Free Annual Test Maintenance Report

Prepared by: [YOUR NAME]

Company: [YOUR COMPANY NAME]

Date of Testing: [DATE]

I. Executive Summary

The Annual Test Maintenance Report for the manufacturing equipment at [YOUR COMPANY NAME] provides a detailed overview of the maintenance activities and testing procedures conducted over the past year. This report outlines the performance of the equipment, identifies any issues encountered, and presents recommendations for future maintenance to ensure the continued efficiency and safety of our manufacturing operations.

II. Introduction

A. Purpose

The purpose of this report is to document the annual maintenance and testing activities for the manufacturing equipment at [YOUR COMPANY NAME]. This report aims to:

Ensure compliance with safety and regulatory standards.

Maintain optimal performance of manufacturing equipment.

Identify and resolve potential issues.

Plan for future maintenance activities.

B. Scope

This report covers all major pieces of equipment used in the manufacturing process, including CNC machines, robotic arms, conveyor systems, and other critical machinery.

III. Testing Procedures

A. Overview

The testing procedures were carried out to assess the functionality, safety, and efficiency of the manufacturing equipment. These procedures included routine inspections, performance tests, safety checks, and calibration activities.

B. Methodology

Routine Inspections: Daily and weekly visual inspections were conducted to identify any visible signs of wear and tear.

Performance Tests: Monthly performance tests were conducted to measure the efficiency and output of the equipment.

Safety Checks: Quarterly safety checks were performed to ensure all equipment meets regulatory safety standards.

Calibration: Annual calibration of equipment was carried out to maintain accuracy and precision in the manufacturing process.

IV. Maintenance Activities

A. Preventive Maintenance

Regular preventive maintenance activities were scheduled and executed to minimize the risk of equipment failure. These activities included:

Lubrication of moving parts.

Replacement of worn-out components.

Cleaning of equipment to remove dust and debris.

B. Corrective Maintenance

Corrective maintenance was performed in response to equipment malfunctions or failures. This included troubleshooting, repair, and replacement of defective parts.

V. Test Results

Equipment | Test Conducted | Date | Results | Actions Taken |

|---|---|---|---|---|

CNC Machine A | Performance Test | 01/15/2050 | Passed | No action needed |

Robotic Arm B | Safety Check | 03/20/2050 | Passed | Safety guard adjusted |

Conveyor System C | Routine Inspection | 05/10/2050 | Issues Found | Belt replaced |

CNC Machine B | Calibration | 07/25/2050 | Passed | No action needed |

Robotic Arm E | Performance Test | 09/15/2050 | Failed | Motor replaced |

VI. Issues and Resolutions

A. Identified Issues

Conveyor System C: The belt showed signs of wear and required replacement.

Robotic Arm E: The motor malfunctioned during a performance test and was replaced.

B. Resolutions

The conveyor belt for System C was replaced to ensure smooth operation.

The malfunctioning motor in Robotic Arm E was replaced, and additional tests were conducted to verify the fix.

VII. Recommendations

A. Short-Term Recommendations

Continue regular preventive maintenance activities to minimize the risk of equipment failure.

Schedule additional training for maintenance staff to ensure proper handling and troubleshooting of equipment.

B. Long-Term Recommendations

Invest in advanced diagnostic tools to enhance the accuracy of performance tests.

Plan for the gradual replacement of older equipment to maintain overall manufacturing efficiency.

VIII. Appendices

Appendix A: Maintenance Logs

Detailed logs of all maintenance activities, including dates, personnel involved, and specific actions taken.

Appendix B: Test Data

Comprehensive data from all performance tests, safety checks, and calibration activities.

[YOUR COMPANY NAME] is committed to maintaining the highest standards of operational efficiency and safety in our manufacturing processes. Our dedicated team of maintenance engineers ensures that all equipment is regularly tested and maintained to support our mission of delivering high-quality products to our customers.

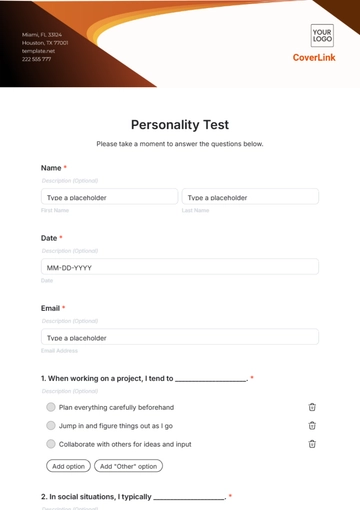

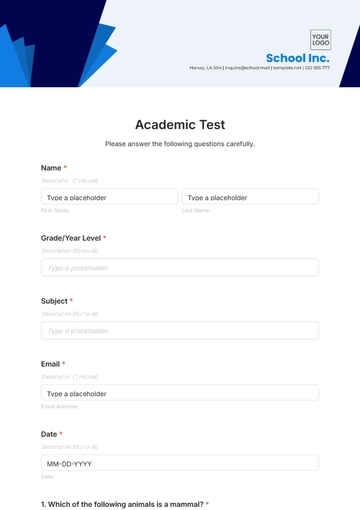

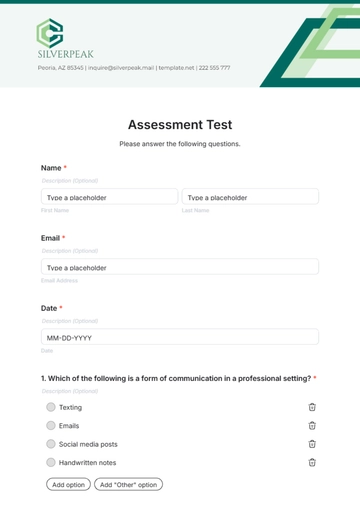

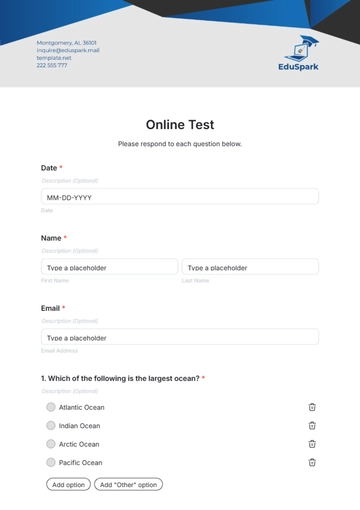

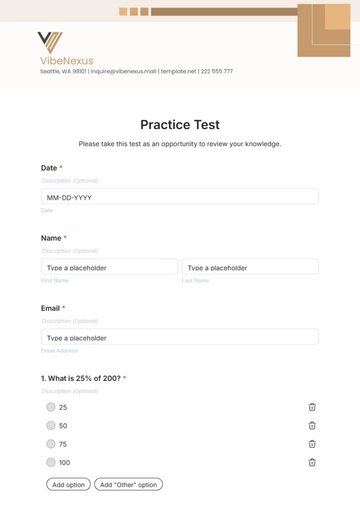

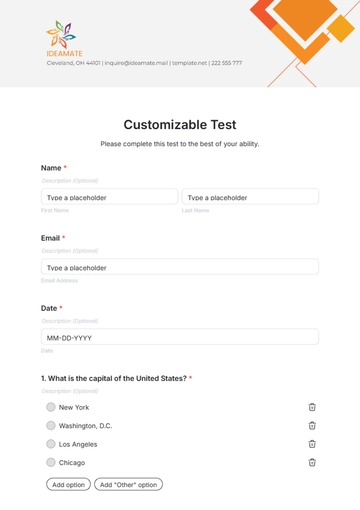

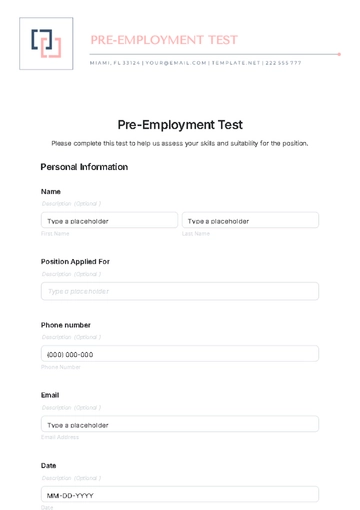

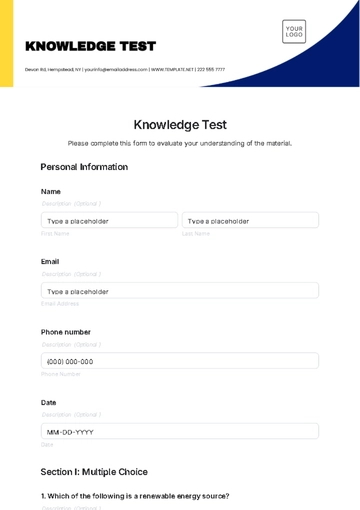

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Track annual maintenance activities with Template.net's Annual Test Maintenance Report Template. This customizable and editable template in our Ai Editor Tool allows for detailed documentation of maintenance tests. It includes sections for test schedules, procedures, results, and recommendations. Keep your annual maintenance activities well-documented and organized with this essential template.