Free Maintenance Checklist

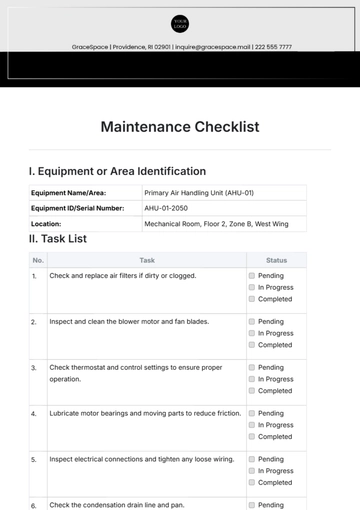

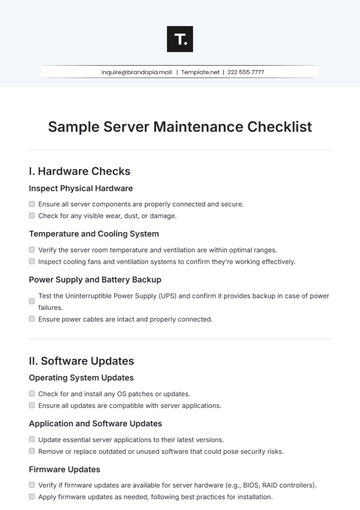

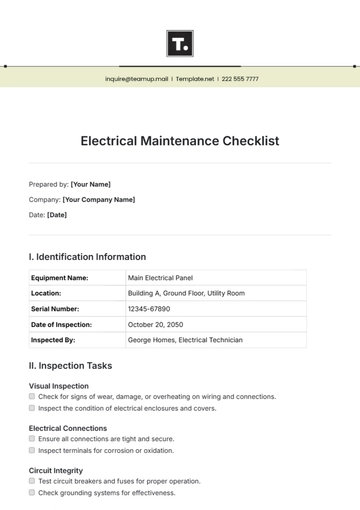

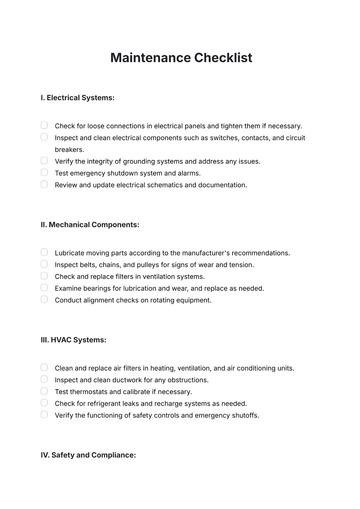

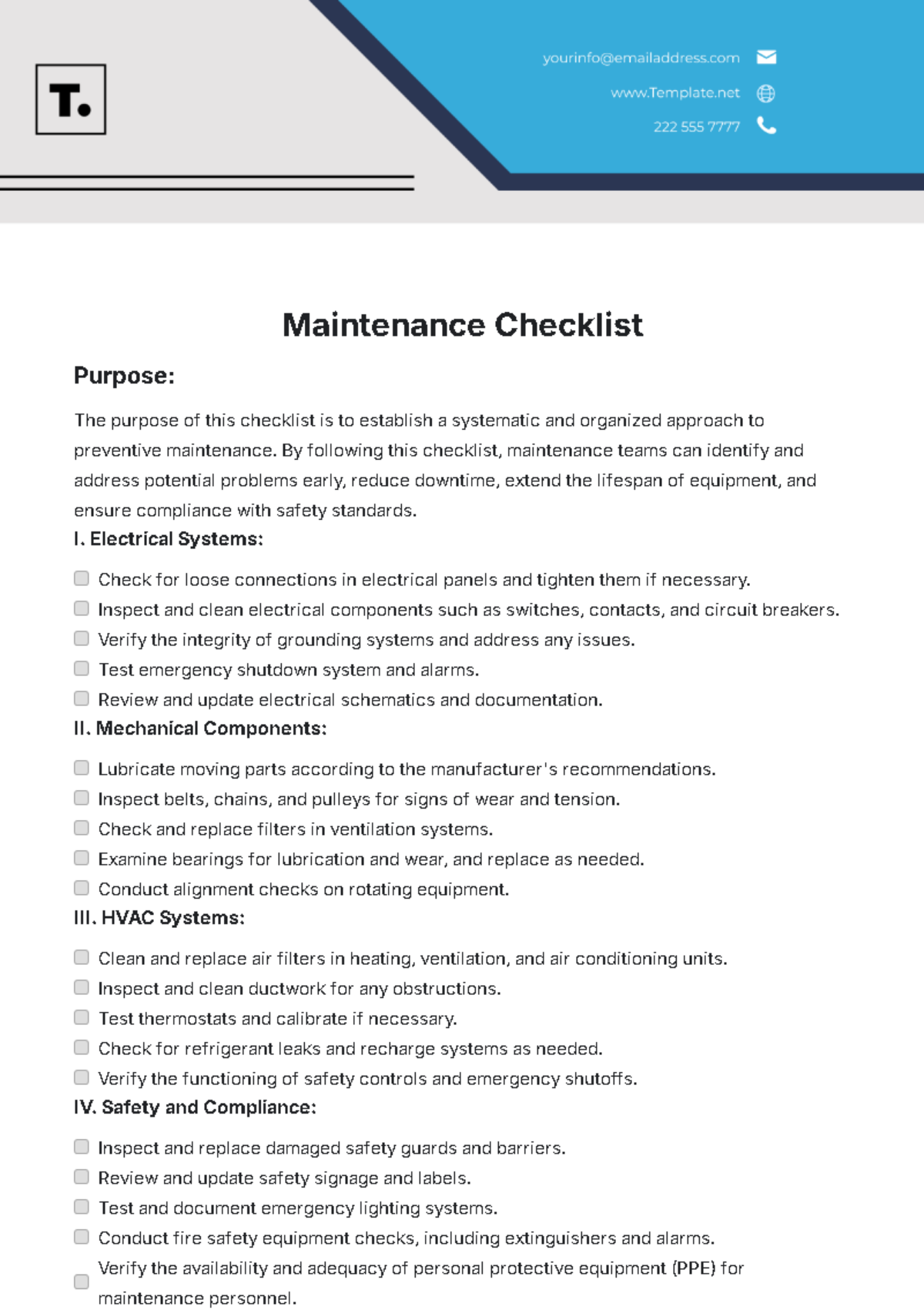

I. Electrical Systems:

Check for loose connections in electrical panels and tighten them if necessary.

Inspect and clean electrical components such as switches, contacts, and circuit breakers.

Verify the integrity of grounding systems and address any issues.

Test emergency shutdown system and alarms.

Review and update electrical schematics and documentation.

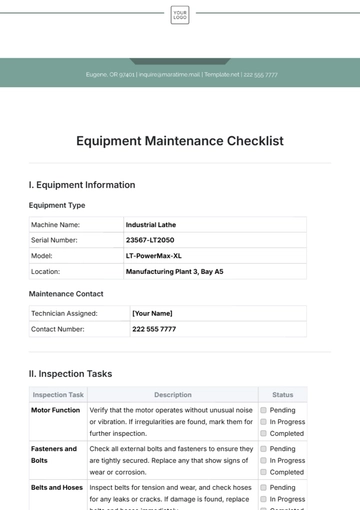

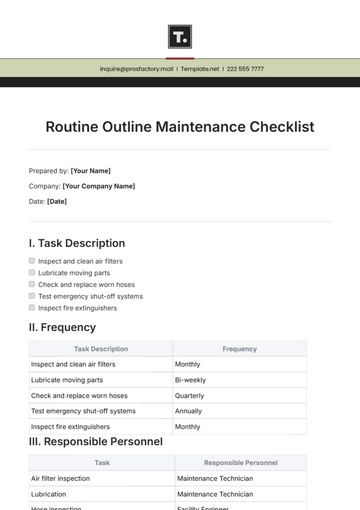

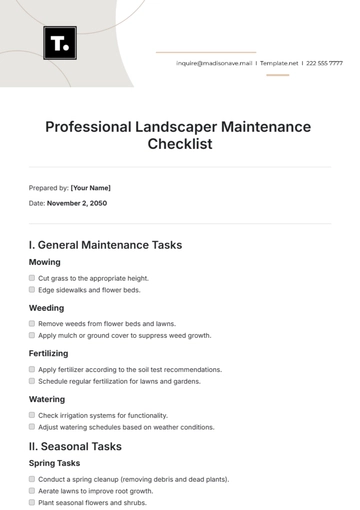

II. Mechanical Components:

Lubricate moving parts according to the manufacturer's recommendations.

Inspect belts, chains, and pulleys for signs of wear and tension.

Check and replace filters in ventilation systems.

Examine bearings for lubrication and wear, and replace as needed.

Conduct alignment checks on rotating equipment.

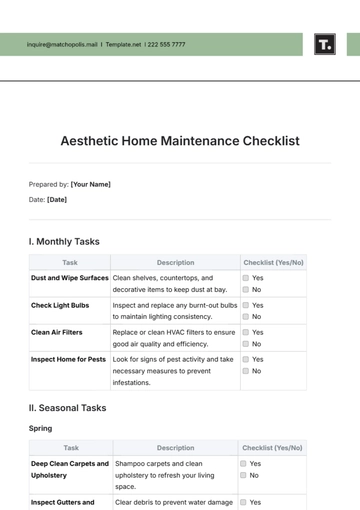

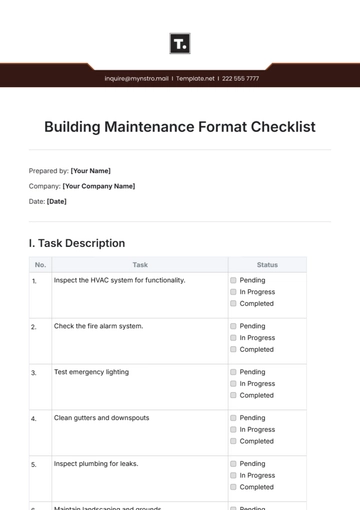

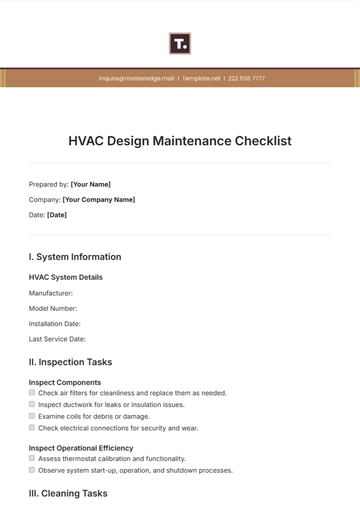

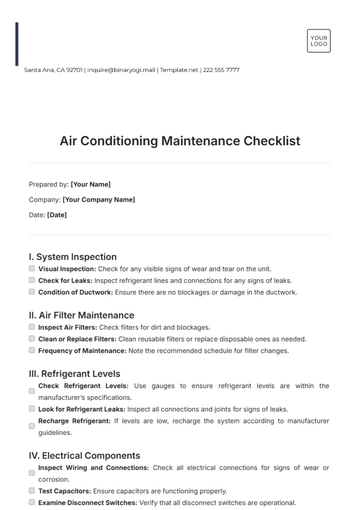

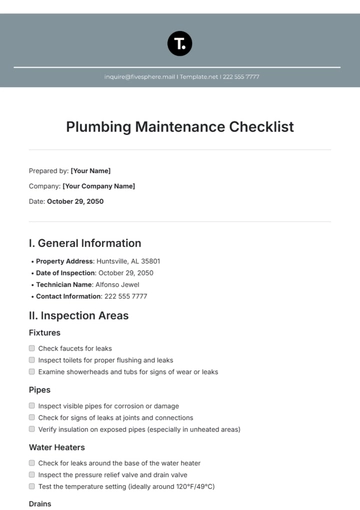

III. HVAC Systems:

Clean and replace air filters in heating, ventilation, and air conditioning units.

Inspect and clean ductwork for any obstructions.

Test thermostats and calibrate if necessary.

Check for refrigerant leaks and recharge systems as needed.

Verify the functioning of safety controls and emergency shutoffs.

IV. Safety and Compliance:

Inspect and replace damaged safety guards and barriers.

Review and update safety signage and labels.

Test and document emergency lighting systems.

Conduct fire safety equipment checks, including extinguishers and alarms.

Verify the availability and adequacy of personal protective equipment (PPE) for maintenance personnel.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

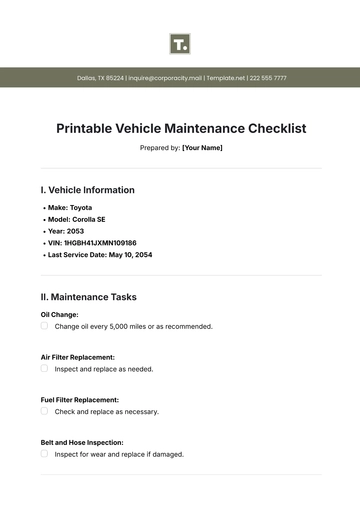

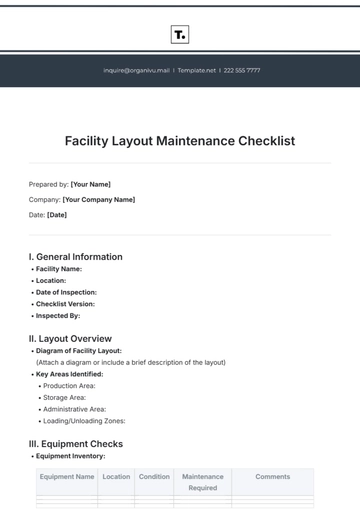

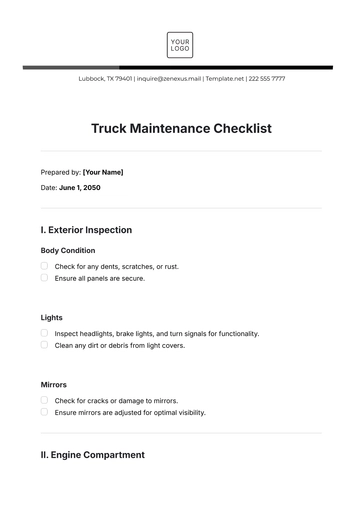

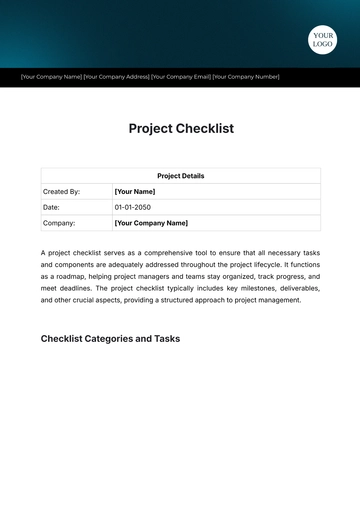

Ensure the smooth operation and longevity of your assets with our Maintenance Checklist Template from Template.net. This customizable and editable template is a comprehensive tool designed to help you organize and track maintenance tasks efficiently. Whether you're managing a facility, equipment, or vehicles, this template provides a user-friendly format to create and monitor your maintenance schedules. Streamline your maintenance processes and enhance productivity with ease.

You may also like

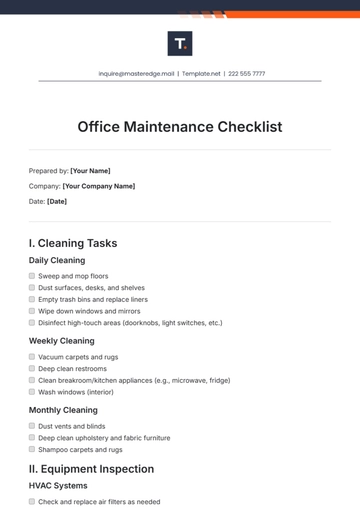

- Cleaning Checklist

- Daily Checklist

- Travel Checklist

- Self Care Checklist

- Risk Assessment Checklist

- Onboarding Checklist

- Quality Checklist

- Compliance Checklist

- Audit Checklist

- Registry Checklist

- HR Checklist

- Restaurant Checklist

- Checklist Layout

- Creative Checklist

- Sales Checklist

- Construction Checklist

- Task Checklist

- Professional Checklist

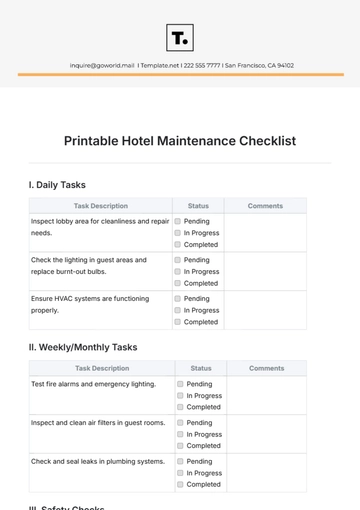

- Hotel Checklist

- Employee Checklist

- Moving Checklist

- Marketing Checklist

- Accounting Checklist

- Camping Checklist

- Packing Checklist

- Real Estate Checklist

- Cleaning Checklist Service

- New Employee Checklist

- Food Checklist

- Home Inspection Checklist

- Advertising Checklist

- Event Checklist

- SEO Checklist

- Assessment Checklist

- Inspection Checklist

- Baby Registry Checklist

- Induction Checklist

- Employee Training Checklist

- Medical Checklist

- Safety Checklist

- Site Checklist

- Job Checklist

- Service Checklist

- Nanny Checklist

- Building Checklist

- Work Checklist

- Office Checklist

- Training Checklist

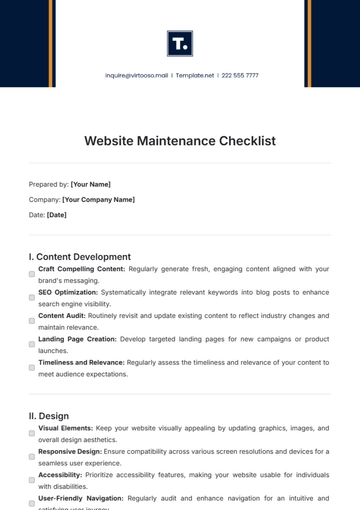

- Website Checklist

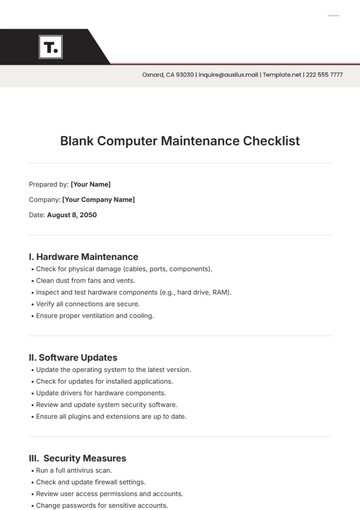

- IT and Software Checklist

- Performance Checklist

- Project Checklist

- Startup Checklist

- Education Checklist

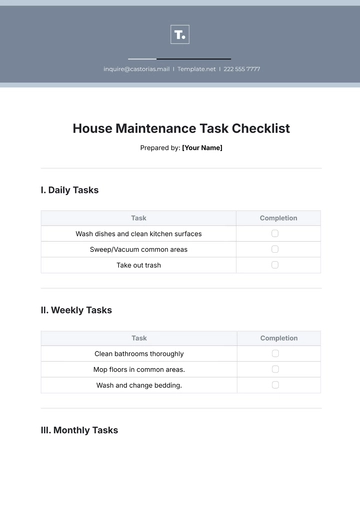

- Home Checklist

- School Checklist

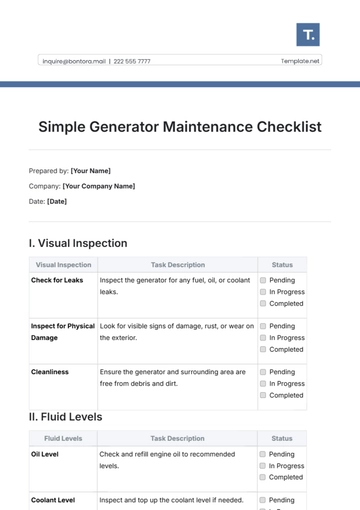

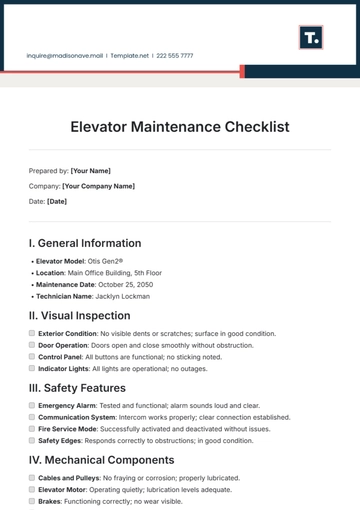

- Maintenance Checklist

- Planning Checklist

- Manager Checklist

- Wedding Checklist

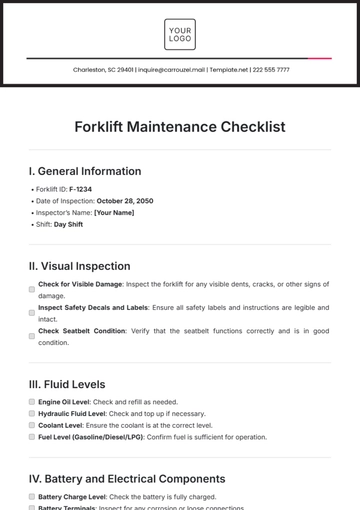

- Vehicle Checklist

- Travel Agency Checklist

- Vehicle Inspection Checklist

- Interior Design Checklist

- Backpacking Checklist

- Business Checklist

- Legal Checklist

- Nursing Home Checklist

- Weekly Checklist

- Recruitment Checklist

- Salon Checklist

- Baby Checklist

- Equipment Checklist

- Trade Show Checklist

- Party Checklist

- Hospital Bag Checklist

- Evaluation Checklist

- Agency Checklist

- First Apartment Checklist

- Hiring Checklist

- Opening Checklist

- Small Business Checklist

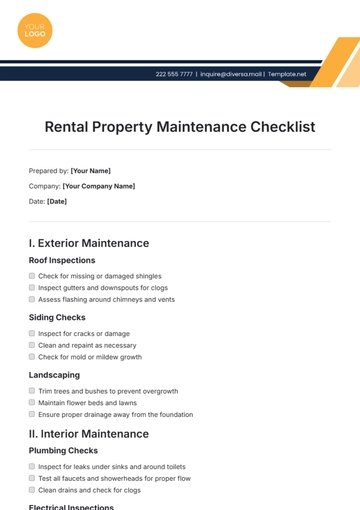

- Rental Checklist

- College Dorm Checklist

- New Puppy Checklist

- University Checklist

- Building Maintenance Checklist

- Work From Home Checklist

- Student Checklist

- Application Checklist