, and magnetic particle inspection. Document all QA/QC activities and maintain records for review.

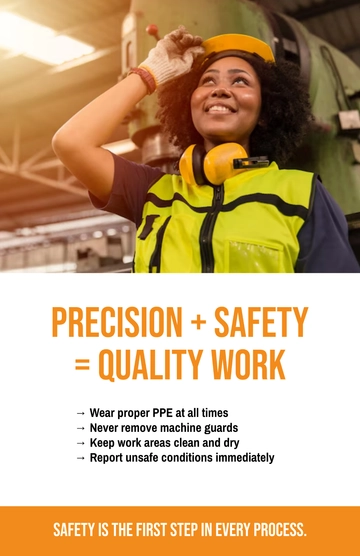

Safety Measures: Adhere to safety protocols at all times, including wearing appropriate personal protective equipment (PPE). Conduct regular safety briefings and toolbox talks. Monitor work environment for potential hazards and take corrective actions as needed.

Project Completion: Conduct final inspections to ensure all welding work meets project standards. Prepare documentation including weld maps, as-built drawings, and welding records. Hand over completed pipeline to the client and provide necessary training if required.

|

Project Deliverables |

|---|

Welded pipeline meeting project specifications. Documentation including welding procedure specifications, inspection reports, and as-built drawings. Comprehensive quality assurance/quality control (QA/QC) reports ensuring adherence to industry standards and client requirements. Final project completion report summarizing key milestones, challenges overcome, and lessons learned for future reference. Handover package containing all necessary documentation and records for the client's reference and future maintenance purposes.

|

Project Team |

Welding Engineer: Welding Supervisor: Welders: QA/QC Inspector: Safety Officer:

| [NAME] [NAME] [LIST OF WELDERS] [NAME] [NAME] |

Notes |

|---|

Safety First: Prioritize safety to prevent accidents and injuries. Adhere strictly to safety protocols and guidelines. Quality Assurance: Maintain high-quality standards throughout the welding process. Document procedures and conduct thorough inspections. Client Communication: Keep open communication with the client to address concerns and ensure alignment with expectations. Timeline and Milestones: Set clear milestones and deadlines to keep the project on track. Provide regular progress updates to stakeholders. Environmental Responsibility: Minimize environmental impact during construction. Follow measures to protect local ecosystems.

|

[SIGNATURE]

[YOUR NAME]

[YOUR COMPANY NAME]

[DATE]

Scope of Work Templates @ Template.net