Free Pump Datasheet

Manufacturer: [YOUR COMPANY NAME]

Model: FF-CEN-2050

Product Code: 2050FF-CEN-01

Issue Date: January 10, 2050

Revision: 1.0

I. GENERAL INFORMATION

Pump Type: Centrifugal Pump

Application: Industrial and Commercial (Water Treatment, Oil & Gas)

Operation: Continuous

Drive Type: Electric Motor-Driven

Certifications: ISO 9001, API 610, CE Marked, ATEX Certified

II. DESIGN SPECIFICATIONS

Pump Size: 4x3x12 (Inlet x Outlet x Impeller Diameter)

Construction Material:

Casing: Stainless Steel (SS316)

Impeller: Duplex Stainless Steel

Shaft: Alloy Steel (ASTM A479)

Seals: Mechanical Seal, Silicon Carbide vs. Carbon

Max Flow Rate: 350 m³/h

Max Head: 150 meters

Max Working Pressure: 25 bar

Max Temperature: 120°C

Weight: 750 kg

III. PERFORMANCE DATA

Flow Rate Range: 50 - 350 m³/h

Head Range: 20 - 150 meters

Pump Efficiency: 85%

NPSHr: 4 meters

Pump Speed: 2900 RPM

Power Requirement: 55 kW

Fluid Handled:

Water (Potable, Raw, and Seawater)

Oil (Crude, Refined)

Chemical Liquids (pH 4-12)

Viscosity Range: 1 to 100 cP

Solid Handling Capacity: Maximum particle size: 5 mm

IV. OPERATIONAL REQUIREMENTS

Motor Type: Induction Motor

Motor Power: 55 kW (75 HP)

Motor Voltage: 400V / 690V

Frequency: 50 Hz / 60 Hz

Protection Class: IP66

Explosion Protection: ATEX Zone 2 compliant

Ambient Temperature Range: -20°C to 50°C

V. DIMENSIONAL DATA

Overall Length: 1800 mm

Overall Width: 900 mm

Overall Height: 1200 mm

Inlet Diameter: 4 inches

Outlet Diameter: 3 inches

Foundation Bolt Size: M16

Suction/Discharge Flange Type: ANSI 150#

VI. CERTIFICATIONS & STANDARDS

Compliance:

ISO 9001:2050

API 610, 12th Edition

ASME B73.1

ATEX 2050 – Explosion Proof Certified

CE Certified

Additional Features

Bearing Type: Anti-Friction Bearings

Cooling System: Water-cooled for Extended Performance

Optional Features:

Variable Frequency Drive (VFD)

Condition Monitoring Sensors (Vibration, Temperature)

Control Panel with Smart IoT Connectivity

VII. MAINTENANCE INFORMATION

Lubrication:

Grease-Lubricated Bearings

Lubrication Interval: Every 2000 operating hours

Spare Parts:

Impeller, Mechanical Seal, Bearing Kit

Standard replacement lead time: 7 days

Recommended Maintenance Schedule:

Annual inspection of seals and bearings

Full overhaul every 5 years under normal operating conditions

Manufacturer Contact Information:

Company: [YOUR COMPANY NAME]

Address: [YOUR COMPANY ADDRESS]

Phone: [YOUR COMPANY NUMBER]

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

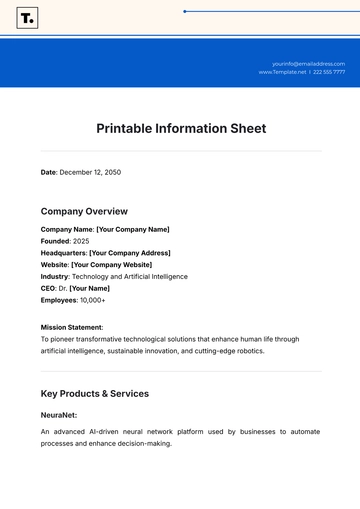

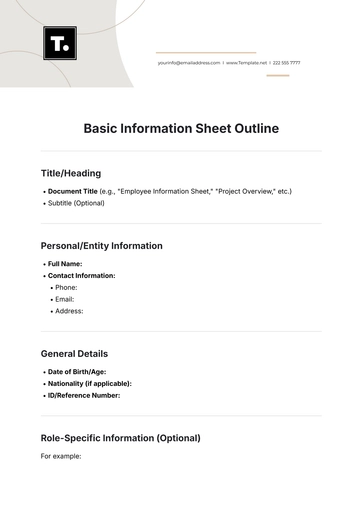

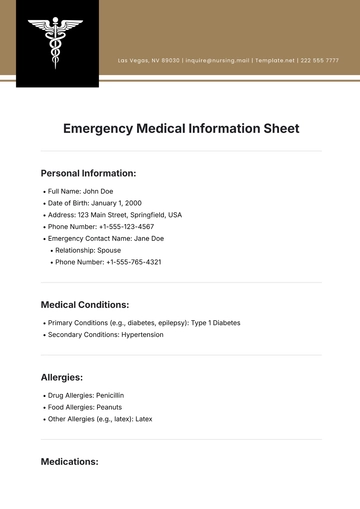

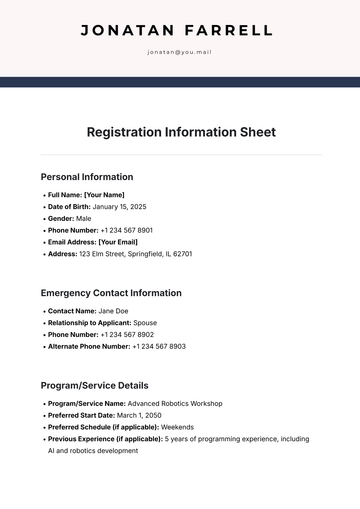

Introducing the Pump Datasheet Template from Template.net—a versatile, customizable solution for precise pump documentation. With our AI Editable Tool, effortlessly modify and personalize details to fit your needs. This editable template streamlines data management, ensuring clarity and efficiency in reporting. Enhance your workflow with this user-friendly, adaptable tool designed for seamless integration.

You may also like

- Attendance Sheet

- Work Sheet

- Sheet Cost

- Expense Sheet

- Tracker Sheet

- Student Sheet

- Tracking Sheet

- Blank Sheet

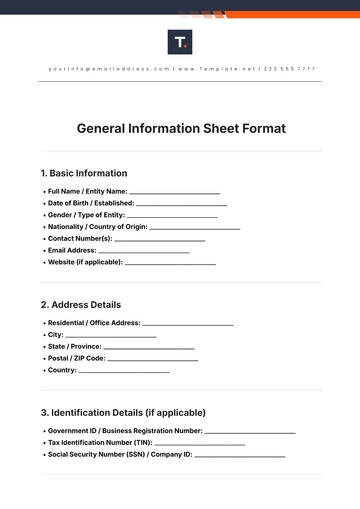

- Information Sheet

- Sales Sheet

- Record Sheet

- Price Sheet

- Plan Sheet

- Score Sheet

- Estimate Sheet

- Evaluation Sheet

- Checklist Sheet

- Bid Sheet

- Call Log Sheet

- Bill Sheet

- Assessment Sheet

- Task Sheet

- School Sheet

- Work From Home Sheet

- Summary Sheet

- Construction Sheet

- Cover Sheet

- Debt Spreadsheet

- Debt Sheet

- Client Information Sheet

- University Sheet

- Freelancer Sheet

- Bookkeeping Sheet

- Itinerary Spreadsheet

- Scorecard Sheet

- Run Sheet

- Monthly Timesheet

- Event Sheet

- Advertising Agency Sheet

- Missing Numbers Worksheet

- Training Sheet

- Production Sheet

- Mortgage Sheet

- Answer Sheet

- Excel Sheet