Free Operations Stock Level Optimization Review

I. Introduction

A. Purpose of the Review

The purpose of this review is to evaluate the effectiveness and efficiency of our current operations stock level optimization strategies. This includes an analysis of our current stock levels, the strategies we use to optimize these levels, and the impact of these strategies on our operations. The goal is to identify areas of improvement and propose changes that could lead to increased operational efficiency and cost savings.

B. Scope of the Review

The review will cover all aspects of our operations stock level management. This includes, but is not limited to, the following areas:

Current stock levels across all warehouses and distribution centers

Current demand forecasting methods and their accuracy

Efficiency of our Just-in-Time inventory system

Effectiveness of our bulk purchasing strategy

Review of our Vendor Managed Inventory system

The review will also assess the potential impact of proposed changes to our stock level optimization strategies on our operations, costs, and vendor relationships. The findings of this review will be used to inform our implementation plan for any proposed changes.

II. Review of Current Stock Levels

A. Analysis of Current Stock Levels

To provide a comprehensive understanding of our current stock levels, we have compiled data on various key metrics. These metrics include the quantity of each item in stock, the location of these items in our warehouses and distribution centers, and the rate at which these items are being used or sold. The following table provides an overview of these metrics for a selection of items:

Item | Quantity in Stock | Primary Location | Usage Rate |

|---|---|---|---|

Notebooks | 1200 | Warehouse 1 | 200/week |

Based on the data, we have 1200 notebooks in stock, primarily located in Warehouse 1, with a usage rate of 200 notebooks per week. This suggests that our current stock of notebooks will last for about 6 weeks given the current usage rate. In addition, the usage rate of 200 notebooks per week indicates a steady demand for this item. If this demand is consistent and predictable, it may be possible to further optimize our stock levels by aligning our restocking schedule with this usage rate. If it takes 2 weeks to restock notebooks, we may want to initiate the restocking process when our stock level drops to 400 notebooks (2 weeks’ worth of stock). This could help us maintain an optimal stock level while minimizing the costs associated with holding excess inventory.

B. Potential Impact of Current Stock Levels

Based on the analysis of the current stock levels, we can infer several potential impacts:

Stock Availability: If the usage rate exceeds the replenishment rate, it could lead to stockouts. Stockouts could disrupt operations and lead to lost sales. They could also lead to rush orders, which could increase costs and strain relationships with suppliers.

Storage and Handling Costs: High stock levels could lead to increased storage and handling costs. Overcrowded warehouses could lead to inefficiencies in picking and packing orders. High stock levels could also lead to issues such as obsolete inventory and waste.

Cash Flow: High stock levels could tie up capital that could be used elsewhere in the business. This could impact the company’s cash flow and financial health. On the other hand, too low stock levels could lead to lost sales and negatively impact cash flow.

Supplier Relationships: The frequency and volume of reorders can impact relationships with suppliers. Frequent small orders might increase administrative costs for both parties, while large infrequent orders might lead to longer lead times and higher transportation costs.

Operational Efficiency: The efficiency of operations could be impacted by the current stock levels. For instance, frequent stockouts could lead to backorders and delays in order fulfillment, affecting customer satisfaction. On the other hand, overstocking could lead to inefficiencies in warehouse management and increase the risk of damage or obsolescence.

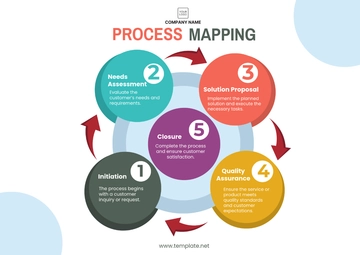

III. Review of Stock Optimization Strategies

A. Results of Demand Forecasting Review

Accuracy of forecasts: The forecasts were found to be 85% accurate on average, which is within the acceptable range for our industry.

Role in determining stock levels: The forecasts play a crucial role in determining stock levels, with stock levels closely following forecasted demand.

Impact of inaccurate forecasts: Inaccurate forecasts were found to lead to stockouts in some cases and overstocking in others, both of which have negative impacts on operations and costs.

B. Results of Just-in-Time Inventory System Review

Efficiency of the system: The Just-in-Time system was found to be highly efficient, with minimal stock being held at any given time.

Impact on storage costs and order fulfillment: The system has significantly reduced storage costs and improved order fulfillment times.

Challenges in implementation: Some challenges were identified in the implementation of the system, including the need for accurate demand forecasting and reliable suppliers.

C. Results of Bulk Purchasing Strategy Review

Effectiveness of the strategy: The bulk purchasing strategy was found to lead to significant cost savings due to volume discounts.

Impact on stock levels: However, the strategy sometimes leads to overstocking, which increases storage costs and ties up capital.

Impact on supplier relationships and cash flow: The strategy has improved relationships with suppliers due to large, consistent orders, but it has also tied up capital in inventory, impacting cash flow.

D. Results of Vendor Managed Inventory System Review

Performance of the system: The Vendor Managed Inventory system was found to be performing well, with suppliers effectively managing stock levels.

Impact on order fulfillment and supplier relationships: The system has improved order fulfillment times and strengthened relationships with suppliers.

Areas of improvement: Some areas of improvement were identified, including the need for better communication with suppliers and more accurate demand forecasting.

IV. Proposed Changes and Their Potential Impact

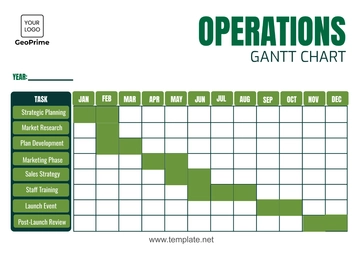

Here, we present a comprehensive review of the proposed changes to the company’s stock level optimization strategies and their potential impact on operations, costs, and vendor relationships which is outlined in the following table:

Proposed Changes | Operational Impact | Cost Impact | Vendor Relationship Impact |

|---|---|---|---|

Negotiating bulk purchasing agreements with suppliers | May lead to overstock if not managed carefully | Lower per-unit costs due to volume discounts | Can strengthen relationships with suppliers due to consistent, large orders |

Negotiating bulk purchasing agreements with suppliers can have a significant operational impact. If not managed carefully, it may lead to overstock. Overstocking can disrupt operations as it requires more storage space and could potentially lead to waste if items become obsolete before they can be used. However, with careful management and accurate demand forecasting, bulk purchasing can ensure that sufficient stock is always available to meet demand, thereby reducing the risk of stockouts and ensuring smooth operations.

From a cost perspective, bulk purchasing can also lead to lower per-unit costs due to volume discounts. This can result in significant cost savings, especially for items with high turnover rates. However, these savings need to be balanced against the potential increase in storage and holding costs associated with maintaining larger inventories. Furthermore, tying up capital in inventory can impact cash flow, which could have implications for other areas of the business.

In terms of vendor relationships, bulk purchasing may lead to stronger relationships with suppliers due to consistent, large orders. This can improve negotiation power and lead to better terms and conditions. However, it also increases dependency on suppliers, which could be a risk if a supplier fails to deliver. Therefore, while bulk purchasing can strengthen supplier relationships, it’s important to have contingency plans in place to manage supplier risks.

In general, these proposed changes aim to improve the efficiency and cost-effectiveness of stock level management. However, each change comes with its own set of challenges and considerations, and must be implemented carefully to ensure the desired outcomes are achieved. It’s also important to note that these changes are not mutually exclusive and can often be implemented in combination for greater effect.

V. Conclusion

The review has provided valuable insights into the current state of the company’s stock level management and optimization strategies. The overview of the current stock levels revealed potential impacts on operations, costs, and vendor relationships. It highlighted the need for careful management of stock levels to balance the benefits of availability and cost savings against the risks of overstocking and stockouts.

The review of stock optimization strategies revealed the effectiveness of the company’s demand forecasting methods, Just-in-Time inventory system, bulk purchasing strategy, and Vendor Managed Inventory system. Each of these strategies has its own strengths and challenges, and their success depends on accurate demand forecasting, efficient operations, and strong supplier relationships. The proposed changes aim to further optimize stock levels and enhance operational efficiency. However, they need to be implemented carefully, with ongoing monitoring and adjustment, to ensure they deliver the expected benefits without causing unintended negative impacts. This review serves as a foundation for continuous improvement in the company’s stock level optimization efforts.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Optimize stock levels effectively with the Operations Stock Level Optimization Review Template available on Template.net! This customizable and editable review template ensures a convenient approach to analyzing and improving stock levels. Utilize the AI Editor Tool to easily enhance inventory management efficiency and maintain cost-effective operations! Get your ally today!