Table of Contents

- 18+ Process Audit Checklist Templates in Excel | PDF

- 1. Audit Template Excel Download

- Checklist Template Bundle

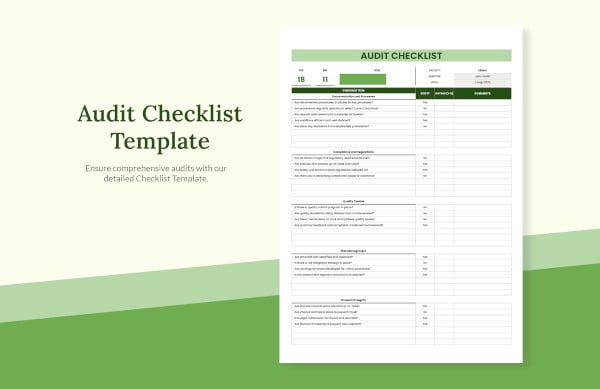

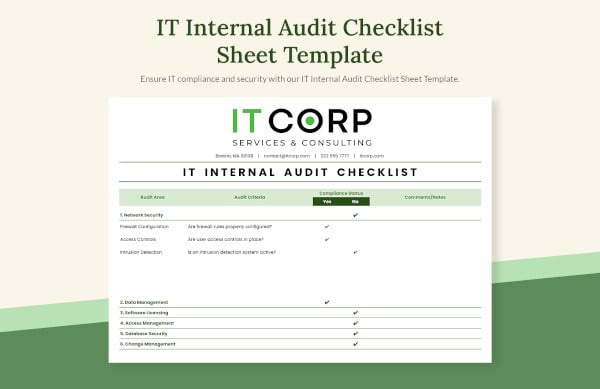

- 2. Audit Checklist Excel

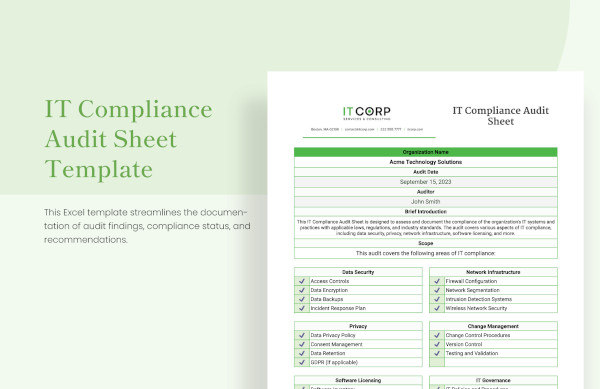

- 3. Process Audit Checklist

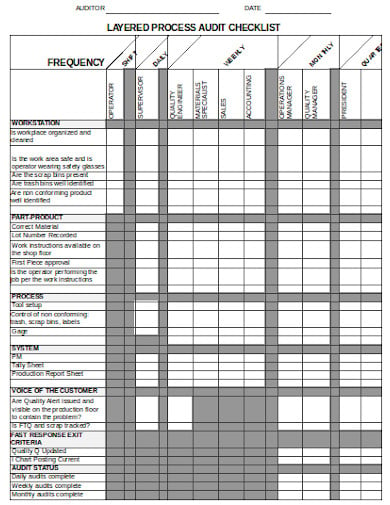

- 4. Internal Audit Checklist Excel

- 5. Audit Sheet Template Excel

- 6. Free Layered Process Audit Checklist Template

- 7. Free Shipping Process Handling Audit Inspection Checklist

- 8. Free Pre Product Quality Process Audit Checklist

- 9. Free SOP Management Process Audit Checklist Template

- 10. Free Special Healthcare Process Evaluation Audit Checklist

- 11. Free Preventive Audit Process for Fire District Checklist

- 12. Free Quality Assurance Work Process Audit Checklist

- 13. Free IT Company Supplier Process Audit Checklist

- 14. Free Warehouse Payroll Manufacturing Process Audit Checklist

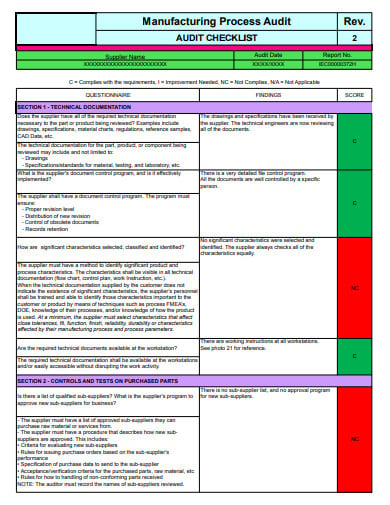

- 15. Free Product Manufacturing Process Audit Checklist

- 16. Free Supplier Business Process Control Audit Checklist

- 17. Free Process Audit Confirmation Checklist Template

- 18. Free Housekeeping Process Audit Checklist Template

- How to Make a Manufacturing Process Audit Checklist

- Safety

- Materials

- Motions

- Workstation Design and Location

- Actions for Reporting Issues

- Declaration of Processes

- Follow-up

- What Does Process Audit Mean?

- Process Audits vs. System Audits

- Importance of a Manufacturing Process Audit Checklist

18+ Process Audit Checklist Templates in Excel | PDF

A process audit checklists helps in examining each process and obedience to the individual specifications and procedures. It helps in maximizing the results of any audit and also assists in staying organized. With proper preparation and with the help of a process audit checklist templates, the auditor will be able to perform an in-depth analysis in a minimum amount of time. Such a sample checklist is suitable for an IT company, preventive healthcare, commercial housekeeping, SOP confirmation, pre product, warehouse payroll template, and much more.

18+ Process Audit Checklist Templates in Excel | PDF

1. Audit Template Excel Download

Checklist Template Bundle

2. Audit Checklist Excel

3. Process Audit Checklist

4. Internal Audit Checklist Excel

5. Audit Sheet Template Excel

6. Free Layered Process Audit Checklist Template

notasdecalidad.files.wordpress.com

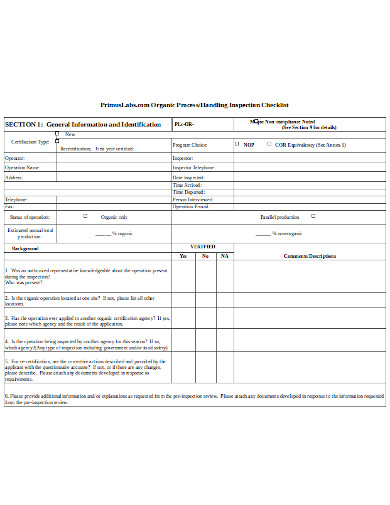

notasdecalidad.files.wordpress.com7. Free Shipping Process Handling Audit Inspection Checklist

primuslabs.com

primuslabs.com8. Free Pre Product Quality Process Audit Checklist

doj.gov.ph

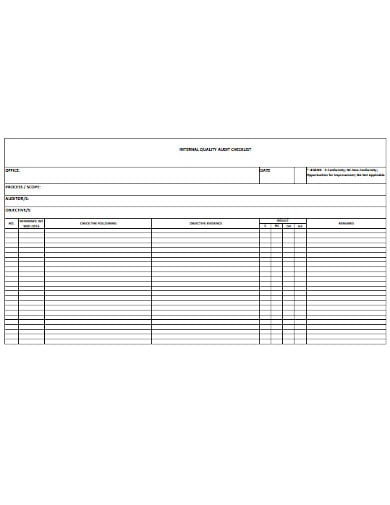

doj.gov.ph9. Free SOP Management Process Audit Checklist Template

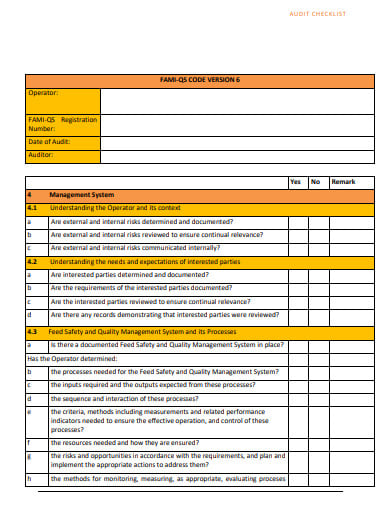

fami-qs.org

fami-qs.org10. Free Special Healthcare Process Evaluation Audit Checklist

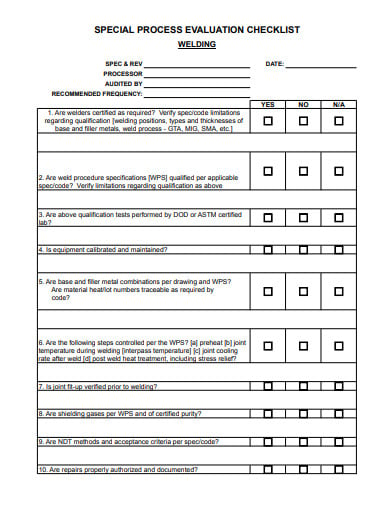

sargentaerospace.com

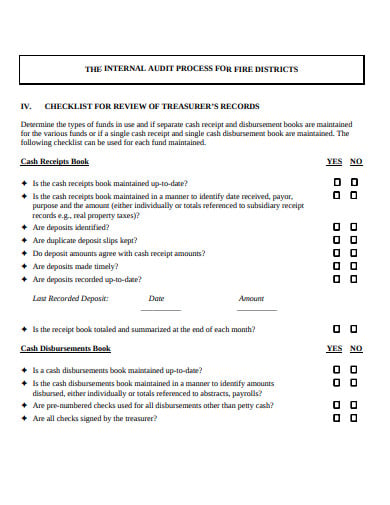

sargentaerospace.com11. Free Preventive Audit Process for Fire District Checklist

osc.state.ny

osc.state.ny12. Free Quality Assurance Work Process Audit Checklist

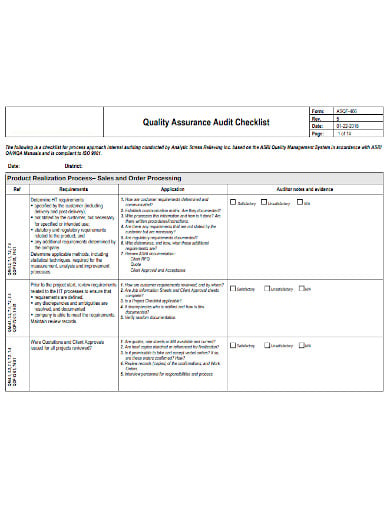

analyticstress.com

analyticstress.com13. Free IT Company Supplier Process Audit Checklist

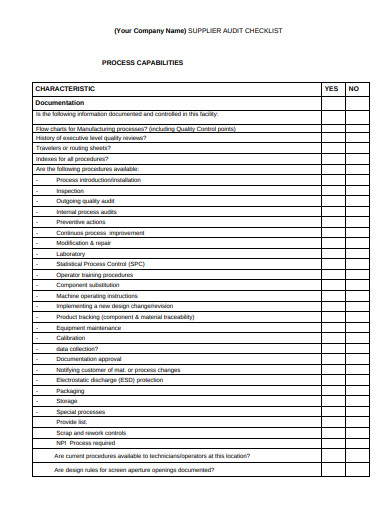

componentsengineering.com

componentsengineering.com14. Free Warehouse Payroll Manufacturing Process Audit Checklist

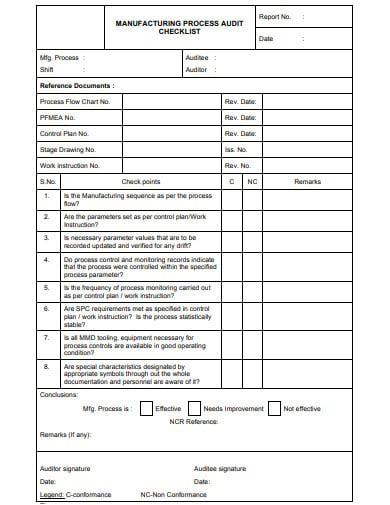

elsmar.com

elsmar.com15. Free Product Manufacturing Process Audit Checklist

proqc.com

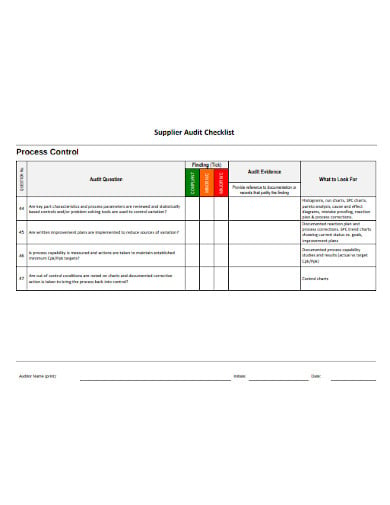

proqc.com16. Free Supplier Business Process Control Audit Checklist

isoconsultantpune.com

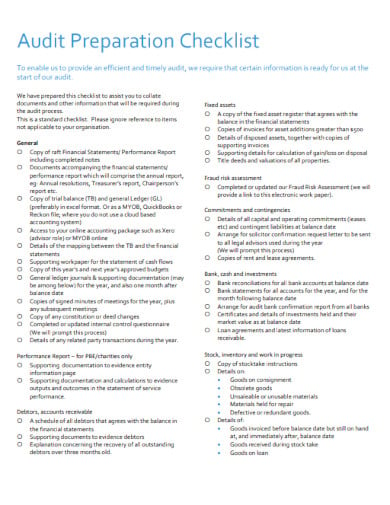

isoconsultantpune.com17. Free Process Audit Confirmation Checklist Template

irp-cdn.multiscreensite.com

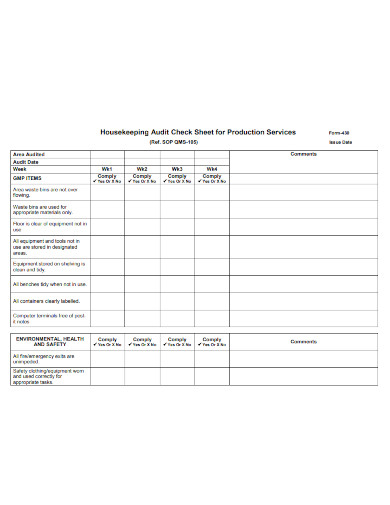

irp-cdn.multiscreensite.com18. Free Housekeeping Process Audit Checklist Template

gmpsop.com

gmpsop.comHow to Make a Manufacturing Process Audit Checklist

Large Organizations that implement an effective process audit system need to be Basically, there are seven types of questions that should be considered for creating a manufacturing process audit strategic checklists. The categories that are discussed below are some of the most common types of questions that are covered in a process audit service checklists. This includes the following:

-

Safety

Safety is the first category that must be included in a process audit checklists in google docs. Both safety and quality influence each other directly, although many organizations consider safety and quality as separate components. Manufacturing process daily checklists must confirm that the equipment is safe, used properly by the workers, and whether the safety protocols are being followed.

-

Materials

The second category includes questions related to the materials. It is quite obvious that the manufacturing quality products must comprise of some satisfactory materials. This makes it a must-have aspect of the manufacturing process audit checklist. You can include questions such as whether all workstations have accurate materials in the exact quantity? Or questions like are all materials being used by the operators in the right sample order?

-

Motions

Questions related to the motions are included in the third category. These particular motions that are used by the workers may influence the quality, efficiency, and safety. That is why manufacturing audit checklist templates generally include motion-related questions. Questions like are the standard work instructions being followed by the employees at each step? Or are the operators moving in the best efficient way, or is there an improved approach to perform the task?

-

Workstation Design and Location

Workstation design and location is the fourth category of questions that are to be considered in the creation of a manufacturing process audit checklist in Pages. Process audit checklists must involve questions that assess the safety and efficiency supported by the workstation itself. You can keep some questions in mind in this regard like is this the finest location in the plant for registering the objectives of the workstation? In which ways does the location contribute to the manufacturing process in terms of shipping, receiving and safety? etc.

-

Actions for Reporting Issues

The fifth category of question is the procedure for reporting issues. Your process audit checklist planning can include questions like what are the available reporting choices that the employees have so they can share their concerns regarding quality, safety, or efficiency? You can also provide questions on whether the operators hold direct contact with the manufacturing engineers for giving feedback on work guidelines?

-

Declaration of Processes

The declaration of processes is generally the second last category to be considered for the question of the audit checklist templates. Documentation is a key element for effective quality processes, especially the standard work guidelines. These can include issues such as what is the standard documentation process for work on the shop floor? Or is it possible to access the most recent instructions by the operator?

-

Follow-up

The last category of a manufacturing process audit checklist in word is follow-up. A productive manufacturing quality checklist should include a follow-up and other action items to ensure that any sort of non-confirmation is controlled properly. Some areas must be considered like what are the suggested modifications to the process? Include questions like how it will be made possible to observe and evaluate follow-up?

What Does Process Audit Mean?

A process audit is considered to be a highly focused inspection of the internal system, processes, and organizations. It is more than just product tracing, sampling as well as measurements. The purpose of process audits is to restrict the plan assessment focus to certain specific procedures, specifications, or routines that are used in a designated small business area.

Process Audits vs. System Audits

Most people are familiar with the system audits because this inspection activity attempts to determine conformity or non-conformity with the established standards. This audit can be considered an enterprise-wide audit that may take an entire week to complete in a large facility. It is an audit that focuses on departmental processes that will evaluate the performance of employees and policy compliance with the individual steps and other activities. Process audits, on the other hand, compare past activities against the predetermined standards to reveal inabilities and improvement areas. Process audits, unlike system audits, cannot mark the overall sample plan and performance of an organization’s small business.

Importance of a Manufacturing Process Audit Checklist

The main purpose of a manufacturing process audit safety checklist is to lay out a framework of questions to keep an auditor on track while performing their job. There has been some debate on the productiveness of audit checklists, but there are clear profits to using one in an auditing process.

Why do you need a manufacturing process audit checklist? Process audit checklists training is commonly known as some useful tool that keep an auditor on task. You can ensure that every audit is performed in a comprehensive and compatible manner by implementing a checklist in the audit process. Even though it is entirely possible to perform a process audit without the use of any blank checklist, you may find out that by having a task checklist, you will see better results from your audits.

In summary, process audits are crucial for ensuring the efficiency and compliance of various operations within an organization. The templates provided by Template.net serve as valuable tools in facilitating these audits, helping organizations maintain high standards of quality and safety. For a more specialized approach, particularly in the context of research, the University of Utah provides a detailed audit checklist, which can be particularly useful for academic and research settings. Utilizing these resources can significantly enhance the effectiveness and thoroughness of your auditing processes