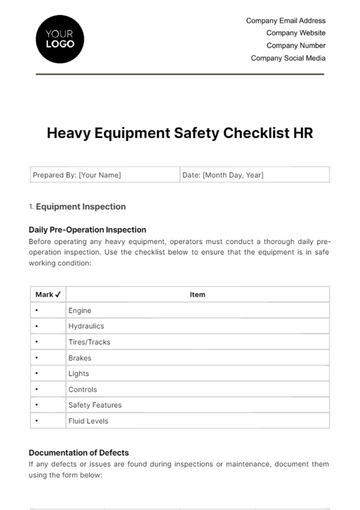

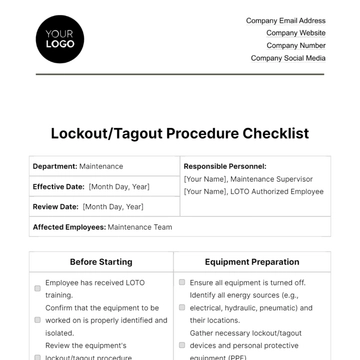

Free Heavy Equipment Safety Checklist HR

Prepared By: [Your Name] | Date: [Month Day, Year] |

Equipment Inspection

Daily Pre-Operation Inspection

Before operating any heavy equipment, operators must conduct a thorough daily pre-operation inspection. Use the checklist below to ensure that the equipment is in safe working condition:

Mark ✔ | Item |

Engine | |

Hydraulics | |

Tires/Tracks | |

Brakes | |

Lights | |

Controls | |

Safety Features | |

Fluid Levels |

Documentation of Defects

If any defects or issues are found during inspections or maintenance, document them using the form below:

Date Detected | Description of Defect | Action Taken | Completed By |

[Month Day, Year] | Crack in hydraulic line | Repaired | Operator |

Procedures for Equipment Malfunctions

In the event of equipment malfunctions, follow these procedures:

Mark ✔ | Process |

If equipment malfunctions during operation, immediately shut it down to prevent further damage or injury. | |

Notify your supervisor and report the issue. | |

Tag out the equipment if required to prevent unauthorized use until repairs are completed. |

Personal Protective Equipment (PPE)

Ensure that all operators have the appropriate PPE and wear it at all times when operating heavy equipment. Operators are required to wear the following PPE while operating heavy equipment:

Mark ✔ | Item |

Helmet | |

Gloves | |

Safety Glasses | |

Steel-Toed Boots | |

High-Visibility Vest |

Safe Operating Procedures

Follow these steps and guidelines to conduct the standard safe operating procedures:

Starting, Operating, and Shutting Down of Equipment

Mark ✔ | Process |

Starting: Insert key, turn ignition to the ON position. | |

Operating: Use joystick to control bucket movement. | |

Shutting Down: Move the gear selector to the "PARK" position, turn off the engine. |

Load Handling Techniques

Mark ✔ | Process |

Ensure loads are properly secured and balanced. | |

Use caution when lifting or lowering loads. | |

Avoid sudden movements or jerks when handling loads. |

Seating and Visibility

Mark ✔ | Process |

Seat and controls are adjusted for operator comfort. | |

Mirrors are properly positioned for optimal visibility. |

Training and Certification

All heavy equipment operators must undergo training and obtain the necessary certifications. Maintain records of training and certification for each operator.

Operator Name | Training Date | Certification Expiry |

Julie Young | [Month Day, Year] | [Month Day, Year] |

Emergency Procedures

In case of accidents, fires, or other emergencies, follow these procedures:

Mark ✔ | Process |

Immediate Response: Ensure the safety of all personnel involved. | |

Notify Supervisor: Inform your supervisor and provide details of the emergency. | |

Emergency Shutdown: If necessary, use emergency shutdown controls as indicated on the equipment. |

General Steps

Follow these final procedures promptly:

Mark ✔ | Process |

Safety Signage: Ensure that warning signs and labels are prominently displayed on the equipment to warn operators and others of potential hazards. | |

Communication: Establish clear communication procedures between operators and ground personnel. Use hand signals, radios, or other approved methods for effective communication. | |

Environmental Considerations: Take precautions to prevent environmental damage, such as spills and leaks. Follow environmental protection guidelines provided for each piece of equipment. | |

Incident Reporting: Promptly report any accidents, near-misses, or safety violations to your supervisor using the company incident reporting form. | |

Compliance with Regulations: Operators must be aware of and comply with all local, state, and federal regulations related to heavy equipment safety. |

By completing this Heavy Equipment Safety Checklist, you contribute to a safer working environment and the protection of lives and equipment at [Your Company Name]. Safety is our top priority, and your diligence in following these guidelines is greatly appreciated.

[Your Company Name] encourages open communication regarding safety concerns or suggestions for improvement. Thank you for your commitment to safety.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Our premade Heavy Equipment Safety Checklist HR Template is a comprehensive solution for ensuring workplace safety in heavy equipment operations. Easily customize this user-friendly template with essential safety guidelines, inspection procedures, and compliance measures. Boost safety, reduce risks, and maintain regulatory compliance effortlessly. Streamline your heavy equipment safety procedures today.

You may also like

- Cleaning Checklist

- Daily Checklist

- Travel Checklist

- Self Care Checklist

- Risk Assessment Checklist

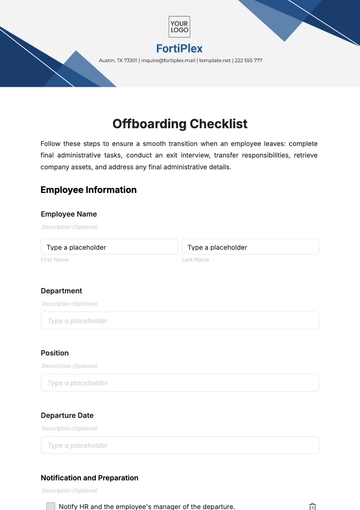

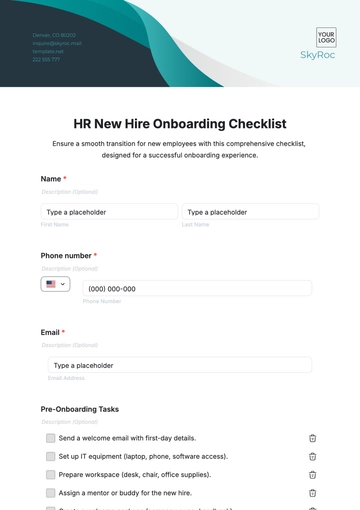

- Onboarding Checklist

- Quality Checklist

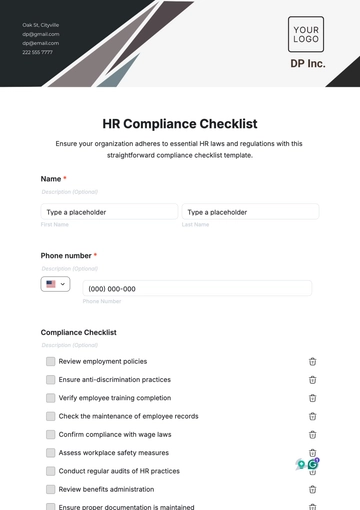

- Compliance Checklist

- Audit Checklist

- Registry Checklist

- HR Checklist

- Restaurant Checklist

- Checklist Layout

- Creative Checklist

- Sales Checklist

- Construction Checklist

- Task Checklist

- Professional Checklist

- Hotel Checklist

- Employee Checklist

- Moving Checklist

- Marketing Checklist

- Accounting Checklist

- Camping Checklist

- Packing Checklist

- Real Estate Checklist

- Cleaning Checklist Service

- New Employee Checklist

- Food Checklist

- Home Inspection Checklist

- Advertising Checklist

- Event Checklist

- SEO Checklist

- Assessment Checklist

- Inspection Checklist

- Baby Registry Checklist

- Induction Checklist

- Employee Training Checklist

- Medical Checklist

- Safety Checklist

- Site Checklist

- Job Checklist

- Service Checklist

- Nanny Checklist

- Building Checklist

- Work Checklist

- Office Checklist

- Training Checklist

- Website Checklist

- IT and Software Checklist

- Performance Checklist

- Project Checklist

- Startup Checklist

- Education Checklist

- Home Checklist

- School Checklist

- Maintenance Checklist

- Planning Checklist

- Manager Checklist

- Wedding Checklist

- Vehicle Checklist

- Travel Agency Checklist

- Vehicle Inspection Checklist

- Interior Design Checklist

- Backpacking Checklist

- Business Checklist

- Legal Checklist

- Nursing Home Checklist

- Weekly Checklist

- Recruitment Checklist

- Salon Checklist

- Baby Checklist

- Equipment Checklist

- Trade Show Checklist

- Party Checklist

- Hospital Bag Checklist

- Evaluation Checklist

- Agency Checklist

- First Apartment Checklist

- Hiring Checklist

- Opening Checklist

- Small Business Checklist

- Rental Checklist

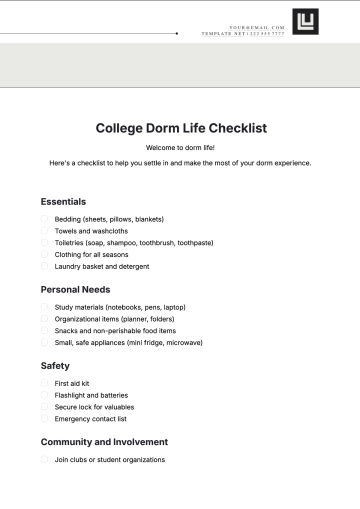

- College Dorm Checklist

- New Puppy Checklist

- University Checklist

- Building Maintenance Checklist

- Work From Home Checklist

- Student Checklist

- Application Checklist