Free Risk Assessment Coursework

I. Introduction

In this coursework, [YOUR NAME] will conduct a comprehensive risk assessment to identify workplace hazards and evaluate risks to employee health and safety at [YOUR COMPANY NAME]. The primary objective is to prevent accidents and injuries by proactively addressing potential risks.

II. Scope and Objectives

The scope of this risk assessment includes all departments and areas within [YOUR COMPANY NAME]. The objectives are as follows:

Identify and document workplace hazards.

Assess the likelihood and severity of risks associated with each hazard.

Develop strategies to mitigate or eliminate identified risks.

Implement control measures to ensure the safety and well-being of employees.

III. Methodology

The risk assessment will be conducted using the following methodology:

Hazard Identification: [YOUR NAME] will systematically identify potential hazards by:

Conducting site inspections.

Reviewing incident reports and near misses.

Consulting with department heads and employees.

Risk Assessment: Once hazards are identified, [YOUR NAME] will assess the risks associated with each hazard by considering:

Probability of occurrence.

Potential severity of consequences.

Exposure of employees.

Risk Control Measures: Based on the risk assessment, [YOUR NAME] will develop control measures to mitigate or eliminate identified risks, including:

Engineering controls.

Administrative controls.

Personal protective equipment (PPE).

Implementation and Monitoring: [YOUR NAME] will oversee the implementation of control measures and establish monitoring mechanisms to ensure their effectiveness.

IV. Hazard Identification

A. Physical Hazards

Slip, trip, and fall hazards.

Machinery hazards.

Ergonomic hazards.

Noise hazards.

Electrical hazards.

B. Chemical Hazards

Exposure to hazardous chemicals.

Improper storage and handling of chemicals.

Inhalation hazards.

C. Biological Hazards

Exposure to infectious agents.

Poor sanitation practices.

Vector-borne diseases.

D. Psychosocial Hazards

Workplace stress.

Bullying and harassment.

Workload issues.

V. Risk Assessment

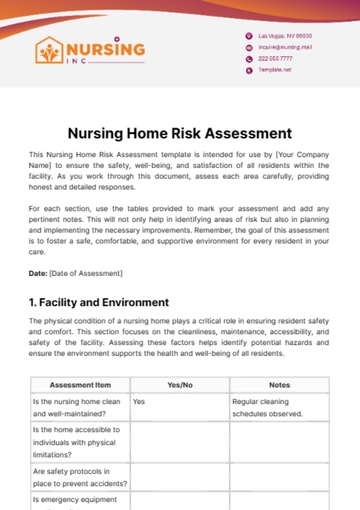

A. Risk Matrix

Likelihood/Consequence | High | Medium | Low |

|---|---|---|---|

High | High | Medium | Low |

Medium | Medium | Medium | Low |

Low | Low | Low | Low |

B. Hazardous Substances Risk Assessment

Chemical | Exposure Level | Risk Rating | Control Measures |

|---|---|---|---|

Benzene | High | High | PPE, Ventilation |

Hydrochloric Acid | Medium | Medium | Training, Labels |

Acetone | Low | Low | Storage Controls |

VI. Risk Control Measures

A. Engineering Controls

Installation of guardrails to prevent falls.

Automated machinery shutdown systems.

Ergonomic workstation design.

B. Administrative Controls

Regular safety training for employees.

Implementing a work rotation schedule to reduce exposure to hazards.

Establishing clear procedures for chemical handling and storage.

C. Personal Protective Equipment (PPE)

Safety goggles and gloves for chemical handling.

Ear protection for noise hazards.

Respirators for exposure to airborne contaminants.

VII. Implementation and Monitoring

Implementation Plan: [YOUR NAME] will develop a detailed plan for implementing control measures, assigning responsibilities, and establishing timelines.

Monitoring and Review: Regular inspections and audits will be conducted to ensure compliance with control measures. [YOUR NAME] will review incident reports and adjust control measures as necessary.

VIII. Conclusion

By systematically identifying hazards, assessing risks, and implementing control measures, [YOUR COMPANY NAME] can create a safer workplace environment for all employees, reducing the likelihood of accidents and injuries.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Enhance your risk assessment prowess with our premium Risk Assessment Coursework Template from Template.net. Tailored for efficiency, this customizable and editable template streamlines your coursework process effortlessly. Seamlessly integrate your data and insights with the AI Editor Tool for a polished output. Optimize your learning journey with this comprehensive resource.