Free Aesthetic HACCP Planning Checklist

I. HACCP Team Information

Name | Role | Signature | Date |

|---|---|---|---|

[YOUR NAME] | HACCP Coordinator | ______________ | October 17, 2060 |

Grace Tate | Quality Assurance Lead | ______________ | October 17, 2060 |

Luke Reese | Production Manager | ______________ | October 17, 2060 |

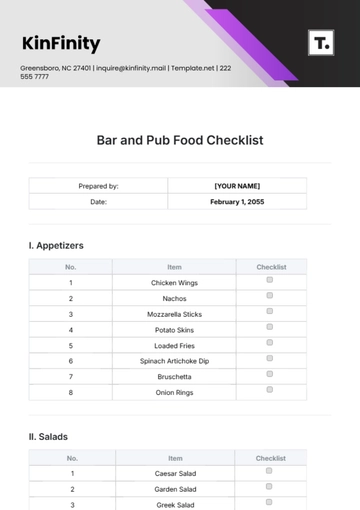

II. Product Description

Product Name: Organic Apple Juice

Ingredients: Organic apples, water, ascorbic acid (vitamin C)

Intended Use: Beverage for retail sale

Packaging: 1-liter glass bottles with tamper-evident caps

III. Process Flow Diagram

Production Process for Organic Apple Juice

Receiving Raw Materials: Inspect and weigh incoming organic apples, and check supplier documentation for organic certification.

Washing and Sorting: Wash apples thoroughly in a clean water bath for 5 minutes and sort to remove any damaged or spoiled apples.

Crushing and Pressing: Crush washed apples to create pulp and press the pulp to extract fresh apple juice.

Pasteurization: Heat the juice to a minimum of 75°C for at least 30 seconds to eliminate pathogens.

Cooling: Rapidly cool the pasteurized juice to below 5°C to prevent microbial growth.

Filling: Fill sterilized 1-liter glass bottles with chilled apple juice, ensuring no visible defects in the bottles.

Capping: Fill the bottles and seal them with tamper-evident caps to maintain product integrity.

Labeling: Label each bottle with product information, including ingredients, expiration date, and storage instructions.

Storage: Store finished products in a temperature-controlled environment (below 5°C) and monitor conditions regularly.

Distribution: Package labeled products for distribution to retailers while ensuring proper transportation conditions.

IV. Hazard Analysis

Hazard Type | Severity (1-5) | Likelihood (1-5) | Risk Level (S x L) | Control Measures |

|---|---|---|---|---|

Biological | 4 | 3 | 12 | Wash apples thoroughly before processing |

Chemical | 3 | 2 | 6 | Source from certified organic suppliers |

Physical | 5 | 1 | 5 | Inspect bottles before filling |

V. Critical Control Points (CCPs)

CCP No. | Description | Critical Limit | Monitoring Procedure | Corrective Actions |

|---|---|---|---|---|

1 | Washing of apples | Must wash for 5 minutes | Visual check of wash time | Rewash applies if the time limit is exceeded |

2 | Pasteurization temperature | Minimum 75°C for 30 seconds | Use a thermometer to monitor | Reprocess if the temperature is too low |

3 | Filling and capping process | No visible defects | Inspect each bottle before sealing | Refill or discard defective bottles |

VI. Verification Procedures

Verification Frequency: Daily

Methods Used: Calibration of thermometers, review of monitoring logs

Responsible Person: Jane Smith

VII. Record Keeping

Record Type | Frequency | Responsible Person | Date Completed |

|---|---|---|---|

Washing Records | Each batch | [YOUR NAME] | _______________ |

Pasteurization Logs | Each batch | Grace Tate | _______________ |

Filling Inspection Records | Each shift | Luke Reese | _______________ |

VIII. Review Section

Reviewed By: John Doe

Date of Review: October 17, 2060

Comments: All procedures reviewed; no changes required.

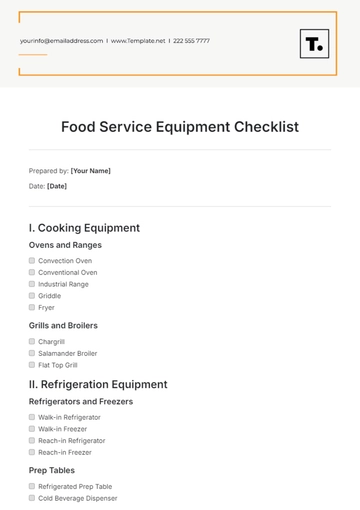

IX. Aesthetic Elements

Color Scheme: Use shades of green and blue for freshness.

Fonts: Use Arial for headings and Calibri for body text.

Icons/Images: Incorporate icons such as checkmarks for completed tasks, warning signs for hazards, and thermometer icons for temperature checks.

X. Checklist Section

Pre-Production Checklist

Inspect all incoming ingredients for quality.

Ensure all cleaning equipment is sanitized.

Verify calibration of temperature monitoring devices.

Confirm staff training on HACCP procedures.

During Production Checklist

Monitor apple washing duration.

Record pasteurization temperatures.

Inspect bottles for defects before filling.

Post-Production Checklist

Review all records for accuracy.

Conduct a final inspection of finished products.

Store product in a temperature-controlled environment.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Combine function with style using this Aesthetic HACCP Planning Checklist Template from Template.net. This editable and customizable template not only ensures your food safety planning is accurate but also visually appealing. Editable in our Ai Editor Tool, you can customize it to suit your unique processes, making it both practical and aesthetically pleasing for internal use or audits.

You may also like

- Cleaning Checklist

- Daily Checklist

- Travel Checklist

- Self Care Checklist

- Risk Assessment Checklist

- Onboarding Checklist

- Quality Checklist

- Compliance Checklist

- Audit Checklist

- Registry Checklist

- HR Checklist

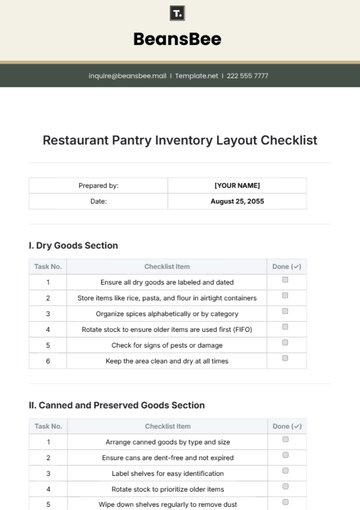

- Restaurant Checklist

- Checklist Layout

- Creative Checklist

- Sales Checklist

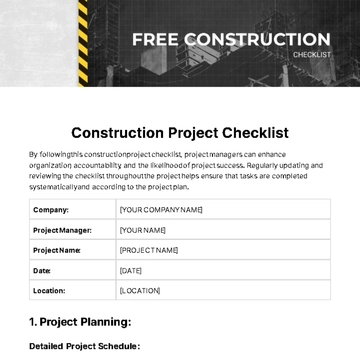

- Construction Checklist

- Task Checklist

- Professional Checklist

- Hotel Checklist

- Employee Checklist

- Moving Checklist

- Marketing Checklist

- Accounting Checklist

- Camping Checklist

- Packing Checklist

- Real Estate Checklist

- Cleaning Checklist Service

- New Employee Checklist

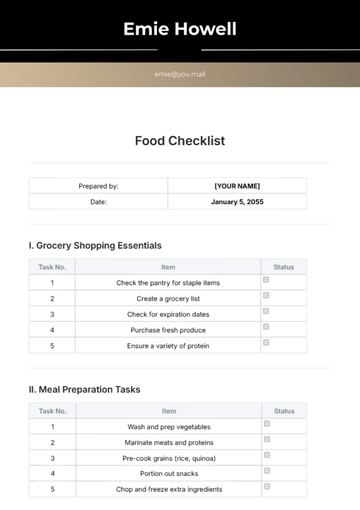

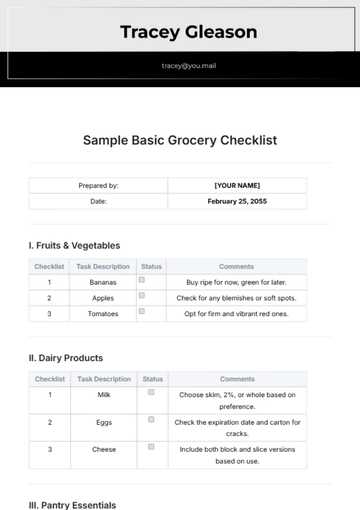

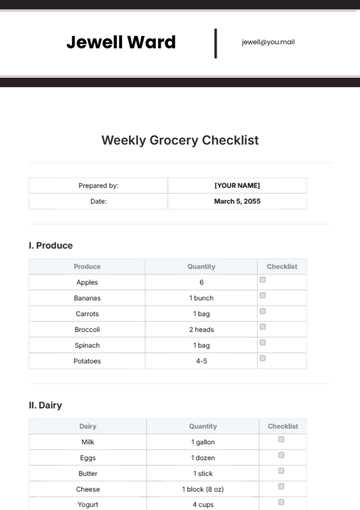

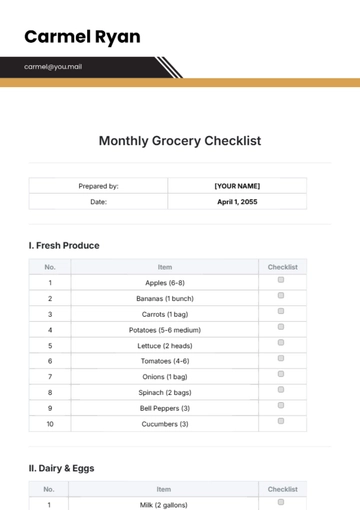

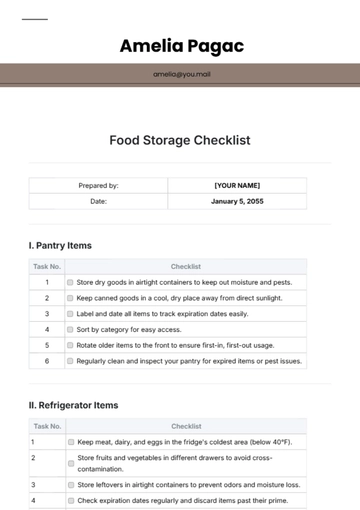

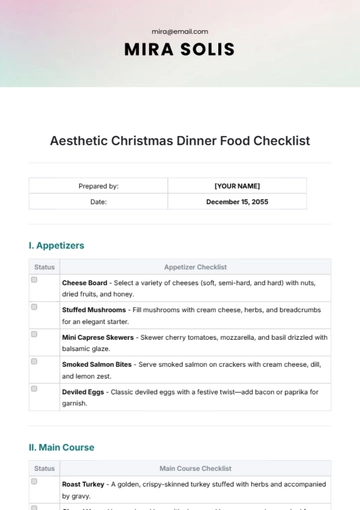

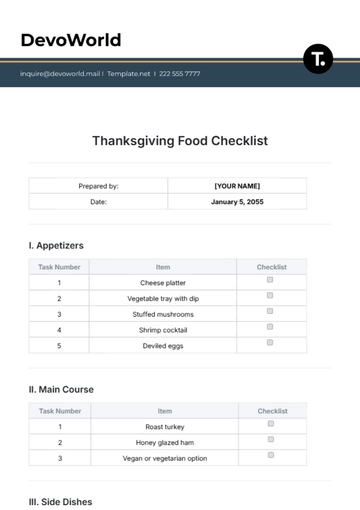

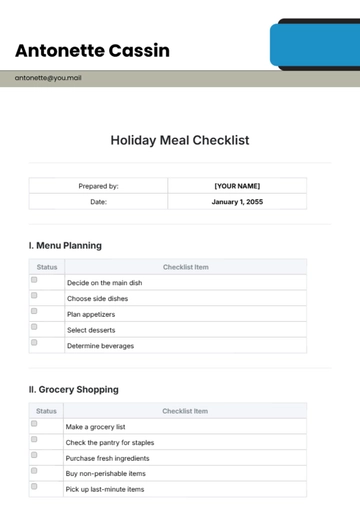

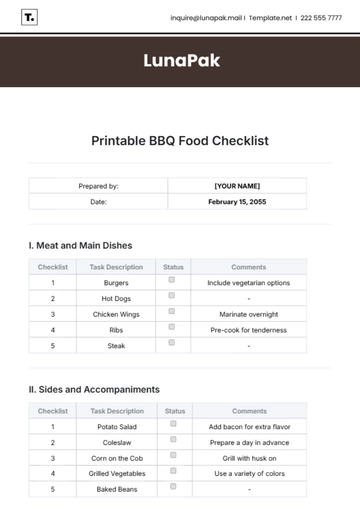

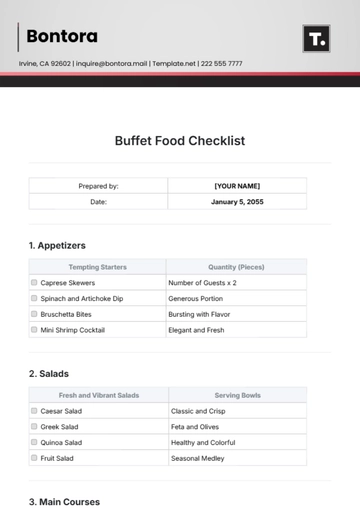

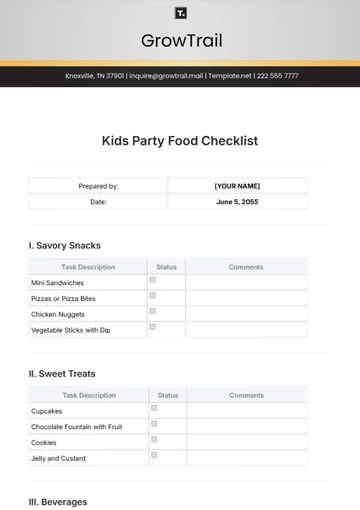

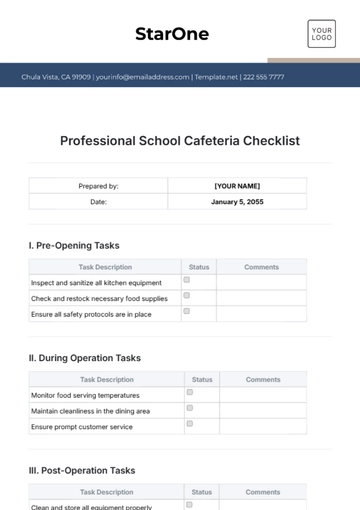

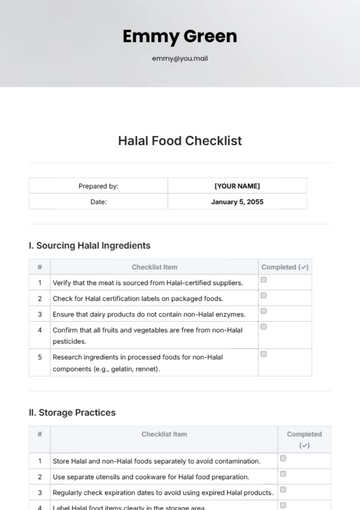

- Food Checklist

- Home Inspection Checklist

- Advertising Checklist

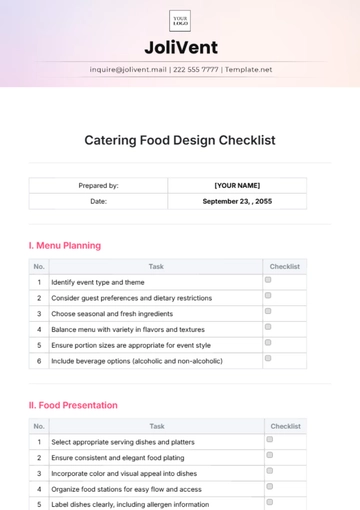

- Event Checklist

- SEO Checklist

- Assessment Checklist

- Inspection Checklist

- Baby Registry Checklist

- Induction Checklist

- Employee Training Checklist

- Medical Checklist

- Safety Checklist

- Site Checklist

- Job Checklist

- Service Checklist

- Nanny Checklist

- Building Checklist

- Work Checklist

- Office Checklist

- Training Checklist

- Website Checklist

- IT and Software Checklist

- Performance Checklist

- Project Checklist

- Startup Checklist

- Education Checklist

- Home Checklist

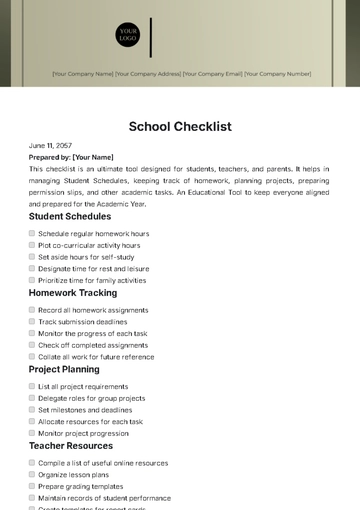

- School Checklist

- Maintenance Checklist

- Planning Checklist

- Manager Checklist

- Wedding Checklist

- Vehicle Checklist

- Travel Agency Checklist

- Vehicle Inspection Checklist

- Interior Design Checklist

- Backpacking Checklist

- Business Checklist

- Legal Checklist

- Nursing Home Checklist

- Weekly Checklist

- Recruitment Checklist

- Salon Checklist

- Baby Checklist

- Equipment Checklist

- Trade Show Checklist

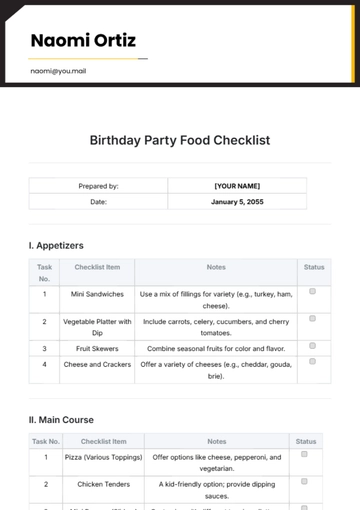

- Party Checklist

- Hospital Bag Checklist

- Evaluation Checklist

- Agency Checklist

- First Apartment Checklist

- Hiring Checklist

- Opening Checklist

- Small Business Checklist

- Rental Checklist

- College Dorm Checklist

- New Puppy Checklist

- University Checklist

- Building Maintenance Checklist

- Work From Home Checklist

- Student Checklist

- Application Checklist