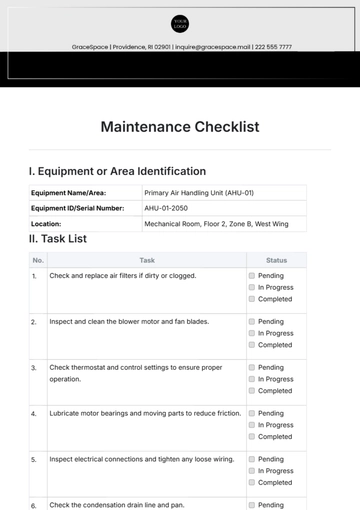

Free Equipment Maintenance Checklist

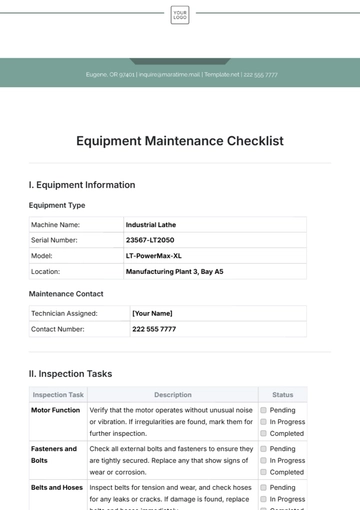

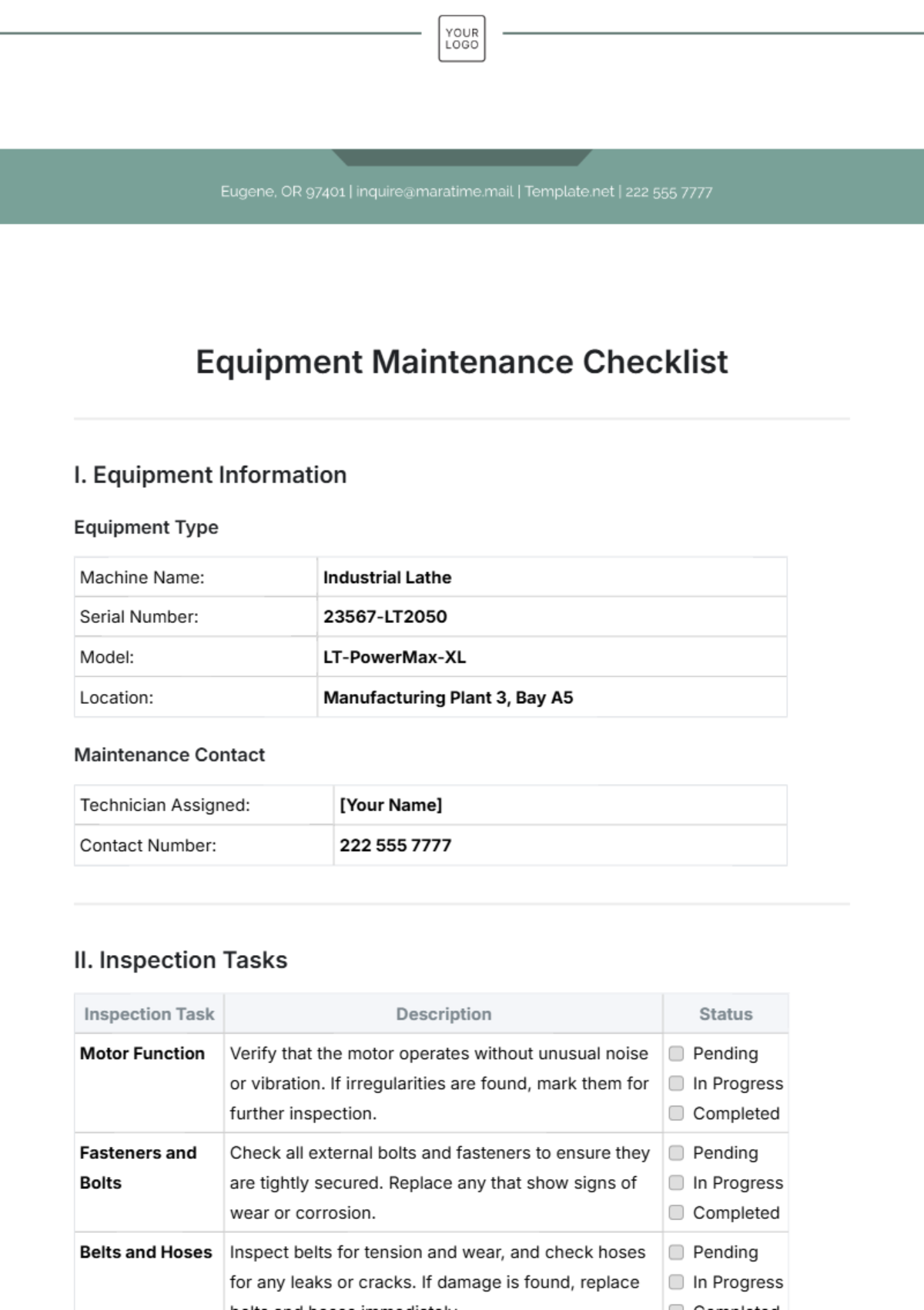

I. Equipment Information

Equipment Type

Machine Name: | Industrial Lathe |

Serial Number: | 23567-LT2050 |

Model: | LT-PowerMax-XL |

Location: | Manufacturing Plant 3, Bay A5 |

Maintenance Contact

Technician Assigned: | [Your Name] |

Contact Number: | 222 555 7777 |

II. Inspection Tasks

Inspection Task | Description | Status |

|---|---|---|

Motor Function | Verify that the motor operates without unusual noise or vibration. If irregularities are found, mark them for further inspection. |

|

Fasteners and Bolts | Check all external bolts and fasteners to ensure they are tightly secured. Replace any that show signs of wear or corrosion. |

|

Belts and Hoses | Inspect belts for tension and wear, and check hoses for any leaks or cracks. If damage is found, replace belts and hoses immediately. |

|

Moving Parts Lubrication | Apply machine-grade oil to all moving parts, especially rotating and sliding components. Note the type and amount of lubricant applied. |

|

Lubricant Levels | Check and refill lubricant reservoirs to appropriate levels. Document any low levels and refill amounts. |

|

Power Connections | Inspect power connections for any signs of overheating, corrosion, or looseness. Tighten connections as necessary. |

|

Wiring | Check all wiring for signs of wear, exposure, or damage. Replace frayed or damaged wires to prevent malfunctions. |

|

III. Frequency

Daily

Visual Inspection: Perform a quick visual inspection to ensure there are no obvious issues, such as leaks or abnormal vibrations.

Safety Guards and Emergency Stops: Verify that all safety guards are securely in place and that emergency stops are functional.

Weekly

Clean External Surfaces: Wipe down the machine to remove dust, dirt, or grime that could impact functionality.

Operating Temperatures: Use a thermal gun to check that the operating temperature remains within safe parameters.

Monthly

Full Inspection: Conduct a thorough check of major components, including bearings, controls, and hydraulic systems.

Calibration Check: Inspect sensors, gauges, and indicators for accuracy and recalibrate if necessary.

IV. Safety Checks

Emergency Procedures

Safety Checks | Description | Status |

|---|---|---|

Emergency Stop Functionality | Test emergency stop buttons and other emergency procedures to confirm they are operational. If any issues are found, schedule repairs immediately. |

|

First Aid Access | Confirm the location and availability of a first aid kit nearby and ensure it is stocked with necessary supplies. |

|

Protective Gear

Safety Checks | Description | Status |

|---|---|---|

Safety Guards | Ensure protective guards are installed around high-speed moving parts and that they are functioning as intended. |

|

Personal Protective Equipment (PPE) | Confirm the availability of PPE, including gloves, goggles, and ear protection. Note if any PPE needs replenishment. |

|

V. Documentation

Maintenance Log

Date of Inspection: | January 7, 2050 |

Technician Name: | [Your Name] |

Issues Found

Motor Sound Variation: The Motor exhibited a slight humming sound. Scheduled for further investigation.

Belt Wear: Minor wear was noticed on the primary belt. Replacement is scheduled during the next monthly inspection.

Wiring Insulation Damage: Minor insulation damage was identified. Repairs are scheduled for January 15, 2050.

VI. Action Items

Immediate Actions

Repair Belt Tensioner: Adjustment required to maintain correct belt tension. Marked for immediate maintenance.

Lubrication Replacement: Replace lubricant in the reservoir by the next inspection date due to minor contamination.

Scheduled Follow-Ups

Next Inspection Date: February 7, 2050

Additional Notes: Monitor motor performance for any further irregular sounds. Recheck belt tension in the weekly inspection.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

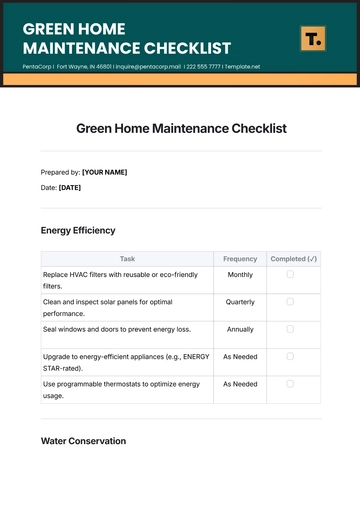

Optimize your operations with our Equipment Maintenance Checklist Template from Template.net. This editable and customizable template is perfect for businesses looking to maintain their machinery effectively. Modify the checklist effortlessly in our Ai Editor Tool to suit your specific equipment and maintenance schedule. Keep your operations running smoothly and reduce downtime with this essential tool for managing maintenance tasks.

You may also like

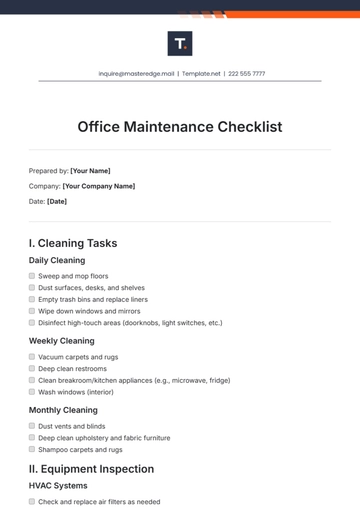

- Cleaning Checklist

- Daily Checklist

- Travel Checklist

- Self Care Checklist

- Risk Assessment Checklist

- Onboarding Checklist

- Quality Checklist

- Compliance Checklist

- Audit Checklist

- Registry Checklist

- HR Checklist

- Restaurant Checklist

- Checklist Layout

- Creative Checklist

- Sales Checklist

- Construction Checklist

- Task Checklist

- Professional Checklist

- Hotel Checklist

- Employee Checklist

- Moving Checklist

- Marketing Checklist

- Accounting Checklist

- Camping Checklist

- Packing Checklist

- Real Estate Checklist

- Cleaning Checklist Service

- New Employee Checklist

- Food Checklist

- Home Inspection Checklist

- Advertising Checklist

- Event Checklist

- SEO Checklist

- Assessment Checklist

- Inspection Checklist

- Baby Registry Checklist

- Induction Checklist

- Employee Training Checklist

- Medical Checklist

- Safety Checklist

- Site Checklist

- Job Checklist

- Service Checklist

- Nanny Checklist

- Building Checklist

- Work Checklist

- Office Checklist

- Training Checklist

- Website Checklist

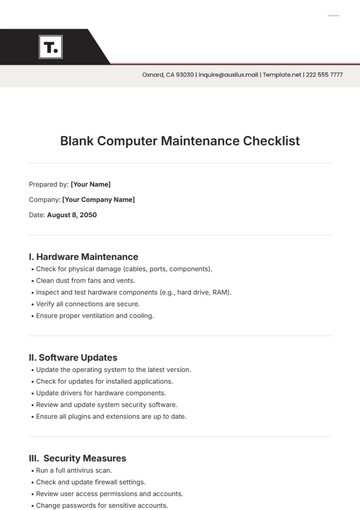

- IT and Software Checklist

- Performance Checklist

- Project Checklist

- Startup Checklist

- Education Checklist

- Home Checklist

- School Checklist

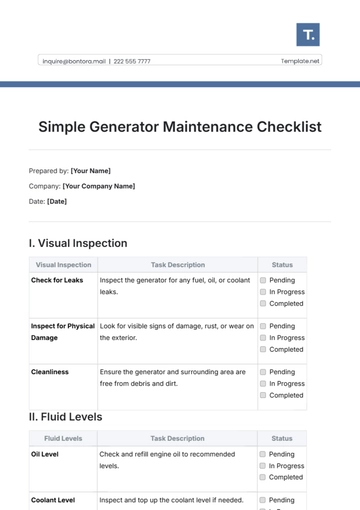

- Maintenance Checklist

- Planning Checklist

- Manager Checklist

- Wedding Checklist

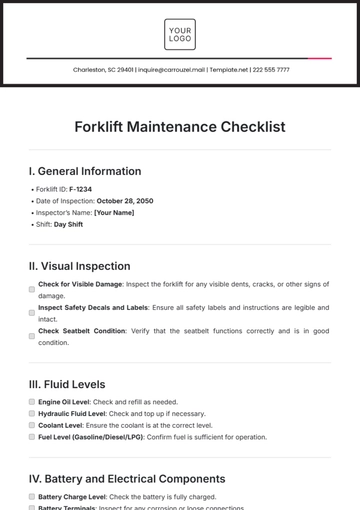

- Vehicle Checklist

- Travel Agency Checklist

- Vehicle Inspection Checklist

- Interior Design Checklist

- Backpacking Checklist

- Business Checklist

- Legal Checklist

- Nursing Home Checklist

- Weekly Checklist

- Recruitment Checklist

- Salon Checklist

- Baby Checklist

- Equipment Checklist

- Trade Show Checklist

- Party Checklist

- Hospital Bag Checklist

- Evaluation Checklist

- Agency Checklist

- First Apartment Checklist

- Hiring Checklist

- Opening Checklist

- Small Business Checklist

- Rental Checklist

- College Dorm Checklist

- New Puppy Checklist

- University Checklist

- Building Maintenance Checklist

- Work From Home Checklist

- Student Checklist

- Application Checklist