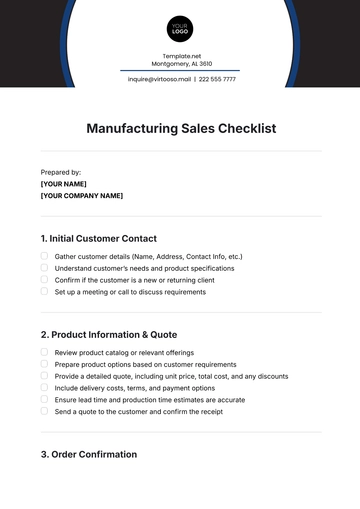

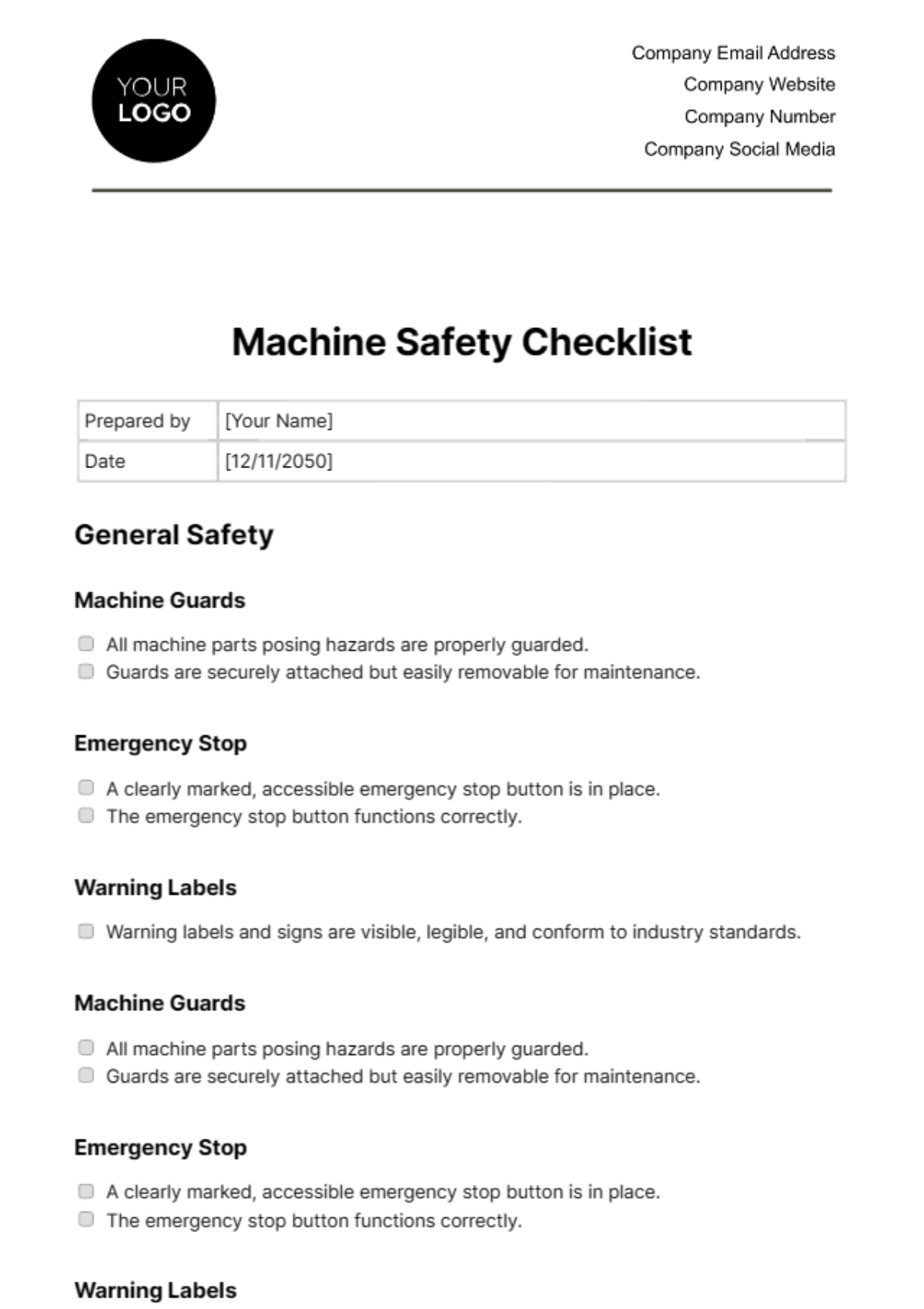

Free Machine Safety Checklist

Prepared by | [Your Name] |

Date | [12/11/2050] |

General Safety

Machine Guards

All machine parts posing hazards are properly guarded.

Guards are securely attached but easily removable for maintenance.

Emergency Stop

A clearly marked, accessible emergency stop button is in place.

The emergency stop button functions correctly.

Warning Labels

Warning labels and signs are visible, legible, and conform to industry standards.

Machine Guards

All machine parts posing hazards are properly guarded.

Guards are securely attached but easily removable for maintenance.

Emergency Stop

A clearly marked, accessible emergency stop button is in place.

The emergency stop button functions correctly.

Warning Labels

Warning labels and signs are visible, legible, and conform to industry standards.

Electrical Safety

Wiring and Cables

All wires and cables are in good condition and properly grounded.

Electrical Panels

Electrical panels are accessible, clearly labeled, and have a disconnect switch for maintenance.

Mechanical Safety

Moving Parts

All moving parts such as gears and belts are properly shielded.

Safety interlocks are in place to prevent machine operation during maintenance.

Vibration and Noise

Vibration levels are within acceptable limits.

Noise is adequately controlled to prevent hearing damage.

Operational Safety

Control Systems

Machine controls are clearly labeled and functioning properly.

Systems prevent unauthorized machine operation.

Maintenance and Inspection Records

Regular maintenance and inspection records are maintained and up-to-date.

Procedures for reporting and fixing faults are established.

Ergonomics and Environmental Safety

Operator Comfort

Machines are designed for comfortable operation, minimizing strain.

Controls and displays are within easy reach and view.

Work Environment

Adequate lighting is provided in the work area.

The work area is clean, organized, and free of clutter.

Personal Protective Equipment (PPE)

PPE Availability

Appropriate personal protective equipment is provided and accessible.

Training on the correct use of PPE is conducted.

Training and Awareness

Operator Training

Operators are trained in safe machine operation.

Ongoing safety training and awareness programs are in place.

Reporting and Emergency Procedures

Incident Reporting

Clear procedures for reporting safety incidents are established.

Employees are trained in emergency response procedures.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Explore the ultimate resource for workplace safety with Template.net's Machine Safety Checklist Template. This editable and customizable template, empowered by our Ai Editor Tool, streamlines the process of assessing and enhancing machine safety protocols. Ensure compliance and mitigate risks effectively with Template.net's innovative and user-friendly solutions.

You may also like

- Cleaning Checklist

- Daily Checklist

- Travel Checklist

- Self Care Checklist

- Risk Assessment Checklist

- Onboarding Checklist

- Quality Checklist

- Compliance Checklist

- Audit Checklist

- Registry Checklist

- HR Checklist

- Restaurant Checklist

- Checklist Layout

- Creative Checklist

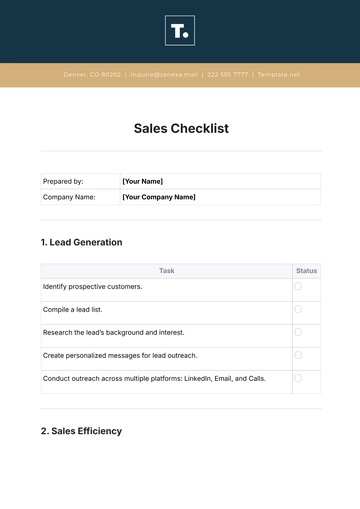

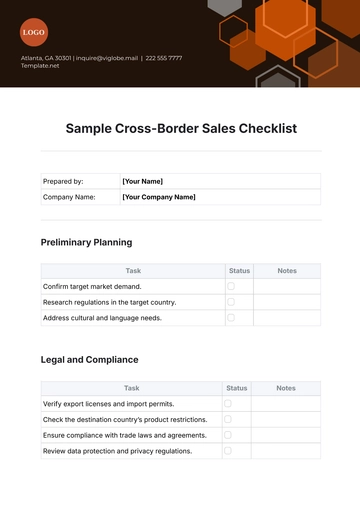

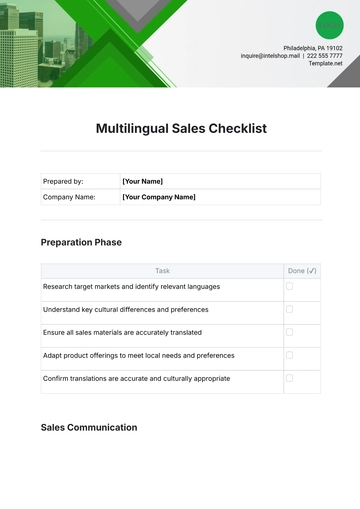

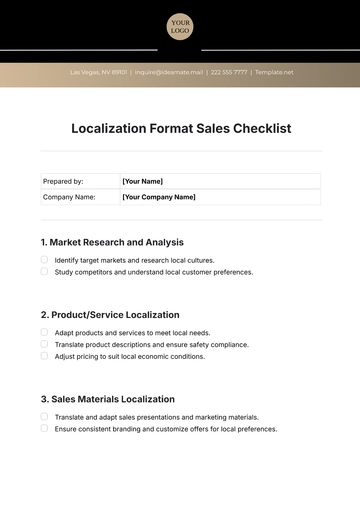

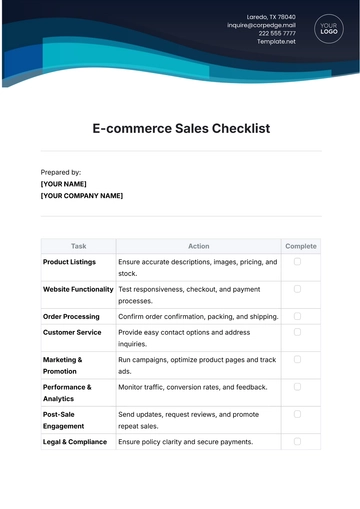

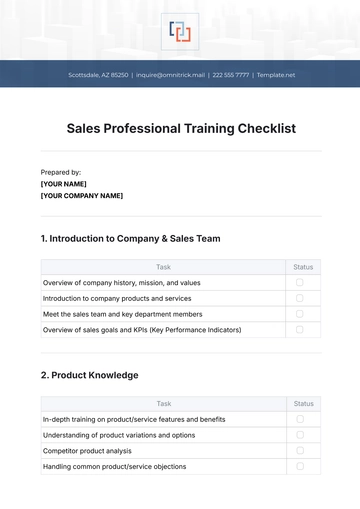

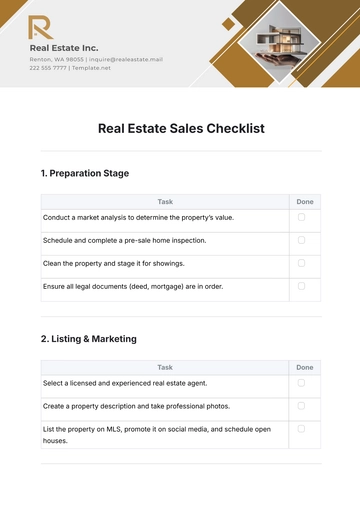

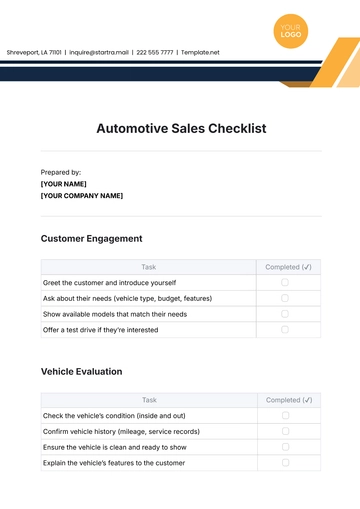

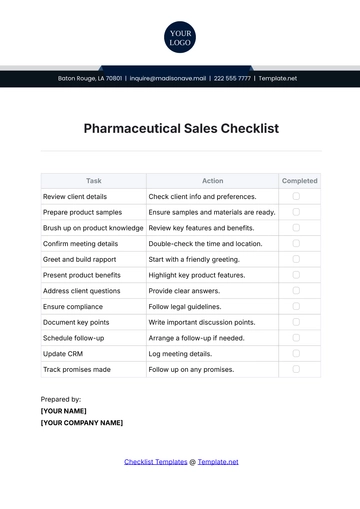

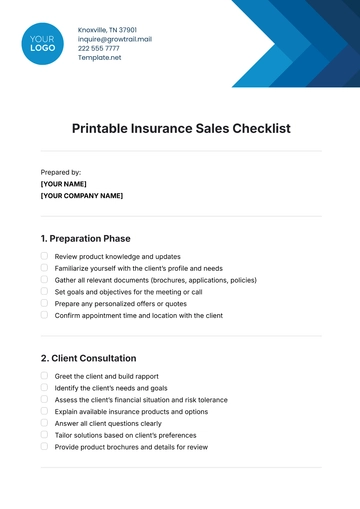

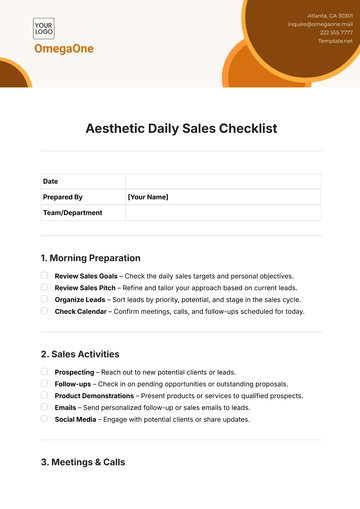

- Sales Checklist

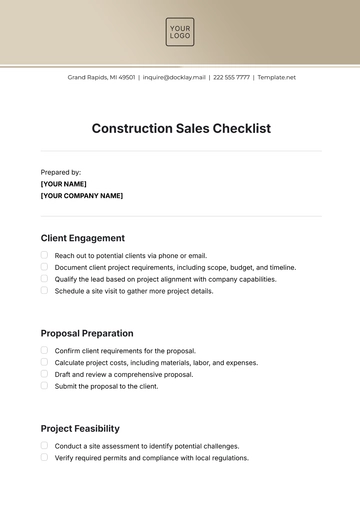

- Construction Checklist

- Task Checklist

- Professional Checklist

- Hotel Checklist

- Employee Checklist

- Moving Checklist

- Marketing Checklist

- Accounting Checklist

- Camping Checklist

- Packing Checklist

- Real Estate Checklist

- Cleaning Checklist Service

- New Employee Checklist

- Food Checklist

- Home Inspection Checklist

- Advertising Checklist

- Event Checklist

- SEO Checklist

- Assessment Checklist

- Inspection Checklist

- Baby Registry Checklist

- Induction Checklist

- Employee Training Checklist

- Medical Checklist

- Safety Checklist

- Site Checklist

- Job Checklist

- Service Checklist

- Nanny Checklist

- Building Checklist

- Work Checklist

- Office Checklist

- Training Checklist

- Website Checklist

- IT and Software Checklist

- Performance Checklist

- Project Checklist

- Startup Checklist

- Education Checklist

- Home Checklist

- School Checklist

- Maintenance Checklist

- Planning Checklist

- Manager Checklist

- Wedding Checklist

- Vehicle Checklist

- Travel Agency Checklist

- Vehicle Inspection Checklist

- Interior Design Checklist

- Backpacking Checklist

- Business Checklist

- Legal Checklist

- Nursing Home Checklist

- Weekly Checklist

- Recruitment Checklist

- Salon Checklist

- Baby Checklist

- Equipment Checklist

- Trade Show Checklist

- Party Checklist

- Hospital Bag Checklist

- Evaluation Checklist

- Agency Checklist

- First Apartment Checklist

- Hiring Checklist

- Opening Checklist

- Small Business Checklist

- Rental Checklist

- College Dorm Checklist

- New Puppy Checklist

- University Checklist

- Building Maintenance Checklist

- Work From Home Checklist

- Student Checklist

- Application Checklist