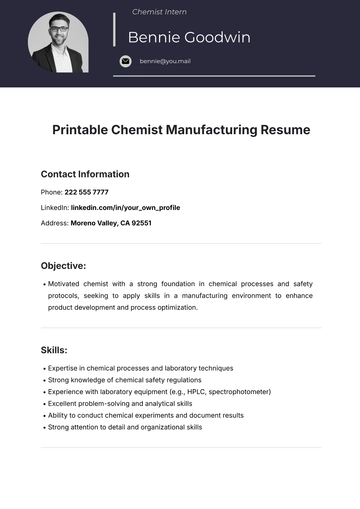

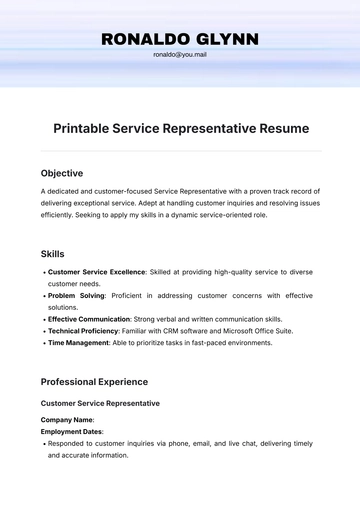

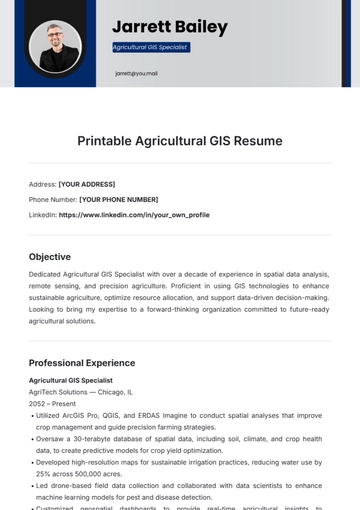

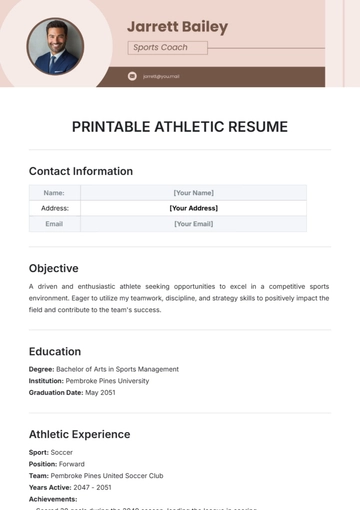

Free Printable Startup Maintenance Manager Resume

Address: [Your Address]

Phone: [Your Number]

LinkedIn: https://www.linkedin.com/in/your_own_profile

Professional Summary

Experienced and results-driven Startup Maintenance Manager with over 10 years of expertise in overseeing maintenance operations in high-growth startup environments. Skilled in facility management, equipment maintenance, process optimization, and team leadership. Adept at implementing cost-effective solutions, ensuring operational efficiency, and maintaining a safe and compliant work environment. Strong communicator and problem-solver, committed to fostering a culture of reliability and continuous improvement.

Core Competencies

Preventive & Corrective Maintenance

Team Leadership & Training

Facility & Equipment Management

Process Optimization & Troubleshooting

Safety Compliance & Risk Management

Budgeting & Cost Control

Vendor Management & Negotiation

Performance Monitoring & Reporting

Inventory & Spare Parts Management

Continuous Improvement Initiatives

Professional Experience

Startup Maintenance Manager

TechShift Innovations – New York, NY | January 2053 – Present

Oversee daily maintenance operations, ensuring equipment functionality and minimizing downtime.

Develop and implement preventive maintenance schedules, boosting efficiency by 30%.

Lead a team of 10 technicians, improving training and safety protocols, reducing accidents by 25%.

Collaborate with engineering and operations to resolve technical issues, ensuring seamless production.

Manage inventory and vendor contracts, reducing maintenance costs by 15%.

Conduct safety audits, ensuring zero safety violations for two years.

Manage a $500,000 maintenance budget, identifying cost-saving opportunities.

Maintenance Supervisor

AutoTech Manufacturing – Detroit, MI | June 2050 – December 2052

Supervised daily maintenance of machinery and facilities, improving operational efficiency.

Developed maintenance strategies, minimizing production delays and improving uptime.

Implemented a CMMS, reducing maintenance response time by 40%.

Trained a team of 12 technicians, ensuring adherence to safety protocols.

Led improvement projects, increasing overall equipment effectiveness by 18%.

Managed vendor relationships, completing projects on time and within budget.

Education

Bachelor of Science in Mechanical Engineering – University of Michigan | Graduated: May 2050

Relevant coursework: Maintenance Engineering, Thermodynamics, Manufacturing Systems, Facility Management.

Certifications

Certified Maintenance Manager (CMM) – Maintenance Management Institute, 2052

OSHA Certification – Occupational Safety and Health Administration, 2051

Six Sigma Green Belt – International Association for Six Sigma Certification, 2050

Technical Skills

Maintenance Management Software (e.g., CMMS, SAP)

HVAC, Electrical, and Plumbing Systems

Equipment Troubleshooting & Repair

Safety Management Tools

MS Office Suite (Excel, Word, PowerPoint)

Root Cause Analysis & Failure Mode Effects Analysis (FMEA)

Predictive Maintenance Techniques

Projects & Achievements

Led a project to overhaul the maintenance scheduling system at TechShift Innovations, improving equipment uptime by 20% and reducing production downtime by 15%.

Reduced annual maintenance costs by 12% at AutoTech Manufacturing by negotiating favorable contracts with equipment suppliers and streamlining spare parts inventory.

Implemented a continuous improvement initiative that resulted in a 25% reduction in unscheduled downtime within the first year of execution.

References

Available upon request.

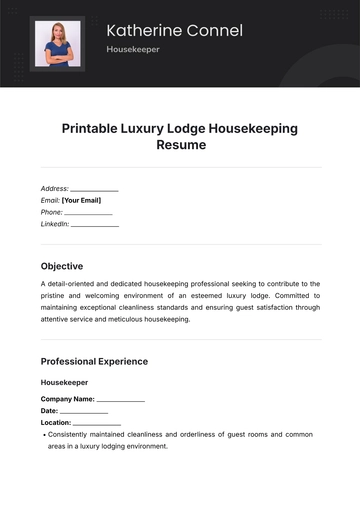

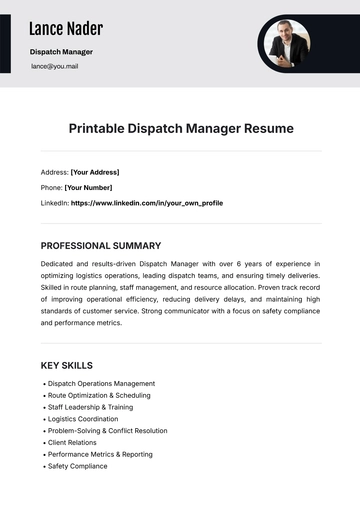

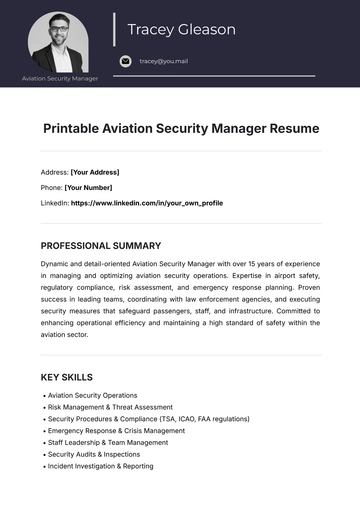

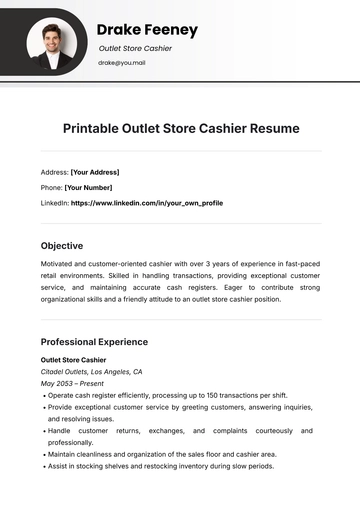

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

The Printable Startup Maintenance Manager Resume Template from Template.net offers a sleek, professional design for your career needs. Fully editable and customizable, this template allows you to tailor every section to highlight your skills and experience. Edit it easily in our AI Editor Tool to create a standout resume that fits your unique profile.

You may also like

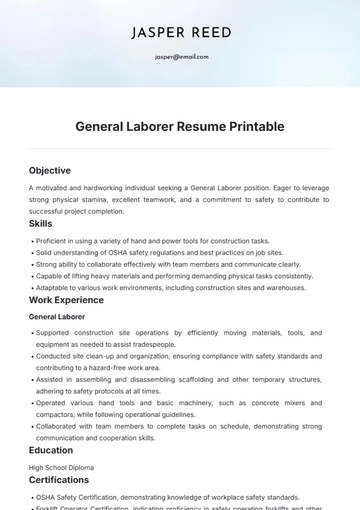

- Simple Resume

- High School Resume

- Actor Resume

- Accountant Resume

- Academic Resume

- Corporate Resume

- Infographic Resume

- Sale Resume

- Business Analyst Resume

- Skills Based Resume

- Professional Resume

- ATS Resume

- Summary Resume

- Customer Service Resume

- Software Engineer Resume

- Data Analyst Resume

- Functional Resume

- Project Manager Resume

- Nurse Resume

- Federal Resume

- Server Resume

- Administrative Assistant Resume

- Sales Associate Resume

- CNA Resume

- Bartender Resume

- Graduate Resume

- Engineer Resume

- Data Science Resume

- Warehouse Resume

- Volunteer Resume

- No Experience Resume

- Chronological Resume

- Marketing Resume

- Executive Resume

- Truck Driver Resume

- Cashier Resume

- Resume Format

- Two Page Resume

- Basic Resume

- Manager Resume

- Supervisor Resume

- Director Resume

- Blank Resume

- One Page Resume

- Developer Resume

- Caregiver Resume

- Personal Resume

- Consultant Resume

- Administrator Resume

- Officer Resume

- Medical Resume

- Job Resume

- Technician Resume

- Clerk Resume

- Driver Resume

- Data Entry Resume

- Freelancer Resume

- Operator Resume

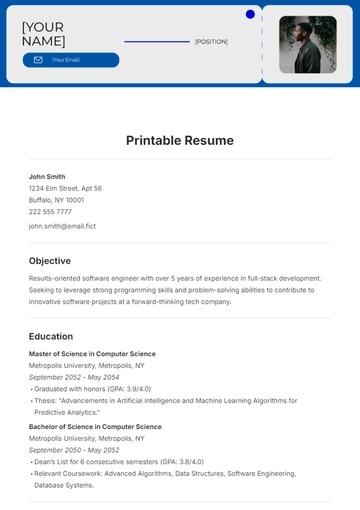

- Printable Resume

- Worker Resume

- Student Resume

- Doctor Resume

- Merchandiser Resume

- Architecture Resume

- Photographer Resume

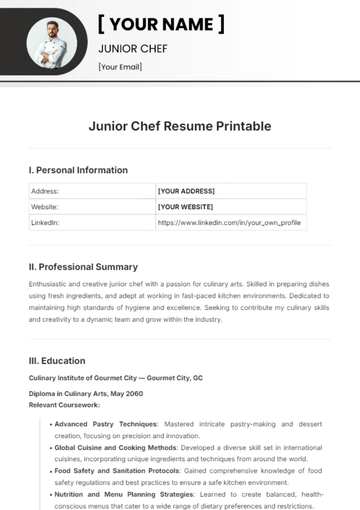

- Chef Resume

- Lawyer Resume

- Secretary Resume

- Customer Support Resume

- Computer Operator Resume

- Programmer Resume

- Pharmacist Resume

- Electrician Resume

- Librarian Resume

- Computer Resume

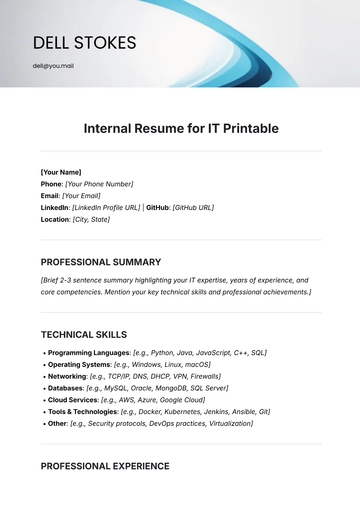

- IT Resume

- Experience Resume

- Instructor Resume

- Fashion Designer Resume

- Mechanic Resume

- Attendant Resume

- Principal Resume

- Professor Resume

- Safety Resume

- Waitress Resume

- MBA Resume

- Security Guard Resume

- Editor Resume

- Tester Resume

- Auditor Resume

- Writer Resume

- Trainer Resume

- Advertising Resume

- Harvard Resume

- Receptionist Resume

- Buyer Resume

- Physician Resume

- Scientist Resume

- 2 Page Resume

- Therapist Resume

- CEO resume

- General Manager Resume

- Attorney Resume

- Project Coordinator Resume

- Bus Driver Resume

- Cook Resume

- Artist Resume

- Pastor Resume

- Recruiter Resume

- Team Leader Resume

- Apprentice Resume

- Police Resume

- Military Resume

- Personal Trainer Resume

- Contractor Resume

- Dietician Resume

- First Job Resume

- HVAC Resume

- Psychologist Resume

- Public Relations Resume

- Support Specialist Resume

- Computer Technician Resume

- Drafter Resume

- Foreman Resume

- Underwriter Resume

- Photo Resume

- Teacher Resume

- Modern Resume

- Fresher Resume

- Creative Resume

- Internship Resume

- Graphic Designer Resume

- College Resume