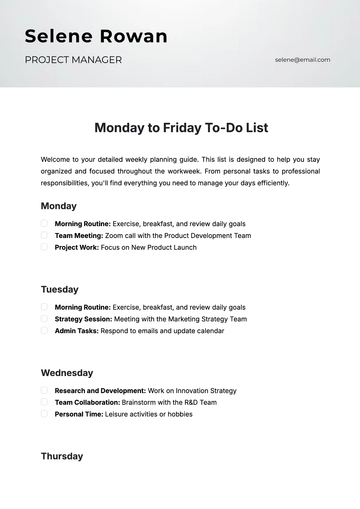

Free Pretest Piping Punch List

I. Introduction

The Pretest Piping Punch List is a comprehensive checklist used to ensure that all piping systems are properly prepared, inspected, and verified before undergoing testing. This document serves as a critical quality control tool to identify and rectify any deficiencies or issues within the piping systems.

II. Purpose

The purpose of the Pretest Piping Punch List is to:

Verify the completion of piping installations.

Ensure compliance with project specifications and standards.

Identify and document any deficiencies or required corrections.

Facilitate a systematic and thorough inspection process.

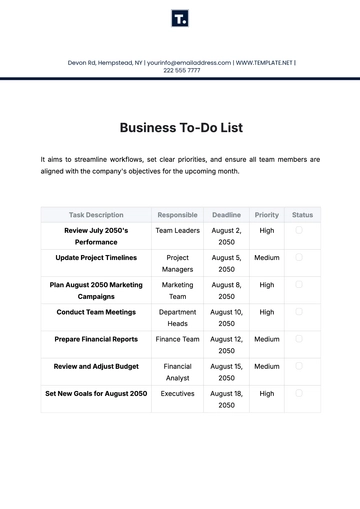

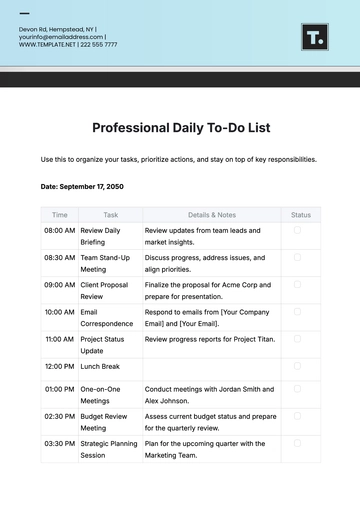

III. General Information

Project Name: | Alpha Plant Expansion |

|---|---|

Location: | Boerne, TX 78006 |

Contractor: | [YOUR COMPANY NAME] |

Date: | July 10, 2050 |

Inspector Name: | Emanuel King |

Piping System: | Steam Distribution |

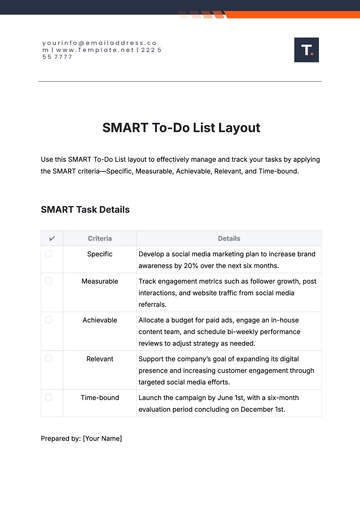

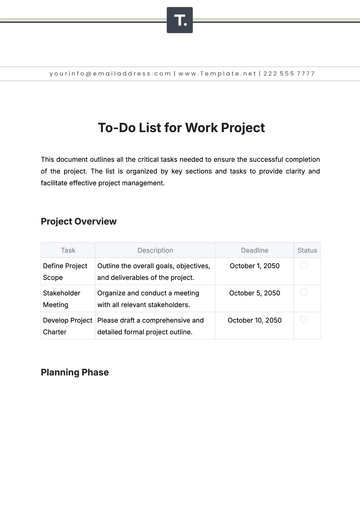

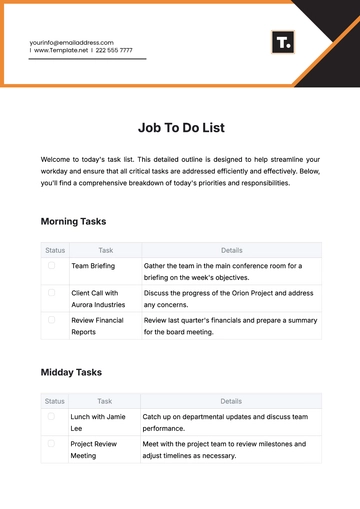

IV. Pretest Piping Punch List

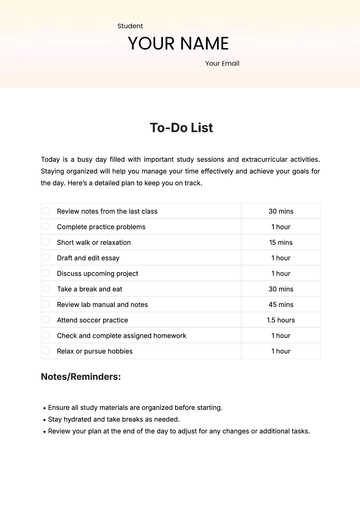

1. Documentation Verification

No. | Description | Status | Remarks |

|---|---|---|---|

1.1 | Verify piping isometric drawings are complete. | - | |

1.2 | Ensure all material certifications are available. | - | |

1.3 | Check the availability of welding procedures. | - | |

1.4 | Verify non-destructive testing (NDT) reports. | - |

2. Visual Inspection

No. | Description | Status | Remarks |

|---|---|---|---|

2.1 | Check for proper installation of supports. | - | |

2.2 | Ensure piping is free from debris and obstructions. | - | |

2.3 | Inspect for proper alignment of pipes. | - | |

2.4 | Check for any visible signs of damage or leaks. | - |

3. Mechanical Inspection

No. | Description | Status | Remarks |

|---|---|---|---|

3.1 | Verify flange connections are tightened. | - | |

3.2 | Check gaskets for correct installation. | - | |

3.3 | Ensure all valves are installed and operable. | - | |

3.4 | Inspect for proper installation of fittings. | - |

4. Pressure Testing Preparation

No. | Description | Status | Remarks |

|---|---|---|---|

4.1 | Verify test boundaries are defined and marked. | - | |

4.2 | Ensure all vents and drains are identified. | - | |

4.3 | Check for proper isolation of the test section. | - | |

4.4 | Confirm pressure gauges are calibrated. | - |

5. Safety Checks

No. | Description | Status | Remarks |

|---|---|---|---|

5.1 | Ensure proper safety signage is in place. | - | |

5.2 | Verify the availability of emergency shutdown procedures. | - | |

5.3 | Check that all personnel are trained on safety protocols. | - | |

5.4 | Confirm the availability of safety equipment. | - |

V. Punch List Summary

No. | Description | Status | Remarks |

|---|---|---|---|

1 | Documentation Verification | - | |

2 | Visual Inspection | - | |

3 | Mechanical Inspection | - | |

4 | Pressure Testing Preparation | - | |

5 | Safety Checks | - |

VI. Signatures

Emanuel King, Inspector

Date: July 10, 2050

[YOUR NAME], Contractor

[YOUR COMPANY NAME]

Date: July 10, 2050

Seth Walsh, Engineer

Date: July 10, 2050

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Ensure flawless pretest piping procedures with this Pretest Piping Punch List Template from Template.net. This customizable template is designed for precision and thoroughness. Editable in our AI Editor Tool, it allows for tailored adjustments to meet specific project requirements. Ideal for maintaining high standards and comprehensive checks in piping pretests.