Free Quality Control Requirements

Prepared by: [Your Name]

Date: [Date]

I. Introduction

The purpose of this Quality Control Requirements document is to outline the standards, criteria, and processes necessary to ensure that products or services meet specific quality standards. This document includes guidelines for testing, inspection, and validation to maintain consistency and reliability in production or service delivery.

II. Quality Standards

We adhere to the following quality standards to ensure that our products and services consistently meet our customers' expectations and regulatory requirements.

ISO 9001: Quality Management Systems

ISO 14001: Environmental Management Systems

ISO 45001: Occupational Health and Safety Management Systems

Industry-specific standards as applicable

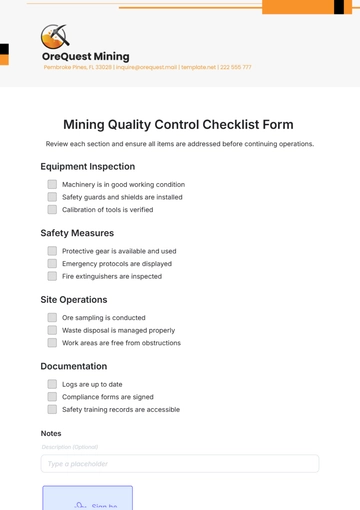

III. Testing and Inspection Procedures

All products and services undergo rigorous testing and inspection procedures to ensure compliance with predefined quality standards. The procedures are outlined as follows:

III.I Initial Inspection

Initial Inspection is conducted at the beginning of the production process to verify the integrity of raw materials and components. This inspection includes:

Material Verification: Raw materials are checked against specifications to ensure they meet required standards. This includes testing for material composition, purity, and physical properties.

Supplier Certification: Documentation and certification from suppliers are reviewed to confirm that the materials meet quality standards and regulatory requirements.

Pre-production Sampling: Samples from the first batch of raw materials are tested for compliance with specifications. Any deviations are reported and addressed before full-scale production begins.

Visual Inspection: A visual examination of materials for any defects, damage, or irregularities.

III.II In-Process Inspection

In-Process Inspection involves continuous monitoring and testing during the production process to ensure adherence to quality standards at each stage. This inspection includes:

Routine Checks: Regular checks are performed at set intervals throughout the production process. These checks include monitoring equipment calibration, machine performance, and environmental conditions.

Process Control: Parameters such as temperature, pressure, and speed are monitored to ensure they remain within specified limits. Adjustments are made as necessary to maintain quality.

Intermediary Testing: Samples are taken from different stages of production to verify that intermediate products meet quality criteria. For example, components are tested for functionality and dimensional accuracy before assembly.

Operator Inspections: Production staff perform checks as part of their routine tasks to ensure that each product conforms to quality standards.

III.III Final Inspection

Final Inspection is carried out at the end of the production line to verify that the final products meet all quality criteria before they are released for distribution. This inspection includes:

Comprehensive Testing: Final products undergo rigorous testing to verify performance, durability, and safety. This may include functional tests, stress tests, and environmental simulations.

Aesthetic Evaluation: Products are inspected for visual defects, such as scratches, dents, or color inconsistencies. Packaging is also checked for proper labeling and presentation.

Compliance Verification: Final products are reviewed to ensure they comply with all regulatory and certification requirements, including safety standards and industry-specific guidelines.

Sampling: A statistically significant sample from the production batch is tested to ensure the entire batch meets quality standards. Any issues identified in the sample can prompt further investigation and corrective action for the entire batch.

Documentation Review: Inspection records and test results are reviewed to ensure all required documentation is complete and accurate. This includes verifying that non-conformance reports have been addressed and corrective actions implemented.

IV. Documentation Requirements

Comprehensive documentation is maintained to ensure traceability and accountability throughout the quality control process. The required documentation includes:

Document Type | Description |

|---|---|

Inspection Reports | Detailed reports of all inspections conducted, including initial, in-process, and final inspections. |

Test Results | Records of all tests performed, including methodologies and outcomes. |

Non-Conformance Records | Documentation of any deviations from quality standards and the corrective actions taken. |

Calibration Certificates | Verification of the accuracy and precision of equipment used in the production and inspection processes. |

V. Non-conformance and Corrective Actions

In the event of non-conformance, the following steps are taken to rectify the issue and prevent recurrence:

V.I Identification

Identification involves the immediate recognition and documentation of any non-conforming products or services. This process includes:

Detection: Non-conformance may be identified through various means such as inspection results, customer complaints, or testing failures. Employees are trained to report issues promptly.

Documentation: All instances of non-conformance are recorded in a Non-conformance Report (NCR). This report includes details such as the nature of the non-conformance, affected products or services, and any relevant observations or test results.

Segregation: Non-conforming products or services are physically segregated to prevent their unintended use or distribution. This ensures that only conforming products proceed to the next stages of processing or delivery.

V.II Root Cause Analysis

Root Cause Analysis involves an in-depth examination to determine the underlying cause of the non-conformance. This analysis includes:

Data Collection: Gathering all relevant information related to the non-conformance, including production records, inspection reports, and personnel statements.

Analysis Techniques: Employing analytical tools such as the "Five Whys," Fishbone Diagram (Ishikawa), or Failure Mode and Effects Analysis (FMEA) to systematically identify potential causes.

Verification: Conducting tests or investigations to confirm the root cause of the non-conformance. This may involve revisiting processes, machinery, or supplier practices.

Documentation: Recording the findings of the root cause analysis in a detailed report that outlines the identified root cause and any contributing factors.

V.III Corrective Actions

Corrective Actions are implemented to address the root cause of the non-conformance and prevent recurrence. This process includes:

Action Plan: Developing a detailed plan that outlines the corrective actions to be taken. This includes specifying the responsible individuals, resources needed, and deadlines for implementation.

Implementation: Executing the corrective actions as outlined in the action plan. Actions may include changes to processes, retraining of staff, or modifications to equipment or materials.

Documentation: All corrective actions are documented in the Corrective Action Report (CAR). This report includes details on the action taken, the person responsible, and the timeline for completion.

Review and Verification: Reviewing the effectiveness of the corrective actions to ensure that they address the root cause and prevent recurrence. This may involve additional testing or inspections to verify that the issue has been resolved.

Preventive Measures: Identifying and implementing any additional preventive measures to avoid similar non-conformance issues in the future. This may include updating procedures, revising quality standards, or enhancing monitoring practices.

VI. Roles and Responsibilities

The following roles are responsible for implementing and maintaining the quality control processes:

Role | Responsibilities |

|---|---|

Quality Control Manager | Oversees the entire quality control process, ensuring compliance with standards and effective implementation of corrective actions. |

Quality Inspectors | Conduct initial, in-process, and final inspections to ensure product and service quality. |

Production Staff | Adhere to quality standards throughout the production process and assist in identifying non-conformances. |

Documentation Specialist | Maintains accurate and comprehensive documentation of all quality control activities. |

VII. Review and Revision History

This document is subject to regular review and revision to ensure continuous improvement in our quality control processes. The review and revision history are documented as follows:

Version | Date | Changes Made | Reviewed By |

|---|---|---|---|

1.0 | 2023-01-01 | Initial Release | Jane Doe |

1.1 | 2023-06-01 | Added Environmental Management Standards | John Smith |

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Ensure top-notch quality with Template.net's Quality Control Requirements Template. This editable and customizable template helps you outline quality standards and procedures for any project. Editable in our AI Editor Tool, it provides a clear and professional structure, making it easy to define and communicate quality control measures tailored to your project's specific needs.