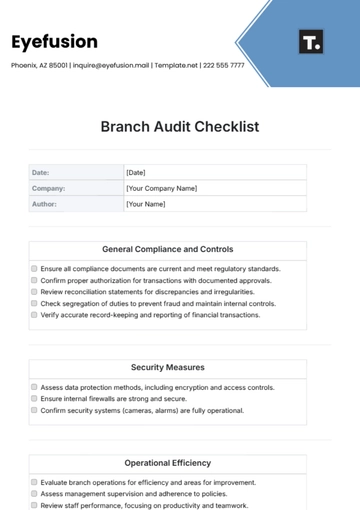

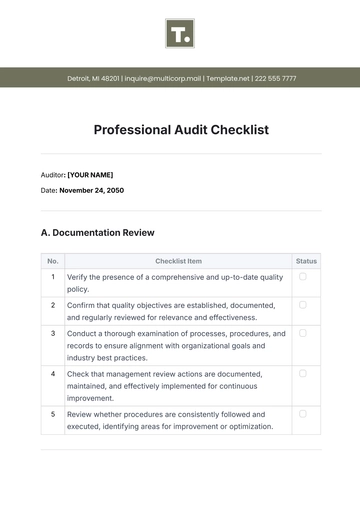

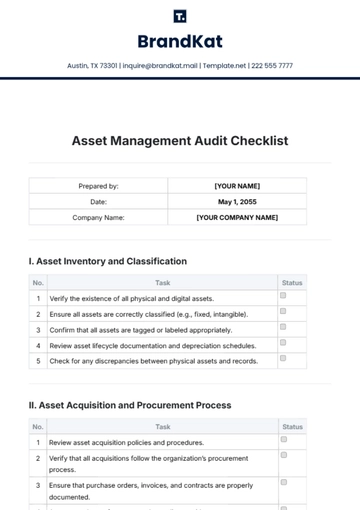

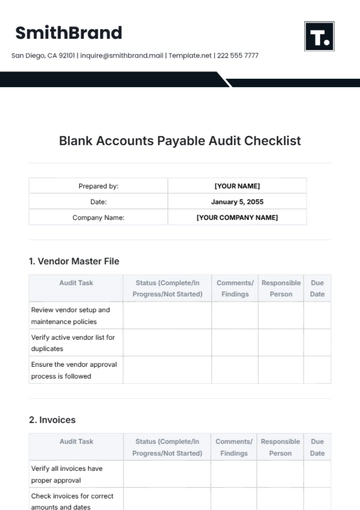

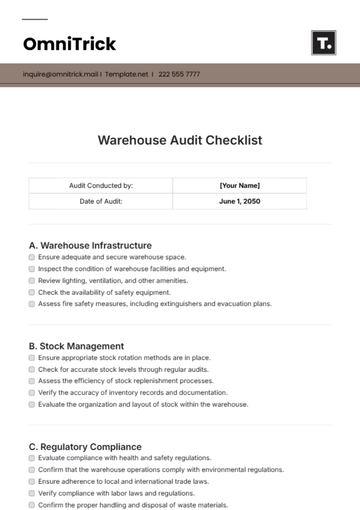

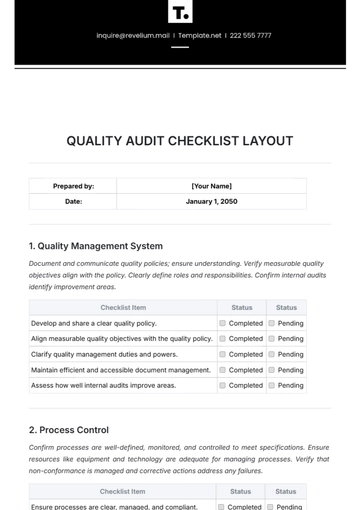

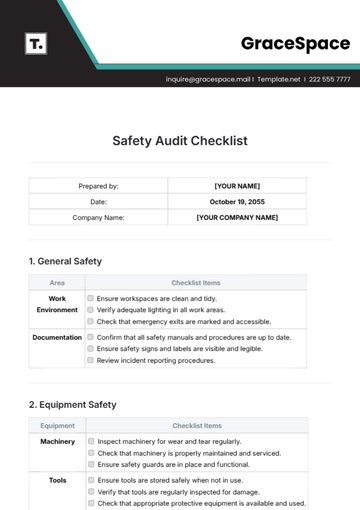

Free Manufacturing Audit Checklist

Audited by: | Date | Company |

|---|---|---|

[Your Name] | [Date] | [Your Company Name] |

Factory Premises and Documentation

Review of manufacturing facility's cleanliness and organization. | |

Check for necessary certifications and compliance with regulatory documents. | |

Examination of safety and sanitary procedures in practice. | |

Assessment of overall facility layout and workflow efficiency. | |

Verification of waste disposal methods and environmental impact considerations. | |

Review of emergency response plans and evacuation procedures. |

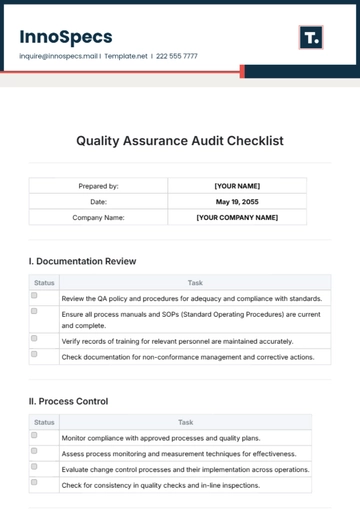

Process Control and Quality Assurance

Evaluate process and product control systems. | |

Verify the effectiveness of error detection and defect prevention methods. | |

Check consistency and reliability of product quality tests. | |

Assessment of process variability and its impact on product quality. | |

Validation of process change control procedures. | |

Review of statistical process control (SPC) implementation and analysis. |

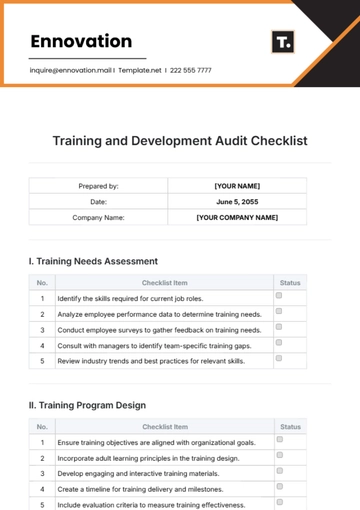

Personnel and Training

Ensure competency of staff based on roles and responsibilities. | |

Review staff training programs and their effectiveness. | |

Assessment of cross-functional training opportunities. | |

Validation of training records and documentation. | |

Review of employee performance appraisal systems. | |

Analysis of employee engagement and satisfaction surveys. |

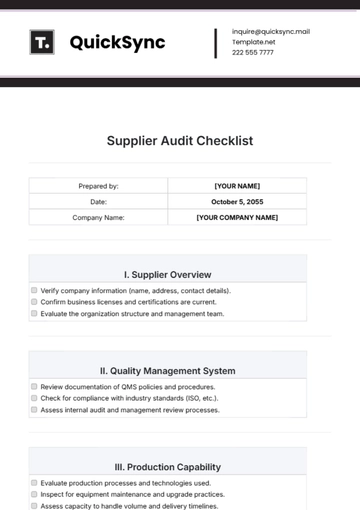

Supplier Quality Management

Evaluate supplier qualification procedures. | |

Analyze the quality of raw materials supplied. | |

Check supplier performance assessment procedures. | |

Validation of supplier communication channels. | |

Assessment of supplier risk management strategies. | |

Review of contingency plans for potential supply chain disruptions. |

Product Handling and Storage Conditions

Verify proper product package conditions for transportation and delivery. | |

Check control mechanisms for storage temperature, humidity, and other necessary parameters. | |

Inspection of stock rotation and expiration date controls. | |

Assessment of product handling procedures during loading and unloading. | |

Validation of inventory management systems. | |

Review of transportation security measures. |

Machine Equipment Maintenance and Calibration

Assessment of preventive maintenance activities. | |

Review of equipment calibration records. | |

Verification of machine functionality and safety features. | |

Evaluation of spare parts availability and inventory management for critical equipment. | |

Validation of equipment change control procedures. | |

Inspection of maintenance logs and documentation of equipment history. |

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Elevate your manufacturing processes with our Manufacturing Audit Checklist Template, available exclusively on Template.net. This editable and customizable tool ensures precision and efficiency in your audits. Seamlessly tailor assessments to your unique requirements using our user-friendly Ai Editor Tool, guaranteeing a streamlined and personalized auditing experience. Upgrade your operations today!

You may also like

- Cleaning Checklist

- Daily Checklist

- Travel Checklist

- Self Care Checklist

- Risk Assessment Checklist

- Onboarding Checklist

- Quality Checklist

- Compliance Checklist

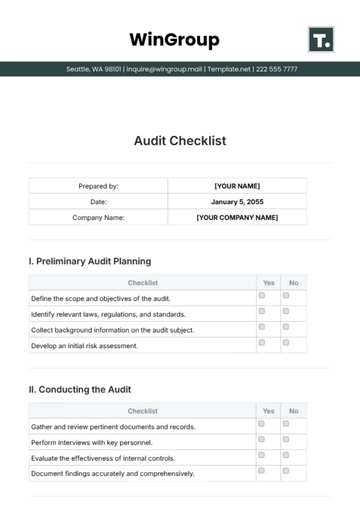

- Audit Checklist

- Registry Checklist

- HR Checklist

- Restaurant Checklist

- Checklist Layout

- Creative Checklist

- Sales Checklist

- Construction Checklist

- Task Checklist

- Professional Checklist

- Hotel Checklist

- Employee Checklist

- Moving Checklist

- Marketing Checklist

- Accounting Checklist

- Camping Checklist

- Packing Checklist

- Real Estate Checklist

- Cleaning Checklist Service

- New Employee Checklist

- Food Checklist

- Home Inspection Checklist

- Advertising Checklist

- Event Checklist

- SEO Checklist

- Assessment Checklist

- Inspection Checklist

- Baby Registry Checklist

- Induction Checklist

- Employee Training Checklist

- Medical Checklist

- Safety Checklist

- Site Checklist

- Job Checklist

- Service Checklist

- Nanny Checklist

- Building Checklist

- Work Checklist

- Office Checklist

- Training Checklist

- Website Checklist

- IT and Software Checklist

- Performance Checklist

- Project Checklist

- Startup Checklist

- Education Checklist

- Home Checklist

- School Checklist

- Maintenance Checklist

- Planning Checklist

- Manager Checklist

- Wedding Checklist

- Vehicle Checklist

- Travel Agency Checklist

- Vehicle Inspection Checklist

- Interior Design Checklist

- Backpacking Checklist

- Business Checklist

- Legal Checklist

- Nursing Home Checklist

- Weekly Checklist

- Recruitment Checklist

- Salon Checklist

- Baby Checklist

- Equipment Checklist

- Trade Show Checklist

- Party Checklist

- Hospital Bag Checklist

- Evaluation Checklist

- Agency Checklist

- First Apartment Checklist

- Hiring Checklist

- Opening Checklist

- Small Business Checklist

- Rental Checklist

- College Dorm Checklist

- New Puppy Checklist

- University Checklist

- Building Maintenance Checklist

- Work From Home Checklist

- Student Checklist

- Application Checklist