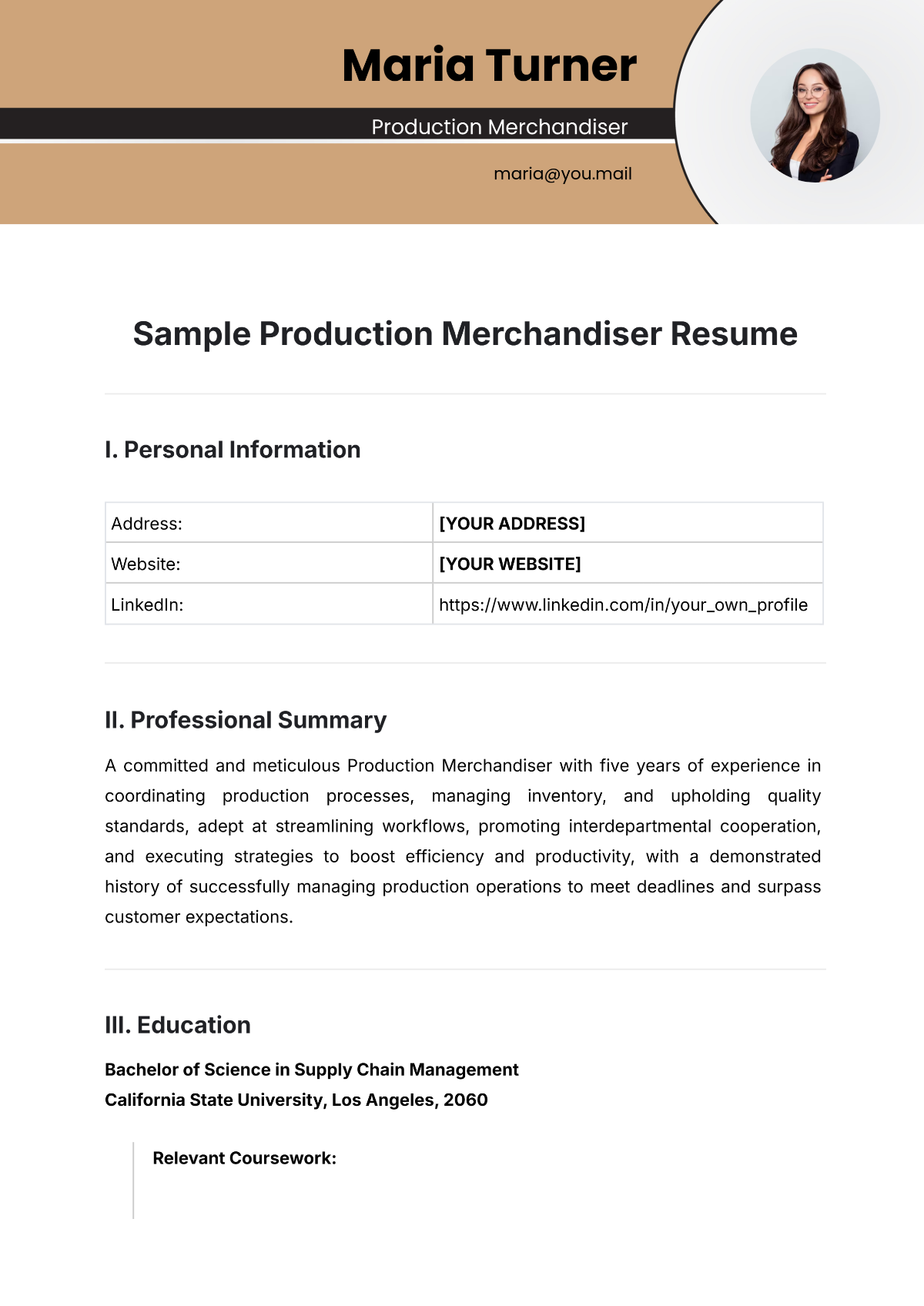

Free Sample Production Merchandiser Resume

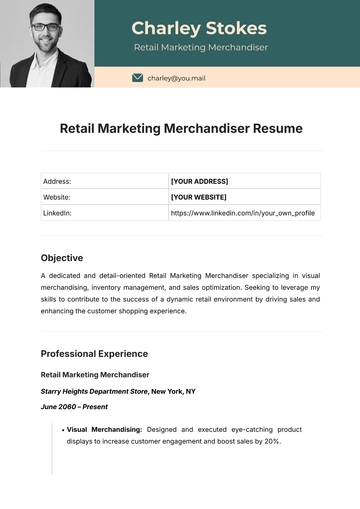

I. Personal Information

Address: | [YOUR ADDRESS] |

Website: | [YOUR WEBSITE] |

LinkedIn: | https://www.linkedin.com/in/your_own_profile |

II. Professional Summary

A committed and meticulous Production Merchandiser with five years of experience in coordinating production processes, managing inventory, and upholding quality standards, adept at streamlining workflows, promoting interdepartmental cooperation, and executing strategies to boost efficiency and productivity, with a demonstrated history of successfully managing production operations to meet deadlines and surpass customer expectations.

III. Education

Bachelor of Science in Supply Chain Management

California State University, Los Angeles, 2060

Relevant Coursework:

Advanced Production Planning and Scheduling: Strategies for optimizing production schedules to meet deadlines and improve workflow efficiency.

Inventory Optimization and Control: Techniques for minimizing waste and ensuring cost-effective inventory management.

Quality Management Systems: Implementation of industry-standard quality assurance processes and ISO compliance.

Procurement and Supplier Management: Best practices for negotiating contracts and managing supplier relationships to achieve cost savings.

Lean Manufacturing Principles: Methods for identifying inefficiencies and implementing lean processes in production.

IV. Work Experience

Production Merchandiser

NextGen Apparel Solutions, Los Angeles, CA

June 2065 – Present

Coordinated with teams for timely, quality product delivery.

Managed inventory and conducted audits to optimize stock and reduce waste.

Ensured product quality through inspections and protocols.

Negotiated contracts and secured favorable supplier pricing.

Improved processes to boost efficiency and cut lead times.

Assistant Production Manager

Innovate Textiles Co., San Francisco, CA

February 2060 – May 2065

Coordinated production: scheduling, allocation, and workflow.

Regularly evaluated production staff and offered coaching and training.

Analyzed data to spot production trends and improvement opportunities.

Coordinated with teams and stakeholders to ensure smooth production.

Resolved issues quickly to minimize downtime and sustain productivity.

V. Qualifications

Production Coordination: Skilled in coordinating production processes, scheduling, resource allocation, and quality control.

Inventory Management: Skilled in managing inventory levels, conducting regular audits, and implementing strategies to minimize waste and optimize stock levels.

Quality Assurance: Experienced in implementing and enforcing quality assurance protocols to ensure products meet or exceed industry standards.

Cross-functional Collaboration: Ability to collaborate effectively with cross-functional teams, including production staff, logistics, and sales, to streamline operations and achieve organizational goals.

Problem-solving Skills: Demonstrated ability to identify issues, analyze root causes, and implement effective solutions to resolve production challenges.

Communication: Strong verbal and written communication skills, with the ability to convey complex information clearly and effectively to diverse audiences.

VI. Achievements

Implemented a new inventory system, cutting holding costs by 15%.

Streamlined production, boosting efficiency by 20% and cutting lead times by 25%.

Boosted productivity and cut errors by 12% through staff training programs.

Negotiated supplier contracts, achieving 10% cost savings on materials.

Received the "Excellence in Production Management" award in 2061.

VII. References

Available upon request.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

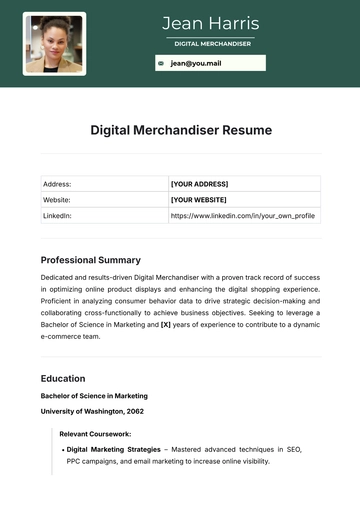

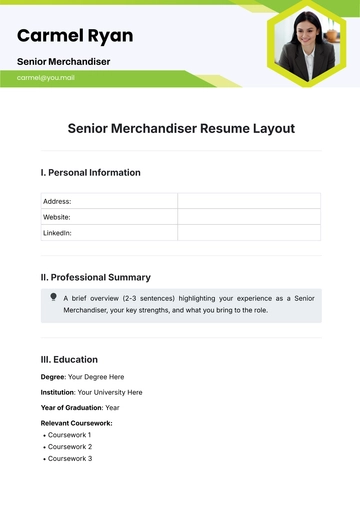

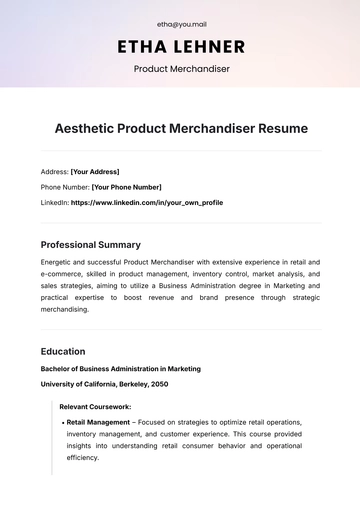

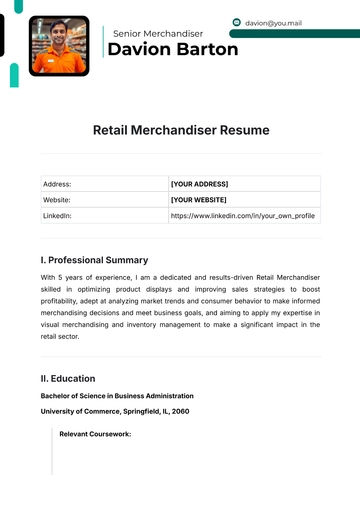

Boost your career with the Production Merchandiser Resume from Template.net. This customizable and editable template is designed for impact. Easily personalize your resume with our Ai Editor Tool to showcase your skills and experience. Make a lasting impression in the production industry with a professional resume tailored to your strengths.

You may also like

- Simple Resume

- High School Resume

- Actor Resume

- Accountant Resume

- Academic Resume

- Corporate Resume

- Infographic Resume

- Sale Resume

- Business Analyst Resume

- Skills Based Resume

- Professional Resume

- ATS Resume

- Summary Resume

- Customer Service Resume

- Software Engineer Resume

- Data Analyst Resume

- Functional Resume

- Project Manager Resume

- Nurse Resume

- Federal Resume

- Server Resume

- Administrative Assistant Resume

- Sales Associate Resume

- CNA Resume

- Bartender Resume

- Graduate Resume

- Engineer Resume

- Data Science Resume

- Warehouse Resume

- Volunteer Resume

- No Experience Resume

- Chronological Resume

- Marketing Resume

- Executive Resume

- Truck Driver Resume

- Cashier Resume

- Resume Format

- Two Page Resume

- Basic Resume

- Manager Resume

- Supervisor Resume

- Director Resume

- Blank Resume

- One Page Resume

- Developer Resume

- Caregiver Resume

- Personal Resume

- Consultant Resume

- Administrator Resume

- Officer Resume

- Medical Resume

- Job Resume

- Technician Resume

- Clerk Resume

- Driver Resume

- Data Entry Resume

- Freelancer Resume

- Operator Resume

- Printable Resume

- Worker Resume

- Student Resume

- Doctor Resume

- Merchandiser Resume

- Architecture Resume

- Photographer Resume

- Chef Resume

- Lawyer Resume

- Secretary Resume

- Customer Support Resume

- Computer Operator Resume

- Programmer Resume

- Pharmacist Resume

- Electrician Resume

- Librarian Resume

- Computer Resume

- IT Resume

- Experience Resume

- Instructor Resume

- Fashion Designer Resume

- Mechanic Resume

- Attendant Resume

- Principal Resume

- Professor Resume

- Safety Resume

- Waitress Resume

- MBA Resume

- Security Guard Resume

- Editor Resume

- Tester Resume

- Auditor Resume

- Writer Resume

- Trainer Resume

- Advertising Resume

- Harvard Resume

- Receptionist Resume

- Buyer Resume

- Physician Resume

- Scientist Resume

- 2 Page Resume

- Therapist Resume

- CEO resume

- General Manager Resume

- Attorney Resume

- Project Coordinator Resume

- Bus Driver Resume

- Cook Resume

- Artist Resume

- Pastor Resume

- Recruiter Resume

- Team Leader Resume

- Apprentice Resume

- Police Resume

- Military Resume

- Personal Trainer Resume

- Contractor Resume

- Dietician Resume

- First Job Resume

- HVAC Resume

- Psychologist Resume

- Public Relations Resume

- Support Specialist Resume

- Computer Technician Resume

- Drafter Resume

- Foreman Resume

- Underwriter Resume

- Photo Resume

- Teacher Resume

- Modern Resume

- Fresher Resume

- Creative Resume

- Internship Resume

- Graphic Designer Resume

- College Resume