Free Operational Assessment

Operational Efficiency

Here we present our findings in a tabular format for clarity.

Metric | Current Value | Target Value | Variance |

|---|---|---|---|

Production Cycle Time | 15 days | 12 days | +3 days |

Resource Utilization Rate | |||

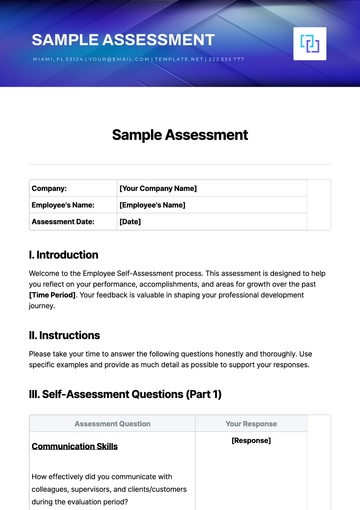

Performance Metrics

Process Area | Current Performance | Target Performance | Performance Gap |

|---|---|---|---|

Production Efficiency | 80% | 95% | 15% |

Customer Response Time | |||

Inventory Turnover | |||

IT System Uptime | |||

Action Plan

Action Item | Responsible Department | Timeline | Status |

|---|---|---|---|

Implement lean manufacturing techniques | Production | Q2 2025 | Pending |

Deploy CRM system for customer service | |||

Integrate automated inventory system | |||

Upgrade IT infrastructure | |||

Overall Performance

The overall performance is evaluated using a balanced scorecard approach.

Performance Area | Score | Description |

|---|---|---|

Financial Perspective | 7/10 | Stable revenue growth, with minor issues in cost management. |

Customer Perspective | /10 | High customer loyalty, slight improvements needed in service quality. |

Internal Processes | /10 | Process optimization needed; focus on reducing cycle times and increasing resource utilization. |

Learning & Growth | /10 | Strong emphasis on employee development and innovation. |

Conclusion

Continuous monitoring and corrective actions are recommended to maintain and improve these standards.

Operation Manager

[Date]

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

The Operational Assessment Template from Template.net is a fully editable and customizable tool designed to evaluate business operations. Easily modify it to suit your specific needs using our Ai Editor Tool. Streamline your operational analysis and gain valuable insights with this flexible template that ensures efficient, tailored assessments.