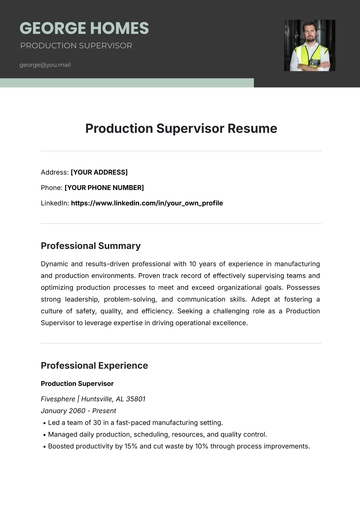

Free Manufacturing Supervisor Resume

Address: [Your Address]

Contact Number: [Your Phone Number]

LinkedIn: https://www.linkedin.com/in/your_own_profile

I. Career Objective

Experienced Manufacturing Supervisor with over 10 years of expertise in overseeing production processes, ensuring quality control, and maintaining safety protocols. Proven track record of increasing efficiency, reducing costs, and leading teams to achieve production targets. Highly skilled in Lean Manufacturing, Six Sigma methodologies, and employee training and development. Committed to driving continuous improvement and operational excellence.

II. Professional Experience

Manufacturing Supervisor | [Current Company Name], [City, State] | [Start Date - End Date]

Supervise and coordinate the activities of production workers in the manufacturing department to ensure optimal productivity and quality.

Implement and enforce safety protocols and procedures, maintaining a zero-incident work environment for over 5 years.

Develop and execute production schedules to meet customer demands while minimizing downtime and waste.

Utilize Lean Manufacturing techniques to streamline processes, resulting in a 20% increase in production efficiency.

Conduct performance evaluations, provide coaching, and facilitate training programs to enhance team skills and performance.

Collaborate with engineering and maintenance teams to troubleshoot and resolve production issues promptly.

Assistant Manufacturing Supervisor | [Previous Company Name], [City, State] | [Start Date - End Date]

Assisted the Manufacturing Supervisor in overseeing daily operations of the production floor.

Monitored production metrics and prepared reports to assess performance against goals.

Provided training and support to new employees, fostering a culture of continuous improvement.

Ensured compliance with safety, quality, and regulatory standards within the department.

Participated in Lean and Six Sigma projects to identify and implement process improvements.

III. Educational Background

Bachelor of Science in Industrial Engineering | [University Name], [City, State] | [Year Graduated]

Relevant Coursework:

Operations Research: Mathematical modeling for decision-making.

Supply Chain Management: Optimization and logistics in supply chains.

Production Planning and Control: Scheduling and control in manufacturing.

Quality Engineering: Statistical methods for quality improvement.

Industrial Ergonomics: Designing safe and efficient work environments.

Operations Research: Mathematical modeling for decision-making.

Supply Chain Management: Optimization and logistics in supply chains.

Production Planning and Control: Scheduling and control in manufacturing.

Quality Engineering: Statistical methods for quality improvement.

Industrial Ergonomics: Designing safe and efficient work environments.

IV. Certifications

Certified Six Sigma Green Belt

Certified Professional in Manufacturing Operations (CPMO)

OSHA 30-Hour General Industry Safety and Health Certification

VI. Skills

Leadership and Team Management

Lean Manufacturing and Six Sigma

Production Planning and Scheduling

Quality Control and Assurance

Safety Protocols and Compliance

Continuous Improvement Strategies

Data Analysis and Reporting

Employee Training and Development

VII. Professional Affiliation

Member, American Society for Quality (ASQ)

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Unlock career opportunities with Template.net's Manufacturing Supervisor Resume templates. Editable and customizable, these templates highlight your leadership skills and industry expertise. Crafted to impress, they're editable in our AI Editor Tool, ensuring your resume stands out in the competitive manufacturing field. Take the next step in your career with a professionally designed resume from Template.net.

You may also like

- Simple Resume

- High School Resume

- Actor Resume

- Accountant Resume

- Academic Resume

- Corporate Resume

- Infographic Resume

- Sale Resume

- Business Analyst Resume

- Skills Based Resume

- Professional Resume

- ATS Resume

- Summary Resume

- Customer Service Resume

- Software Engineer Resume

- Data Analyst Resume

- Functional Resume

- Project Manager Resume

- Nurse Resume

- Federal Resume

- Server Resume

- Administrative Assistant Resume

- Sales Associate Resume

- CNA Resume

- Bartender Resume

- Graduate Resume

- Engineer Resume

- Data Science Resume

- Warehouse Resume

- Volunteer Resume

- No Experience Resume

- Chronological Resume

- Marketing Resume

- Executive Resume

- Truck Driver Resume

- Cashier Resume

- Resume Format

- Two Page Resume

- Basic Resume

- Manager Resume

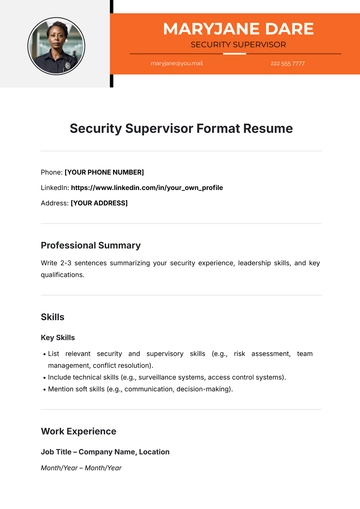

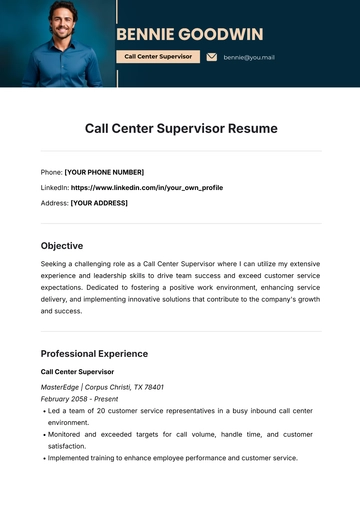

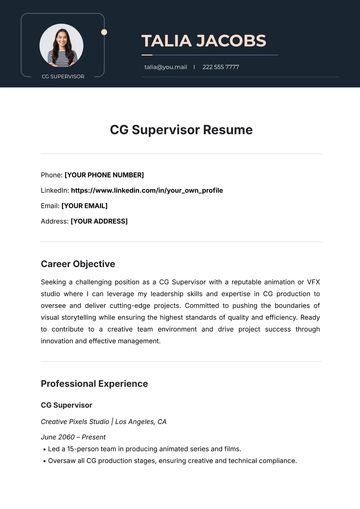

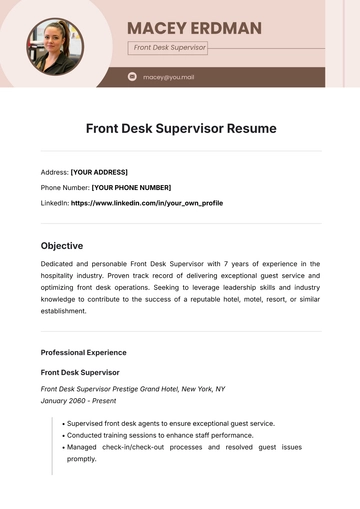

- Supervisor Resume

- Director Resume

- Blank Resume

- One Page Resume

- Developer Resume

- Caregiver Resume

- Personal Resume

- Consultant Resume

- Administrator Resume

- Officer Resume

- Medical Resume

- Job Resume

- Technician Resume

- Clerk Resume

- Driver Resume

- Data Entry Resume

- Freelancer Resume

- Operator Resume

- Printable Resume

- Worker Resume

- Student Resume

- Doctor Resume

- Merchandiser Resume

- Architecture Resume

- Photographer Resume

- Chef Resume

- Lawyer Resume

- Secretary Resume

- Customer Support Resume

- Computer Operator Resume

- Programmer Resume

- Pharmacist Resume

- Electrician Resume

- Librarian Resume

- Computer Resume

- IT Resume

- Experience Resume

- Instructor Resume

- Fashion Designer Resume

- Mechanic Resume

- Attendant Resume

- Principal Resume

- Professor Resume

- Safety Resume

- Waitress Resume

- MBA Resume

- Security Guard Resume

- Editor Resume

- Tester Resume

- Auditor Resume

- Writer Resume

- Trainer Resume

- Advertising Resume

- Harvard Resume

- Receptionist Resume

- Buyer Resume

- Physician Resume

- Scientist Resume

- 2 Page Resume

- Therapist Resume

- CEO resume

- General Manager Resume

- Attorney Resume

- Project Coordinator Resume

- Bus Driver Resume

- Cook Resume

- Artist Resume

- Pastor Resume

- Recruiter Resume

- Team Leader Resume

- Apprentice Resume

- Police Resume

- Military Resume

- Personal Trainer Resume

- Contractor Resume

- Dietician Resume

- First Job Resume

- HVAC Resume

- Psychologist Resume

- Public Relations Resume

- Support Specialist Resume

- Computer Technician Resume

- Drafter Resume

- Foreman Resume

- Underwriter Resume

- Photo Resume

- Teacher Resume

- Modern Resume

- Fresher Resume

- Creative Resume

- Internship Resume

- Graphic Designer Resume

- College Resume