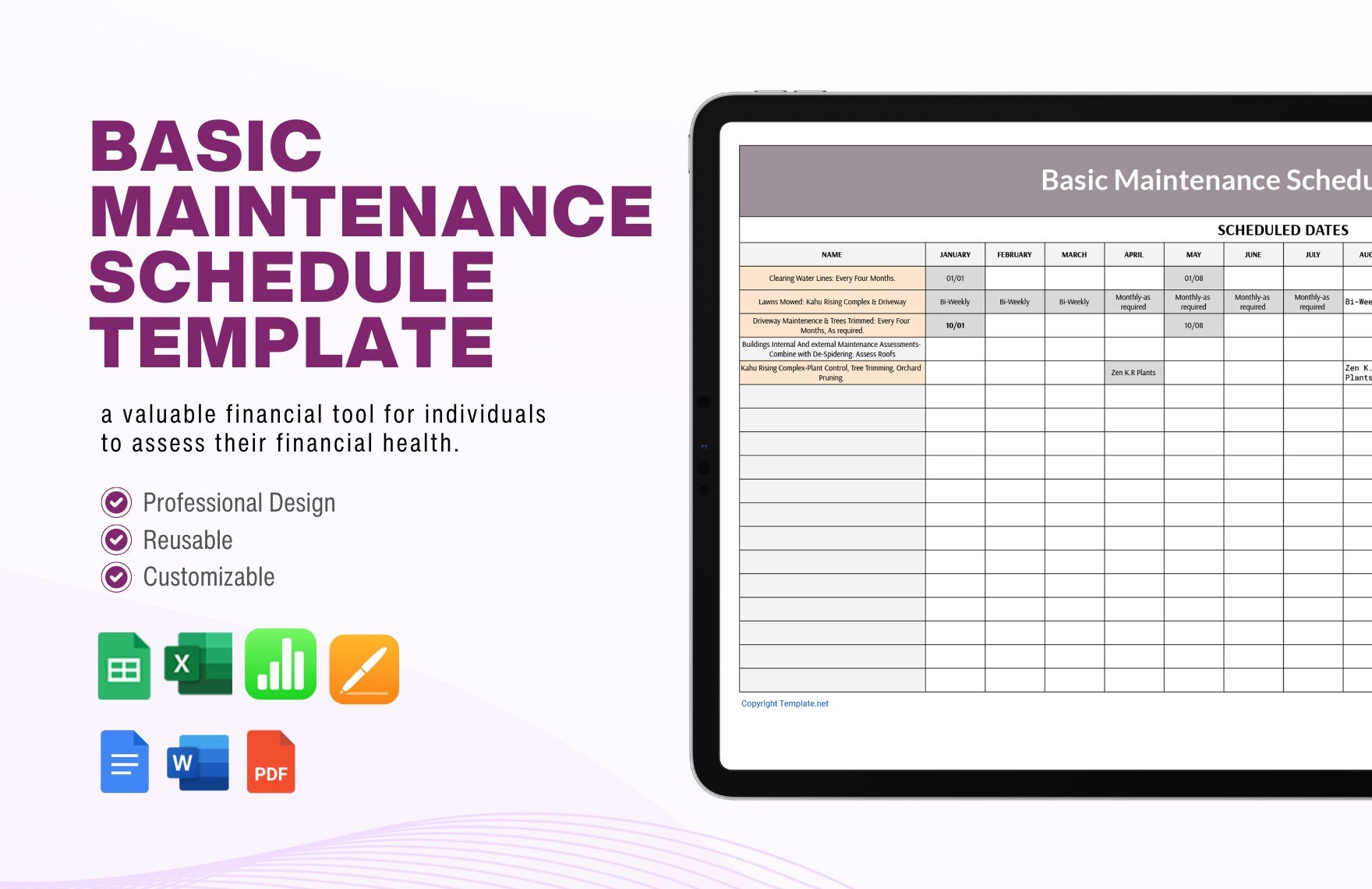

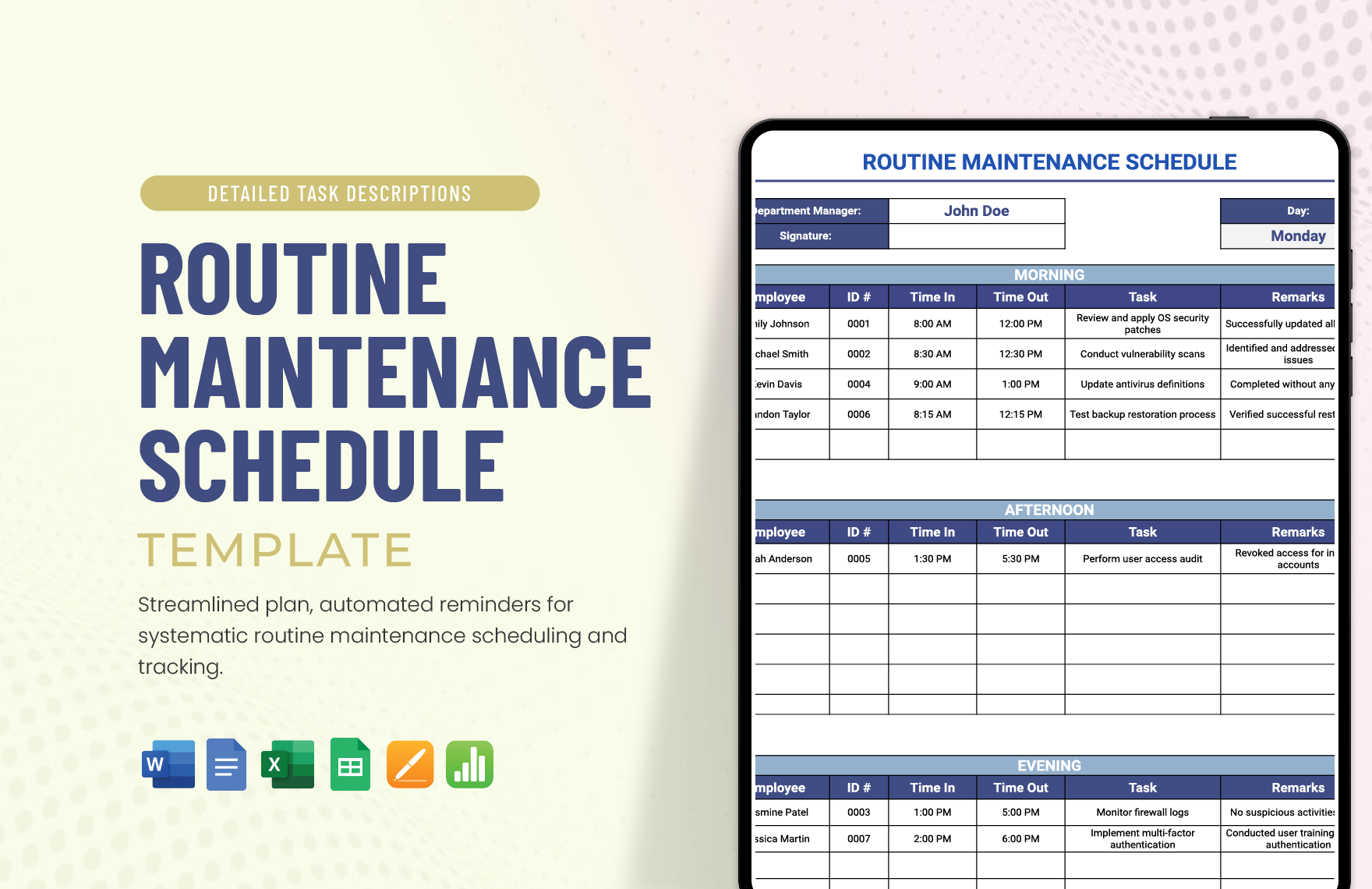

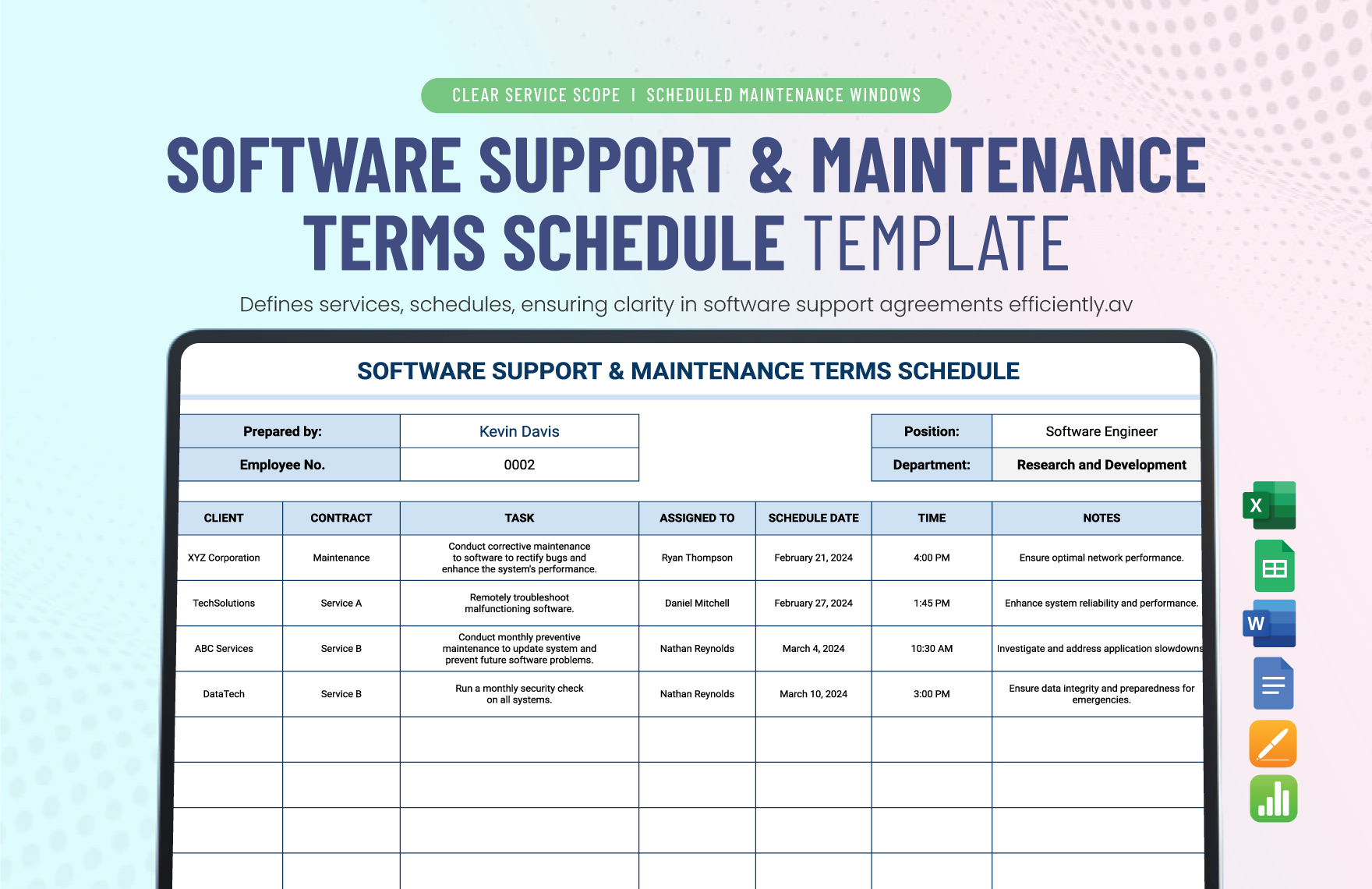

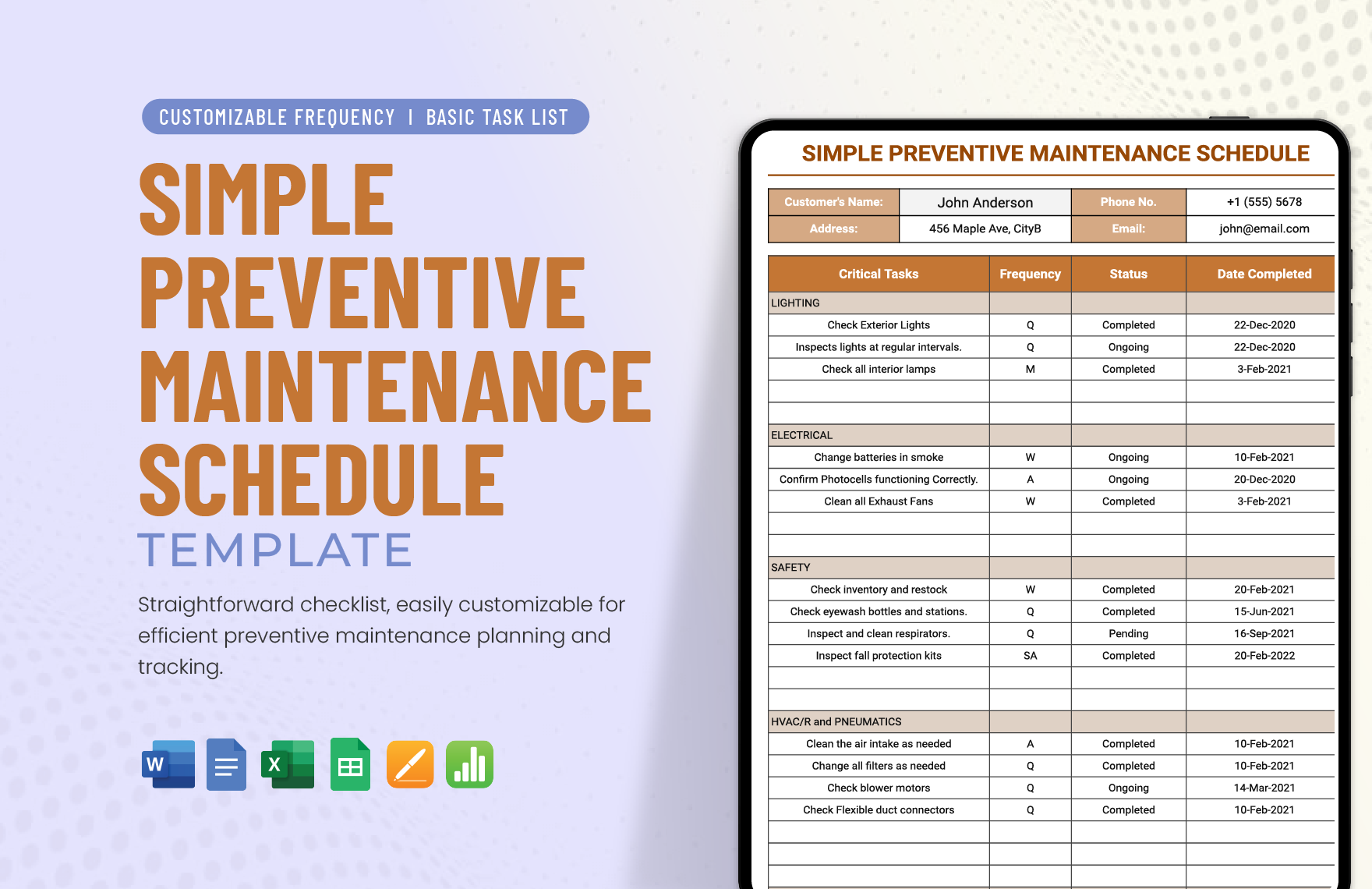

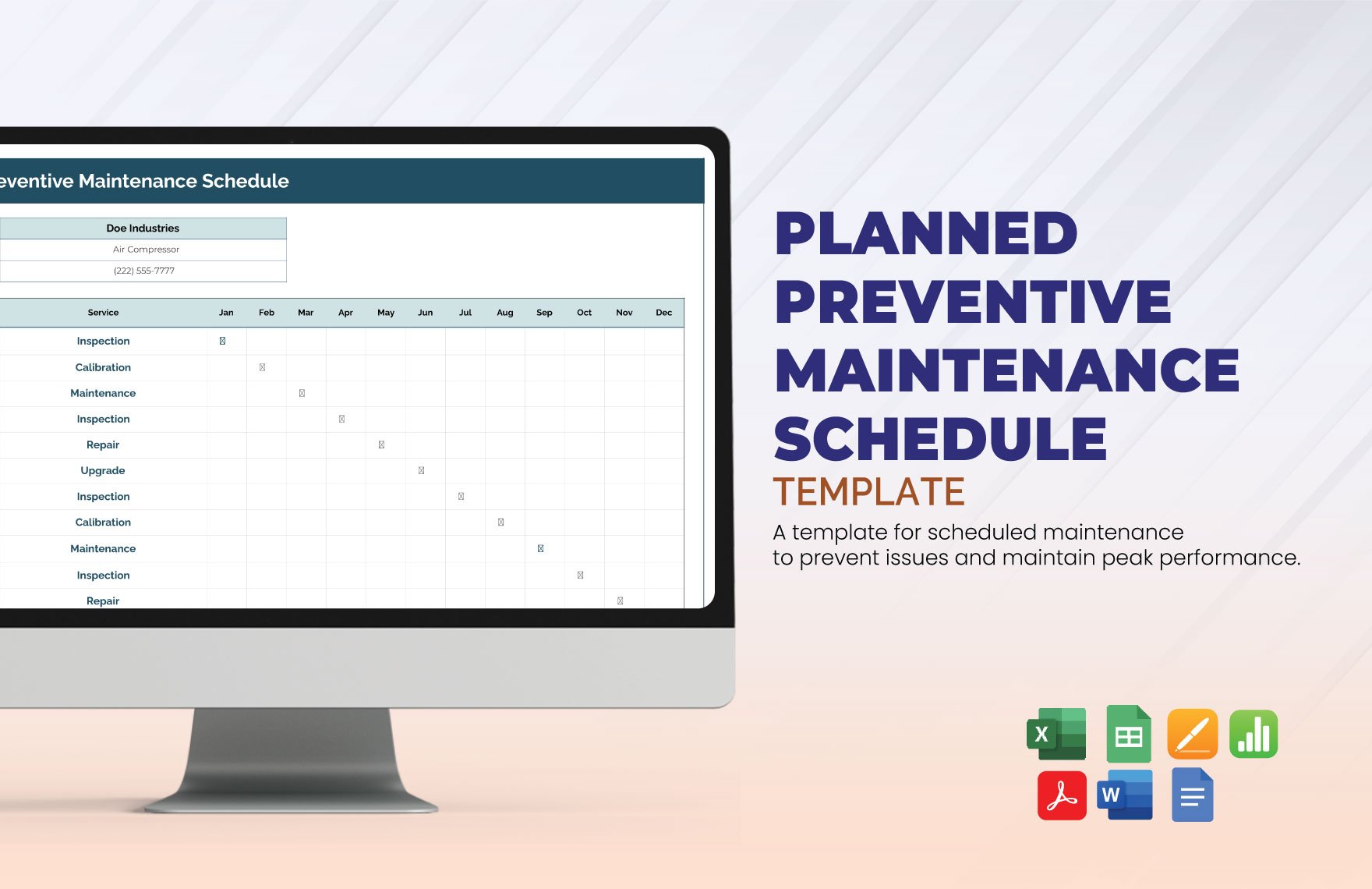

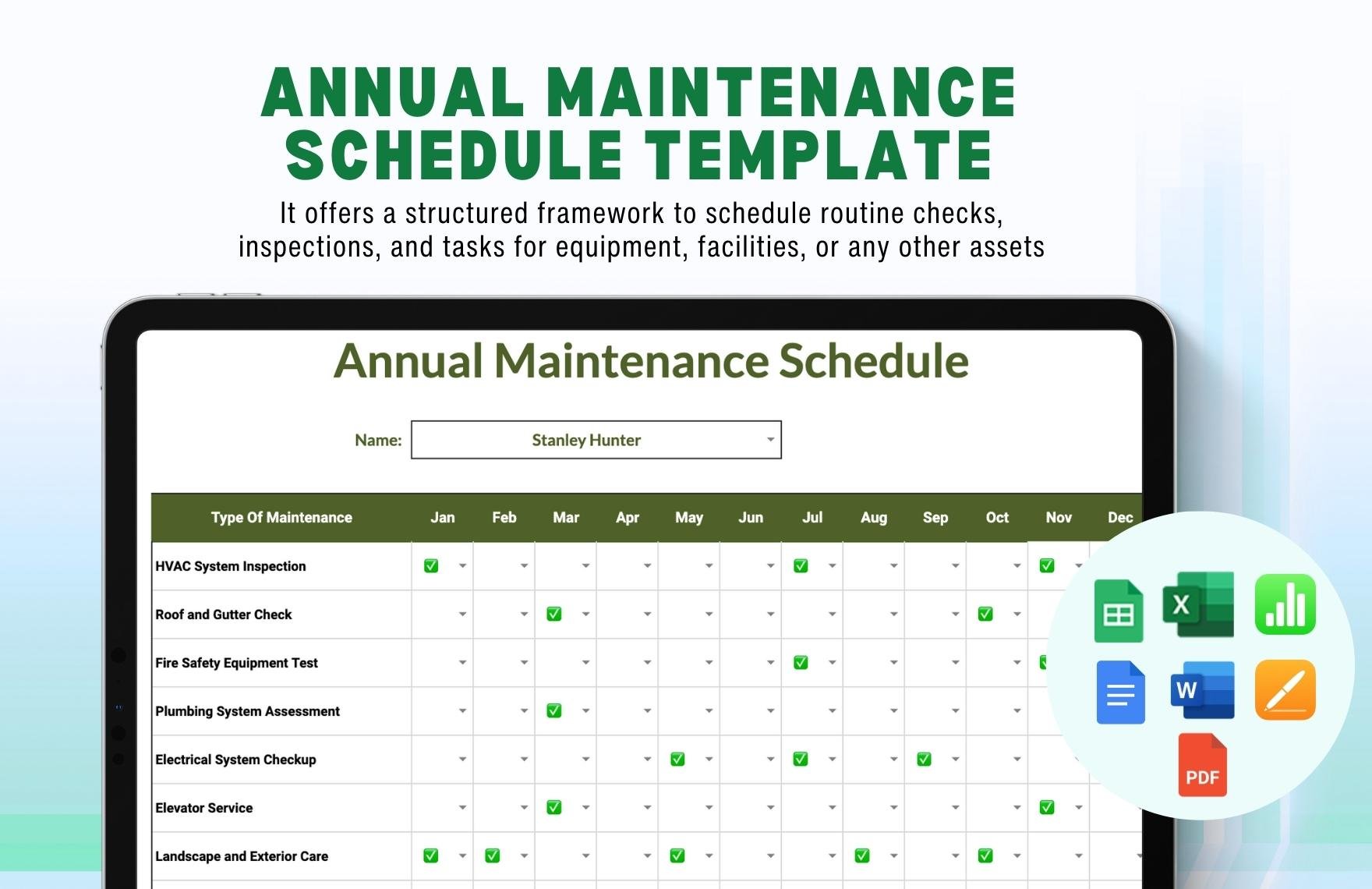

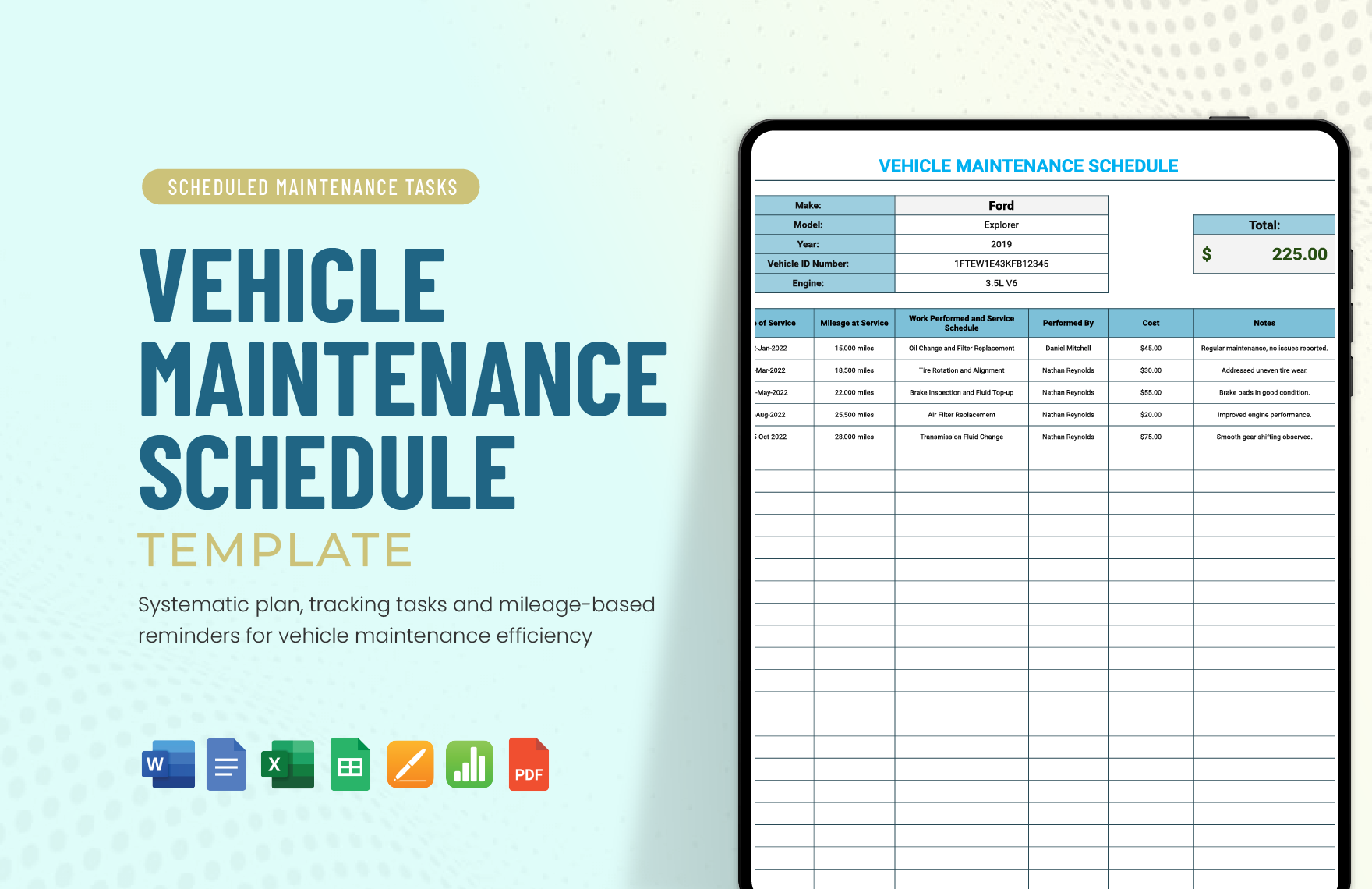

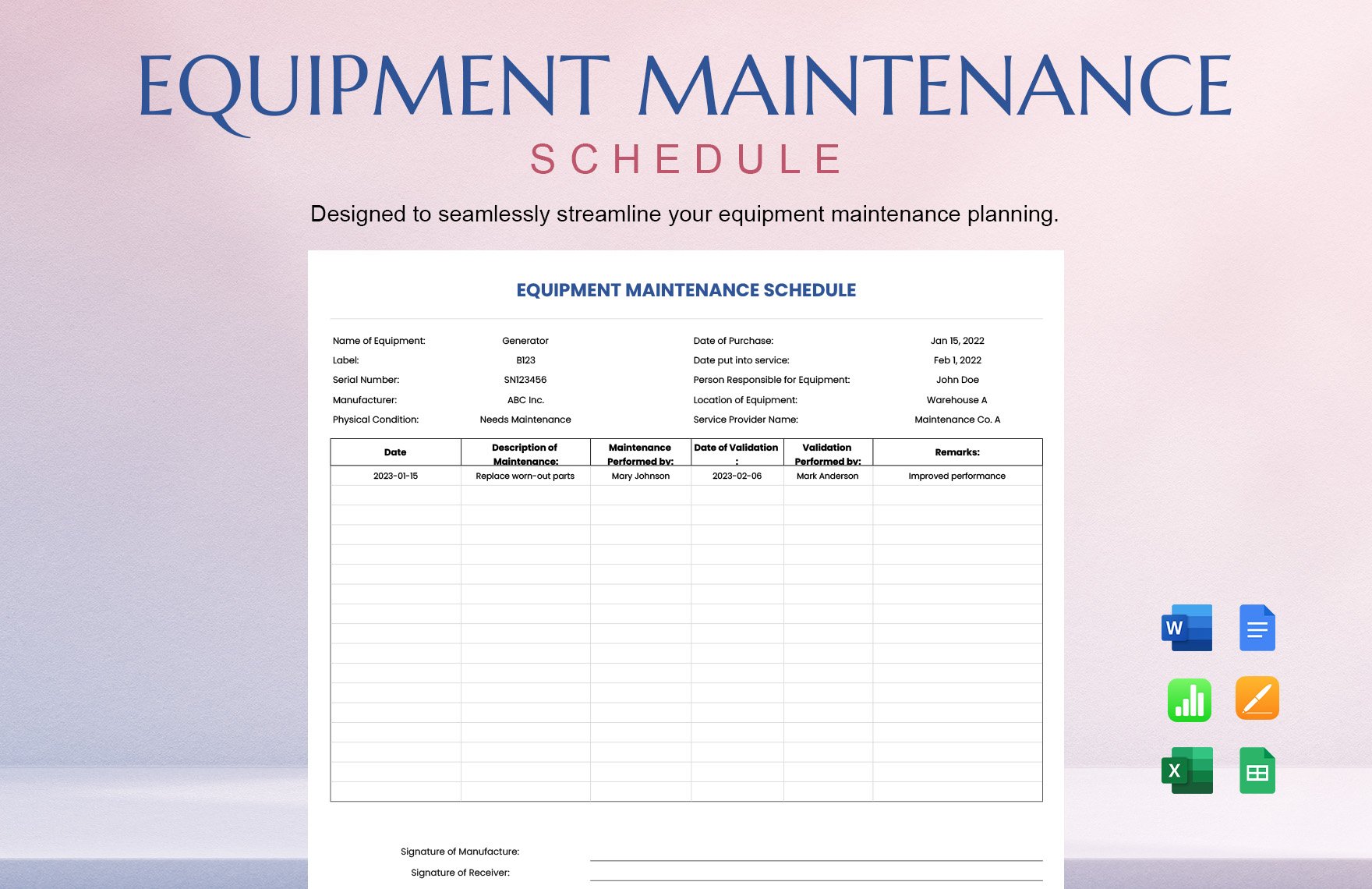

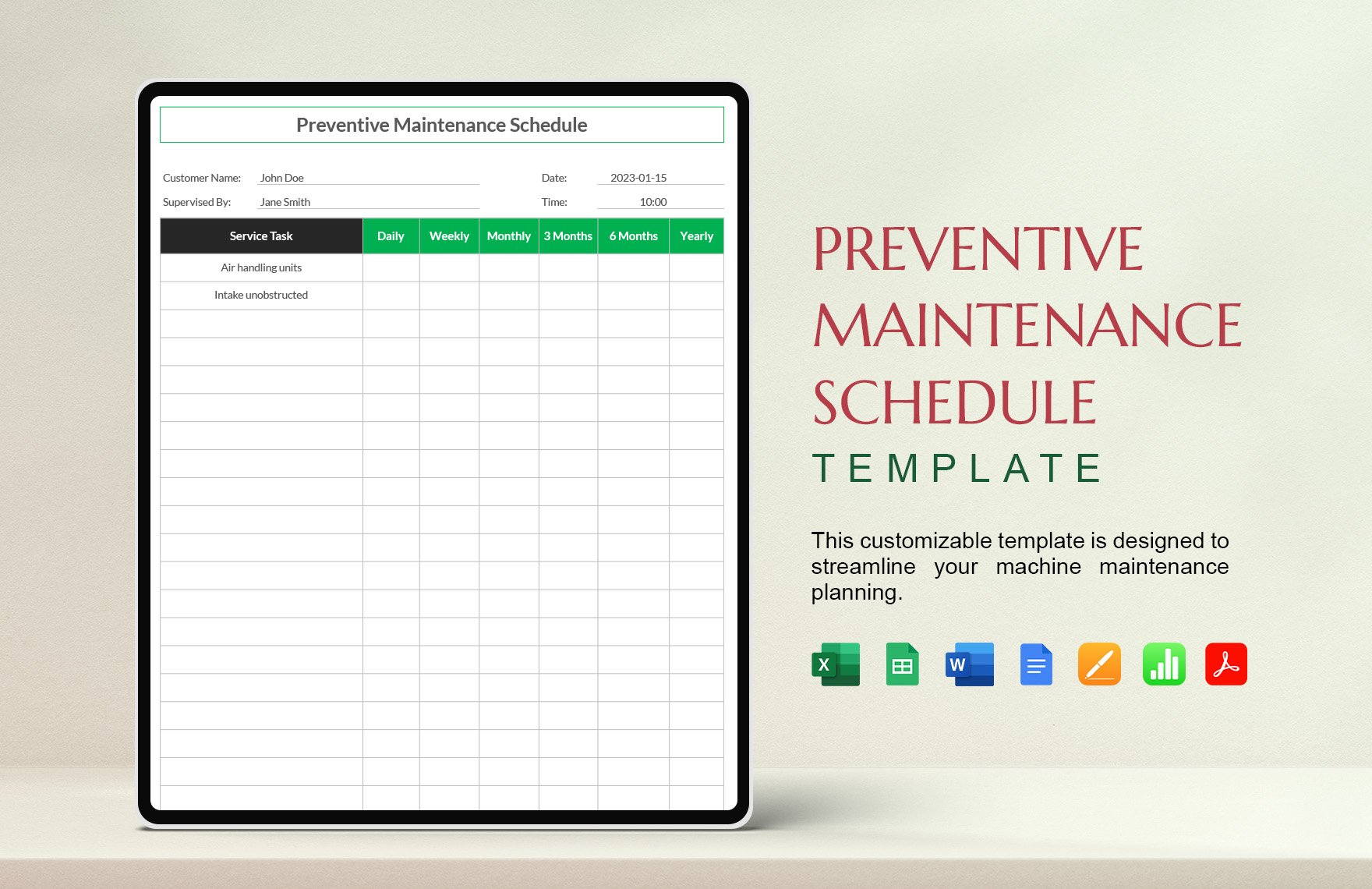

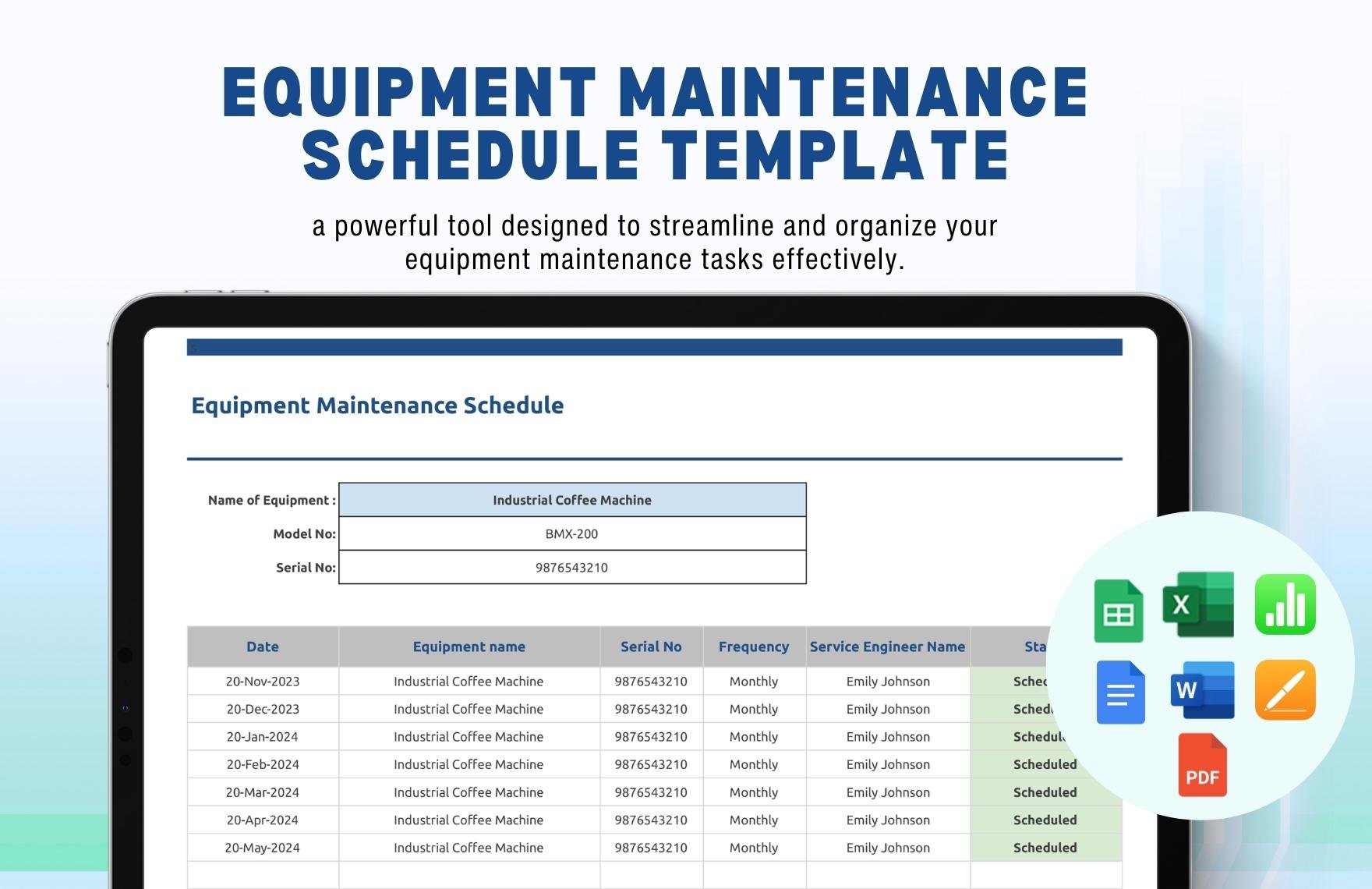

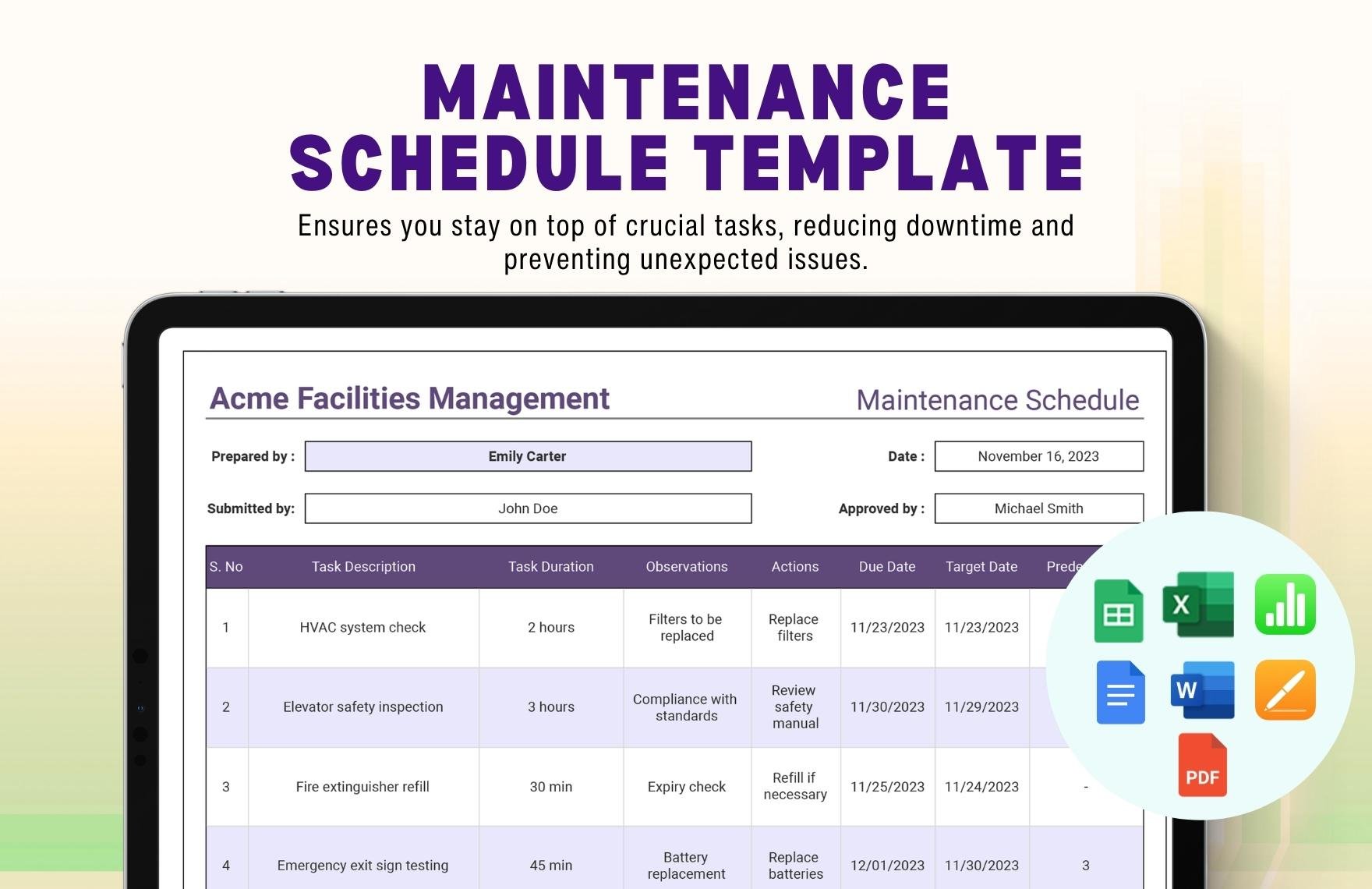

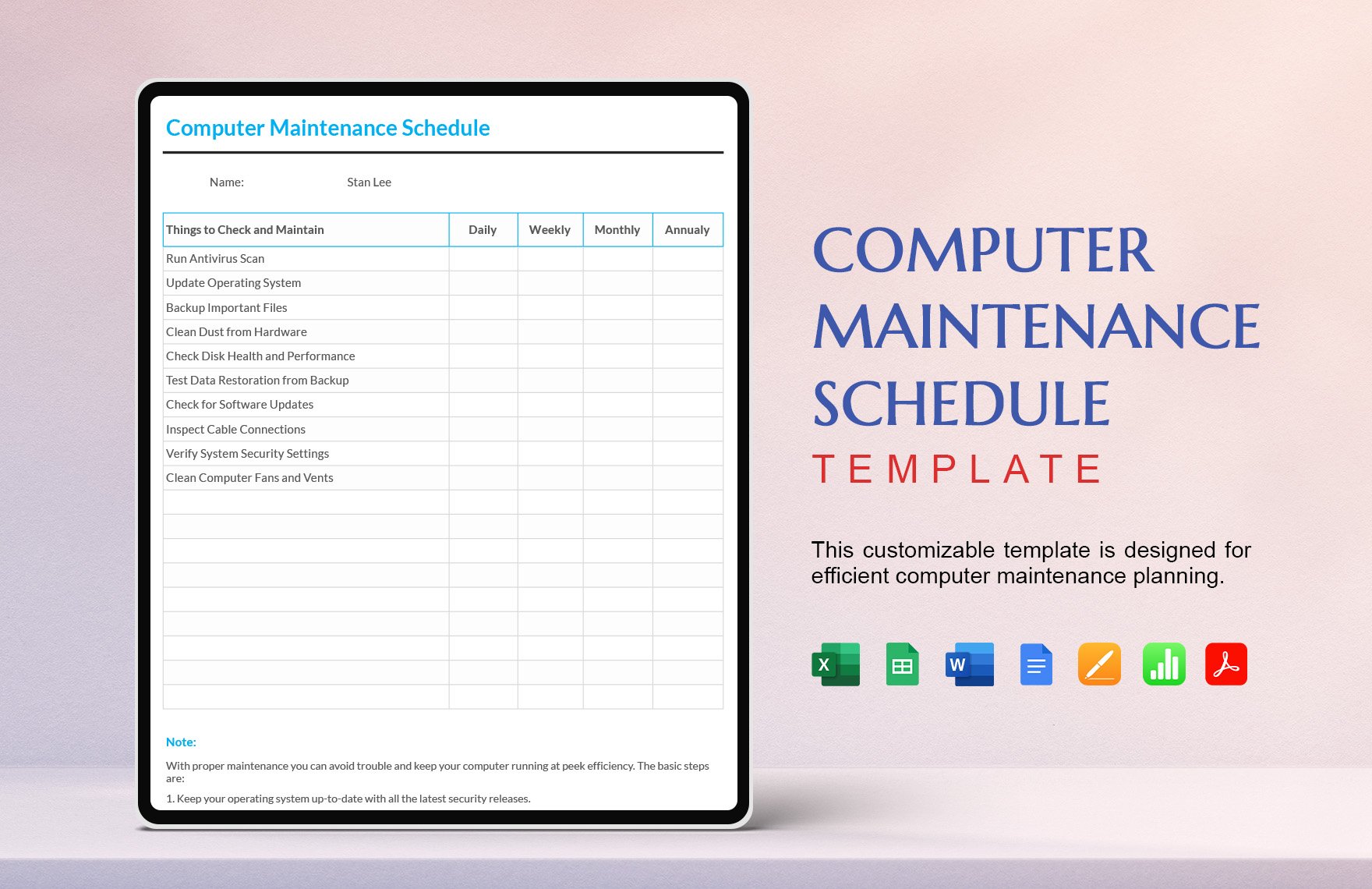

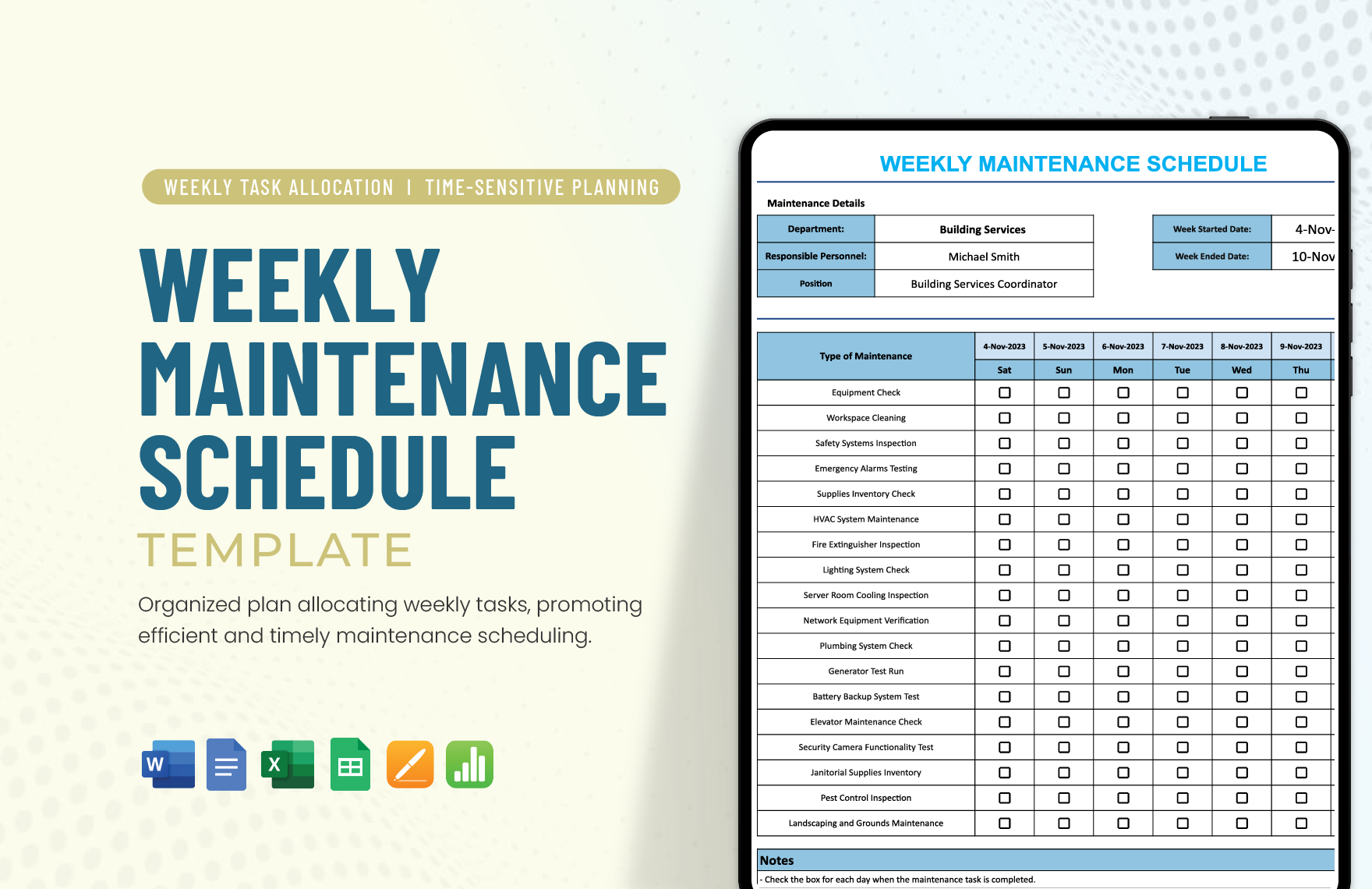

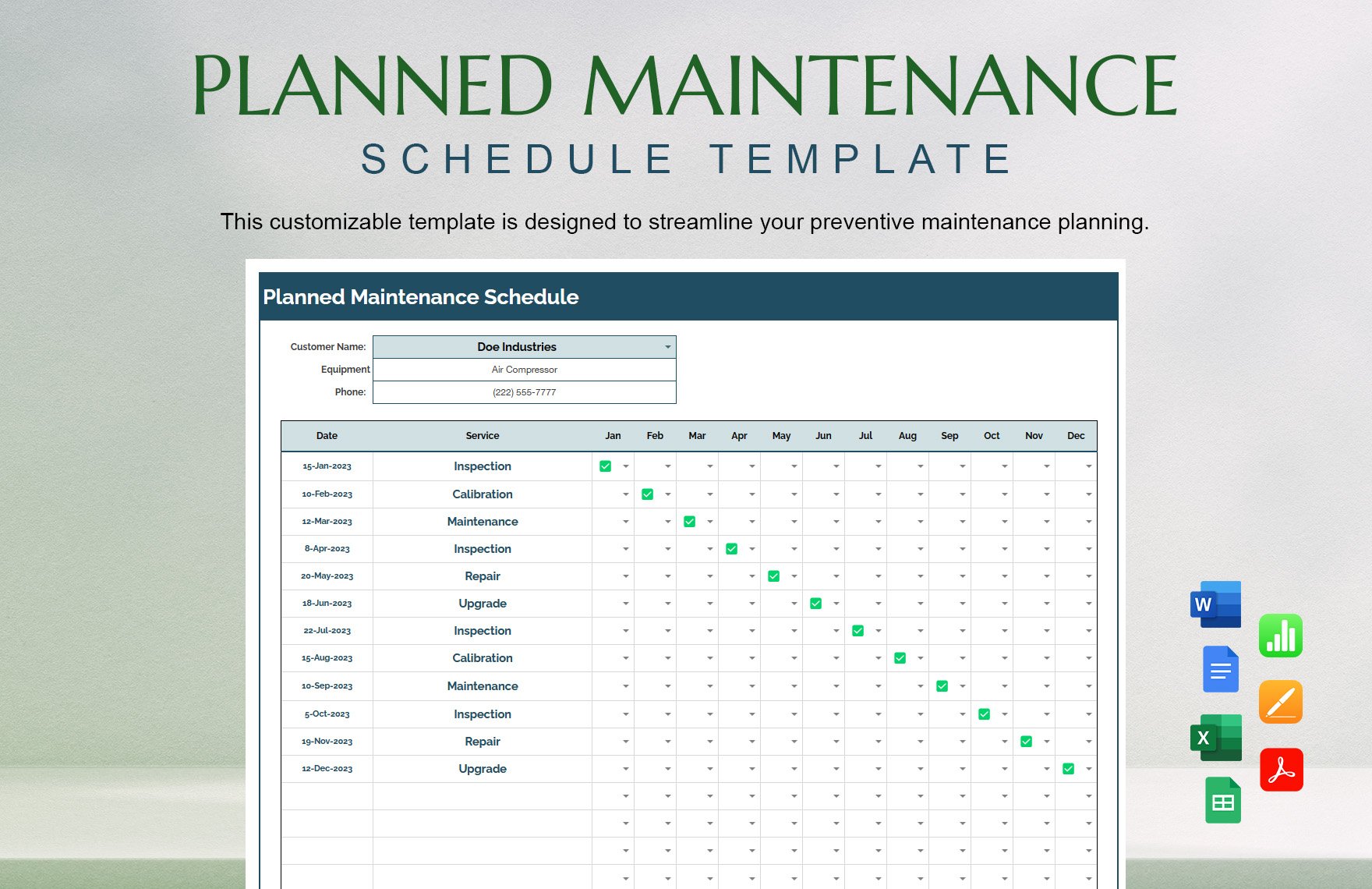

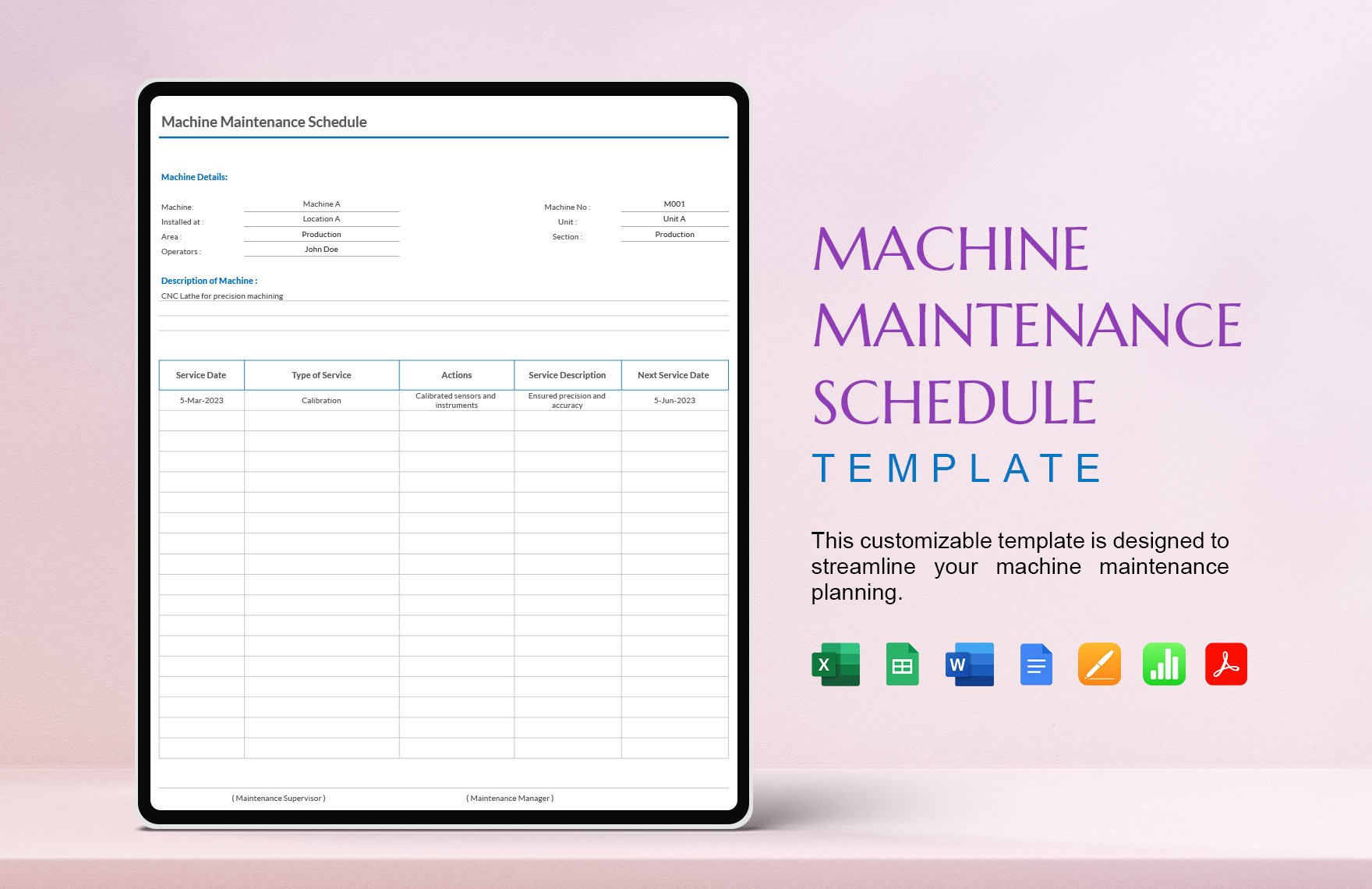

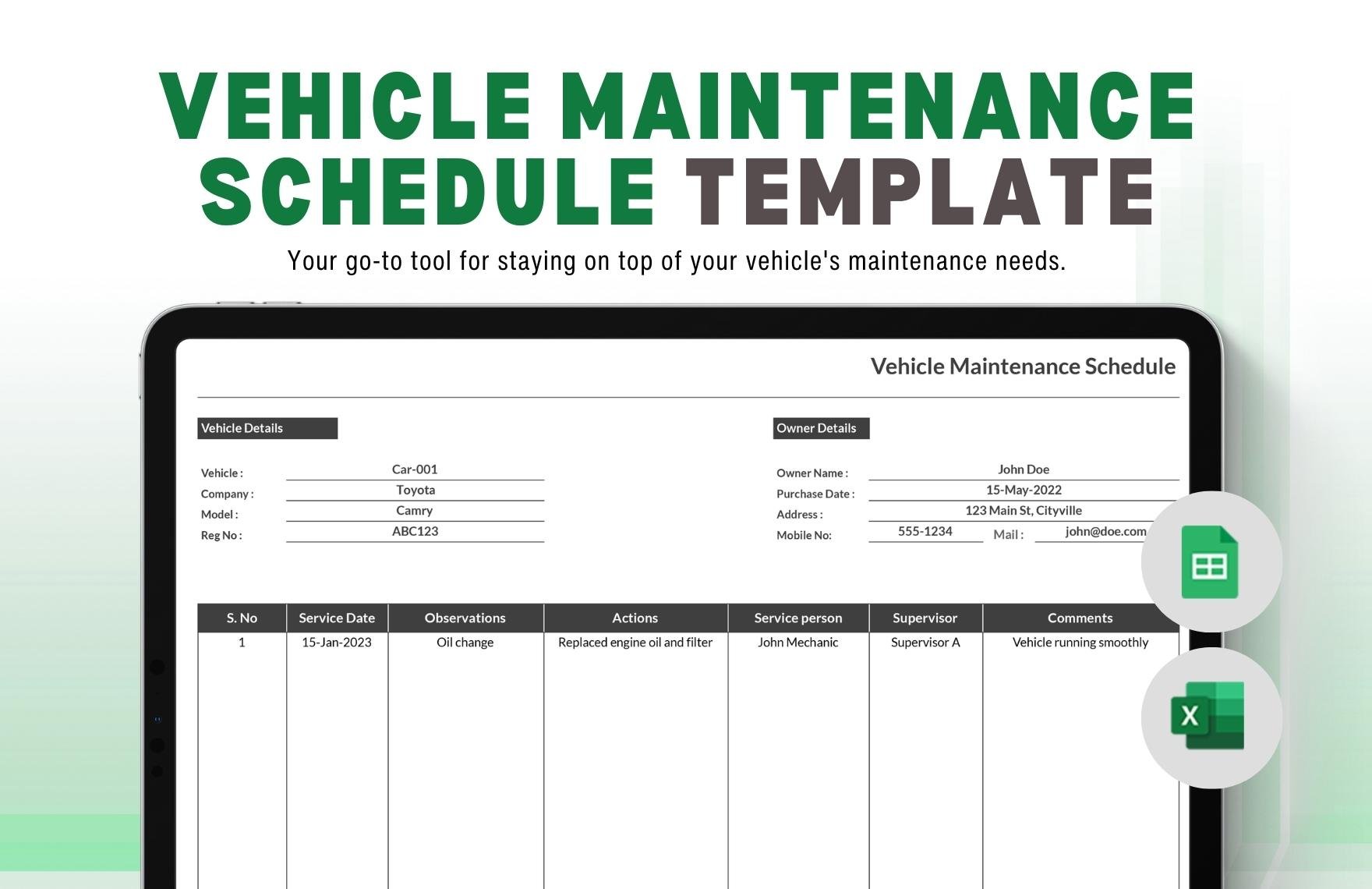

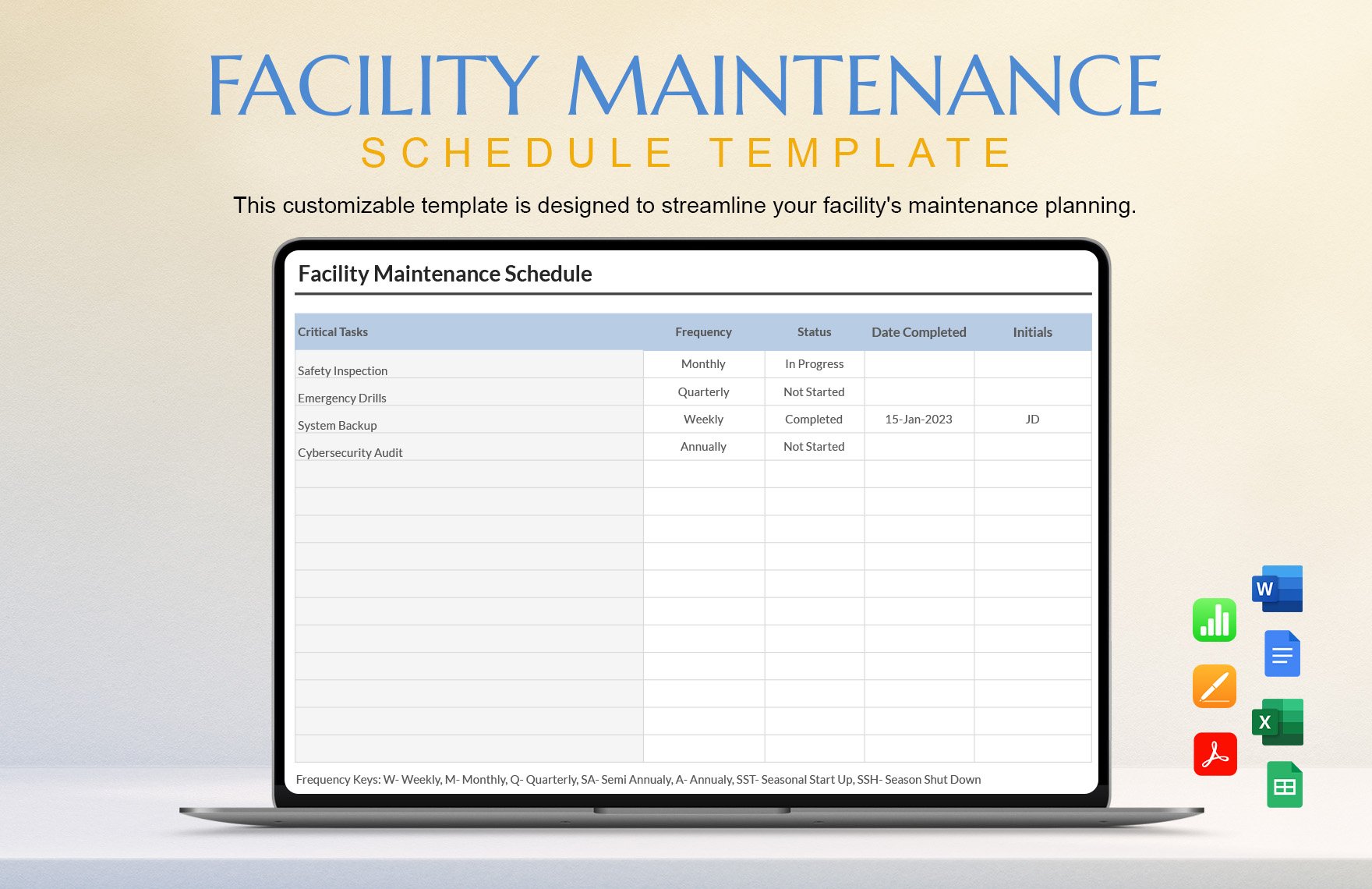

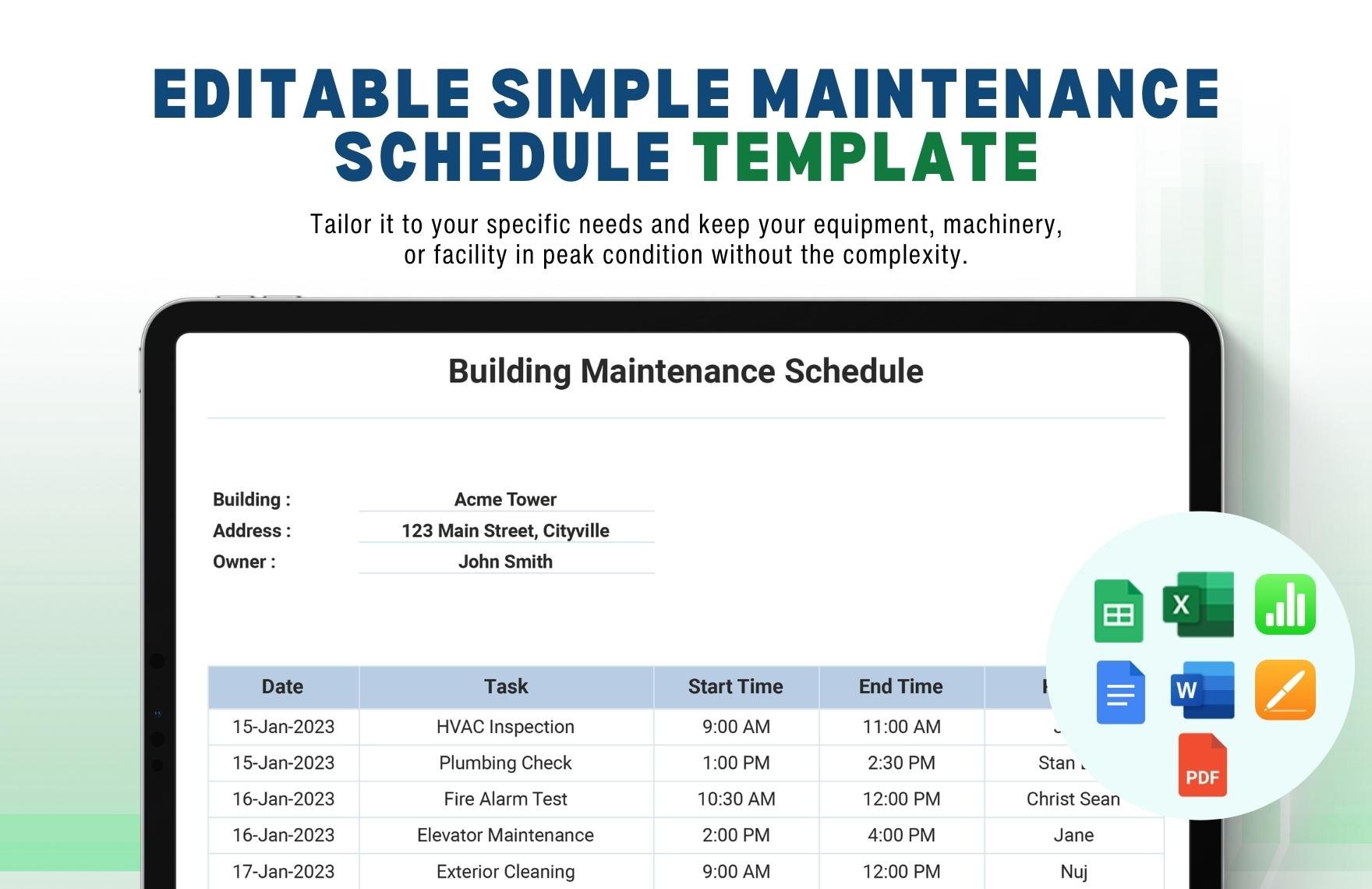

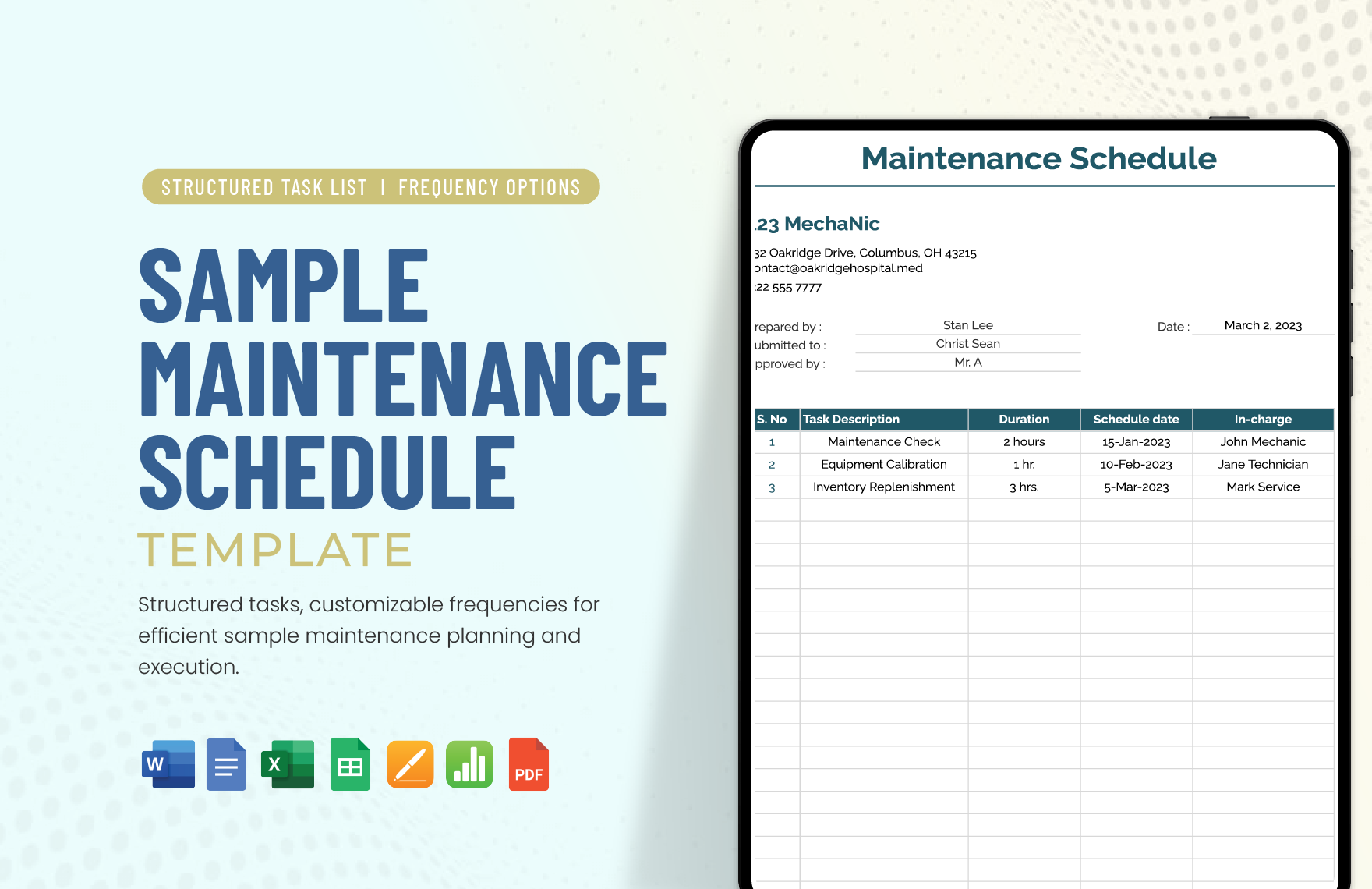

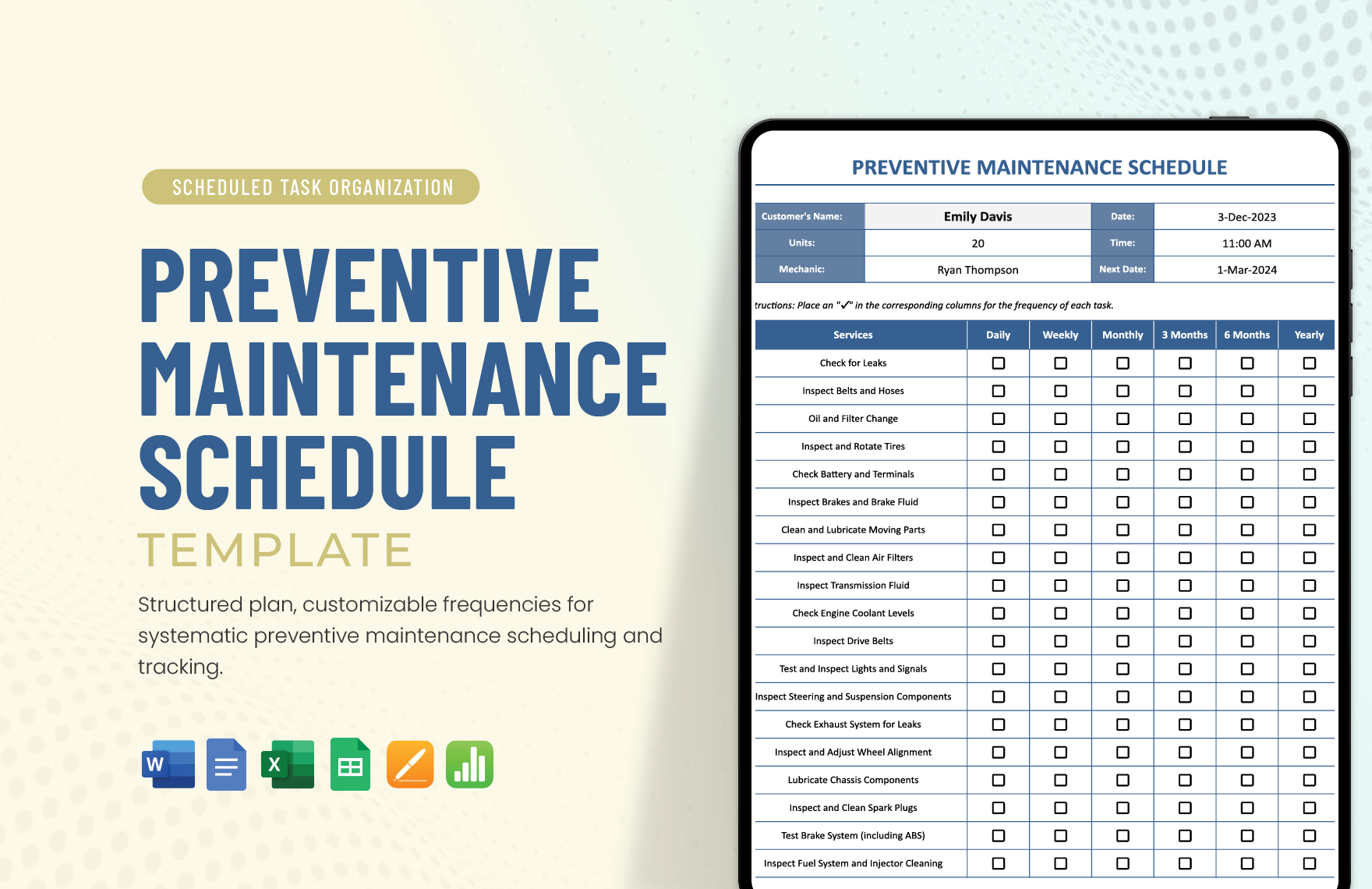

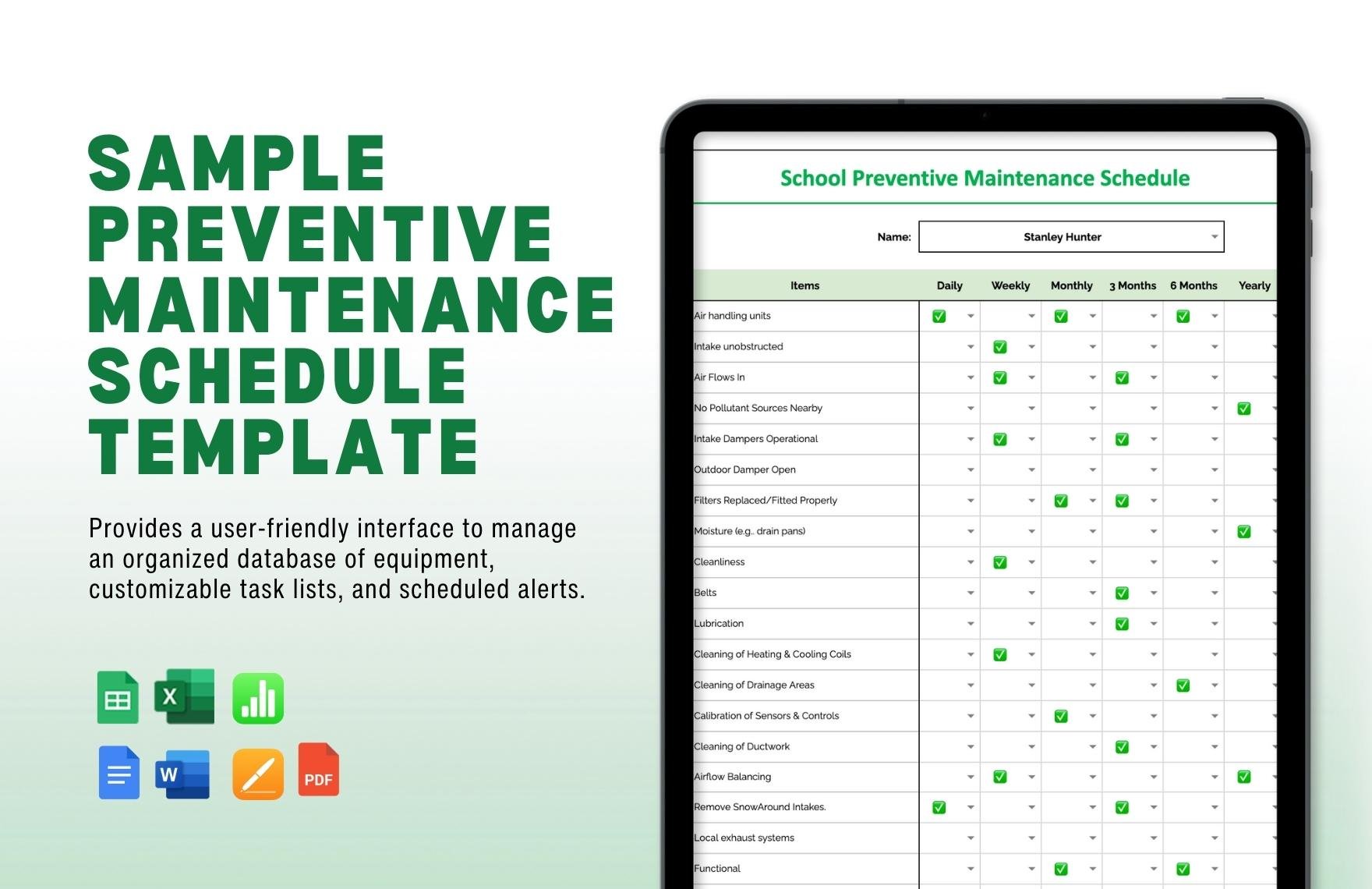

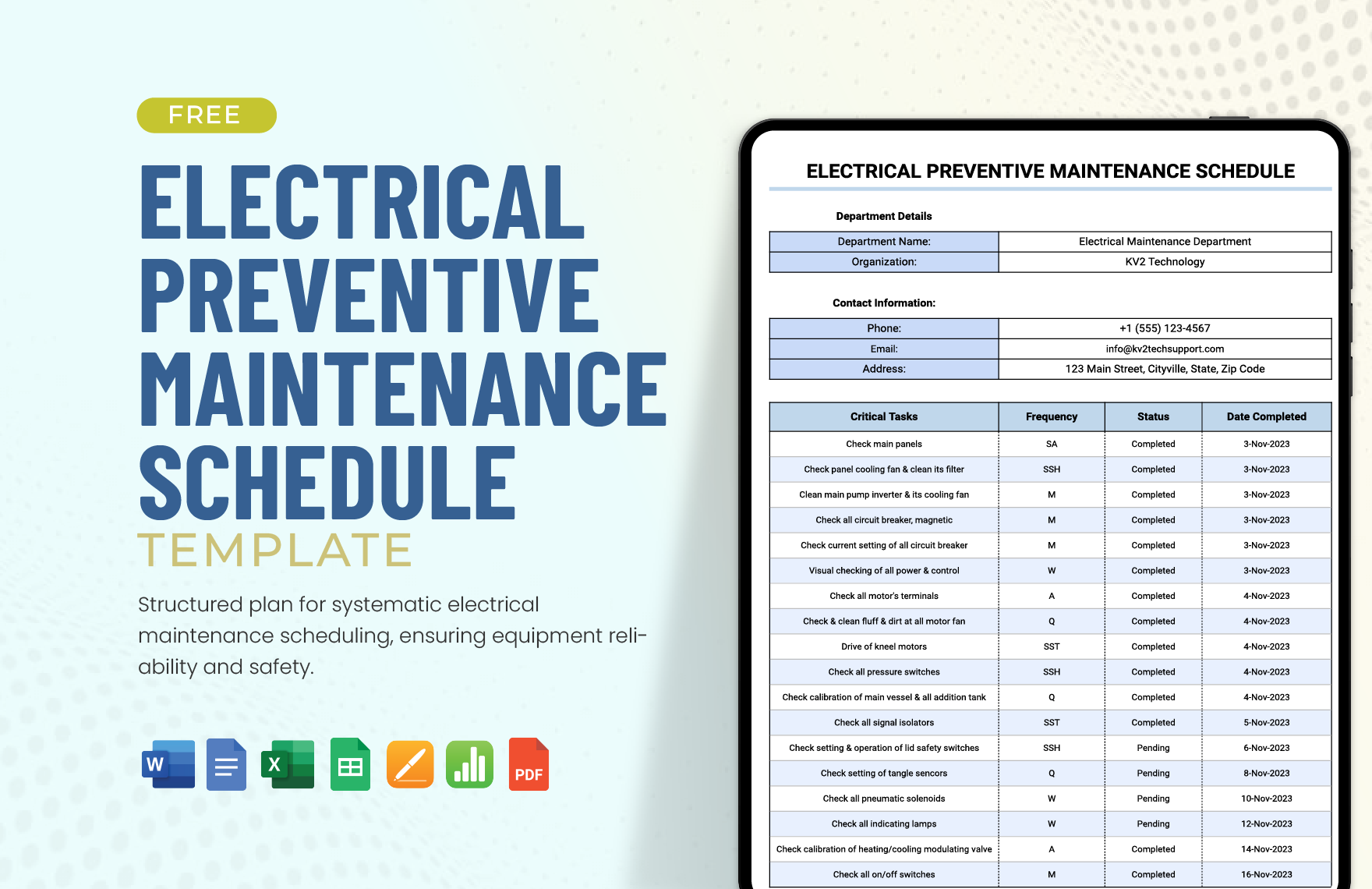

Keeping track of maintenance work can be pretty overwhelming especially if there are a lot of things that need to be monitored and maintained. To make this task easier for you, get yourself an efficient Maintenance Schedule Template in Pages to use for any maintenance scheduling purposes. Template.net has a wide selection of ready-made templates that are fully downloadable, 100% customizable, and highly printable. With the help of these templates, you'll be designing and printing high-quality and professionally made maintenance schedules in no time. So what else do you need to know about what we have to offer? It would be best for you to find it out yourselves. Go ahead and start subscribing to our Maintenance Schedule Templates in Pages right away.

Maintenance Schedule Templates in Apple Numbers

Explore professionally designed, customizable maintenance schedule templates in Apple Numbers. Free to download and print. Get started now!